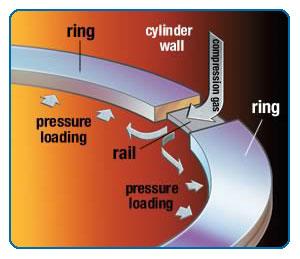

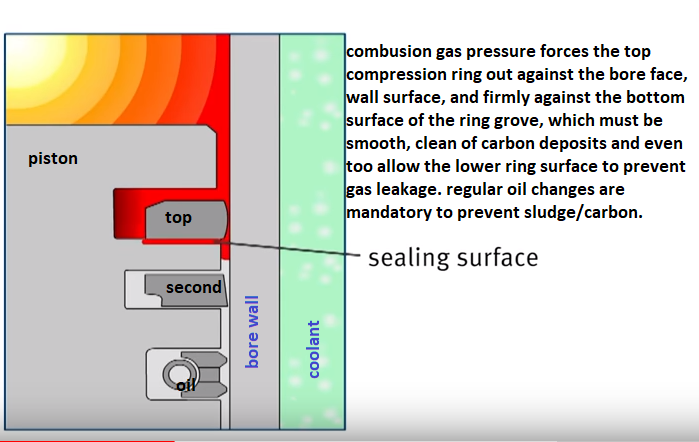

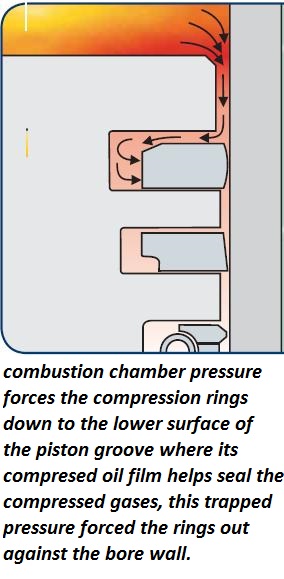

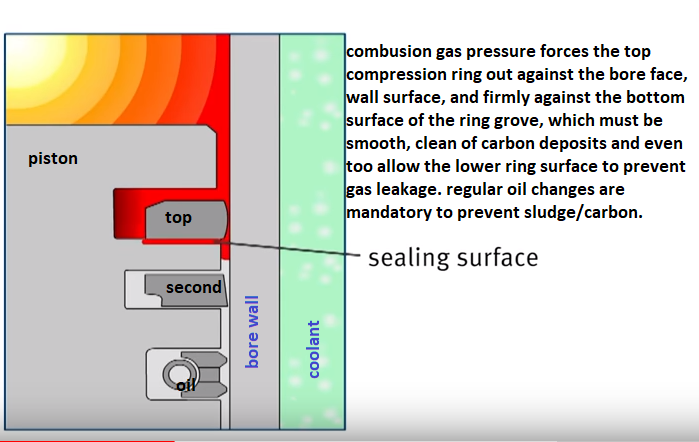

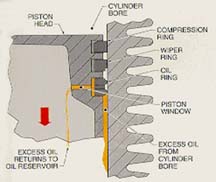

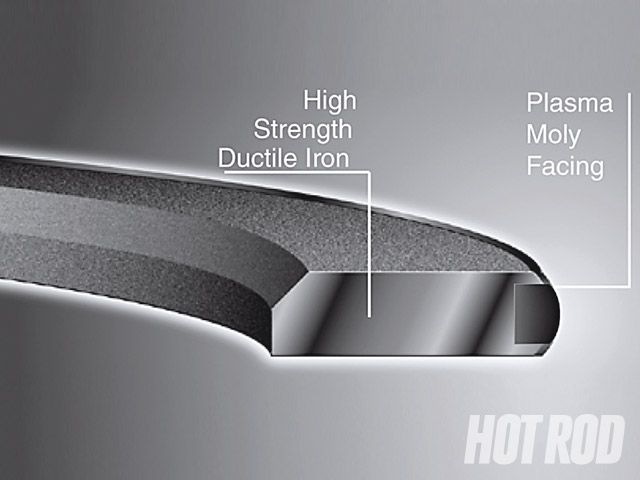

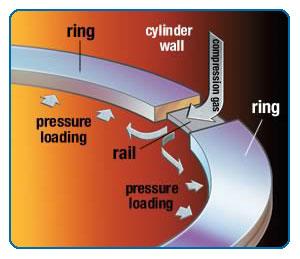

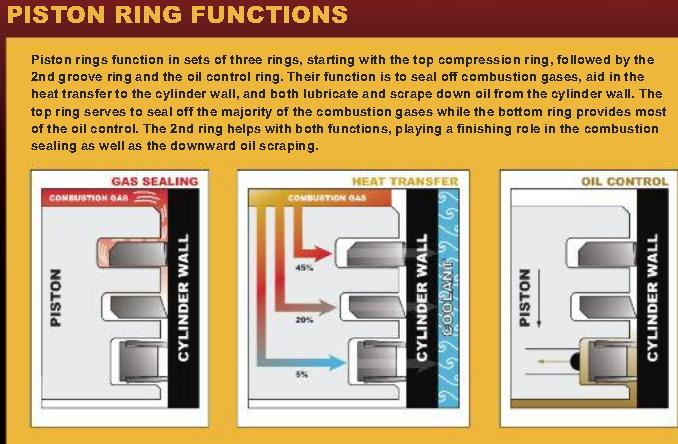

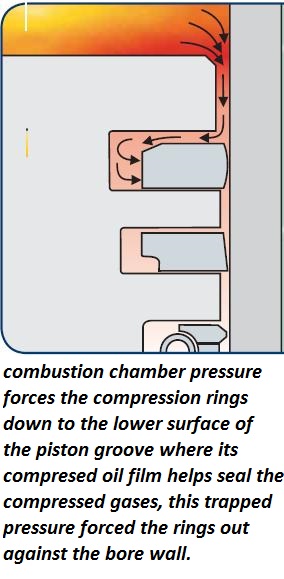

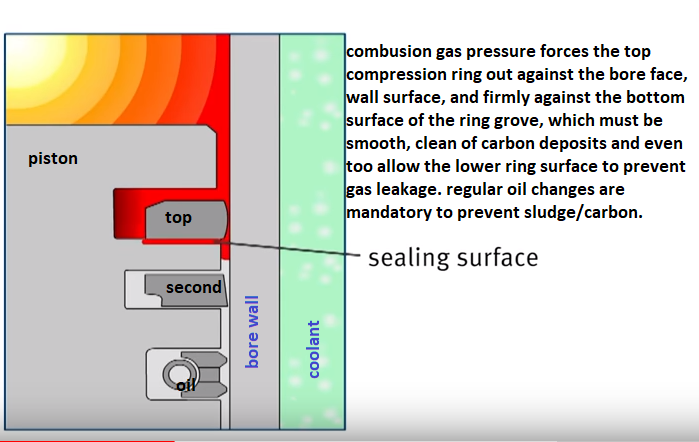

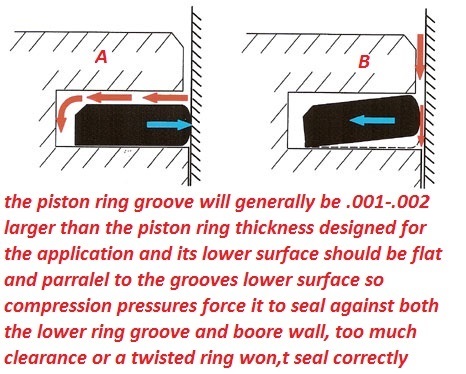

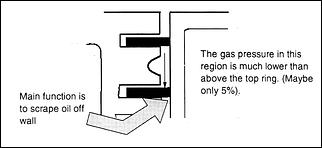

the job of the rings is to provide a high pressure gas tight seal preventing pressure in the combustion chamber during the compression, exhaust and power strokes above the piston from leaking past the rings and piston, the combination of slight inertial loads friction and pressure above the piston

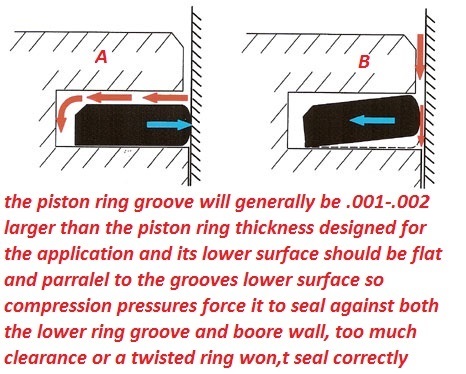

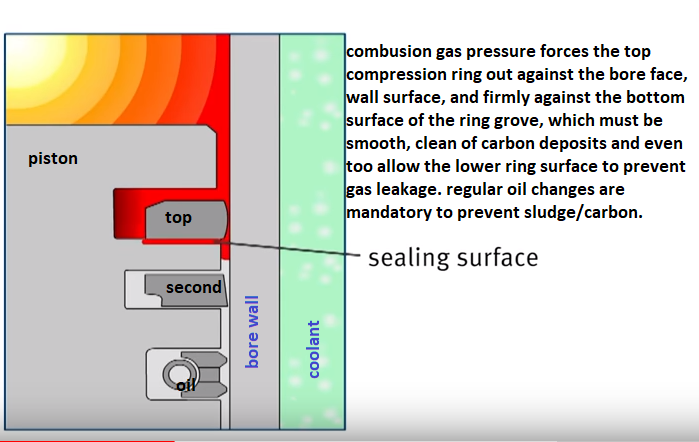

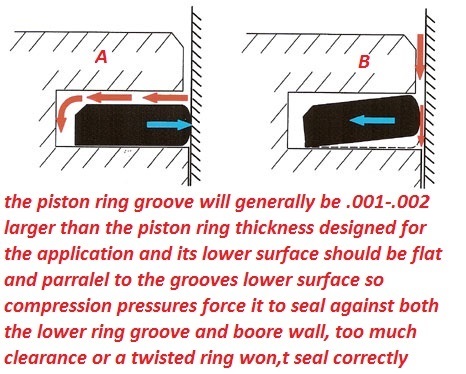

forced the rings down against the lower groove surface, theres a slight gap between the upper ring surface and the piston groove that allows high pressure gases to get in behind the ring and along with some minor ring tension this expands the ring out to firmly contact and ride the bore surface. as that gas pressure increases the ring is held ever more firmly seated against the bore surface.the small gap above the ring in its groove and behind the ring that allow that high gas pressure to seat the ring is critical to proper function,keep in mind its the SPACING, indexing and relationship to the rings, is designed to minimize the loss of cylinder pressure thru the ring gaps, thats key, here, not where the gaps are exactly located , because the fact is that piston rings do tend to rotate in the piston groves in most engines, and its rare to find the ring gaps in the same location once the engines been run for several hours. Id also point out that failure to have the bore honed with the correct deck plates tends to reduce the ring seal. in fact having the rings rotate in the piston grooves tends to reduce bore wear, and keep the grooves clearance free from carbon build up

theres at least a few hours of very worth while , and quite useful reading in this thread and links that will prevent you wasting time and money, keep in mind the sub links contain a huge wealth of additional info youll need

what seems to be over-looked in many engine builds is simply the fact you'll almost always DEEPLY regret jumping into the engine build with both feet and waving your check book as you sink ever deeper into piles of parts receipts and machine shop bills, rather than stepping back with a legal pad, and a calculator and listing in minute detail exactly what you want to accomplish, and taking the time and effort too list and check out in detail what each machine shop procedure costs, why its required and how much each components costs, what your options are and how each component will add too or benefit the completed combo (or in some cases cause you time and grief)

stepping back and thinking things through in detail and listing the cost and potential problems and finding the solutions BEFORE you dive into the process may be a lot less fun, but in the long term its sure to cost less and result in a far better finished project!

you might be amazed at what a couple hours research into the subject will do to help you build a much more durable engine, and actually reading thru links and sub-links and asking questions helps a great deal

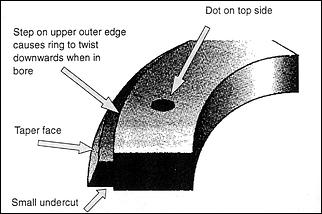

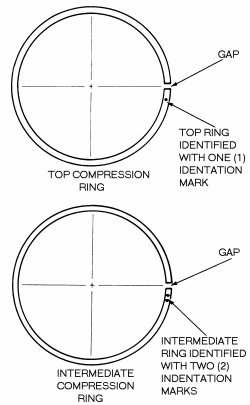

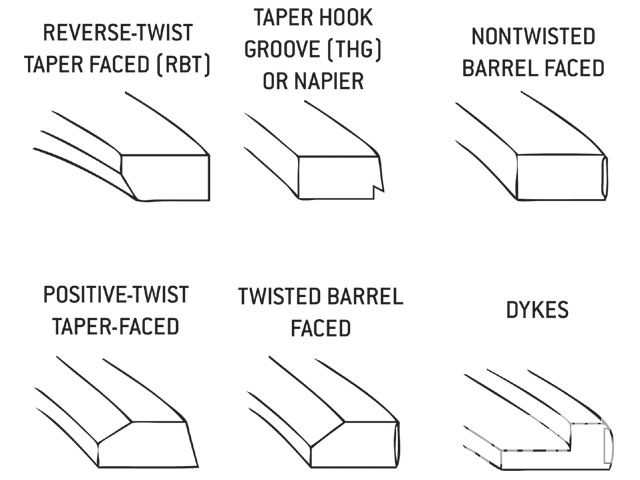

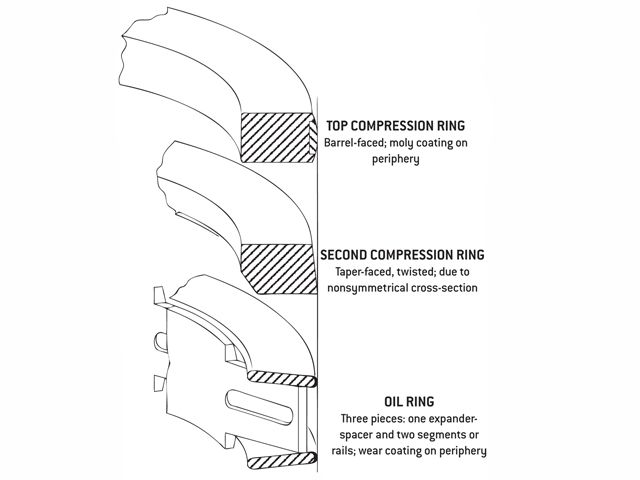

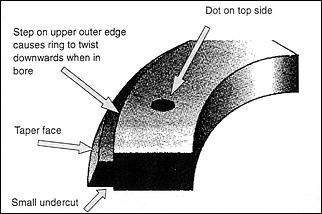

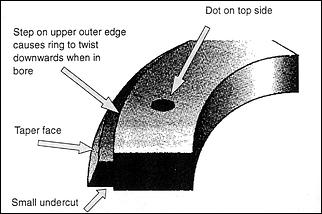

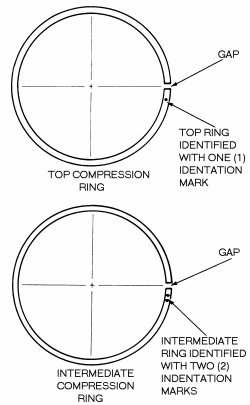

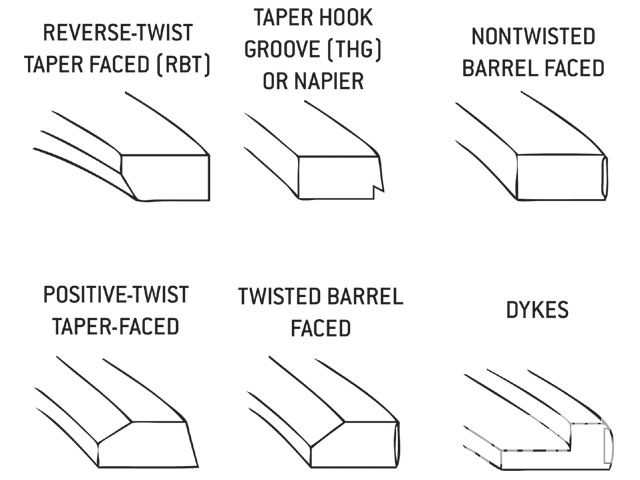

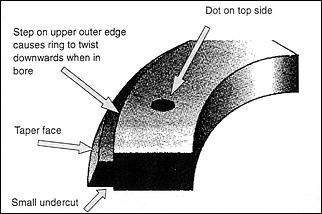

BTW, most piston compression rings have a dot on the upper surface to indicate the side designed to face the top of the piston

BTW GAPLESS PISTON RINGS HAVE TWO PIECES THAT EACH MUST BE GAPPED< THE IDEA IS THAT THE TWO GAPS IN THE SET ARE ON OPOSIRE SIDES OF THE PISTON GROOVE

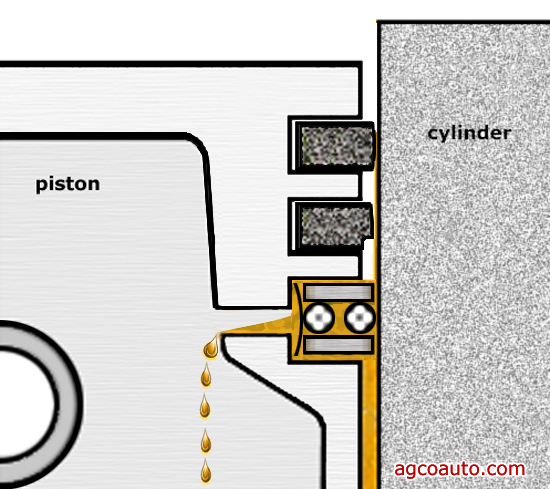

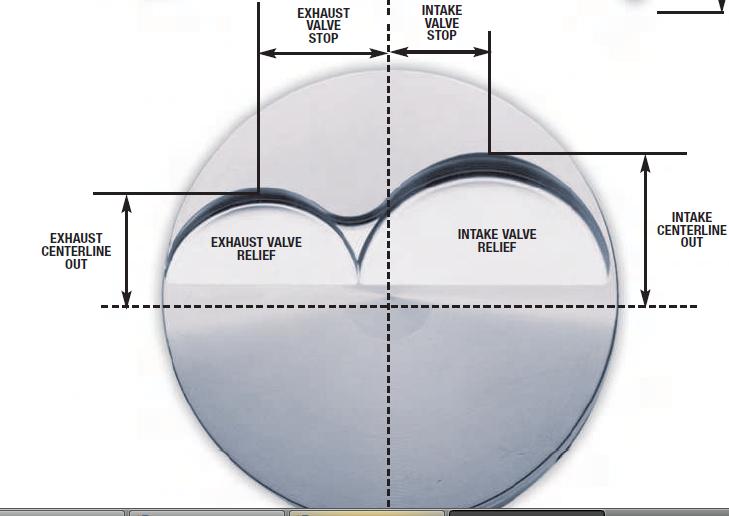

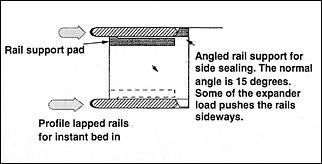

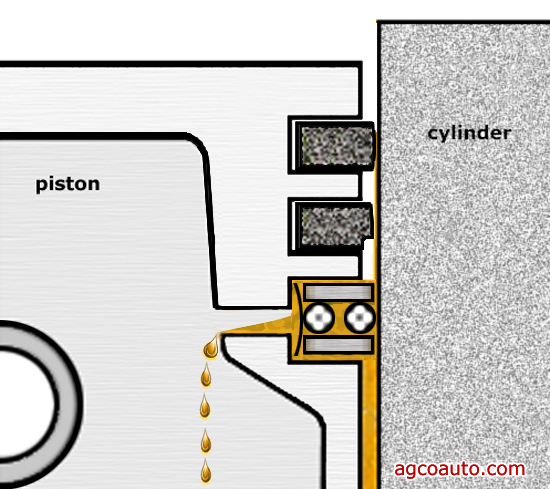

NOTICE the two totally different OIL ring scraper ring widths in this picture above,OIL RINGS come in dozens of designs so, you can not use all oil rings on all pistons and you can,t swap expanders and wipe rings thru different designs, and you must verify piston groove measurements , measure carefully as the piston groove depth and back clearance must match the rings you use or youll have major problems

http://www.superstreetonline.com/how-to/engine/impp-1110-piston-anatomy-tech-knowledge/

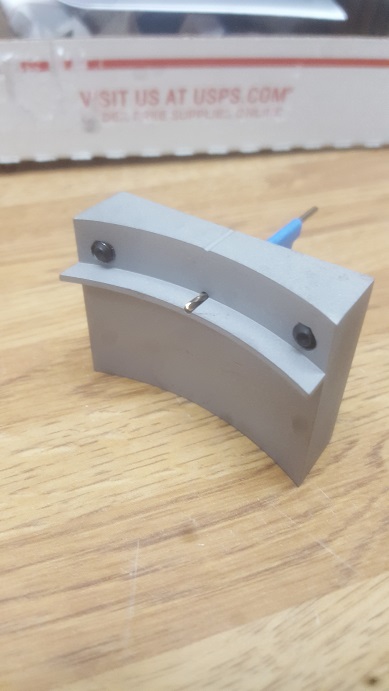

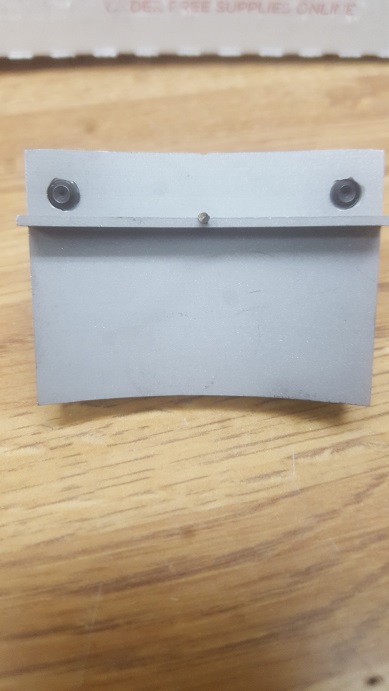

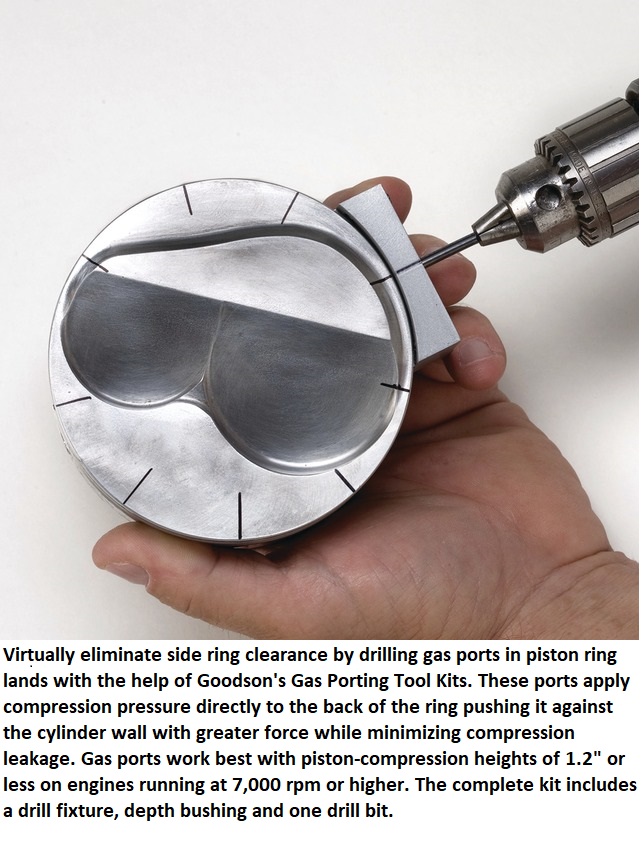

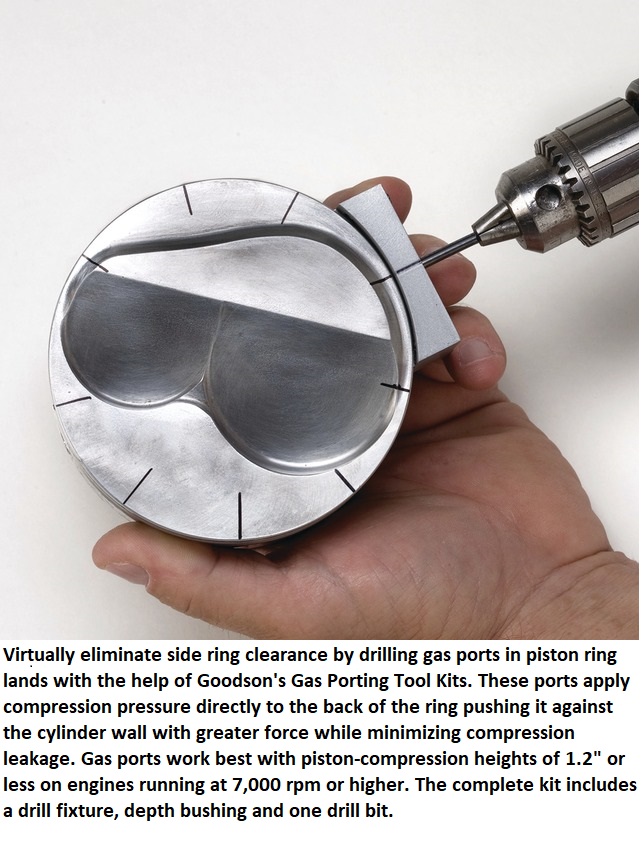

https://goodson.com/products/gas-porting-tools

these tools come in various ring sizes ,(but the various piston diameters are not as critical as ring width, it should be obvious that you MUST USE the tool that places the drilled gas port at the correct place in the upper ring groove roof and you damn sure better not drill deeper than the rear edge of the ring groove or youll destroy the piston

most piston compression rings have a dot on the upper surface to indicate the side designed to face the top of the piston

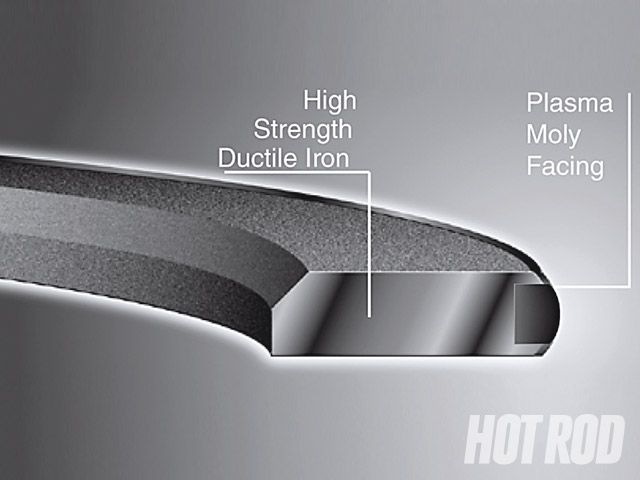

ideally the pressure above the piston gets behind the top compression ring and increases the force holding the ring face to the bore surface, noticeably more than the ring tension alone can do.

most piston compression rings have a dot on the upper surface to indicate the side designed to face the top of the piston

ideally the pressure above the piston gets behind the top compression ring and increases the force holding the ring face to the bore surface, noticeably more than the ring tension alone can do.

http://www.grumpysperformance.com/nov2017/ringgg4.pn

g

Ive heard a few engine builders say that rings don,t really wear out as much as its crud and varnish from old burnt oil building up behind and around the rings in the piston ring grooves thats prevents the gas pressure from building up behind them and allowing them to seal properly

(a great reason to change oil frequently, and use ash-less synthetic oils that clean varnish build-up)

the rings ride on a micro layer of oil trapped in the bore walls by the micro honed scratches, that allows the rings to ride on that micro layer and prevents most ring and bore wear.

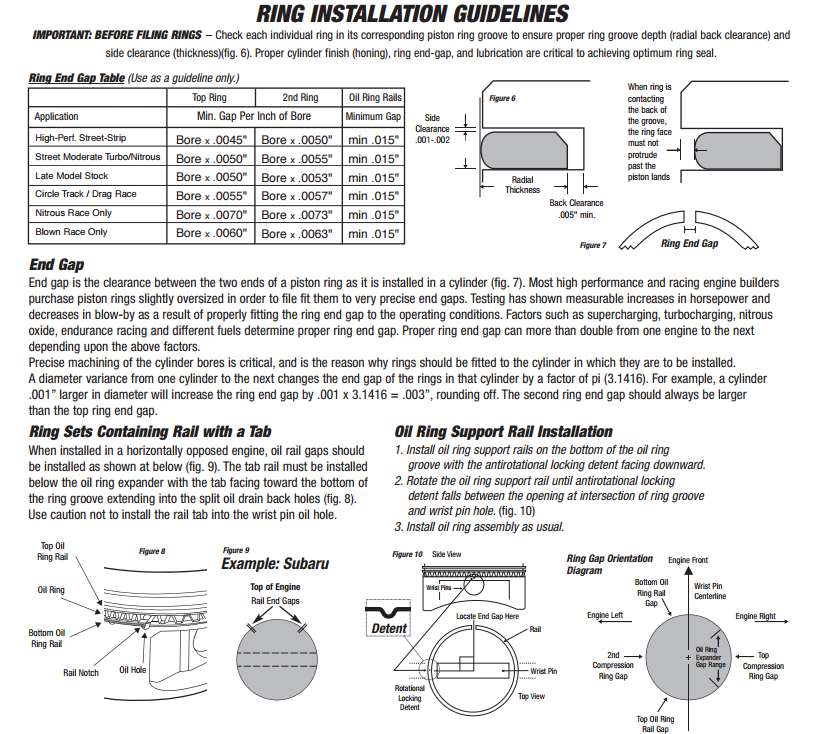

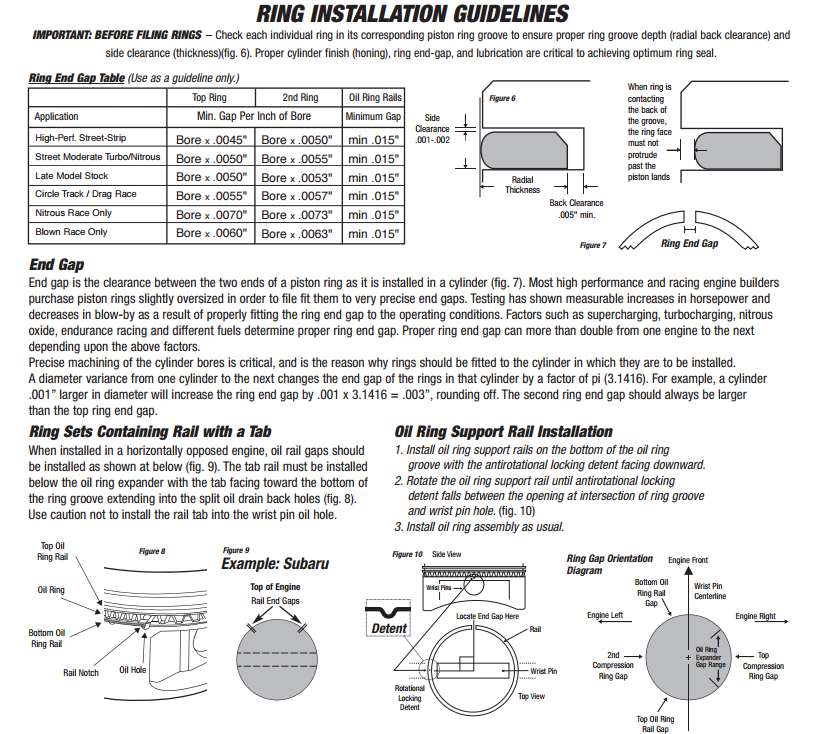

rings get hot during operation and expand, the amount they expand varies with the ring design and operating temps but generally a MINIMUM OF .0040 per inch of bore diam, ring end gap is required to prevent the ring ends from firmly butting and locking the ring in the bore destroying both ring and piston.

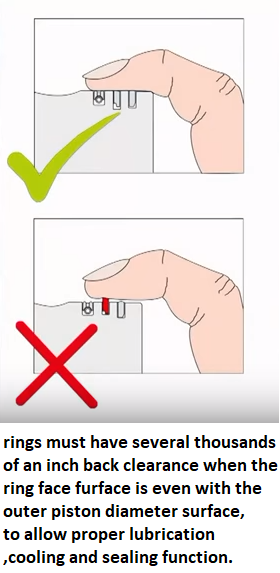

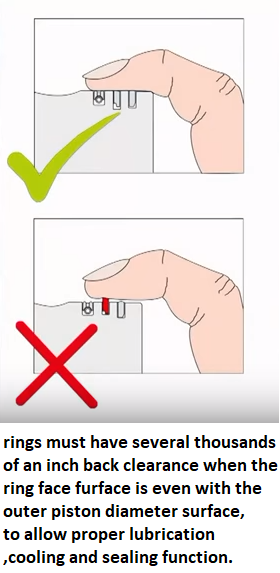

the ring must have a small back space when its outer surface is flush with the pistons outer diam. to allow high pressure gasses to expand the rings outward and allow the rings to float in the ring groove to maintain oil cooling.both the piston and rings expand under high heat during operational conditions so clearances tend to get slightly smaller.

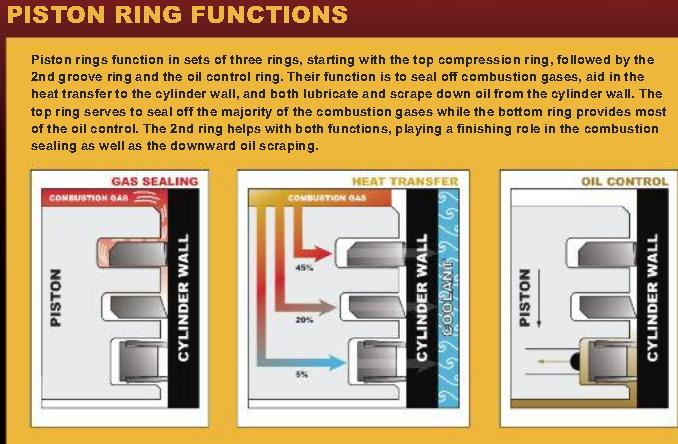

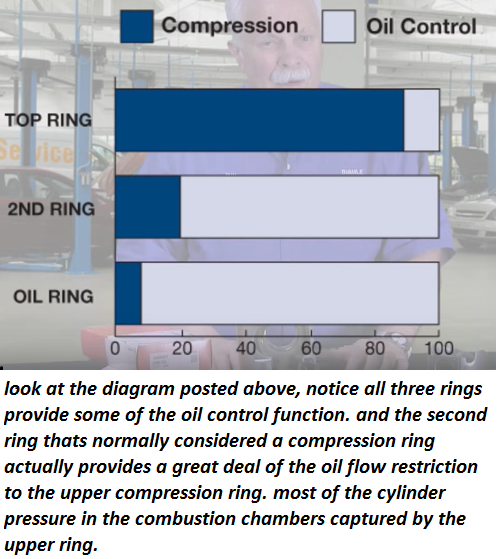

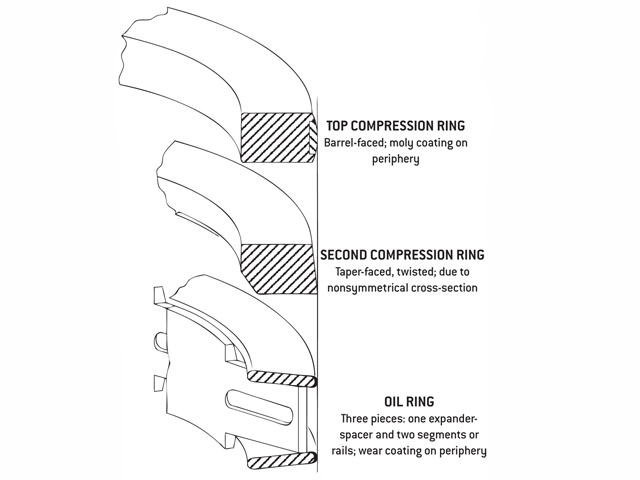

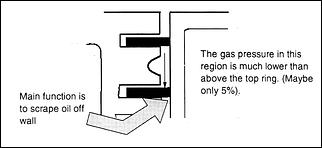

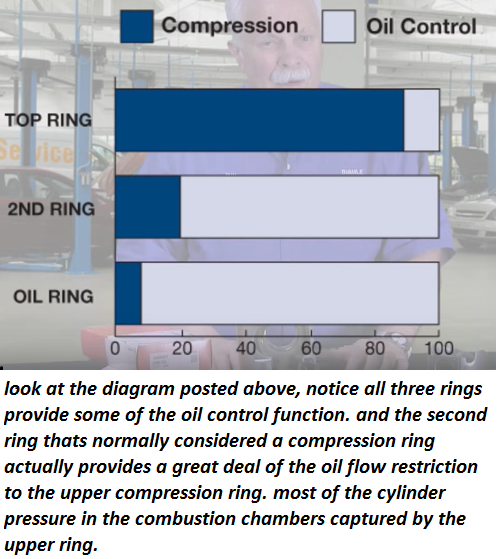

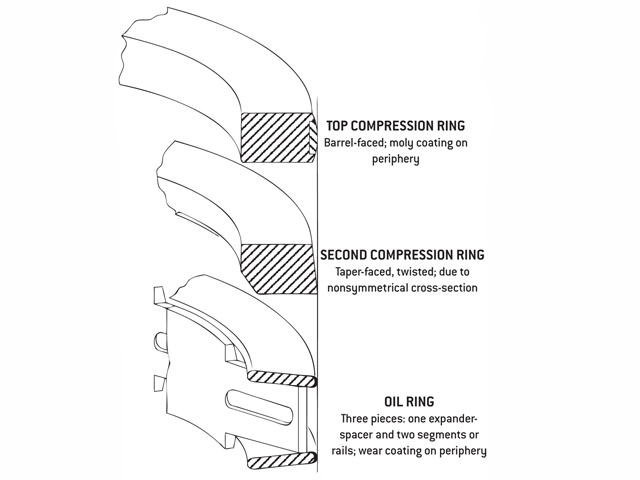

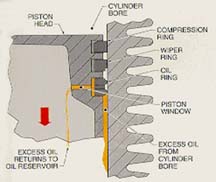

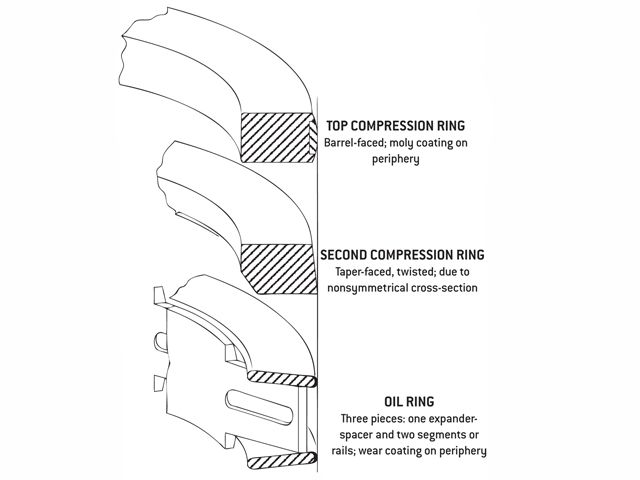

the top ring does about 90% plus to the sealing of pressure the second ring reduces pressure loss but its main job is reducing oil on the bore surface so the top ring can seal better, the lower oil ring is mostly a scraper to channel oil on the cylinder walls back thru vents in the rear of its groove in the piston to cool the piston and reduce oil the second ring needs to deal with

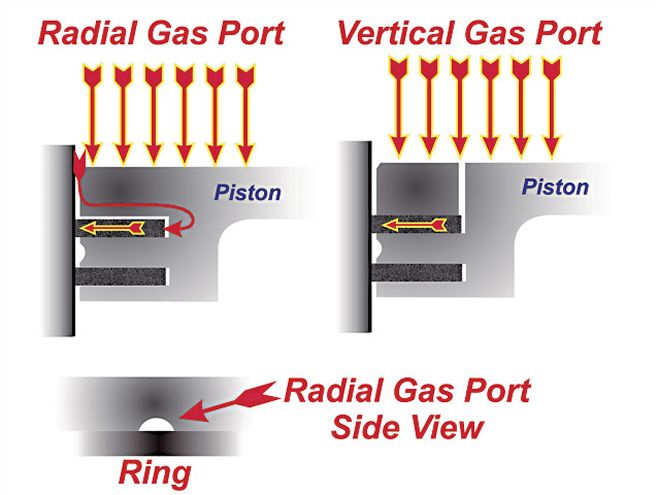

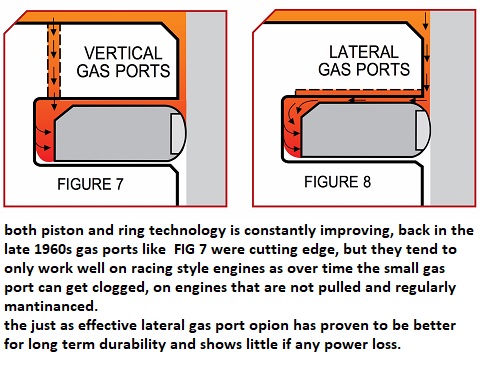

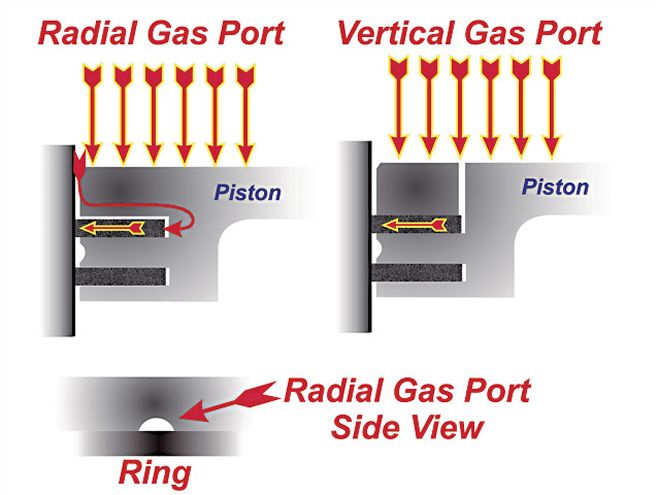

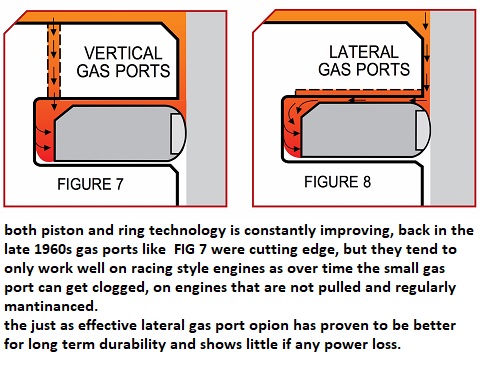

originally when it was understood how important it was to get high combustion gas flow and pressure behind the rings on race cars to get every advantage, in ring seal, gas port holes were drilled vertically from the piston top down to the first ring land (right piston). But vertical holes can get carbon-plugged, and they may promote crack formation resulting in piston failure above the groove. An alternative method is micro “half-moon†lateral holes in the top of the groove (left piston) LOOK CLOSELY AT THE MINI SEMI CIRCULAR GROOVES CUT IN THE UPPER RING SLOT ROOF ON THE TOP RING LANDS LOWER SURFACE this generally requires a fixture and a mill to do correctly, Ive used 1/16" diam half circle groves about every 30 degrees , I can,t tell you it made a noticeable difference because gas porting rarely helps a great deal below 6000rpm, or 4000fpm in piston speed, but it won,t hurt either, but above 6000 rpm or 4000fpm in piston speed dyno testing has shown a power advantage many times

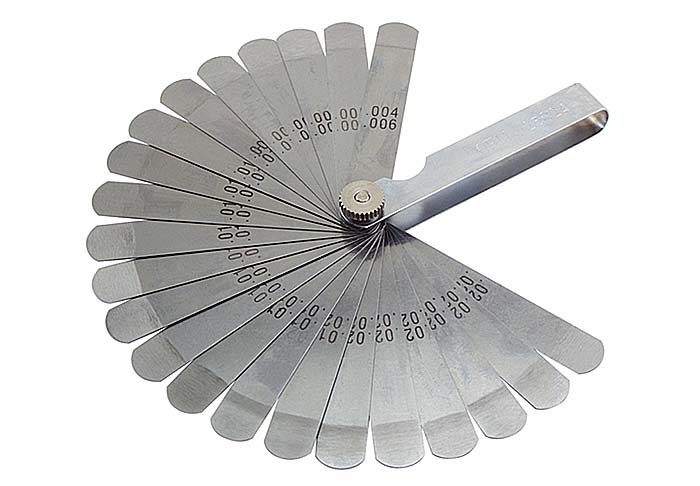

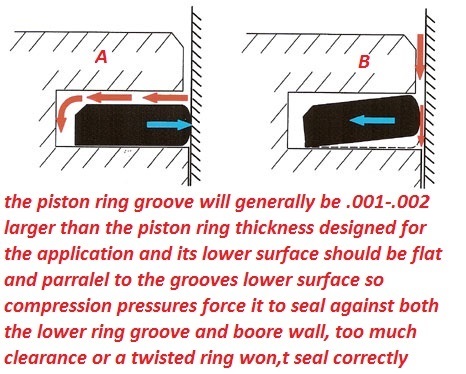

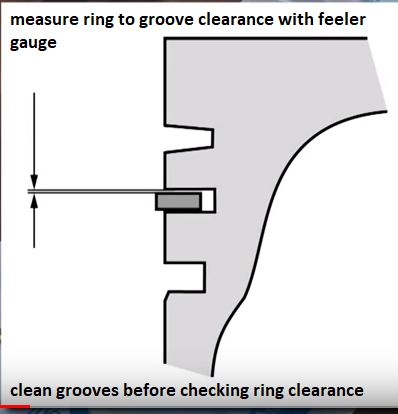

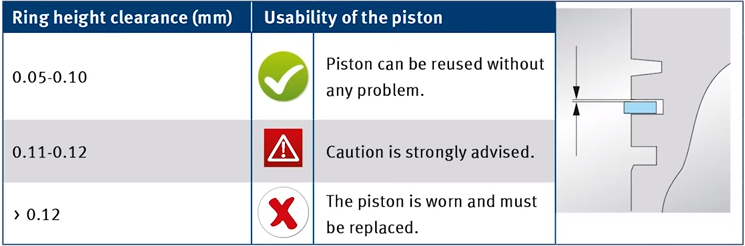

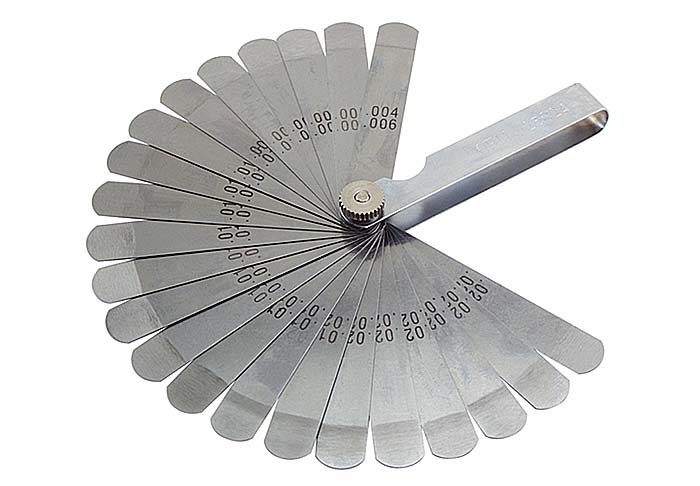

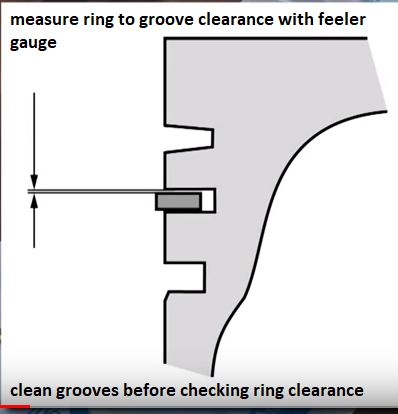

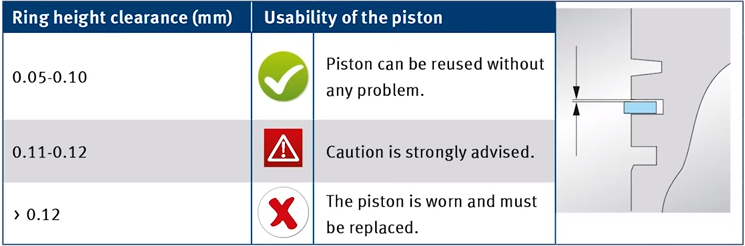

check the vertical clearance with respect to the ring and ring land. This will be different for various engines, and pistons so check with both the ring and piston supplier for their input here. 0.0008-inch -.0012 vertical clearance is about the normal range,

(READ CAREFULLY THAT'S AROUND A ONE THOUSANDTH OF AN INCH CLEARANCE) but CHECK with inch feeler gauges to determine these. remember ,Don’t hold these gauges in your hand for long; they will change thickness due to temperature very easily, when dealing with only a single one thousandth of an inch

Read more: http://www.circletrack.com/howto/4639_m ... z1Xn3l3t9n

Read more: http://www.carcraft.com/techarticles/pi ... z1XmADGNoq

http://garage.grumpysperformance.co...gine-project-dart-shp.3814/page-12#post-17457

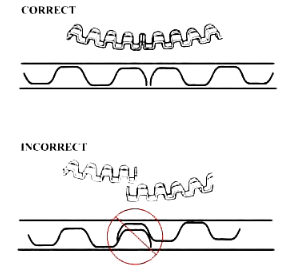

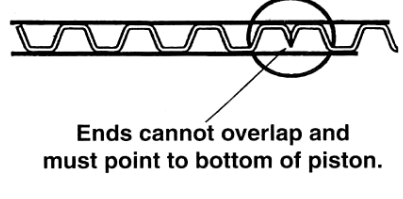

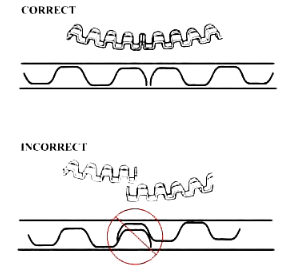

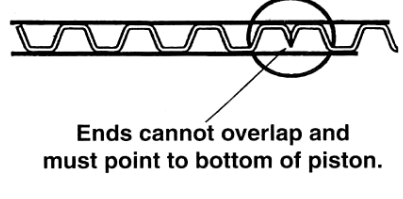

if you have oil ring expanders with the plastic bits,they are there to prevent you from over lapping the ends of the oil ring expander, theres some oil ring expander s that are vertical ,some horizontal, but all have the ends butt , none over-lap

READ THE LINKS AND SUB LINKS

http://www.kb-silvolite.com/news.php?ac ... ad&N_id=27

http://www.circletrack.com/techarticles ... index.html

http://www.circletrack.com/howto/34098_ ... index.html

http://www.circletrack.com/techarticles ... index.html

viewtopic.php?f=53&t=852

viewtopic.php?f=53&t=247

viewtopic.php?f=53&t=3897

viewtopic.php?f=53&t=4630

viewtopic.php?f=53&t=509

viewtopic.php?f=53&t=4472

http://www.elstars.com.au/pdf/piston_rings_guide.pdf

http://www.hotrod.com/techarticles/engi ... ewall.html

http://autospeed.com/cms/title_Piston-R ... ticle.html

http://www.ret-monitor.com/articles/pdf/rings.pdf

http://www.rosspistons.com/information/ ... lation.pdf

http://www.enginebuildermag.com/Article ... power.aspx

http://www.jepistons.com/PDFs/TechCorne ... atures.pdf

HOW DO RINGS WORK?

The information contained in this document is for general purposes. It only represents technical

opinions at the time of publishing. It does not guarantee any or effect any product warranties given.

Information was taken from TOTAL SEAL Company website and provided AS IS.

Reference link: http://www.totalseal.com/howdoo.html

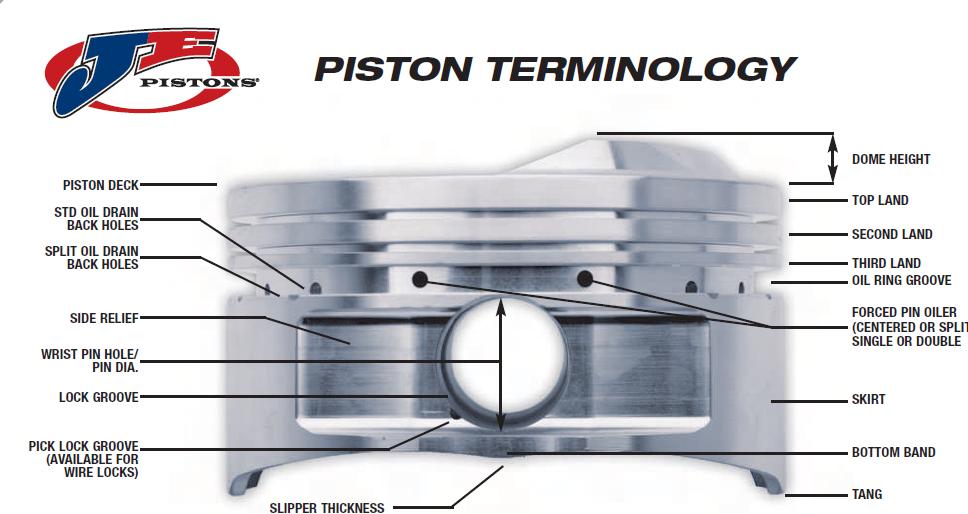

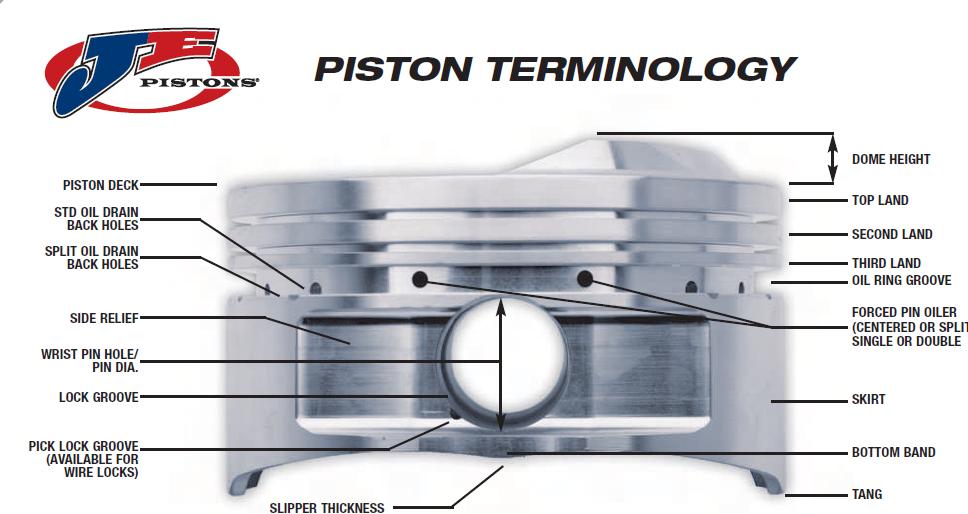

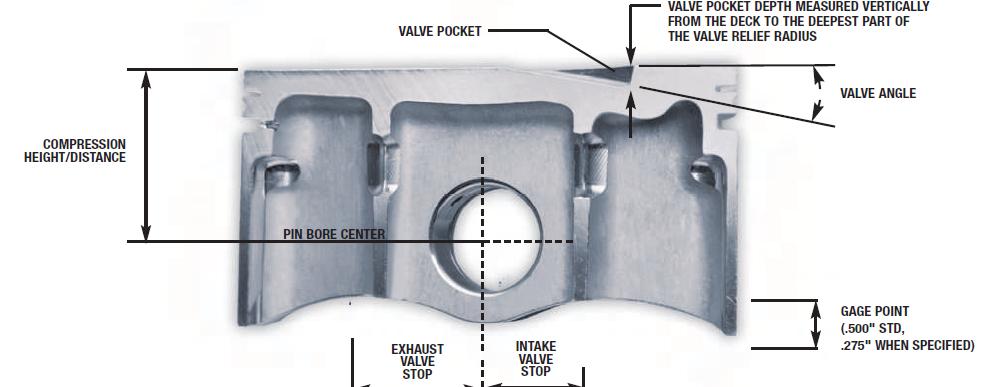

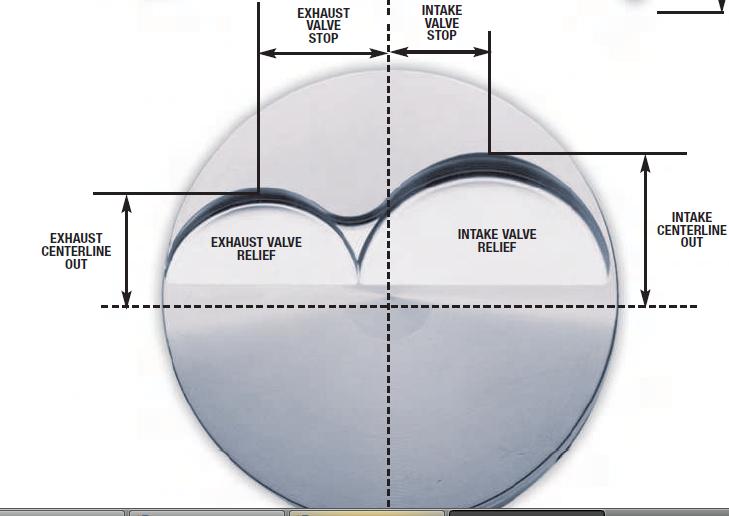

(I) Minor Thrust Face: The side of the

piston opposite the major thrust face.

(J) Piston Pin Bushing: If used, the

bushing between the piston pin bore and

the pin.

(N) Scuff Band: One or more raised bands

of piston material used in some piston

designs to reduce scuffing.

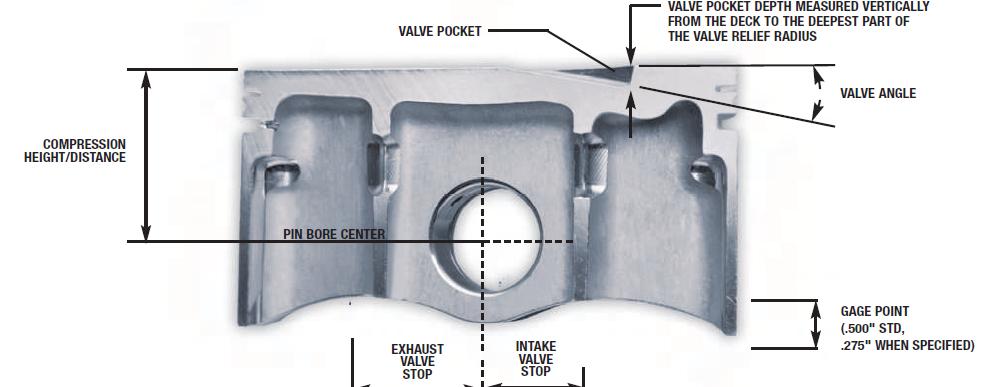

(O) Groove Depth: The distance between

the back of the ring groove and the

cylinder wall with the piston centered.

(P) Groove Root Diameter: Piston diameter measured at the back of the groove.

May vary on the same piston between ring grooves.

(Q) Land Diameter: Diameter of a given land. Can sometimes vary by design from

top to bottom.

(R) Land clearance: The difference in diameter between the cylinder bore and the

land diameter. "R" is 1/2 the total.

(S) Skirt Clearance: The difference in diameter between the cylinder bore and skirt

diameter. "S" is 1/2 the total.

(T) Skirt Groove: A ring groove cut below the pin bore to carry an oil ring.

(U) Pin Bore Offset: The distance the pin bore is offset from center.

(V) Groove Spacer: Used on re-grooved pistons to return a ring groove to specs or in

some performance applications to facilitate the use of narrower ring sets than the

grooves were originally cut for.

Ring Terms And Measurements

(A) Free gap: The ring end clearance when the ring is uncompressed.

(B) Compressed gap: Also known as ring gap, it is the end gap measured when the

ring is installed.

(C) Radial Wall Thickness: the distance between the inside and outside faces of the

ring wall.

forced the rings down against the lower groove surface, theres a slight gap between the upper ring surface and the piston groove that allows high pressure gases to get in behind the ring and along with some minor ring tension this expands the ring out to firmly contact and ride the bore surface. as that gas pressure increases the ring is held ever more firmly seated against the bore surface.the small gap above the ring in its groove and behind the ring that allow that high gas pressure to seat the ring is critical to proper function,keep in mind its the SPACING, indexing and relationship to the rings, is designed to minimize the loss of cylinder pressure thru the ring gaps, thats key, here, not where the gaps are exactly located , because the fact is that piston rings do tend to rotate in the piston groves in most engines, and its rare to find the ring gaps in the same location once the engines been run for several hours. Id also point out that failure to have the bore honed with the correct deck plates tends to reduce the ring seal. in fact having the rings rotate in the piston grooves tends to reduce bore wear, and keep the grooves clearance free from carbon build up

theres at least a few hours of very worth while , and quite useful reading in this thread and links that will prevent you wasting time and money, keep in mind the sub links contain a huge wealth of additional info youll need

what seems to be over-looked in many engine builds is simply the fact you'll almost always DEEPLY regret jumping into the engine build with both feet and waving your check book as you sink ever deeper into piles of parts receipts and machine shop bills, rather than stepping back with a legal pad, and a calculator and listing in minute detail exactly what you want to accomplish, and taking the time and effort too list and check out in detail what each machine shop procedure costs, why its required and how much each components costs, what your options are and how each component will add too or benefit the completed combo (or in some cases cause you time and grief)

stepping back and thinking things through in detail and listing the cost and potential problems and finding the solutions BEFORE you dive into the process may be a lot less fun, but in the long term its sure to cost less and result in a far better finished project!

you might be amazed at what a couple hours research into the subject will do to help you build a much more durable engine, and actually reading thru links and sub-links and asking questions helps a great deal

BTW, most piston compression rings have a dot on the upper surface to indicate the side designed to face the top of the piston

BTW GAPLESS PISTON RINGS HAVE TWO PIECES THAT EACH MUST BE GAPPED< THE IDEA IS THAT THE TWO GAPS IN THE SET ARE ON OPOSIRE SIDES OF THE PISTON GROOVE

NOTICE the two totally different OIL ring scraper ring widths in this picture above,OIL RINGS come in dozens of designs so, you can not use all oil rings on all pistons and you can,t swap expanders and wipe rings thru different designs, and you must verify piston groove measurements , measure carefully as the piston groove depth and back clearance must match the rings you use or youll have major problems

http://www.superstreetonline.com/how-to/engine/impp-1110-piston-anatomy-tech-knowledge/

https://goodson.com/products/gas-porting-tools

these tools come in various ring sizes ,(but the various piston diameters are not as critical as ring width, it should be obvious that you MUST USE the tool that places the drilled gas port at the correct place in the upper ring groove roof and you damn sure better not drill deeper than the rear edge of the ring groove or youll destroy the piston

most piston compression rings have a dot on the upper surface to indicate the side designed to face the top of the piston

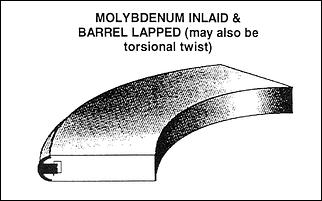

ideally the pressure above the piston gets behind the top compression ring and increases the force holding the ring face to the bore surface, noticeably more than the ring tension alone can do.

most piston compression rings have a dot on the upper surface to indicate the side designed to face the top of the piston

ideally the pressure above the piston gets behind the top compression ring and increases the force holding the ring face to the bore surface, noticeably more than the ring tension alone can do.

http://www.grumpysperformance.com/nov2017/ringgg4.pn

g

Ive heard a few engine builders say that rings don,t really wear out as much as its crud and varnish from old burnt oil building up behind and around the rings in the piston ring grooves thats prevents the gas pressure from building up behind them and allowing them to seal properly

(a great reason to change oil frequently, and use ash-less synthetic oils that clean varnish build-up)

the rings ride on a micro layer of oil trapped in the bore walls by the micro honed scratches, that allows the rings to ride on that micro layer and prevents most ring and bore wear.

rings get hot during operation and expand, the amount they expand varies with the ring design and operating temps but generally a MINIMUM OF .0040 per inch of bore diam, ring end gap is required to prevent the ring ends from firmly butting and locking the ring in the bore destroying both ring and piston.

the ring must have a small back space when its outer surface is flush with the pistons outer diam. to allow high pressure gasses to expand the rings outward and allow the rings to float in the ring groove to maintain oil cooling.both the piston and rings expand under high heat during operational conditions so clearances tend to get slightly smaller.

the top ring does about 90% plus to the sealing of pressure the second ring reduces pressure loss but its main job is reducing oil on the bore surface so the top ring can seal better, the lower oil ring is mostly a scraper to channel oil on the cylinder walls back thru vents in the rear of its groove in the piston to cool the piston and reduce oil the second ring needs to deal with

originally when it was understood how important it was to get high combustion gas flow and pressure behind the rings on race cars to get every advantage, in ring seal, gas port holes were drilled vertically from the piston top down to the first ring land (right piston). But vertical holes can get carbon-plugged, and they may promote crack formation resulting in piston failure above the groove. An alternative method is micro “half-moon†lateral holes in the top of the groove (left piston) LOOK CLOSELY AT THE MINI SEMI CIRCULAR GROOVES CUT IN THE UPPER RING SLOT ROOF ON THE TOP RING LANDS LOWER SURFACE this generally requires a fixture and a mill to do correctly, Ive used 1/16" diam half circle groves about every 30 degrees , I can,t tell you it made a noticeable difference because gas porting rarely helps a great deal below 6000rpm, or 4000fpm in piston speed, but it won,t hurt either, but above 6000 rpm or 4000fpm in piston speed dyno testing has shown a power advantage many times

check the vertical clearance with respect to the ring and ring land. This will be different for various engines, and pistons so check with both the ring and piston supplier for their input here. 0.0008-inch -.0012 vertical clearance is about the normal range,

(READ CAREFULLY THAT'S AROUND A ONE THOUSANDTH OF AN INCH CLEARANCE) but CHECK with inch feeler gauges to determine these. remember ,Don’t hold these gauges in your hand for long; they will change thickness due to temperature very easily, when dealing with only a single one thousandth of an inch

Read more: http://www.circletrack.com/howto/4639_m ... z1Xn3l3t9n

Read more: http://www.carcraft.com/techarticles/pi ... z1XmADGNoq

http://garage.grumpysperformance.co...gine-project-dart-shp.3814/page-12#post-17457

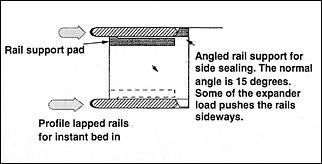

if you have oil ring expanders with the plastic bits,they are there to prevent you from over lapping the ends of the oil ring expander, theres some oil ring expander s that are vertical ,some horizontal, but all have the ends butt , none over-lap

READ THE LINKS AND SUB LINKS

http://www.kb-silvolite.com/news.php?ac ... ad&N_id=27

http://www.circletrack.com/techarticles ... index.html

http://www.circletrack.com/howto/34098_ ... index.html

http://www.circletrack.com/techarticles ... index.html

viewtopic.php?f=53&t=852

viewtopic.php?f=53&t=247

viewtopic.php?f=53&t=3897

viewtopic.php?f=53&t=4630

viewtopic.php?f=53&t=509

viewtopic.php?f=53&t=4472

http://www.elstars.com.au/pdf/piston_rings_guide.pdf

http://www.hotrod.com/techarticles/engi ... ewall.html

http://autospeed.com/cms/title_Piston-R ... ticle.html

http://www.ret-monitor.com/articles/pdf/rings.pdf

http://www.rosspistons.com/information/ ... lation.pdf

http://www.enginebuildermag.com/Article ... power.aspx

http://www.jepistons.com/PDFs/TechCorne ... atures.pdf

HOW DO RINGS WORK?

The information contained in this document is for general purposes. It only represents technical

opinions at the time of publishing. It does not guarantee any or effect any product warranties given.

Information was taken from TOTAL SEAL Company website and provided AS IS.

Reference link: http://www.totalseal.com/howdoo.html

(I) Minor Thrust Face: The side of the

piston opposite the major thrust face.

(J) Piston Pin Bushing: If used, the

bushing between the piston pin bore and

the pin.

(N) Scuff Band: One or more raised bands

of piston material used in some piston

designs to reduce scuffing.

(O) Groove Depth: The distance between

the back of the ring groove and the

cylinder wall with the piston centered.

(P) Groove Root Diameter: Piston diameter measured at the back of the groove.

May vary on the same piston between ring grooves.

(Q) Land Diameter: Diameter of a given land. Can sometimes vary by design from

top to bottom.

(R) Land clearance: The difference in diameter between the cylinder bore and the

land diameter. "R" is 1/2 the total.

(S) Skirt Clearance: The difference in diameter between the cylinder bore and skirt

diameter. "S" is 1/2 the total.

(T) Skirt Groove: A ring groove cut below the pin bore to carry an oil ring.

(U) Pin Bore Offset: The distance the pin bore is offset from center.

(V) Groove Spacer: Used on re-grooved pistons to return a ring groove to specs or in

some performance applications to facilitate the use of narrower ring sets than the

grooves were originally cut for.

Ring Terms And Measurements

(A) Free gap: The ring end clearance when the ring is uncompressed.

(B) Compressed gap: Also known as ring gap, it is the end gap measured when the

ring is installed.

(C) Radial Wall Thickness: the distance between the inside and outside faces of the

ring wall.

Last edited by a moderator: