now Ive posted much of this info before, but I recently helped tune a guys 13.7:1 compression big block chevy where the guy could not get the car to run correctly at first because he had failed to check a few clearances and on several cylinders the piston domes were barely contacting the spark plug ground electrodes and closing the gaps down to less than .010-.020 thousands.

this should help,your quench distance should be between .038-.044,

you might want to INDEX the plugs so the ground strap faces up minimizing the chance the piston can contact the plug ground electrode at TDC

when he failed to index the plugs (something he had never encountered before and was totally un-aware of as a potential problem)

just by chance most of the plugs indexed so the ground electrodes didn,t contact the piston domes but a few did, and it seemed to be a random deal to him because sometimes the plugs worked sometimes they failed, he never figured out the cause. well the only reason I spotted it almost instantly was EXPERIENCE, having been that route about 38 years ago with my first real high compression 489 BBC where the pop-up piston domes made indexing the plugs mandatory

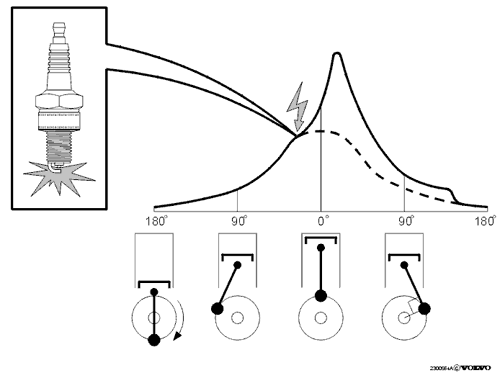

read the links below, if you want to take the time to index the spark plugs in your heads you'll need to carefully mark where the electrode ground is on the plugs insulator where you can easily see it with a permanent marker and use spacer washers to insure that the open area of the plug faces the area between the valves, keep in mind,in most cases plug indexing is done for clearance issues relating to domed pistons, but it can help ignition speed in a few cases especially in some combustion chamber designs,indexing the open gap slightly favoring the exhaust valve location, WITH THE GROUND ELECTRODE INDEXED UPWARD TOWARD THE COMBUSTION CHAMBER ROOF , can help in some cases, remember the piston compressed nothing until both valves are seated and the ignition and burn will occur while the valves are fully seated if you've got everything correctly timed

remember in some high compression applications, its fairly common for the pop-up piston dome to contact the ground electrode and bend it, closing the gap if the plugs ground electrode is placed in the lower 270 degrees of its possible indexed rotation on the plug when its installed , especially ,if you failed to correctly check clearances, between the piston and combustion chamber.

now IM sure you can find info indicating the ground should be indexed differently, but think about where ignition occurs, the pistons rapidly swinging from btdc to after tdc and theres very little volume or space around the plugs ignition point and having the open part of the plug facing the piston as it approaches and moves away makes sense as the flame front has ignite far more in that direction than the couple ccs of combustion chamber volume between the plugs ground electrode and the chamber roof, remember the valves have been fully seated for quite some time on that compression stroke before ignition takes place, and the quench and squish between the piston and head are forcing everything (the compressed f/a mix) towards the open part of the plug under those conditions

in this example directly below the plugs GROUND electrode is ALMOST EXACTLY OPPOSITE, OF THE IDEAL INDEXED location , as its located wher the piston has the best chance of contacting the ground electrode,

example , now ideally youll want the ground electrode facing the roof of the combustion chamber for max clearance and flame propagation

similar too...THESE TWO PICTURES POSTED BELOW

In theory having the ground electrode between the green liines is the idea. having it located at or closer to the red location is ideal , in theory,the idea is to have the ground electrode face toward the chamber roof and the open arc of the ignition face slightly to the exhaust valve but as long as the ground electrode is located toward the chamber roof it works fine

if your using high compression pistons like these youll soon see the reason for indexing plug ground electrodes, to gain max clearance to the piston dome, this is also one reason why the multi ground electrodes are a waste of money, as the more ground electrodes the more the spark is shielded from igniting the compressed F/A charge, packed in around it.

http://performanceunlimited.com/documents/plugsidegapping.html

side gaping or cutting back on the ground electrode to increase the flame exposure helps on race cars with very high compression ratios, BUT ITS ALSO A USEFUL TIP TO GAIN ADDED COMBUSTION CHAMBER CLEARANCE, BETWEEN DOME PISTONS AND PLUGS

http://performanceunlimited.com/documen ... pping.html

OBVIOUSLY A PLUG SOCKET DESIGNED TO HELP INDEX PLUGS IS HELPFUL AT TIMES

http://www.jegs.com/i/JEGS-Performance- ... 0/10002/-1

,this can in some cases smooth the idle slightly and add a few hp, in other applications its basically wasted effort, but in some cases the engine clearances make it mandatory, a good deal depends on the compression, intake runner and combustion chamber design, and it should be obvious that if your not running up close to the limits on your ignition advance curve and octane limits on your fuel you probably won,t notice the slight improvements in ignition,only careful testing in your engine will tell you if its worth the effort in your combination.....now I have guys that tell me its always wasted effort, and if you use the 2-4 electrode ground strap plugs is not going to change, well thats true, if you have several ground straps on the plugs you shroud the spark enough that youve effectively reduced its efficiency too ignite a clean flame front, so yeah if you use those its wasted effort[/color]

related info

http://www.bullittarchive.com/5005.htm

http://dodgeram.info/Engine-Gas/SparkPl ... dexing.htm

http://www.eatonbalancing.com/blog/2009 ... -indexing/

there are several types of spacer washers for both taper seat and standard plug designs that allow you to index plugs

http://www.shop.speedunlimited.com/p-58 ... -seat.aspx

Moroso #71900 Spark Plug Index Washers, Copper, Tapered Seat, for 14mm Plugs, Sizes .010, .021, .032 in., 10 of Each, Set of 30.

M28-71900

http://www.jegs.com/i/Moroso/710/71910/10002/-1

http://www.summitracing.com/parts/MOR-71900/?rtype=10

this should help,your quench distance should be between .038-.044,

you might want to INDEX the plugs so the ground strap faces up minimizing the chance the piston can contact the plug ground electrode at TDC

when he failed to index the plugs (something he had never encountered before and was totally un-aware of as a potential problem)

just by chance most of the plugs indexed so the ground electrodes didn,t contact the piston domes but a few did, and it seemed to be a random deal to him because sometimes the plugs worked sometimes they failed, he never figured out the cause. well the only reason I spotted it almost instantly was EXPERIENCE, having been that route about 38 years ago with my first real high compression 489 BBC where the pop-up piston domes made indexing the plugs mandatory

spark plug info

spark plug info..SO!...read thru the links theres a ton of good info, but its spread over all the links, if you can get that skill mastered your well ahead of most guys who fail to take the time and effort to learn that skill guys frequently ask me what plug gap to use, Provided your ignition...

garage.grumpysperformance.com

read the links below, if you want to take the time to index the spark plugs in your heads you'll need to carefully mark where the electrode ground is on the plugs insulator where you can easily see it with a permanent marker and use spacer washers to insure that the open area of the plug faces the area between the valves, keep in mind,in most cases plug indexing is done for clearance issues relating to domed pistons, but it can help ignition speed in a few cases especially in some combustion chamber designs,indexing the open gap slightly favoring the exhaust valve location, WITH THE GROUND ELECTRODE INDEXED UPWARD TOWARD THE COMBUSTION CHAMBER ROOF , can help in some cases, remember the piston compressed nothing until both valves are seated and the ignition and burn will occur while the valves are fully seated if you've got everything correctly timed

remember in some high compression applications, its fairly common for the pop-up piston dome to contact the ground electrode and bend it, closing the gap if the plugs ground electrode is placed in the lower 270 degrees of its possible indexed rotation on the plug when its installed , especially ,if you failed to correctly check clearances, between the piston and combustion chamber.

now IM sure you can find info indicating the ground should be indexed differently, but think about where ignition occurs, the pistons rapidly swinging from btdc to after tdc and theres very little volume or space around the plugs ignition point and having the open part of the plug facing the piston as it approaches and moves away makes sense as the flame front has ignite far more in that direction than the couple ccs of combustion chamber volume between the plugs ground electrode and the chamber roof, remember the valves have been fully seated for quite some time on that compression stroke before ignition takes place, and the quench and squish between the piston and head are forcing everything (the compressed f/a mix) towards the open part of the plug under those conditions

in this example directly below the plugs GROUND electrode is ALMOST EXACTLY OPPOSITE, OF THE IDEAL INDEXED location , as its located wher the piston has the best chance of contacting the ground electrode,

example , now ideally youll want the ground electrode facing the roof of the combustion chamber for max clearance and flame propagation

similar too...THESE TWO PICTURES POSTED BELOW

In theory having the ground electrode between the green liines is the idea. having it located at or closer to the red location is ideal , in theory,the idea is to have the ground electrode face toward the chamber roof and the open arc of the ignition face slightly to the exhaust valve but as long as the ground electrode is located toward the chamber roof it works fine

if your using high compression pistons like these youll soon see the reason for indexing plug ground electrodes, to gain max clearance to the piston dome, this is also one reason why the multi ground electrodes are a waste of money, as the more ground electrodes the more the spark is shielded from igniting the compressed F/A charge, packed in around it.

http://performanceunlimited.com/documents/plugsidegapping.html

side gaping or cutting back on the ground electrode to increase the flame exposure helps on race cars with very high compression ratios, BUT ITS ALSO A USEFUL TIP TO GAIN ADDED COMBUSTION CHAMBER CLEARANCE, BETWEEN DOME PISTONS AND PLUGS

http://performanceunlimited.com/documen ... pping.html

OBVIOUSLY A PLUG SOCKET DESIGNED TO HELP INDEX PLUGS IS HELPFUL AT TIMES

http://www.jegs.com/i/JEGS-Performance- ... 0/10002/-1

,this can in some cases smooth the idle slightly and add a few hp, in other applications its basically wasted effort, but in some cases the engine clearances make it mandatory, a good deal depends on the compression, intake runner and combustion chamber design, and it should be obvious that if your not running up close to the limits on your ignition advance curve and octane limits on your fuel you probably won,t notice the slight improvements in ignition,only careful testing in your engine will tell you if its worth the effort in your combination.....now I have guys that tell me its always wasted effort, and if you use the 2-4 electrode ground strap plugs is not going to change, well thats true, if you have several ground straps on the plugs you shroud the spark enough that youve effectively reduced its efficiency too ignite a clean flame front, so yeah if you use those its wasted effort[/color]

related info

http://www.bullittarchive.com/5005.htm

http://dodgeram.info/Engine-Gas/SparkPl ... dexing.htm

http://www.eatonbalancing.com/blog/2009 ... -indexing/

there are several types of spacer washers for both taper seat and standard plug designs that allow you to index plugs

http://www.shop.speedunlimited.com/p-58 ... -seat.aspx

Moroso #71900 Spark Plug Index Washers, Copper, Tapered Seat, for 14mm Plugs, Sizes .010, .021, .032 in., 10 of Each, Set of 30.

M28-71900

http://www.jegs.com/i/Moroso/710/71910/10002/-1

http://www.summitracing.com/parts/MOR-71900/?rtype=10

Last edited by a moderator: