I know several of the potential readers of these holley tuning threads, would rather be boiled in oil that read links,

but heres a good deal of useful info,

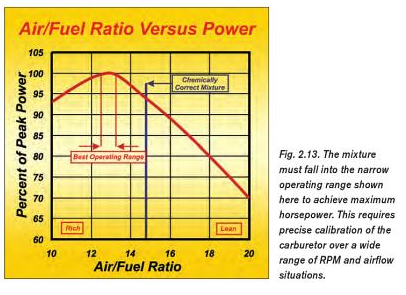

your carb has several inter-dependent systems that work together and/or at different throttle positions and vacuum levels.

your carb venturie size , engine displacement, cam shaft profile, and carb booster style have a big effect on fuel flow rates,as does the power valve you use, float levels and jets,

first Holley sells two common accelerator pump sizes, most carbs come with a 30cc a 50cc conversion is available, larger pump volume extends the time the fuel from the pump flows, add a larger squirter size and the flow volume also increases. the accelerator pump cam gives different results when you change t different squirters, or swap to the larger accelerator pump, changing boosters and power valves and jets will also noticeably alter your fuel/air ratio under acceleration.

power valves also control fuel flow as the throttle blades open and vacuum drops off, you can and should take the time and effort to correctly tune your engine.

reading through the links below CAREFULLY will help

http://garage.grumpysperformance.com/index.php?threads/holley-accelerator-pumps-cams.1790/

http://garage.grumpysperformance.com/index.php?threads/holley-annular-vs-down-leg-boosters.5229/

http://garage.grumpysperformance.com/index.php?threads/holley-carb-power-valves.1639/

http://garage.grumpysperformance.co...-4150-and-4160-series-carbs.10736/#post-54321

http://garage.grumpysperformance.co...-emmulsion-tube-tuning-info.11557/#post-53445

http://garage.grumpysperformance.com/index.php?threads/carb-tuning-info-and-links.109/

http://www.hotrod.com/how-to/engine/ccrp-0807-holley-carburetors-basics-guide/

http://garage.grumpysperformance.co...lley-air-bleed-jets-related.11859/#post-56233

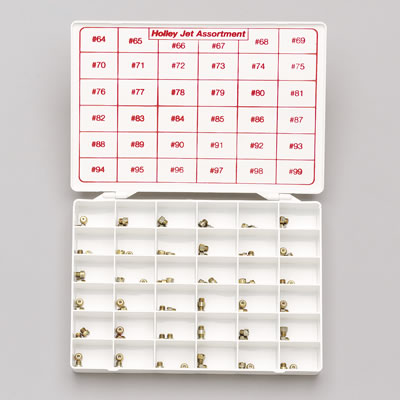

summit sells air bleed jets

http://www.summitracing.com/search/...Ascending&tw=emulsion&sw=Holley Emulsion Jets

but heres a good deal of useful info,

your carb has several inter-dependent systems that work together and/or at different throttle positions and vacuum levels.

your carb venturie size , engine displacement, cam shaft profile, and carb booster style have a big effect on fuel flow rates,as does the power valve you use, float levels and jets,

first Holley sells two common accelerator pump sizes, most carbs come with a 30cc a 50cc conversion is available, larger pump volume extends the time the fuel from the pump flows, add a larger squirter size and the flow volume also increases. the accelerator pump cam gives different results when you change t different squirters, or swap to the larger accelerator pump, changing boosters and power valves and jets will also noticeably alter your fuel/air ratio under acceleration.

power valves also control fuel flow as the throttle blades open and vacuum drops off, you can and should take the time and effort to correctly tune your engine.

reading through the links below CAREFULLY will help

http://garage.grumpysperformance.com/index.php?threads/holley-accelerator-pumps-cams.1790/

http://garage.grumpysperformance.com/index.php?threads/holley-annular-vs-down-leg-boosters.5229/

http://garage.grumpysperformance.com/index.php?threads/holley-carb-power-valves.1639/

http://garage.grumpysperformance.co...-4150-and-4160-series-carbs.10736/#post-54321

http://garage.grumpysperformance.co...-emmulsion-tube-tuning-info.11557/#post-53445

http://garage.grumpysperformance.com/index.php?threads/carb-tuning-info-and-links.109/

http://www.hotrod.com/how-to/engine/ccrp-0807-holley-carburetors-basics-guide/

http://garage.grumpysperformance.co...lley-air-bleed-jets-related.11859/#post-56233

summit sells air bleed jets

http://www.summitracing.com/search/...Ascending&tw=emulsion&sw=Holley Emulsion Jets

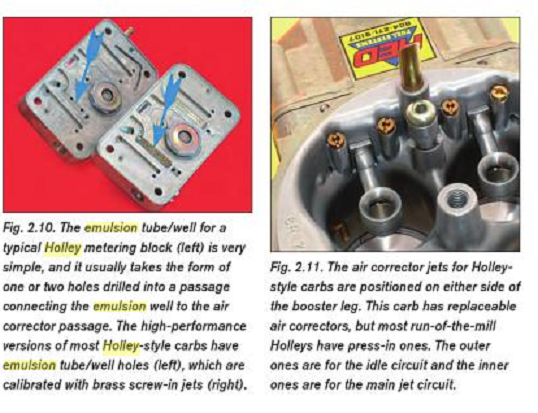

Holley emulsion holes?

Tuner,

I was hoping you could take the time to explain the emulsion "circuit" in a Holley metering block. Specifically how the holes position and size effects fuel delivery/quality and how the high speed bleed interacts with the process. I seek the fundamentals and would like to know when, if ever a change is warranted. I have both Holleys and a couple of Claws that have tunable metering blocks but just haven't dared. I have come close to replicating a Holley metering block on one of the Claws as they have a different area and position than the Holleys but just haven't yet as I've just been a puss.

Thanks in advance for any light you care to shine on the subject.

In the thread “750 Holley carb help” Klaus made this statement, “On carbs it's very important that the correct two-phase flow gets established during emulsion. Otherwise you will see RPM dependency of AFR.” Thank you Klaus, but forgive me if I see your remark as a profound understatement. Incorrect two-phase flow is at the root of all this aggravation. People who have drill bits but don’t know why to use them have been molesting innocent carburetors for a long time. Now some of them are in charge of the manufacture of new carbs and they think they have improved them by using larger drill bits to make the air bleed and “emulsion” orifices. I guess the guys that engineered the original carburetors on the old muscle cars were pretty stupid or they would have “improved the emulsion” 40 or 50 years ago when they had their chance. After all, they had the awesome power of the single-point ignition system at their disposal, they shouldn’t have been afraid of a little soot.

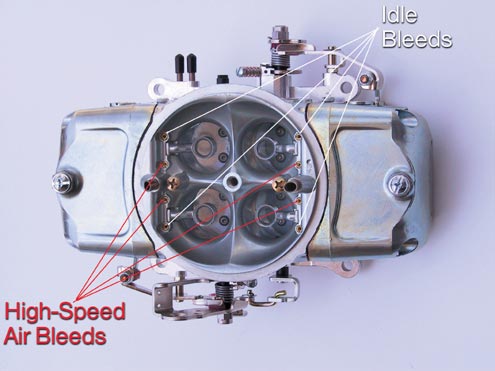

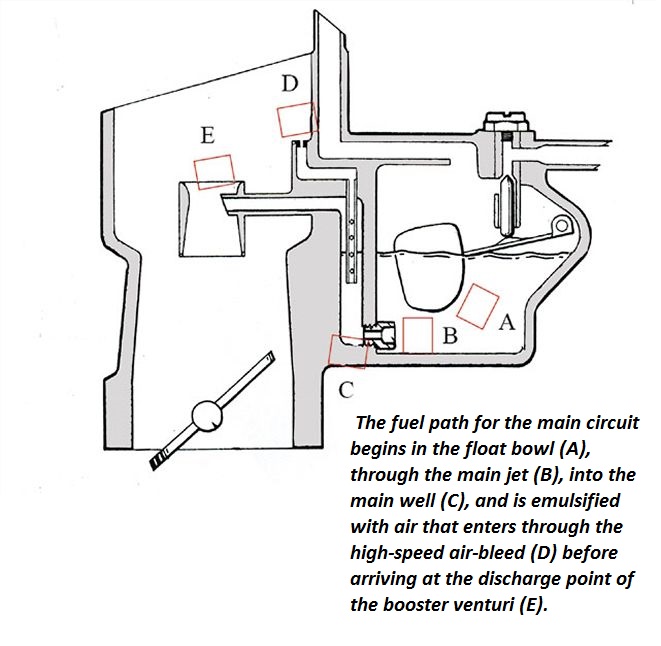

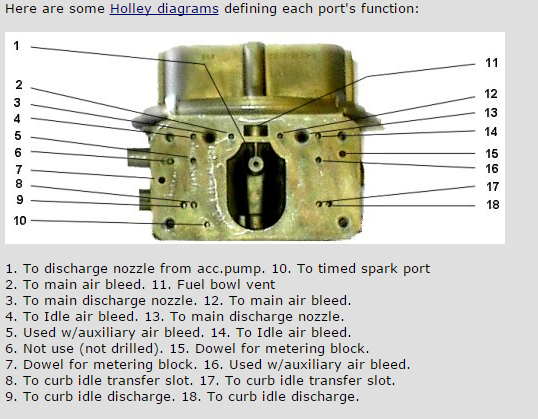

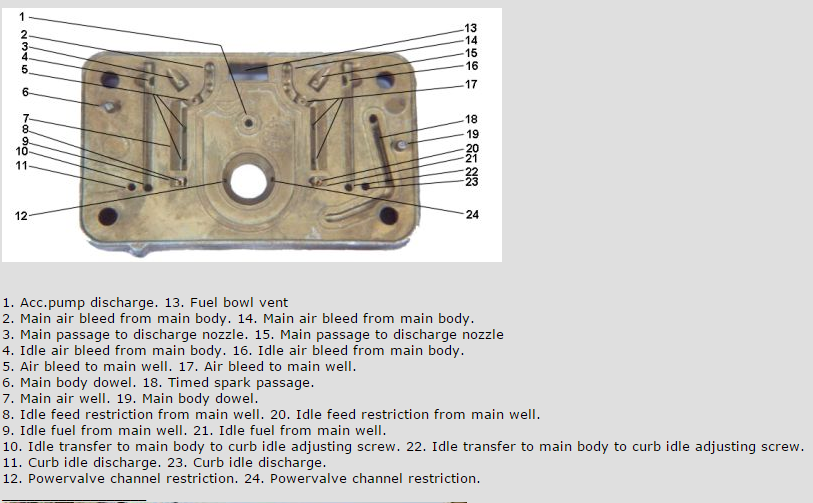

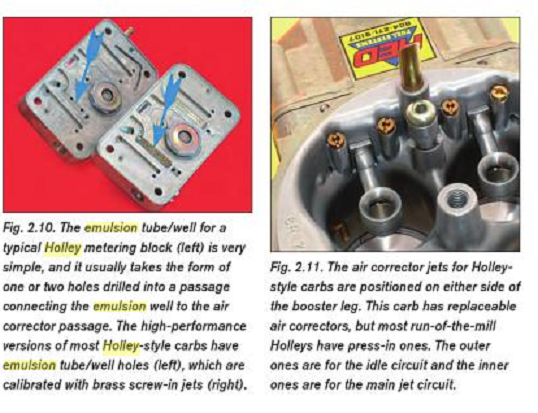

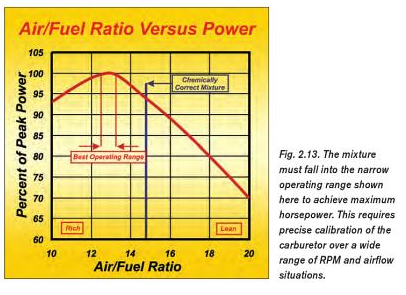

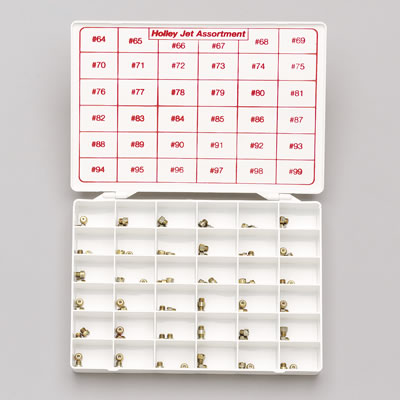

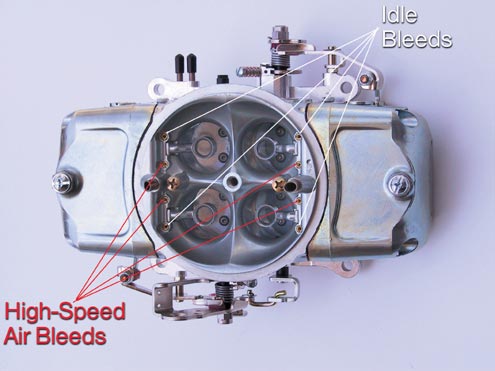

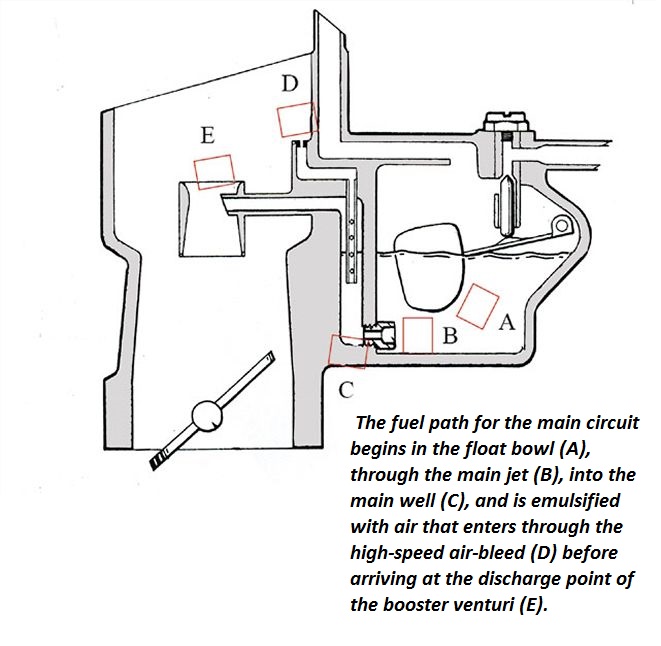

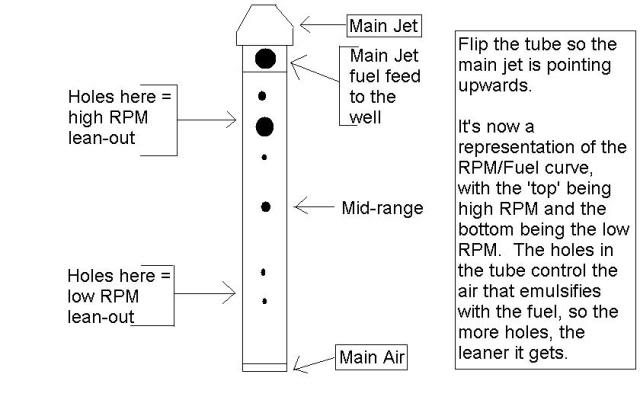

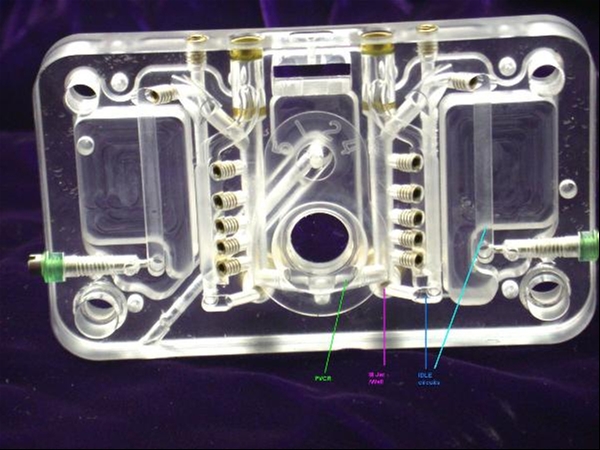

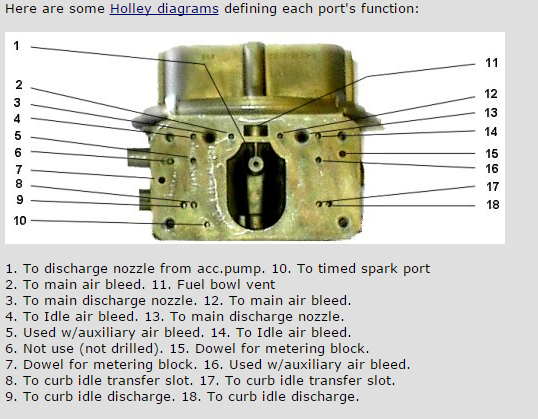

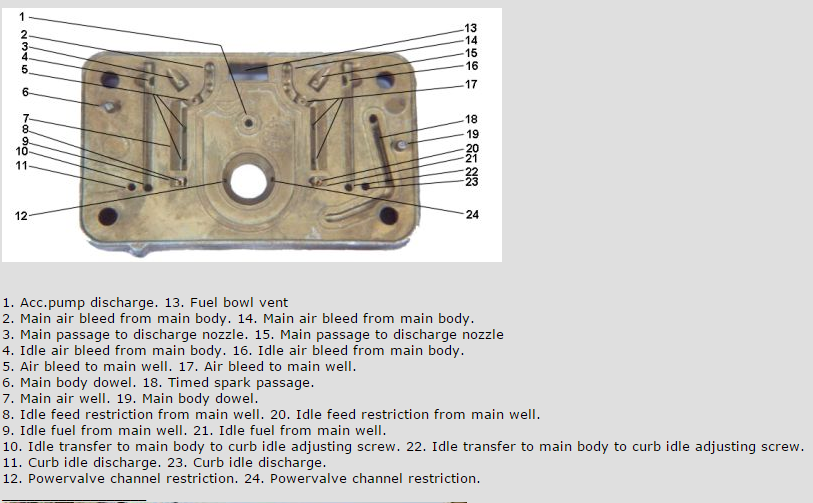

It is well documented that introducing air into the main well encourages low signal flow and can encourage or discourage high signal flow. The natural characteristic of a plain jet and nozzle (no air) is to get richer as airflow increases. The purpose of the air bleed system is to modify that behavior to accomplish a constant (or the desired) air/fuel ratio over as wide a range of airflows as possible. The particular ratios for power and cruise are realized by the selection of jet and rod or jet and auxiliary jet (power valve channel). The purpose of air bleeds is not to emulsify but to accomplish the correct fuel delivery. Emulsion is just a beneficial side effect.

What I’m going on about here is Klaus’ remark about “correct two-phase flow”. That is the description of a fluid flow that is made up of a liquid and a gas flowing together in the same conduit. As the ratio of gas to liquid increases (more gas, less liquid), at some point the gas bubbles coalesce from many small ones into a few big ones and the flow starts to “slug” and become erratic. The carburetor nozzle spits like a garden hose with air in it when there is too much “emulsion” air.

An emulsion of air and fuel has reduced density, surface tension and viscosity compared to fuel alone. This increases the flow of fuel considerably, particularly in low-pressure difference operation, at low throttle openings or lower engine speeds. Just how much of an increase (richer) is dependant upon where and how much air is introduced into the fuel flow.

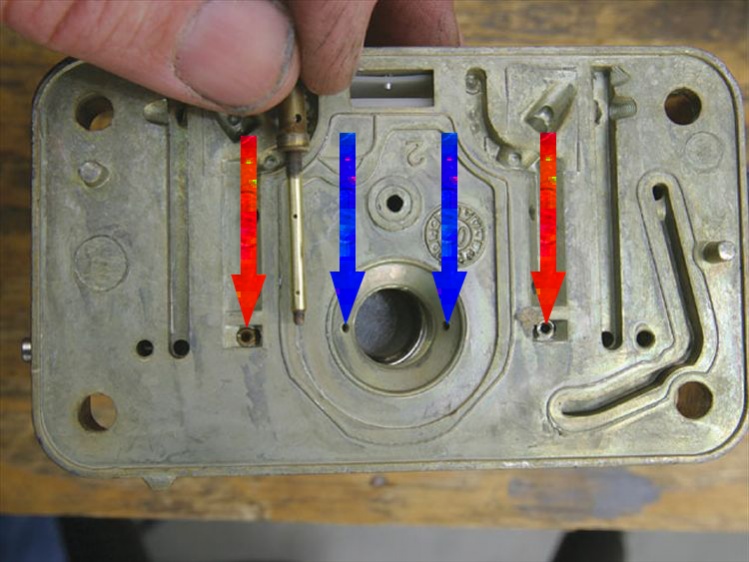

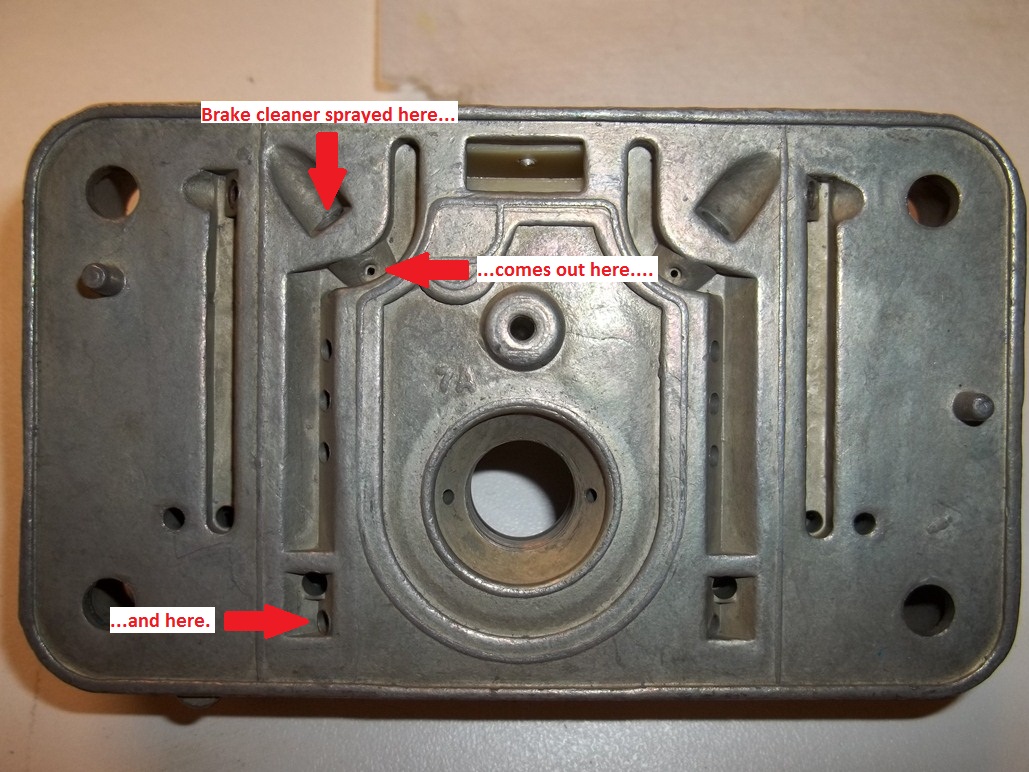

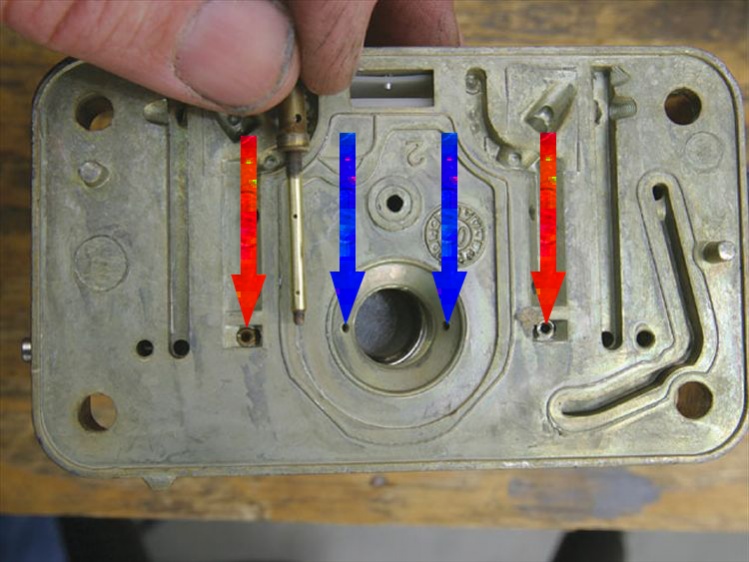

Mainly, what must be understood is that because the fuel discharge nozzle connects the venturi to the main well, whatever the low pressure (vacuum) is in the venturi, it is also the pressure in the main well. The air bleed is in the carb air horn or somewhere else where it is exposed to essentially atmospheric pressure, which is higher than the venturi pressure. This pressure difference causes air from the air bleed to flow through the emulsion system into the main well and to the nozzle. The flow of air can have very high velocities, approaching sonic in some orifices. The airflow literally blows the fuel toward and through the nozzle. A larger main air bleed will admit more air to the emulsion system and that can increase or decrease fuel flow to the engine. The size, number and location of the other air holes in the emulsion system, the size of the main well flow area, the size of the nozzle and the specific pressure difference at the moment are the determining factors. The ratios of air volume to fuel volume to flow area, with the air volume's expansion with the venturi velocity induced pressure reduction being the key. The bubbles expand as the pressure drop increases with airflow. Suck on an empty balloon to experience the effect.

The fuel flow through the main jet is the result of the pressure difference between the atmospheric pressure in the float bowl and the venturi air velocity induced vacuum acting on the nozzle and the main well. The venturi vacuum in the well is reduced (the pressure is raised) by the "air leak" from the air bleed. This reduces the pressure difference that causes the flow through the main jet. If the air bleed were big enough, the pressure in the well would be the same as in the float bowl and no fuel would flow. Think about drinking through a soda straw with a hole in it above liquid level. Bigger hole, less soda. Suck harder, not much more soda. Big enough hole, no soda. This is the means by which the emulsion system can "lean it out on the top end". Incidentally, the vacuum that lifts water up a soda straw is in the most sensitive operating range for emulsion systems.

It is in the lowest range of throttle opening, at the start of main system flow, that the effect of adjusting the introduced emulsion air (and it's effect in increasing the main fuel flow) is most critical. Small changes can have large and sometimes unexpected or counter-intuitive consequences. The goal is to seamlessly blend the rising main flow with the declining idle/transition system fuel delivery to accomplish smooth engine operation during opening of the throttle in all conditions, whether from curb idle or any higher engine speed. The high speed and load mixture correction is usually easily accomplished, in comparison.

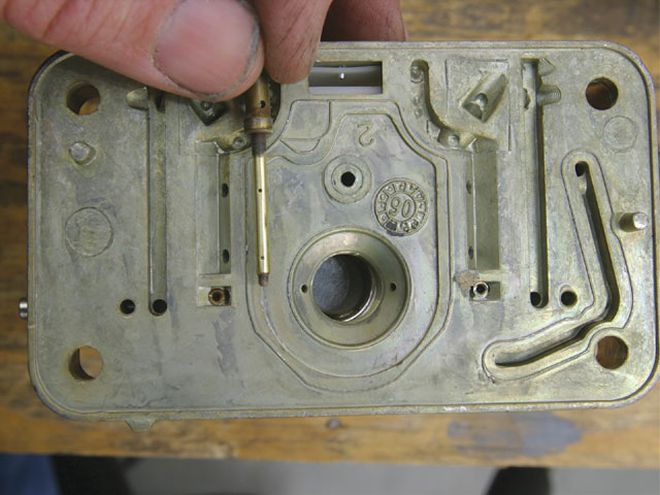

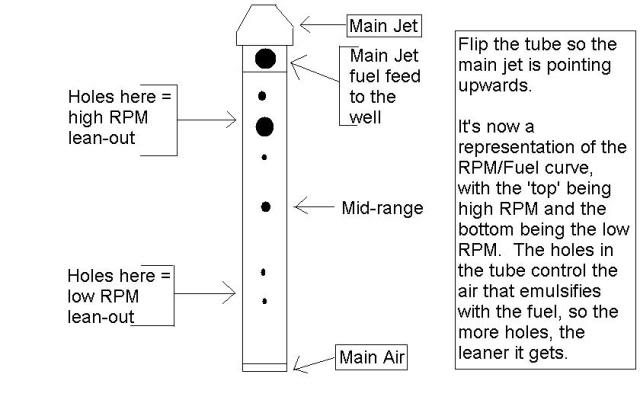

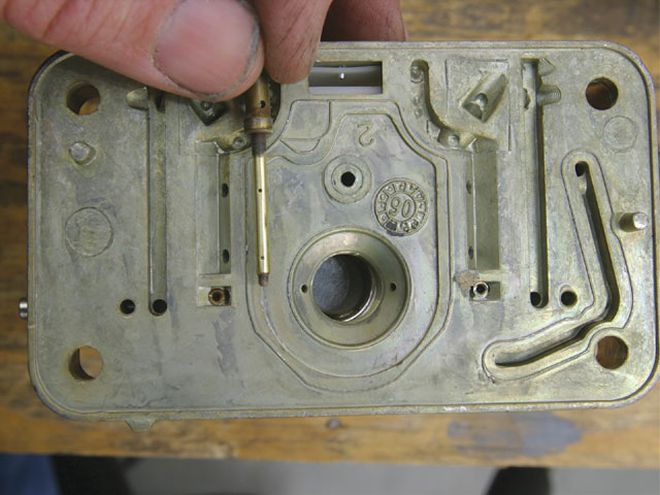

The vertical location of the bleeds entering the main well influences the fuel flow in the following ways.

1: Orifices above float level or between the well and the nozzle allow bled air to raise the pressure (reduce the vacuum) in the nozzle and above the fuel in the well. That delays the initial start of fuel flow from the nozzle to a higher air flow through the venturi and is used to control the point in the early throttle opening where the main starts.

2: Orifices at float level increase low range (early throttle opening) fuel flow by carrying fuel with the airflow to the nozzle.

3: Orifices below float level increase fuel flow by the effect of lowering the level of fuel in the well to the hole(s) admitting air. This is like raising the float level a similar amount (increases the effect of gravity in the pressure difference across the main jet) and also adds to the airflow carrying fuel to the nozzle. Locating the orifices at different vertical positions influences this effect’s progression.

4: The "emulsion holes" influence is greatest at low flows and the "main air bleed" has most influence at high flows.

In the first three cases above, once fuel flow is established it is greater than it would be with fewer or smaller holes. Visualize wind blowing spray off of the top of water waves. It doesn’t take much pressure difference to cause the velocity of the airflow through the bleed orifices to have significant velocity in the orifice, even approaching sonic (1100 F.P.S.) if the orifices are small. The phenomena of critical flow is what limits the total air flow through an orifice and allows tuning by changing bleed size.

Essentially, the emulsion effect will richen the low flow and the air bleed size, main well and nozzle restrictions will control the increase or reduction of high flow. Again, the desired air/fuel ratio is the primary purpose of the bleed system. "Improved emulsion" is an oxymoron if the modification of air bleeds to "improve emulsion" results in an incorrect air/fuel ratio in some range of engine operation. Correct proportioning of all the different bleeds (and, of course, the idle, transition and power circuits) will give the correct air/fuel ratios over the total range of speeds and loads and a flat air/fuel ratio characteristic at wide open throttle.

Last edited: