NEW/HEADS, you should NOT just bolt them on!

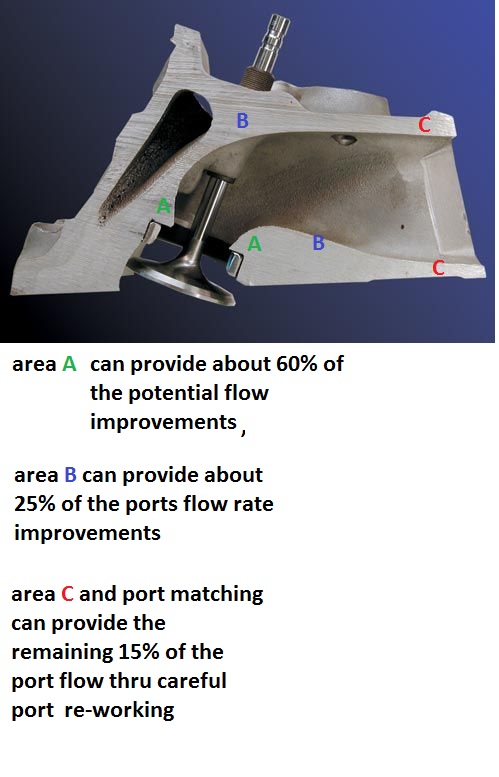

(1) open throat to 85%-90% of valve size

(2)cut a 4 angle seat with 45 degree angle .065-.075 wide where the valve seats and about .100 at 60 degrees below and a .030 wide 30 degree cut above and a 20 degree cut above that rolled and blended into the combustion chamber

(3)blend the spark plug boss slightly and lay back the combustion chamber walls near the valves

(4)narrow but dont shorten the valve guide

(5) open and straiten and blend the upper two port corner edges along the port roof

(6) gasket match to/with intake and raise the port roof slightly

(7) back cut valves at 30 degrees

(8) polish valve face and round outer edges slightly

(9)polish combustion chamber surface and blend edges slightly

(10) remove and smooth away all casting flash , keep the floor of the port slightly rough but the roof and walls smoothed but not polished.

(11) use a head gasket to see the max you can open the combustion chamber walls

(12) blend but don,t grind away the short side radius

now Ill probably tick some guys off here, but I see enought heads come thru the shop to point out a comon problem, and its NOT limited to one or a couple manufacturers, Ive seen it on nearly every brand and type of cylinder head!, what Im refering to is bits of casting flash, bits of aluminum or cast iron chips from machine work or sloppy assembly, burred threads, threads that are not cleanly cut,ETC. on new out of the box cylinder heads, I won,t name brands BUT some of the top names have bits of aluminum chips/dust/crud left in the ports in as shipped heads and disassembly and use of a stiff tooth brush, high pressure air and carb cleaner spray along with reassembly with the proper lubricants and running a tap thru threads and cleaning all machined surfaces with solvent,is almost mandatory if your don,t want bits of crud washing around in the engine durring first starting the engine. it sure doesn,t hurt to check the spring bind and other clearances, and that the valve seals are correctly installed either

IM sure the manufacturers used a high pressure air hose to blow out the ports and water passages, but theres comonly some crud remaining so inspect carefully, and clean those new heads BEFORE installing them

, yes the cheaper brands seem more prone to this problem but even the best brands are comonly seen to be recieved in less than steller condition, and need some basic clean-up

BTW, one of these tools comes in handy durring the inspection process

http://store.summitracing.com/partdetai ... toview=sku

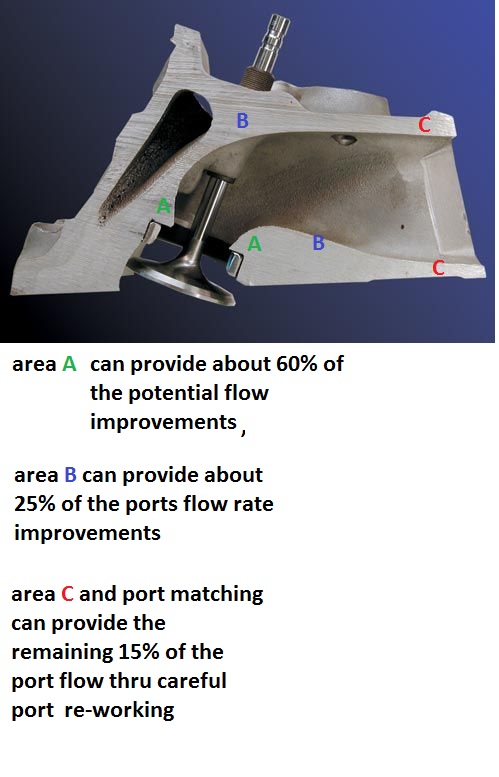

(1) open throat to 85%-90% of valve size

(2)cut a 4 angle seat with 45 degree angle .065-.075 wide where the valve seats and about .100 at 60 degrees below and a .030 wide 30 degree cut above and a 20 degree cut above that rolled and blended into the combustion chamber

(3)blend the spark plug boss slightly and lay back the combustion chamber walls near the valves

(4)narrow but dont shorten the valve guide

(5) open and straiten and blend the upper two port corner edges along the port roof

(6) gasket match to/with intake and raise the port roof slightly

(7) back cut valves at 30 degrees

(8) polish valve face and round outer edges slightly

(9)polish combustion chamber surface and blend edges slightly

(10) remove and smooth away all casting flash , keep the floor of the port slightly rough but the roof and walls smoothed but not polished.

(11) use a head gasket to see the max you can open the combustion chamber walls

(12) blend but don,t grind away the short side radius

now Ill probably tick some guys off here, but I see enought heads come thru the shop to point out a comon problem, and its NOT limited to one or a couple manufacturers, Ive seen it on nearly every brand and type of cylinder head!, what Im refering to is bits of casting flash, bits of aluminum or cast iron chips from machine work or sloppy assembly, burred threads, threads that are not cleanly cut,ETC. on new out of the box cylinder heads, I won,t name brands BUT some of the top names have bits of aluminum chips/dust/crud left in the ports in as shipped heads and disassembly and use of a stiff tooth brush, high pressure air and carb cleaner spray along with reassembly with the proper lubricants and running a tap thru threads and cleaning all machined surfaces with solvent,is almost mandatory if your don,t want bits of crud washing around in the engine durring first starting the engine. it sure doesn,t hurt to check the spring bind and other clearances, and that the valve seals are correctly installed either

IM sure the manufacturers used a high pressure air hose to blow out the ports and water passages, but theres comonly some crud remaining so inspect carefully, and clean those new heads BEFORE installing them

, yes the cheaper brands seem more prone to this problem but even the best brands are comonly seen to be recieved in less than steller condition, and need some basic clean-up

BTW, one of these tools comes in handy durring the inspection process

http://store.summitracing.com/partdetai ... toview=sku