Im constantly amazed at the number of guys I talk with that are totally clueless about the identity of the cam shaft in the engine they have, or what cam is in their cars engine, or what cam to select for the next upgrade.

you do realize that , if you want to be sure of the cam you have in that new engine you purchased, you need to verify it and not take the sellers word...(if he even remembers)you could simply pull the water pump accessories and timing chain cover and look at the cam, I realize that that may seem like a big deal to the guys that have not done that hundreds of times, but even a new guy could get it done in a single days time.

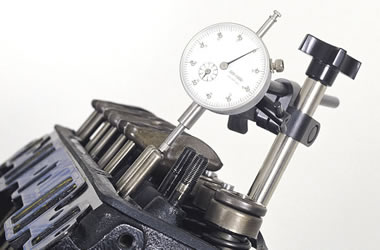

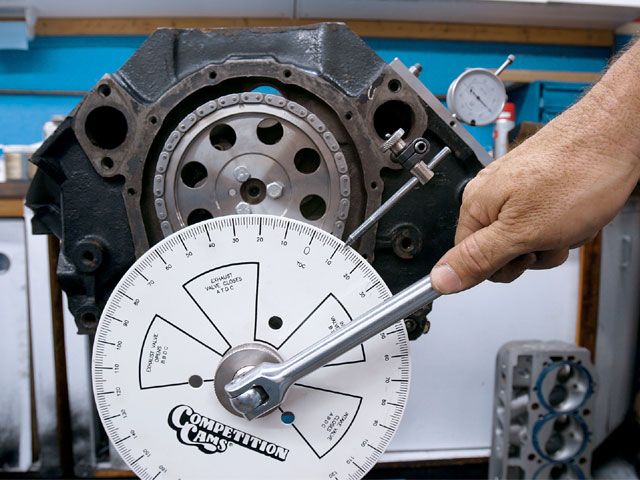

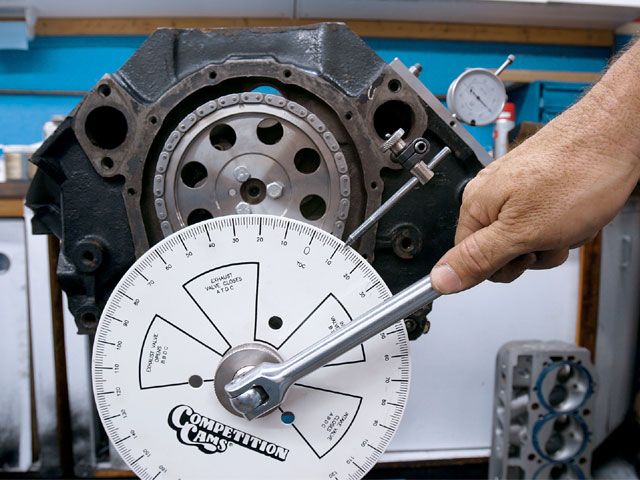

besides its a great excuse to buy a dial indicator, and a stand and degree wheel and damper puller (NEW TOOLS)

Damper tool (yes the damper needs to come off and the timing chain and upper gear too look at the end of the cam

http://www.amazon.com/OTC-4531-Harmonic-Balancer-Installer/dp/B000F5LIW4/?tag=viglink22466-20

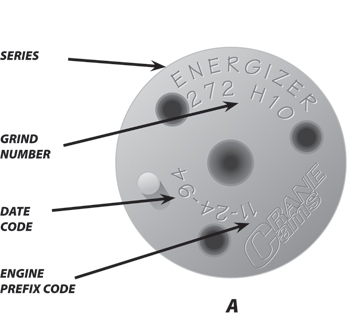

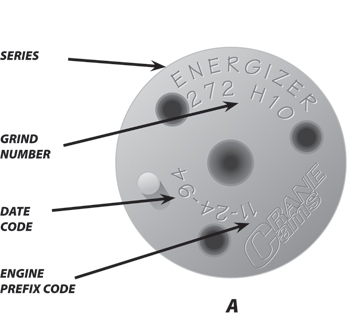

most manufacturers IDENTIFY OR mark cams under the timing gear mount surface

READ LINK

http://garage.grumpysperformance.com/index.php?threads/identify-that-cam.8582/

OR

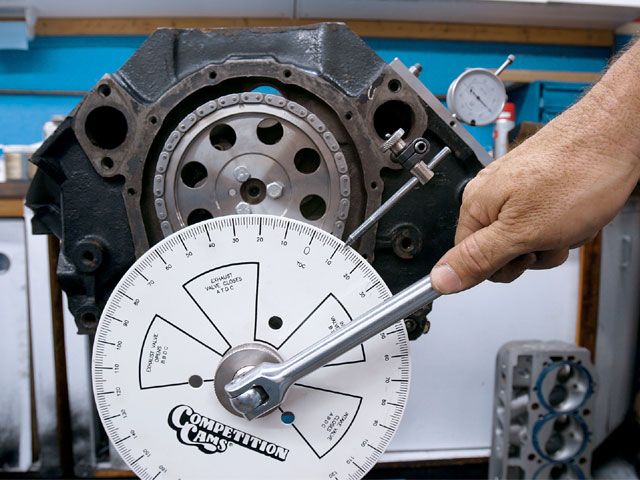

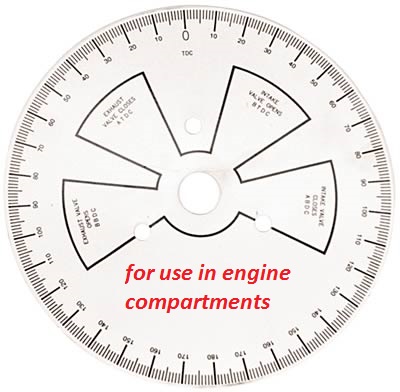

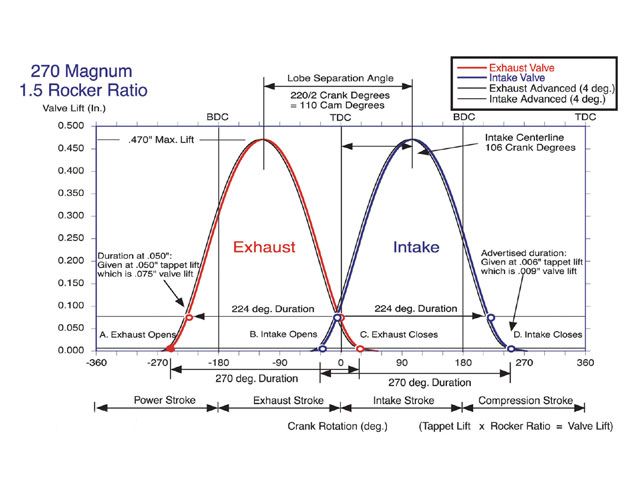

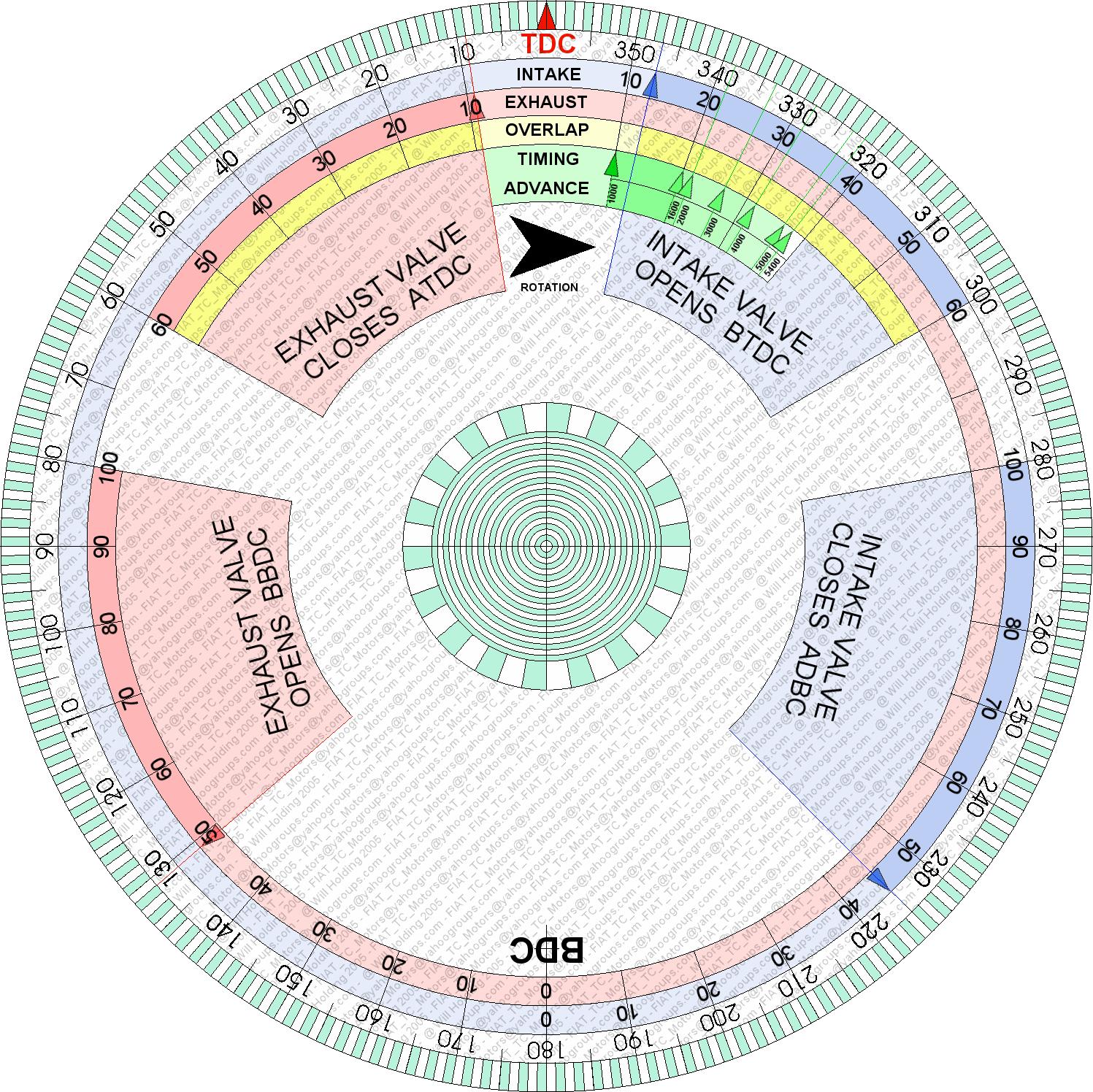

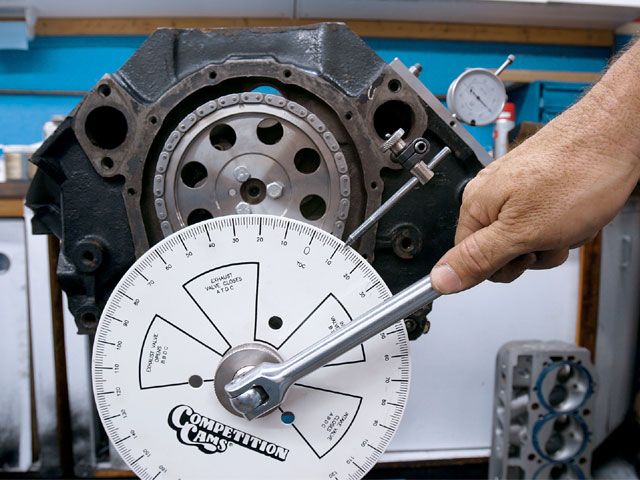

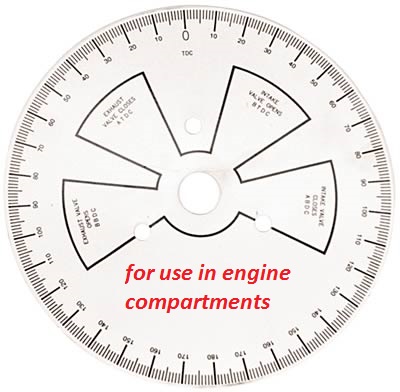

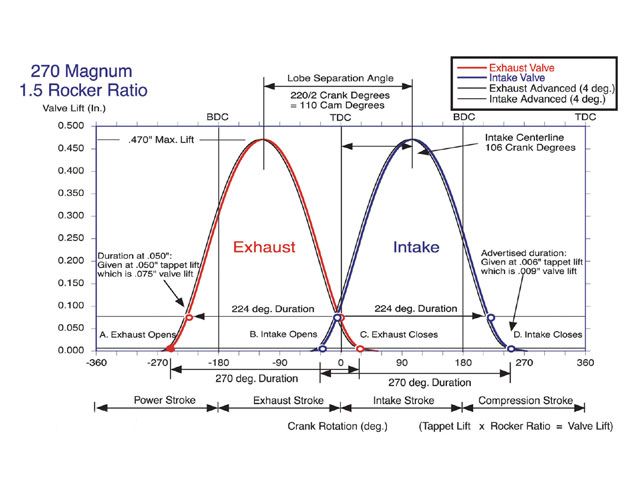

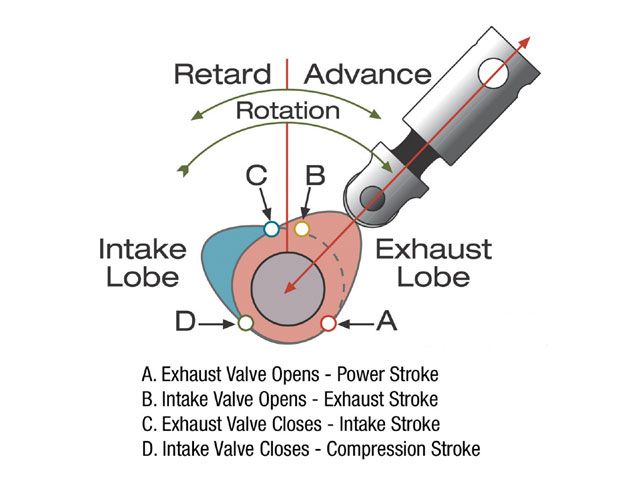

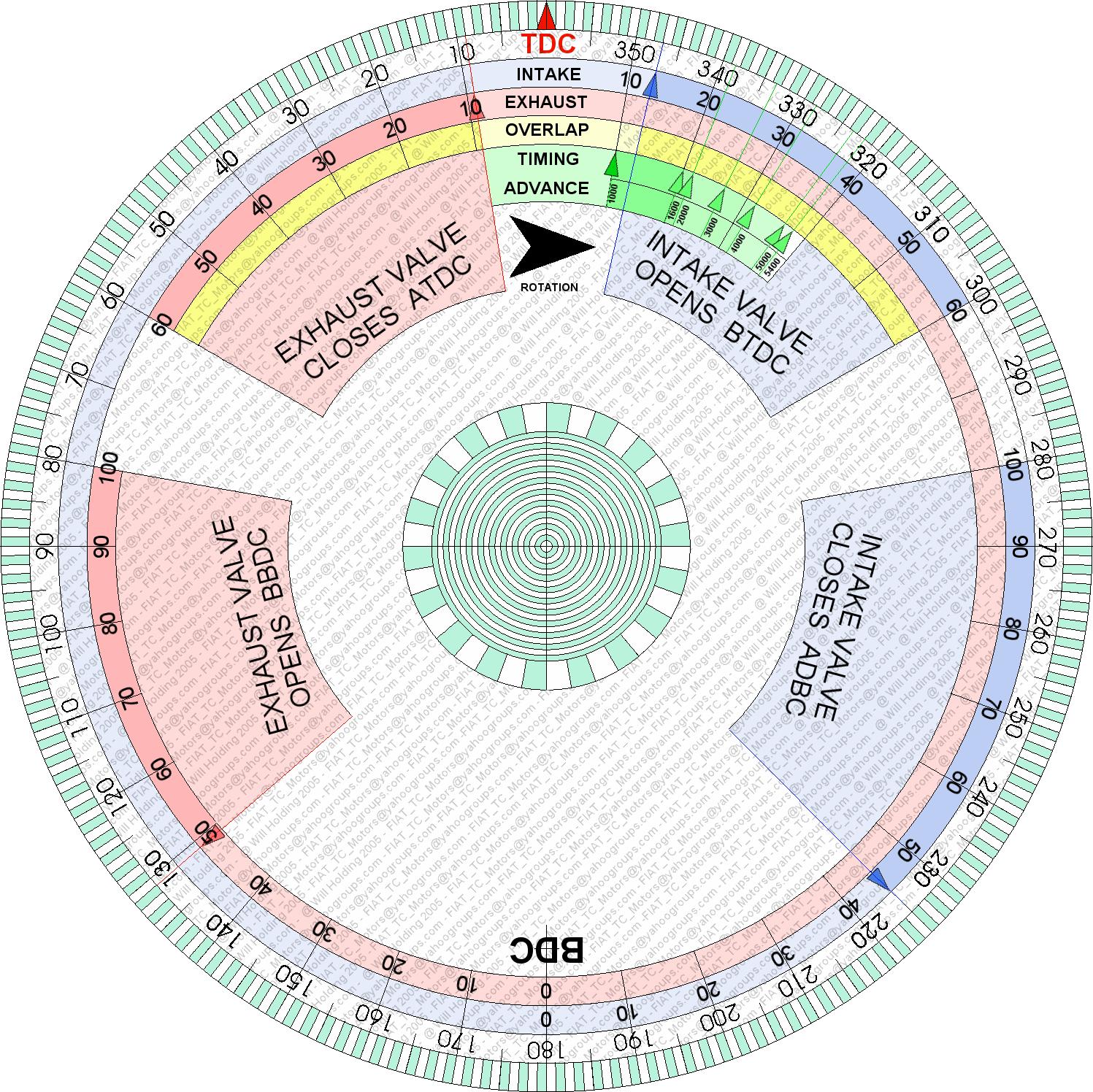

KNOWING WHAT YOUR DEALING WITH HELPS, you can use a degree wheel and a crank turning tool and graph out the lift vs degree of rotation, to verify the cam lobe lift/duration if you have the correct tools,

https://www.summitracing.com/parts/cca-4790/overview/

get the smaller 9" version for use in the car , cam degree checking

the 18" versions for checking on the engine stand

the knurled ring, on the damper crank turn tool, below, comes off the damper turn socket so the degree wheel slides on, then its replaced

https://www.summitracing.com/parts/mor-62191/overview/

a crank snout, turning socket,

Now obviously if you buy the car used you have zero idea what parts were installed, and more than a few guys will be surprised to find the engine has a stock or aftermarket cam installed.

but I also find guys that have either had a friend select and install the cam, or build an engine or guys that have lost the documentation.

most aftermarket cams are stamped with ID numbers that can be used on the various manufacturers web sites to get a good idea about your cams specifications.

ok, if your engine runs good theres no real reason to worry about it, and it helps to keep accurate records if your the one doing the work on your cars engine, and you sure need to verify clearances during the assembly process.

keep good records as the info may prove to be very useful.

there are very good software cam profile programs available if you build engines frequently that would be well worth the cost to buy if you need to know what your dealing with, but for most guys theres two logical routes to take.

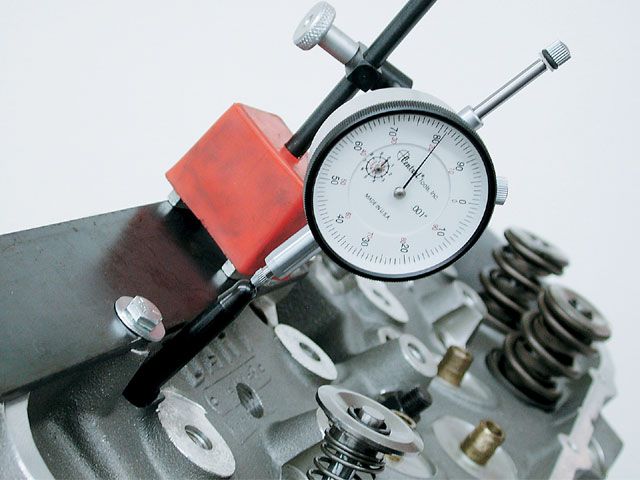

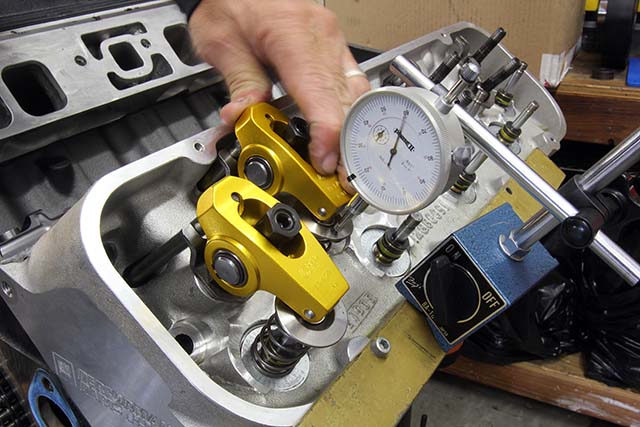

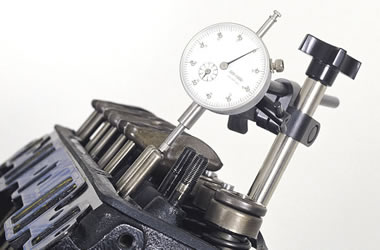

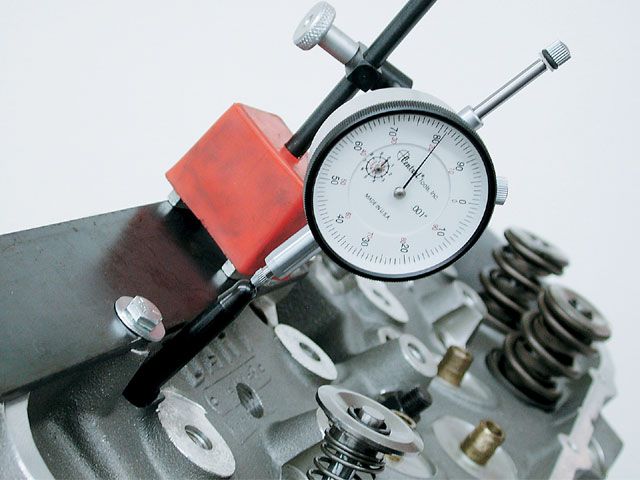

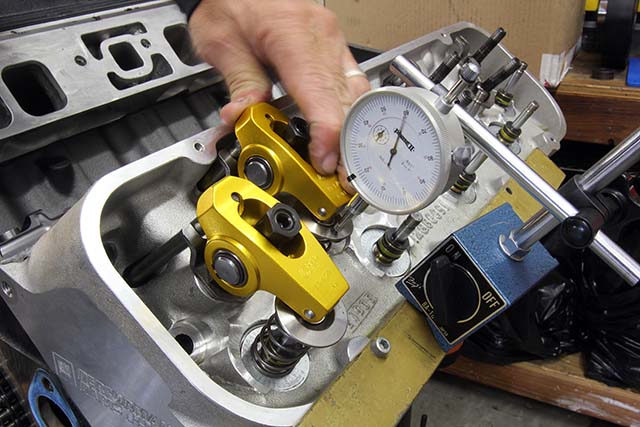

yeah, it takes a bit of work and a few accurate tools, but you don,t need to do much compared to tearing the engine totally appart to expose the cam, you can meassure lift and duration accurately at a valve retainer or even more accurately with the rockers removed at a push rod tip

a simple dial indicator fixture, on a push rod tip after removing the rockers from the Number 1 cylinder, and a degree wheel on the crank hub,and a piece of graph paper and your time to graph out the lift vs degree of rotation, would give accurate info, that is going to be a whole lot less work and gives you FACTS VS guessing at the answer

related threads

http://garage.grumpysperformance.co...et-it-to-last-cam-install-info.90/#post-57942

http://garage.grumpysperformance.co...train-clearances-and-problems.528/#post-57678

http://garage.grumpysperformance.co...ng-cam-and-shifting-the-lca.10553/#post-44949

http://garage.grumpysperformance.com/index.php?threads/cam-degreeing.9010/#post-35474

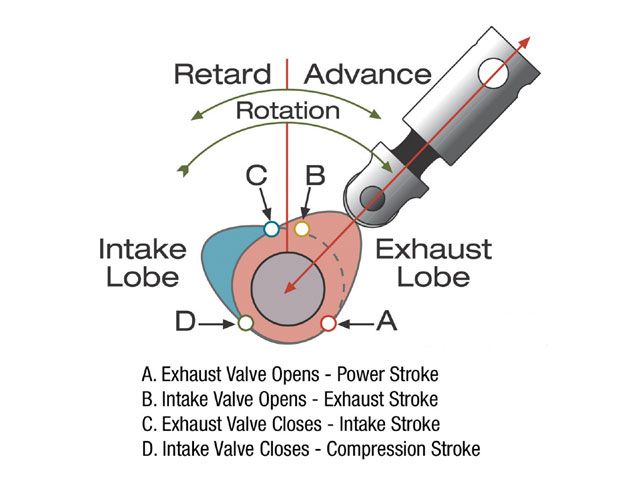

because a cam basically controls the valve train its function has a huge effect on the engine characteristics and power potential so it makes sense to know exactly what your dealing with, and to take the time and effort to verify the cams lift duration and lobe center-line is both known and correctly indexed and to take the time to verify your valve train geometry and clearances.

you will need to know factors like valve train clearance, spring load rates compression,displacement, intended rpm range, and drive train gearing before selecting a cam.

HAVING THE CORRECT TOOLS HELPS

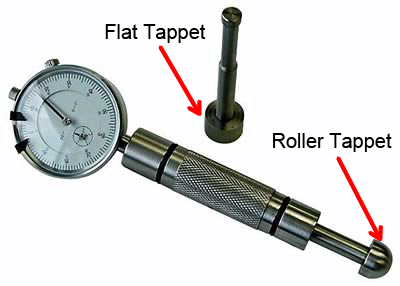

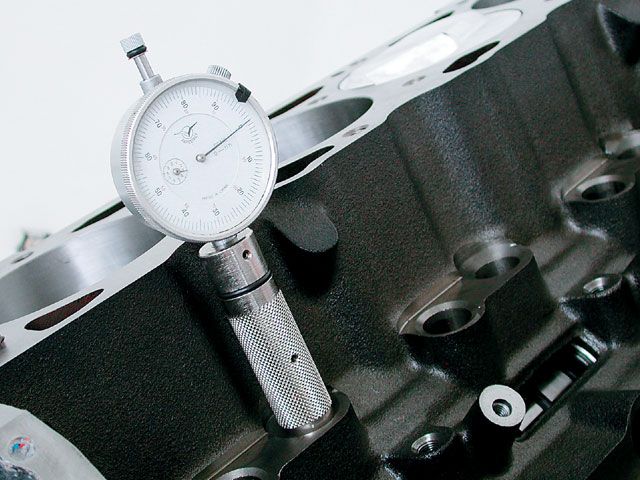

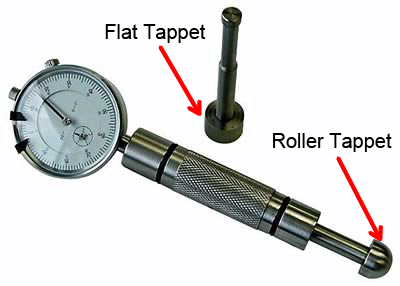

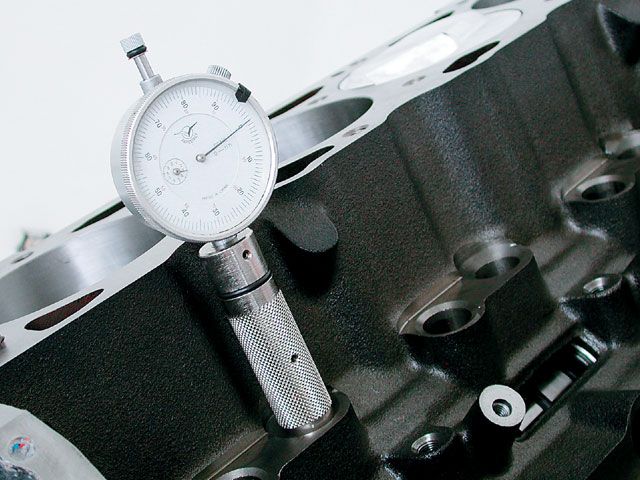

You can start by verifying lift and duration at .050 lifter lift , with a dial indicator and test lifter tool, that won,t take long and verifying the lobe separation angle with the degree wheel will also help you identify the cam your dealing with,you can learn a good deal with a dial indicator, checking lifter and a degree wheel. btw look at both ends of the cam if its out of the engine as at times both ends have some info stamped

MANY BUT NOT ALL cams will be stamped with ID info numbers like this crane cam, which may or may not be useful when compared to a catalog page like this one

http://www.cranecams.com/120-125.pdf

(1) you can buy a new cam, to replace the cam you currently have, and most guys will assume the manufacturer got it correct and the cam card that comes with the new cams correct.

(2) OR YOU CAN ACTUALLY BOTHER TO CHECK AND VERIFY WHAT CAM YOU HAVE INSTALLED CURRENTLY THRU SOME RESEARCH, KNOWING THE SPECS YOUR DEALING WITH AND MEASURING, LIFT DURATION AND L.S.A. (LOBE SEPARATION ANGLES)ACTUALLY DEGREEING IN THE CAM, PUTS YOU WELL AHEAD OF THE AVERAGE GUYS SKILL LEVELS

FOR THE GUYS THAT ACTUALLY CARE, A FEW TOOLS WILL BE USEFUL

and don,t assume that the info that might be stamped on the cam is correct, as cams can be re-ground, cam lobes wear and cams are frequently installed incorrectly

KNOWING WHAT YOUR DEALING WITH HELPS

related info, AND LINKS TO CAM CHECKING INFO

viewtopic.php?f=52&t=90

viewtopic.php?f=52&t=133&p=163&hilit=stock+chevy+cams#p163

viewtopic.php?f=52&t=5520&p=29274&hilit=cam+degree+tools#p29274

viewtopic.php?f=52&t=1070

viewtopic.php?f=52&t=5154

viewtopic.php?f=52&t=181

viewtopic.php?f=52&t=82

viewtopic.php?f=52&t=4299

http://racingarticles.com/article_racing-69.html

http://performancetrends.com/ca20.htm

http://performancetrends.com/cam_test_stand.htm

you do realize that , if you want to be sure of the cam you have in that new engine you purchased, you need to verify it and not take the sellers word...(if he even remembers)you could simply pull the water pump accessories and timing chain cover and look at the cam, I realize that that may seem like a big deal to the guys that have not done that hundreds of times, but even a new guy could get it done in a single days time.

besides its a great excuse to buy a dial indicator, and a stand and degree wheel and damper puller (NEW TOOLS)

Damper tool (yes the damper needs to come off and the timing chain and upper gear too look at the end of the cam

http://www.amazon.com/OTC-4531-Harmonic-Balancer-Installer/dp/B000F5LIW4/?tag=viglink22466-20

most manufacturers IDENTIFY OR mark cams under the timing gear mount surface

READ LINK

http://garage.grumpysperformance.com/index.php?threads/identify-that-cam.8582/

OR

KNOWING WHAT YOUR DEALING WITH HELPS, you can use a degree wheel and a crank turning tool and graph out the lift vs degree of rotation, to verify the cam lobe lift/duration if you have the correct tools,

https://www.summitracing.com/parts/cca-4790/overview/

get the smaller 9" version for use in the car , cam degree checking

the 18" versions for checking on the engine stand

the knurled ring, on the damper crank turn tool, below, comes off the damper turn socket so the degree wheel slides on, then its replaced

https://www.summitracing.com/parts/mor-62191/overview/

a crank snout, turning socket,

Now obviously if you buy the car used you have zero idea what parts were installed, and more than a few guys will be surprised to find the engine has a stock or aftermarket cam installed.

but I also find guys that have either had a friend select and install the cam, or build an engine or guys that have lost the documentation.

most aftermarket cams are stamped with ID numbers that can be used on the various manufacturers web sites to get a good idea about your cams specifications.

ok, if your engine runs good theres no real reason to worry about it, and it helps to keep accurate records if your the one doing the work on your cars engine, and you sure need to verify clearances during the assembly process.

keep good records as the info may prove to be very useful.

there are very good software cam profile programs available if you build engines frequently that would be well worth the cost to buy if you need to know what your dealing with, but for most guys theres two logical routes to take.

On a sbc motor installed and running, there is suspicion that there may be an slightly warmer cam installed. Short of taking The top of this motor apart Is there anyway to confirm through testing of any kind? Like vacuum if there is anything other than an OEM cam installed?

yeah, it takes a bit of work and a few accurate tools, but you don,t need to do much compared to tearing the engine totally appart to expose the cam, you can meassure lift and duration accurately at a valve retainer or even more accurately with the rockers removed at a push rod tip

a simple dial indicator fixture, on a push rod tip after removing the rockers from the Number 1 cylinder, and a degree wheel on the crank hub,and a piece of graph paper and your time to graph out the lift vs degree of rotation, would give accurate info, that is going to be a whole lot less work and gives you FACTS VS guessing at the answer

related threads

http://garage.grumpysperformance.co...et-it-to-last-cam-install-info.90/#post-57942

http://garage.grumpysperformance.co...train-clearances-and-problems.528/#post-57678

http://garage.grumpysperformance.co...ng-cam-and-shifting-the-lca.10553/#post-44949

http://garage.grumpysperformance.com/index.php?threads/cam-degreeing.9010/#post-35474

because a cam basically controls the valve train its function has a huge effect on the engine characteristics and power potential so it makes sense to know exactly what your dealing with, and to take the time and effort to verify the cams lift duration and lobe center-line is both known and correctly indexed and to take the time to verify your valve train geometry and clearances.

you will need to know factors like valve train clearance, spring load rates compression,displacement, intended rpm range, and drive train gearing before selecting a cam.

HAVING THE CORRECT TOOLS HELPS

You can start by verifying lift and duration at .050 lifter lift , with a dial indicator and test lifter tool, that won,t take long and verifying the lobe separation angle with the degree wheel will also help you identify the cam your dealing with,you can learn a good deal with a dial indicator, checking lifter and a degree wheel. btw look at both ends of the cam if its out of the engine as at times both ends have some info stamped

MANY BUT NOT ALL cams will be stamped with ID info numbers like this crane cam, which may or may not be useful when compared to a catalog page like this one

http://www.cranecams.com/120-125.pdf

(1) you can buy a new cam, to replace the cam you currently have, and most guys will assume the manufacturer got it correct and the cam card that comes with the new cams correct.

(2) OR YOU CAN ACTUALLY BOTHER TO CHECK AND VERIFY WHAT CAM YOU HAVE INSTALLED CURRENTLY THRU SOME RESEARCH, KNOWING THE SPECS YOUR DEALING WITH AND MEASURING, LIFT DURATION AND L.S.A. (LOBE SEPARATION ANGLES)ACTUALLY DEGREEING IN THE CAM, PUTS YOU WELL AHEAD OF THE AVERAGE GUYS SKILL LEVELS

FOR THE GUYS THAT ACTUALLY CARE, A FEW TOOLS WILL BE USEFUL

and don,t assume that the info that might be stamped on the cam is correct, as cams can be re-ground, cam lobes wear and cams are frequently installed incorrectly

KNOWING WHAT YOUR DEALING WITH HELPS

related info, AND LINKS TO CAM CHECKING INFO

viewtopic.php?f=52&t=90

viewtopic.php?f=52&t=133&p=163&hilit=stock+chevy+cams#p163

viewtopic.php?f=52&t=5520&p=29274&hilit=cam+degree+tools#p29274

viewtopic.php?f=52&t=1070

viewtopic.php?f=52&t=5154

viewtopic.php?f=52&t=181

viewtopic.php?f=52&t=82

viewtopic.php?f=52&t=4299

http://racingarticles.com/article_racing-69.html

http://performancetrends.com/ca20.htm

http://performancetrends.com/cam_test_stand.htm

Last edited by a moderator: