Carlos

Active Member

Winter time...as usual time to work on a project.

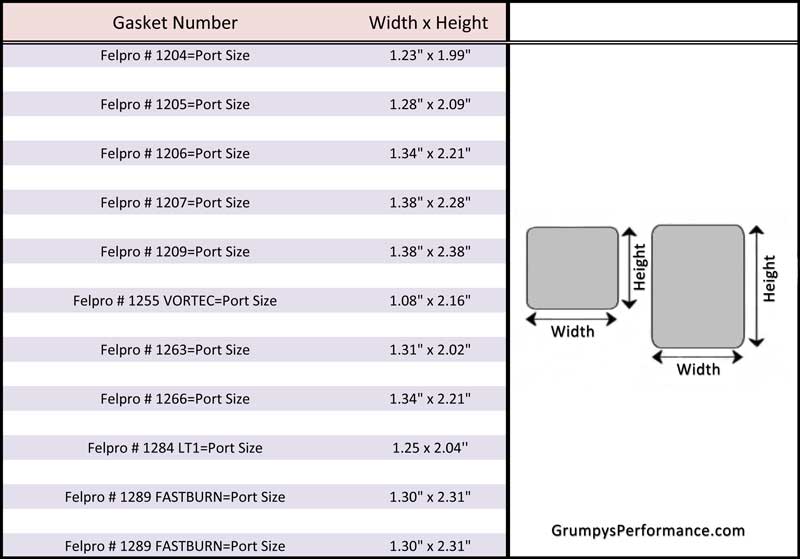

The manifold of my SBC is leaking more and more, so I'll take it off and do the sealing.

Btw...is there any "best before" date on the intake gaskets? I have mine sitting around for probably 5 years now, maybe better getting new ones?

Any recommendation ?

But here is the real main question for the experts....

Since I added the TWM induction I did not find the time to go to the dyno for final tuning, what should happen in spring now :mrgreen: .

Due to lack of space I cannot add any air filter to my air horns, also... how ugly would that look like ?

?

However, after the first trip I found plenty of very little gravel sitting on my intake manifold, which made me a bit nervous.

The only way to be a bit more on the safe side, I thought, is adding thin stainless mesh between the horns and the throttle bodies, so I had them laser cut to fit well.

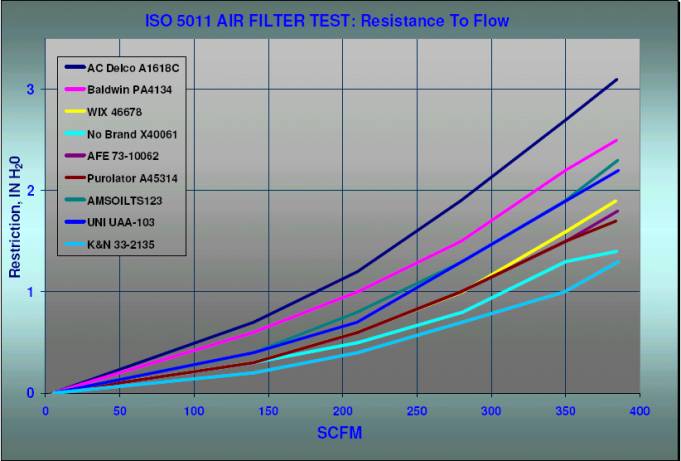

Now-whilst I fully understand there is a restriction in air flow by putting the mesh in, I have no proof about any negative effect.

Theoretically I could calculate the restriction purely by the wire diameter of the mesh, however is that correct and meaningful? A round wire behaves different than a square one...

I heard many guys telling stories this mesh will kill the overall performance, where none of them ever had an own experience on dyno runs.

On the other hand side same guys are using air horns looking more like a simple sharp edged funnel, rather than a real air horn, which to my understanding impcacts performance as well (even more?).

So any help is really aprecciated, maybe there is even somebody who has experienc on a dyno

Thanks a lot

Carlos

PS: I might even do the testing with and w/o mesh on the dyno, but as they are sealed to avoid air being sucked in sideways, it is quite an effort to exchange them in a clean manner.

The manifold of my SBC is leaking more and more, so I'll take it off and do the sealing.

Btw...is there any "best before" date on the intake gaskets? I have mine sitting around for probably 5 years now, maybe better getting new ones?

Any recommendation ?

But here is the real main question for the experts....

Since I added the TWM induction I did not find the time to go to the dyno for final tuning, what should happen in spring now :mrgreen: .

Due to lack of space I cannot add any air filter to my air horns, also... how ugly would that look like

However, after the first trip I found plenty of very little gravel sitting on my intake manifold, which made me a bit nervous.

The only way to be a bit more on the safe side, I thought, is adding thin stainless mesh between the horns and the throttle bodies, so I had them laser cut to fit well.

Now-whilst I fully understand there is a restriction in air flow by putting the mesh in, I have no proof about any negative effect.

Theoretically I could calculate the restriction purely by the wire diameter of the mesh, however is that correct and meaningful? A round wire behaves different than a square one...

I heard many guys telling stories this mesh will kill the overall performance, where none of them ever had an own experience on dyno runs.

On the other hand side same guys are using air horns looking more like a simple sharp edged funnel, rather than a real air horn, which to my understanding impcacts performance as well (even more?).

So any help is really aprecciated, maybe there is even somebody who has experienc on a dyno

Thanks a lot

Carlos

PS: I might even do the testing with and w/o mesh on the dyno, but as they are sealed to avoid air being sucked in sideways, it is quite an effort to exchange them in a clean manner.