" GRUMPY?

how much power will a cast crank work with, at what point do I need to swap or upgrade to a forged crank?"

Thats an excellent question and a great deal of the answer depends on both the application, the block strength,how well its balanced and the stroke and piston speeds, cast cranks come in both cast iron and cast steel versions, and both big block and small block sizes.

what your really asking to some degree is whats likely to cause a cast crank to fail, a forged crank is significantly less likely to fail due to torsional stress but thats not the only factor or reason cranks break.

BTW SCAT cast STEEL cranks are usually significantly stronger than cast iron cranks

the truth is cranks don,t fail all that often, but cranks and rotating assembly's do get damaged and fail due to other factors, no crank or connecting rod or piston lasts long if you exceed its limitations and get into detonation damage, over heat or fail to adequately cool or lubricate the components,or float the valves and break valve train components

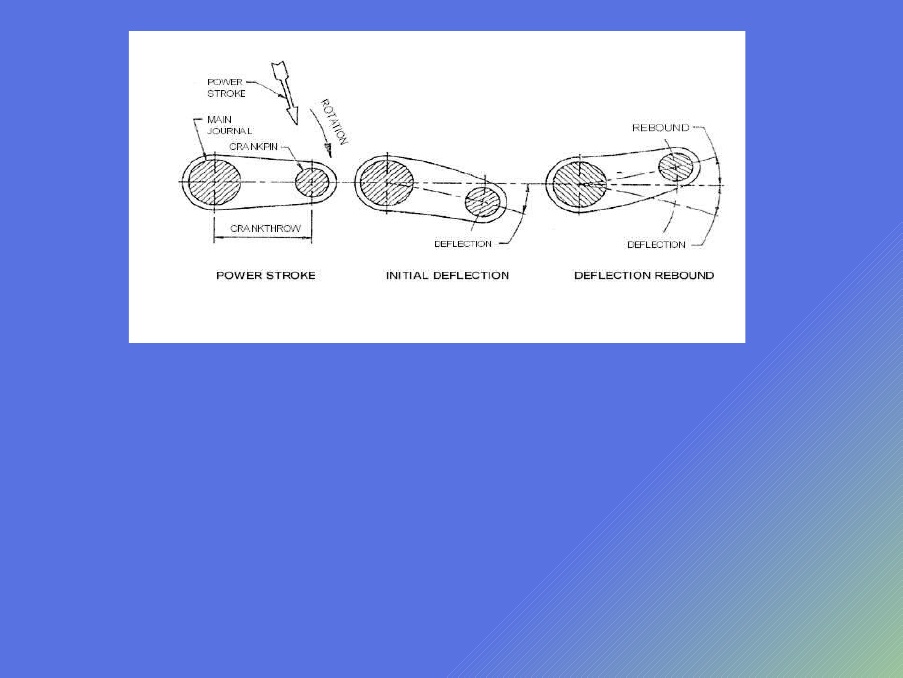

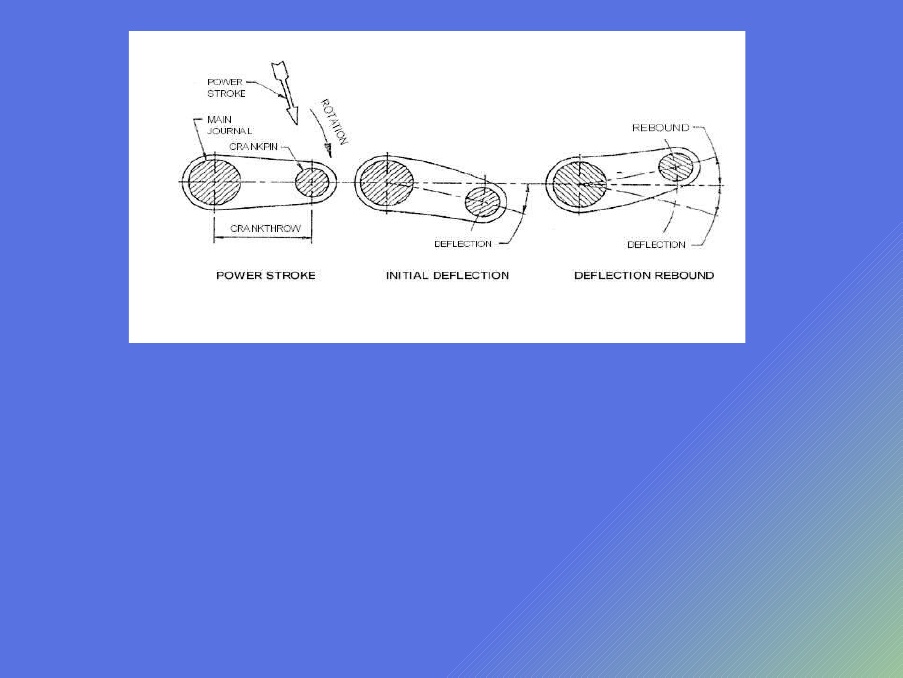

stress is cumulative and the higher the twisting or torsional load is, the more likely you are to break it over time just as if you were bending a piece of wire repeatedly in the same point, it will eventually fail if pushed past the materials elastic limits.

longer stroke lengths provide more leverage so torsional loads on the crank increase, a 283 with its 3" stroke can last darn near for every if properly lubricated and cooled if its stays under 4000 feet per minute in piston speed, compared to a 400 sbc with its 3.75" stroke but other factors will cause problems well before the 283 crank rpm and torsional loads.

Ive pushed cast small block cranks to 430-450 hp and cast big blocks to 500-550hp with zero problems, big block cranks are larger and the casting is thicker giving it more potential resistance to torsional stress, Im sure I could push a properly set up cast steel crank, like SCAT SELLS, to higher stress than the cheaper O.E.M cast iron cranks that might already have had decades of stress, but I generally advise swapping to a good forged crank if nitrous, a supercharger or piston speeds over about 4200rpm are planed and swapping to the better aftermarket connecting rods with 7/16" ARP rod bolts , at 4000 fpm in piston speed and obviously you need to have the correct balance and clearance work done, the block checked for straitness, line honed and a stable valve train.

harmonics and torsional load is more likely to break it than making HP, and if the blocks main caps allow the crank to flex its far more likely to fail.

generally as long as you stay at about 4000 feet per minute in piston speed with a properly balanced rotating assembly you have little chance of having a failure on a non-supercharged or nitrous boosted engine. I see lots of guys exceed those limitations but I also see fairly frequent and expensive failures and in most cases its not the crank that failed, but the connecting rods,rod bolts , detonation issues ,a failure to get the engine properly balanced, a failure to verify valve train or rotating assembly clearances, or the valve train being pushed past its limitations that caused the problem

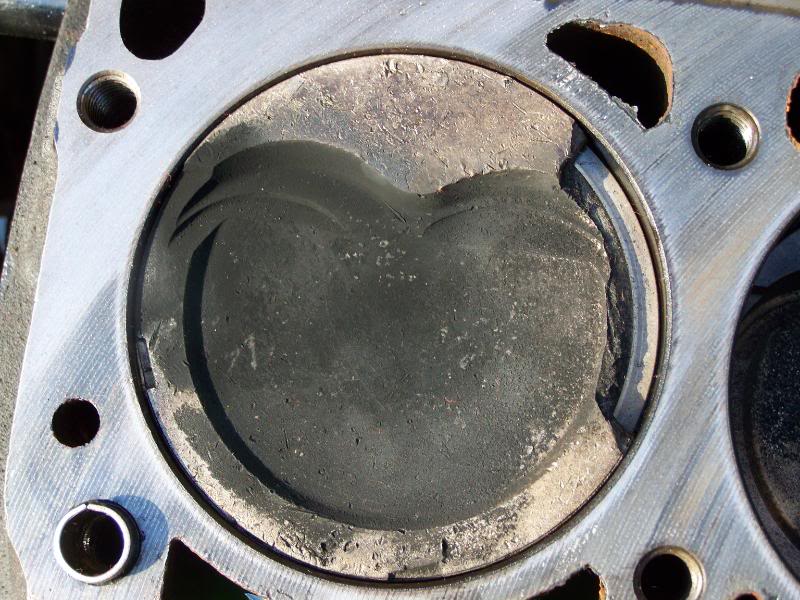

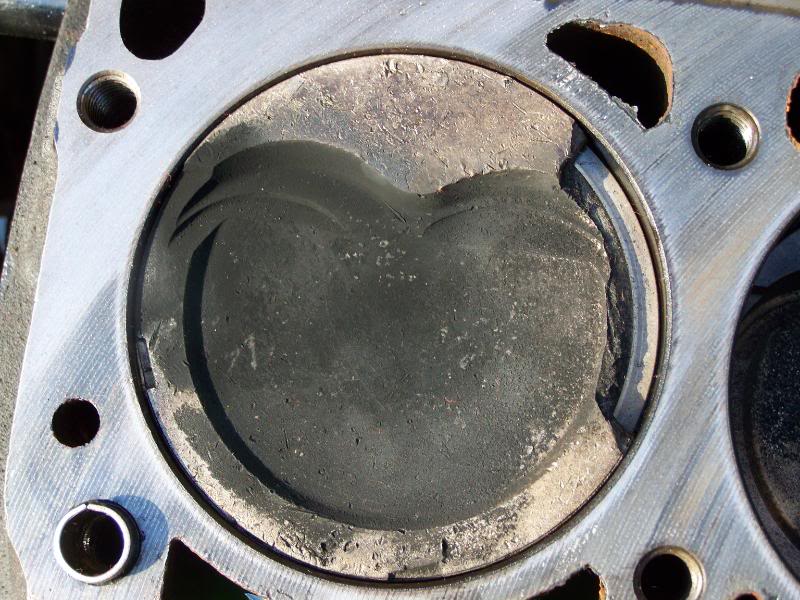

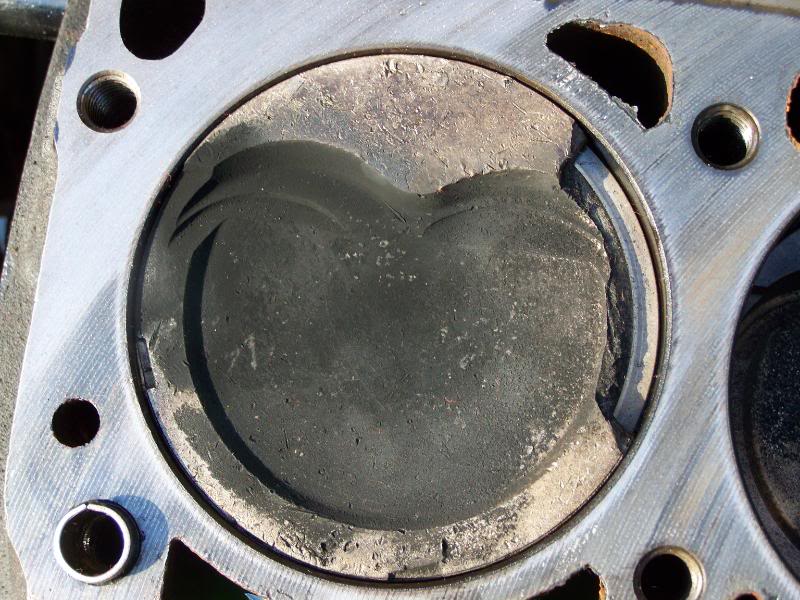

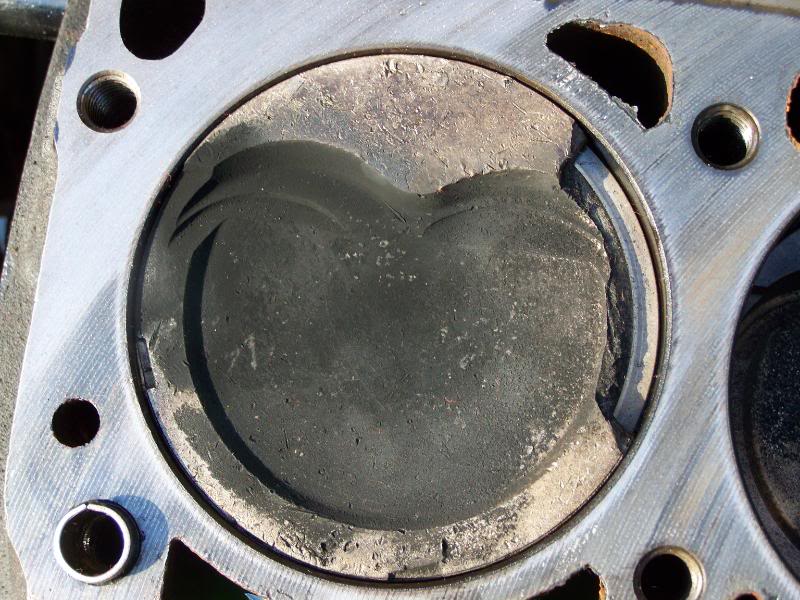

damage to the ring lands can be caused by detonation or just the ring gaps set to tightly

detonation from crappy octane fuel or the wrong ignition advance curve way out of adjustment can beat pistons to death

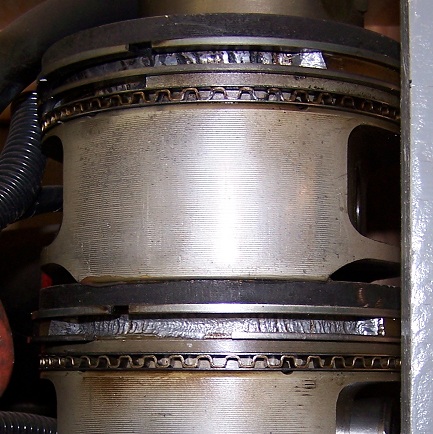

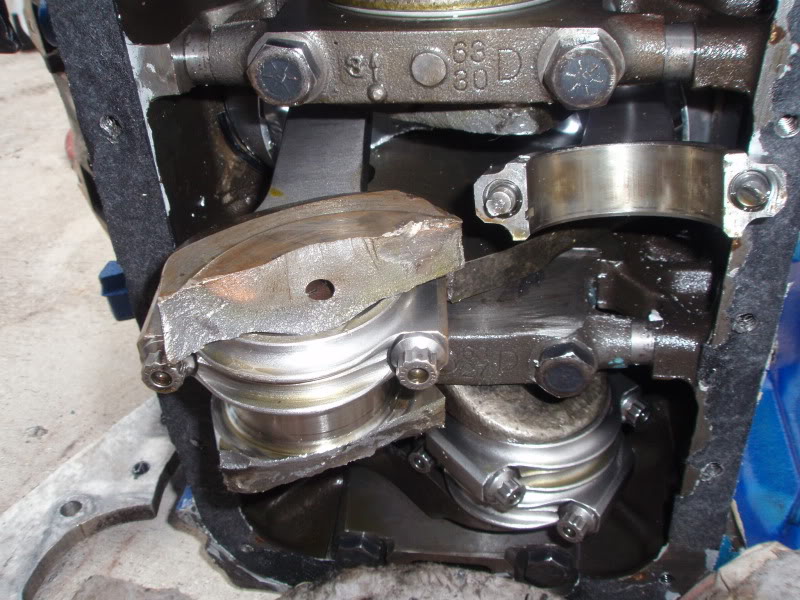

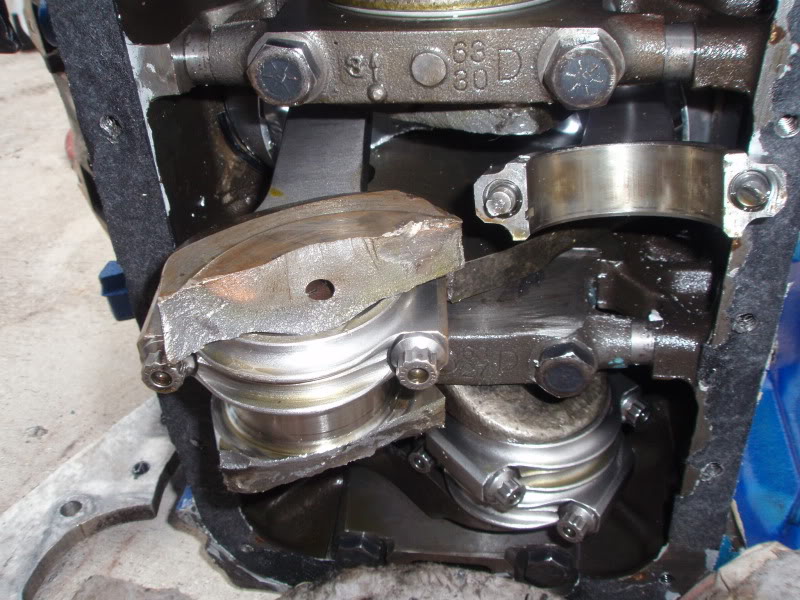

why cast cranks and high stress and rpm are a bad idea

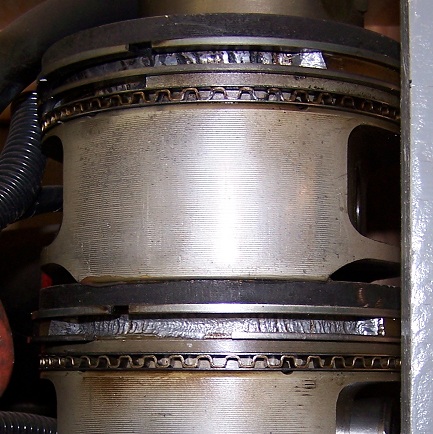

DAMAGE LIKE THIS (picture posted above) IS far MORE FREQUENT WITH cast CRANKS AND ITS FREQUENTLY THE RESULT OF A DAMAGED OR DEFECTIVE BALANCER OR DAMPER! the reason its usually the front two cylinders or front of the crank that fails is because its that front counter weight and crank journal that absorbs the highest amplitude harmonic stress.

so be darn sure you replace the damper and have the new rotating assembly balanced correctly.

Now keep in mind ,Im not inferring you were in any way at fault, if your stock engines crank fails, Ive seen similar damage on a neighbors buick which he maintained very carefully, but the damper self destructed ,allowing the outer balance weight to rotate randomly in relation to his inner hub, which he never realized, other that to say the car intermittently ran rough for no known reason,at a bit over 120K miles and shortly after his crank snapped

READ THESE THREADS, AND SUB LINKED INFO!

yes it may take you awhile but its sure to help your understanding of increased engine durability

http://www.scatcrankshafts.com/

http://scatcrankshafts.com/

viewtopic.php?f=53&t=141&p=175&hilit=balance#p175

viewtopic.php?f=53&t=204

viewtopic.php?f=53&t=343&p=1170&hilit=redline#p1170

viewtopic.php?f=54&t=2187

viewtopic.php?f=53&t=510&p=1158&hilit=cross+drill#p1158

viewtopic.php?f=51&t=6162&p=19172&hilit=main+caps+dowels#p19172

viewtopic.php?f=53&t=3554&p=26564&hilit=balancer+damper#p26564

viewtopic.php?f=53&t=509&p=11324&hilit=torque+settings#p11324

viewtopic.php?f=53&t=2726

viewtopic.php?f=53&t=247&p=1089&hilit=torque+settings#p1089

viewtopic.php?f=52&t=399

viewtopic.php?f=52&t=181

viewtopic.php?f=53&t=1168&p=12205&hilit=cleaning+rods#p12205

how much power will a cast crank work with, at what point do I need to swap or upgrade to a forged crank?"

Thats an excellent question and a great deal of the answer depends on both the application, the block strength,how well its balanced and the stroke and piston speeds, cast cranks come in both cast iron and cast steel versions, and both big block and small block sizes.

what your really asking to some degree is whats likely to cause a cast crank to fail, a forged crank is significantly less likely to fail due to torsional stress but thats not the only factor or reason cranks break.

BTW SCAT cast STEEL cranks are usually significantly stronger than cast iron cranks

the truth is cranks don,t fail all that often, but cranks and rotating assembly's do get damaged and fail due to other factors, no crank or connecting rod or piston lasts long if you exceed its limitations and get into detonation damage, over heat or fail to adequately cool or lubricate the components,or float the valves and break valve train components

stress is cumulative and the higher the twisting or torsional load is, the more likely you are to break it over time just as if you were bending a piece of wire repeatedly in the same point, it will eventually fail if pushed past the materials elastic limits.

longer stroke lengths provide more leverage so torsional loads on the crank increase, a 283 with its 3" stroke can last darn near for every if properly lubricated and cooled if its stays under 4000 feet per minute in piston speed, compared to a 400 sbc with its 3.75" stroke but other factors will cause problems well before the 283 crank rpm and torsional loads.

Ive pushed cast small block cranks to 430-450 hp and cast big blocks to 500-550hp with zero problems, big block cranks are larger and the casting is thicker giving it more potential resistance to torsional stress, Im sure I could push a properly set up cast steel crank, like SCAT SELLS, to higher stress than the cheaper O.E.M cast iron cranks that might already have had decades of stress, but I generally advise swapping to a good forged crank if nitrous, a supercharger or piston speeds over about 4200rpm are planed and swapping to the better aftermarket connecting rods with 7/16" ARP rod bolts , at 4000 fpm in piston speed and obviously you need to have the correct balance and clearance work done, the block checked for straitness, line honed and a stable valve train.

harmonics and torsional load is more likely to break it than making HP, and if the blocks main caps allow the crank to flex its far more likely to fail.

generally as long as you stay at about 4000 feet per minute in piston speed with a properly balanced rotating assembly you have little chance of having a failure on a non-supercharged or nitrous boosted engine. I see lots of guys exceed those limitations but I also see fairly frequent and expensive failures and in most cases its not the crank that failed, but the connecting rods,rod bolts , detonation issues ,a failure to get the engine properly balanced, a failure to verify valve train or rotating assembly clearances, or the valve train being pushed past its limitations that caused the problem

damage to the ring lands can be caused by detonation or just the ring gaps set to tightly

detonation from crappy octane fuel or the wrong ignition advance curve way out of adjustment can beat pistons to death

why cast cranks and high stress and rpm are a bad idea

DAMAGE LIKE THIS (picture posted above) IS far MORE FREQUENT WITH cast CRANKS AND ITS FREQUENTLY THE RESULT OF A DAMAGED OR DEFECTIVE BALANCER OR DAMPER! the reason its usually the front two cylinders or front of the crank that fails is because its that front counter weight and crank journal that absorbs the highest amplitude harmonic stress.

so be darn sure you replace the damper and have the new rotating assembly balanced correctly.

Now keep in mind ,Im not inferring you were in any way at fault, if your stock engines crank fails, Ive seen similar damage on a neighbors buick which he maintained very carefully, but the damper self destructed ,allowing the outer balance weight to rotate randomly in relation to his inner hub, which he never realized, other that to say the car intermittently ran rough for no known reason,at a bit over 120K miles and shortly after his crank snapped

READ THESE THREADS, AND SUB LINKED INFO!

yes it may take you awhile but its sure to help your understanding of increased engine durability

http://www.scatcrankshafts.com/

http://scatcrankshafts.com/

viewtopic.php?f=53&t=141&p=175&hilit=balance#p175

viewtopic.php?f=53&t=204

viewtopic.php?f=53&t=343&p=1170&hilit=redline#p1170

viewtopic.php?f=54&t=2187

viewtopic.php?f=53&t=510&p=1158&hilit=cross+drill#p1158

viewtopic.php?f=51&t=6162&p=19172&hilit=main+caps+dowels#p19172

viewtopic.php?f=53&t=3554&p=26564&hilit=balancer+damper#p26564

viewtopic.php?f=53&t=509&p=11324&hilit=torque+settings#p11324

viewtopic.php?f=53&t=2726

viewtopic.php?f=53&t=247&p=1089&hilit=torque+settings#p1089

viewtopic.php?f=52&t=399

viewtopic.php?f=52&t=181

viewtopic.php?f=53&t=1168&p=12205&hilit=cleaning+rods#p12205

Last edited by a moderator: