Interested to see what a simulation would show.

Rick as requested.

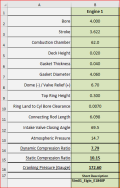

Dynomation 6 Input Variables

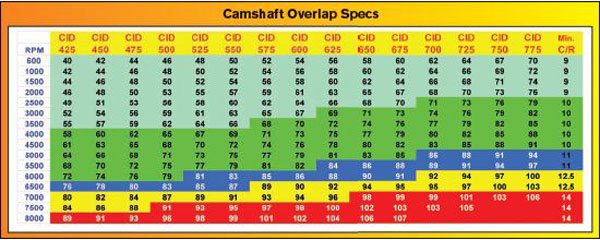

Bore & Stroke: 4.00 X 3.622 (LQ4)

Displacement: cubic inches: 364

Rod Length: 6.098

Heads Make/Model with flow numbers: Flow (CFM) at several lift points.

Combustion Chamber Size in CC’s: 62

Dome Volume: For a domed piston use a (-) negative number. +6.7 (dished)

Valve Relief Volume: For a piston with valve reliefs or dish, use a (+) positive number. see above

Deck Clearance: (Piston to Block Surface) - not measured... assume 0.00"??

Head Gasket Bore: 4.06

Head Gasket Thickness: .040"

Valve Sizes Intake/Exhaust: 2.00/ 1.55

Intake Manifold Type: [Single or Dual Plane] - Dual

Manufacture/Model #: Edelbrock - RPM LS 71187

Carburetor Size or EFI (CFM): 770, vac secondary Holley

Blower/Turbo Make/Model: N/A

Belt Ratio: N/A

Header Tube Diameter: 1-5/8", 1-3/4", 1-7/8", 2.0" - 1 -7/8"

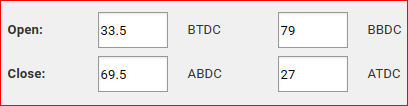

Cam Part Number: Elgin E-1840-P

Cam Specs: Need all 8 valve timing events at seat-to-seat and at 0.050” plus lobe lift or valve lift OR post Cam Card OR give me what you have.

0.006" and 0.050"

Rocker Ratio - Intake/Exhaust: 1.7

Cam Installed per Cam Card, or Retarded or Advanced: as per above, installed as per card with ground in 4 degree advance

Fuel Used: Gasoline (Octane ?), Methanol, Ethanol, E85 ..... gas 89 (mid grade where I live 87,89,91)

Rick as requested.

Dynomation 6 Input Variables

Bore & Stroke: 4.00 X 3.622 (LQ4)

Displacement: cubic inches: 364

Rod Length: 6.098

Heads Make/Model with flow numbers: Flow (CFM) at several lift points.

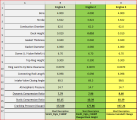

| 0.050 | 31.1 | 24.7 |

| 0.100 | 65.4 | 52.6 |

| 0.200 | 142.2 | 98.1 |

| 0.300 | 193.5 | 133.5 |

| 0.400 | 230.2 | 160.1 |

| 0.500 | 243.4 | 175.5 |

| 0.600 | 248.1 | 185.8 |

| 0.650 | 249.3 | 188.2 |

| 0.700 | 250.2 | 191.1 |

Dome Volume: For a domed piston use a (-) negative number. +6.7 (dished)

Valve Relief Volume: For a piston with valve reliefs or dish, use a (+) positive number. see above

Deck Clearance: (Piston to Block Surface) - not measured... assume 0.00"??

Head Gasket Bore: 4.06

Head Gasket Thickness: .040"

Valve Sizes Intake/Exhaust: 2.00/ 1.55

Intake Manifold Type: [Single or Dual Plane] - Dual

Manufacture/Model #: Edelbrock - RPM LS 71187

Carburetor Size or EFI (CFM): 770, vac secondary Holley

Blower/Turbo Make/Model: N/A

Belt Ratio: N/A

Header Tube Diameter: 1-5/8", 1-3/4", 1-7/8", 2.0" - 1 -7/8"

Cam Part Number: Elgin E-1840-P

Cam Specs: Need all 8 valve timing events at seat-to-seat and at 0.050” plus lobe lift or valve lift OR post Cam Card OR give me what you have.

0.006" and 0.050"

Rocker Ratio - Intake/Exhaust: 1.7

Cam Installed per Cam Card, or Retarded or Advanced: as per above, installed as per card with ground in 4 degree advance

Fuel Used: Gasoline (Octane ?), Methanol, Ethanol, E85 ..... gas 89 (mid grade where I live 87,89,91)