"HEY GRUMPY HOW DO YOU PRE-FILL HYDRAULIC LIFTERS?"

READ ALL THE WAY THROUGH THESE THREADS FIRST

http://garage.grumpysperformance.co...s-on-a-new-engine-or-cam-swap.985/#post-18690

http://garage.grumpysperformance.co...or-soaking-hydraulic-lifters.5947/#post-18316

IF THEY ARE FLAT TAPPET LIFTERS

You don,t really pre-fill them, you make 100% sure they are coated in oil, by letting them sit for a few minutes in a container filled with, marvel mystery oil or some other quality light viscosity machine oil,

you then, INSTALL THEM IN THE CAR engine, after letting them sit for a few minutes in marvel mystery oil or some other quality light viscosity machine oil,

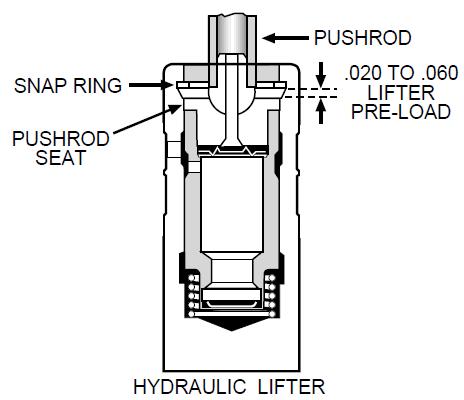

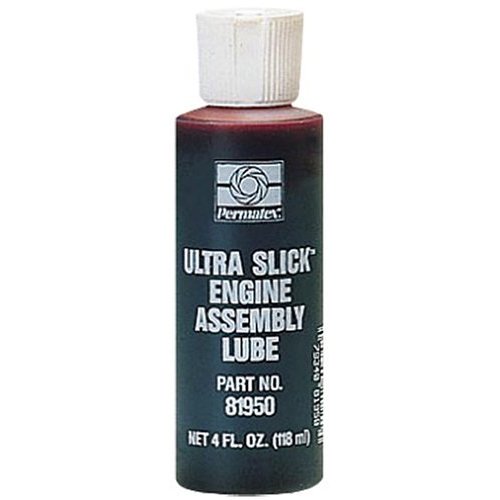

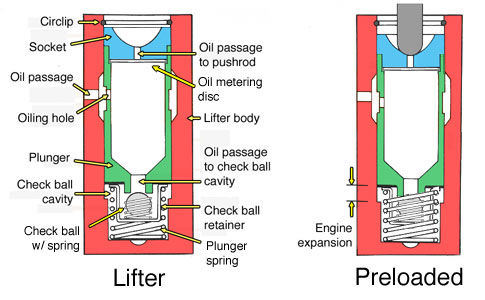

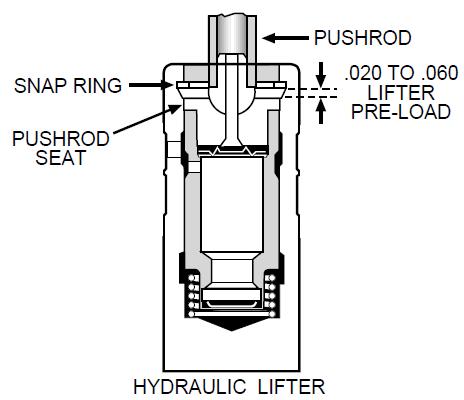

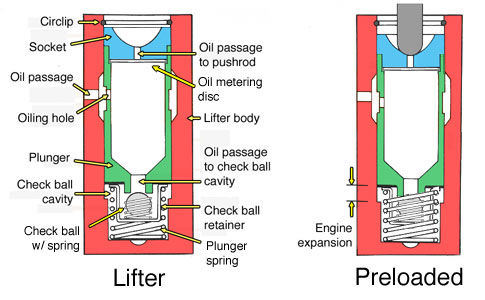

but remember to coat the cam lobes and lifter bases with MOLY assembly lube, before dropping them in their lifter bores, you then cold adjust the rockers with minimal preload per the instructions in the links, take the time to take up the valve train clearance slowly and check carefully as you pre-prime the engine and slowly manually turn the engine, to allow oil to fill the lifters and push rods and allow oil to flow from the rockers BEFORE starting the engine and breaking in the cam, and use an engine prime tool to pressurize the oil passages, lifters will fill to the correct levels within seconds as you prime and slowly manually spin the engine over until you get oil running out of the rockers,once that's done correctly you can start the engine and do the final adjustment at idle during the last part of the cam break-in procedure after the cams spend 30-minutes lapping in at 2500-3000 rpm during its break-in.

pre- fill the oil filter as it speed the oil reaching the rockers

you can get the valves very close to correct using the cold adjustment methods and get them finely adjusted once the engines up to temp with a at idle adjustment that takes into account the thermal expansion of components and wear during the break-in process

why is everyone so darned reluctant to set or finely tweak the valve pre-load, by simply being old school and adjusting the valves at idle, with the engine up to temp, once the cams broken in correctly?

yes Ill freely admit its a bit messy (especially if you don,t have a tall valve cover with the top cut out for access during the process) and yes if you have the correct tools its far LESS messy but it does give consistent results if your even semi skilled!

IF THEY ARE ROLLER LIFTERS

youll want to inspect them carefully as a first step, if they seem to be in good shape , and the roller wheel spins easily ,with your finger on the roller wheel, you,ll want to find a clean container like tuper-ware or something similar like an old, carefully cleaned plastic container, and fill it to about 6" deep with a mix of about 20% moly assembly lube and 80% light machine oil like MARVEL MYSTERY OIL, drop the lifters in and let them soak a couple minutes then install them.the bearings have the rollers prepacked with a assembly lube and they don,t want you washing that packing lube with its high load rate moly additive out of the roller bearing, off in solvent so the roller bearing in the lifters wheel, runs (DRY) for the first few minutes under load.but theres no reason not to add a bit of insurance by coating those roller bearings with fresh moly assembly lube and oil as the bearing races and rollers lap in during the rings breaking in, remember to swap oil filters after the first couple hours and adding several magnets in the engine to trap metallic crud sure helps durability

read these

viewtopic.php?f=53&t=3449&p=10012&hilit=assembly+moly#p10012

viewtopic.php?f=52&t=4589&p=12227#p12227

viewtopic.php?f=44&t=799&p=6574&hilit=priming#p6574

viewtopic.php?f=54&t=120&p=150&hilit=magnets#p150

viewtopic.php?f=54&t=4611&hilit=magnets

http://www.crower.com/misc/product/dl/ZDDP_clr.pdf

read this

Molybdenum Disulfide (Moly) has been used for decades in lubricating pastes and greases because it is slippery and forms a protective coating on metal parts:

Single Molecule of MolyMoly exists as microscopic hexagonal crystal platelets Several molecules make up one of these platelets. A single molecule of Moly contains two sulfur atoms and one molybdenum atom. Moly platelets are attracted to metal surfaces. This attraction and the force of moving engine parts rubbing across one another provide the necessary thermochemical reaction necessary for Moly to form an overlapping protective coating like armor on all of your engine parts. This protective armor coating has a number of properties that are very beneficial for your engine.

The Moly platelets that make up the protective layers on your engine surfaces slide across one another very easily. Instead of metal rubbing against metal, you have Moly platelets moving across one another protecting and lubricating the metal engine parts.

This coating effectively fills in the microscopic pores that cover the surface of all engine parts, making them smoother. This feature is important in providing an effective seal on the combustion chamber. By filling in the craters and pores Moly improves this seal allowing for more efficient combustion and engine performance.

This overlapping coating of Moly also gives protection against loading (perpendicular) forces. These forces occur on the bearings, and lifters. The high pressures that occur between these moving parts tend to squeeze normal lubricants out

there's several ways to set the valves cold with a non-running engine, during the assembly stage,but even thought IVE used all of them at one time or another I always find that adjusting the valves at idle with the engine up to running temp with specially modified valve covers to limit the oil splash loss gives the most satisfactory results

one little known bit of engine trivia, the thread pitch on the rocker studs is a known value, and therefore you can use that info to get a close approximate lash clearance.

THAT INFO IS GOOD TO KNOW WITH SOLID LIFTERS

ok, HOW you ask?

if the rocker studs have a comon NF thread theres a pitch or number of threads per inch, now obviously youll need to carefully verify what the thread pitch, and the clearances are with a feeler gauge on your engine, while its not running and take into account the rocker ratio but lets assume

3/8" 24 Threads Per Inch

7/16" 20 Threads Per Inch

Threads per Inch Distance per 1/4 of a Full Turn

24 .0104â€

28 .0089â€

32 .0078â€

36 .0068â€

40 .0063â€

READING THRU these links should help

viewtopic.php?f=52&t=196

viewtopic.php?f=44&t=799&p=6574&hilit=priming#p6574

viewtopic.php?f=54&t=2187

viewtopic.php?f=52&t=181

viewtopic.php?f=52&t=1489&p=3360#p3360

READ ALL THE WAY THROUGH THESE THREADS FIRST

http://garage.grumpysperformance.co...s-on-a-new-engine-or-cam-swap.985/#post-18690

http://garage.grumpysperformance.co...or-soaking-hydraulic-lifters.5947/#post-18316

IF THEY ARE FLAT TAPPET LIFTERS

You don,t really pre-fill them, you make 100% sure they are coated in oil, by letting them sit for a few minutes in a container filled with, marvel mystery oil or some other quality light viscosity machine oil,

you then, INSTALL THEM IN THE CAR engine, after letting them sit for a few minutes in marvel mystery oil or some other quality light viscosity machine oil,

but remember to coat the cam lobes and lifter bases with MOLY assembly lube, before dropping them in their lifter bores, you then cold adjust the rockers with minimal preload per the instructions in the links, take the time to take up the valve train clearance slowly and check carefully as you pre-prime the engine and slowly manually turn the engine, to allow oil to fill the lifters and push rods and allow oil to flow from the rockers BEFORE starting the engine and breaking in the cam, and use an engine prime tool to pressurize the oil passages, lifters will fill to the correct levels within seconds as you prime and slowly manually spin the engine over until you get oil running out of the rockers,once that's done correctly you can start the engine and do the final adjustment at idle during the last part of the cam break-in procedure after the cams spend 30-minutes lapping in at 2500-3000 rpm during its break-in.

pre- fill the oil filter as it speed the oil reaching the rockers

you can get the valves very close to correct using the cold adjustment methods and get them finely adjusted once the engines up to temp with a at idle adjustment that takes into account the thermal expansion of components and wear during the break-in process

why is everyone so darned reluctant to set or finely tweak the valve pre-load, by simply being old school and adjusting the valves at idle, with the engine up to temp, once the cams broken in correctly?

yes Ill freely admit its a bit messy (especially if you don,t have a tall valve cover with the top cut out for access during the process) and yes if you have the correct tools its far LESS messy but it does give consistent results if your even semi skilled!

IF THEY ARE ROLLER LIFTERS

youll want to inspect them carefully as a first step, if they seem to be in good shape , and the roller wheel spins easily ,with your finger on the roller wheel, you,ll want to find a clean container like tuper-ware or something similar like an old, carefully cleaned plastic container, and fill it to about 6" deep with a mix of about 20% moly assembly lube and 80% light machine oil like MARVEL MYSTERY OIL, drop the lifters in and let them soak a couple minutes then install them.the bearings have the rollers prepacked with a assembly lube and they don,t want you washing that packing lube with its high load rate moly additive out of the roller bearing, off in solvent so the roller bearing in the lifters wheel, runs (DRY) for the first few minutes under load.but theres no reason not to add a bit of insurance by coating those roller bearings with fresh moly assembly lube and oil as the bearing races and rollers lap in during the rings breaking in, remember to swap oil filters after the first couple hours and adding several magnets in the engine to trap metallic crud sure helps durability

read these

viewtopic.php?f=53&t=3449&p=10012&hilit=assembly+moly#p10012

viewtopic.php?f=52&t=4589&p=12227#p12227

viewtopic.php?f=44&t=799&p=6574&hilit=priming#p6574

viewtopic.php?f=54&t=120&p=150&hilit=magnets#p150

viewtopic.php?f=54&t=4611&hilit=magnets

http://www.crower.com/misc/product/dl/ZDDP_clr.pdf

read this

Molybdenum Disulfide (Moly) has been used for decades in lubricating pastes and greases because it is slippery and forms a protective coating on metal parts:

Single Molecule of MolyMoly exists as microscopic hexagonal crystal platelets Several molecules make up one of these platelets. A single molecule of Moly contains two sulfur atoms and one molybdenum atom. Moly platelets are attracted to metal surfaces. This attraction and the force of moving engine parts rubbing across one another provide the necessary thermochemical reaction necessary for Moly to form an overlapping protective coating like armor on all of your engine parts. This protective armor coating has a number of properties that are very beneficial for your engine.

The Moly platelets that make up the protective layers on your engine surfaces slide across one another very easily. Instead of metal rubbing against metal, you have Moly platelets moving across one another protecting and lubricating the metal engine parts.

This coating effectively fills in the microscopic pores that cover the surface of all engine parts, making them smoother. This feature is important in providing an effective seal on the combustion chamber. By filling in the craters and pores Moly improves this seal allowing for more efficient combustion and engine performance.

This overlapping coating of Moly also gives protection against loading (perpendicular) forces. These forces occur on the bearings, and lifters. The high pressures that occur between these moving parts tend to squeeze normal lubricants out

there's several ways to set the valves cold with a non-running engine, during the assembly stage,but even thought IVE used all of them at one time or another I always find that adjusting the valves at idle with the engine up to running temp with specially modified valve covers to limit the oil splash loss gives the most satisfactory results

one little known bit of engine trivia, the thread pitch on the rocker studs is a known value, and therefore you can use that info to get a close approximate lash clearance.

THAT INFO IS GOOD TO KNOW WITH SOLID LIFTERS

ok, HOW you ask?

if the rocker studs have a comon NF thread theres a pitch or number of threads per inch, now obviously youll need to carefully verify what the thread pitch, and the clearances are with a feeler gauge on your engine, while its not running and take into account the rocker ratio but lets assume

3/8" 24 Threads Per Inch

7/16" 20 Threads Per Inch

Threads per Inch Distance per 1/4 of a Full Turn

24 .0104â€

28 .0089â€

32 .0078â€

36 .0068â€

40 .0063â€

READING THRU these links should help

viewtopic.php?f=52&t=196

viewtopic.php?f=44&t=799&p=6574&hilit=priming#p6574

viewtopic.php?f=54&t=2187

viewtopic.php?f=52&t=181

viewtopic.php?f=52&t=1489&p=3360#p3360

Last edited by a moderator: