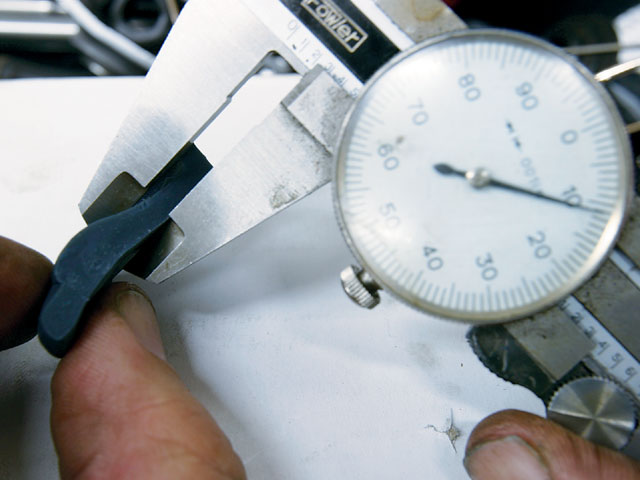

there's two ways ,...... you can use the correct tool, which is ADVISABLE!

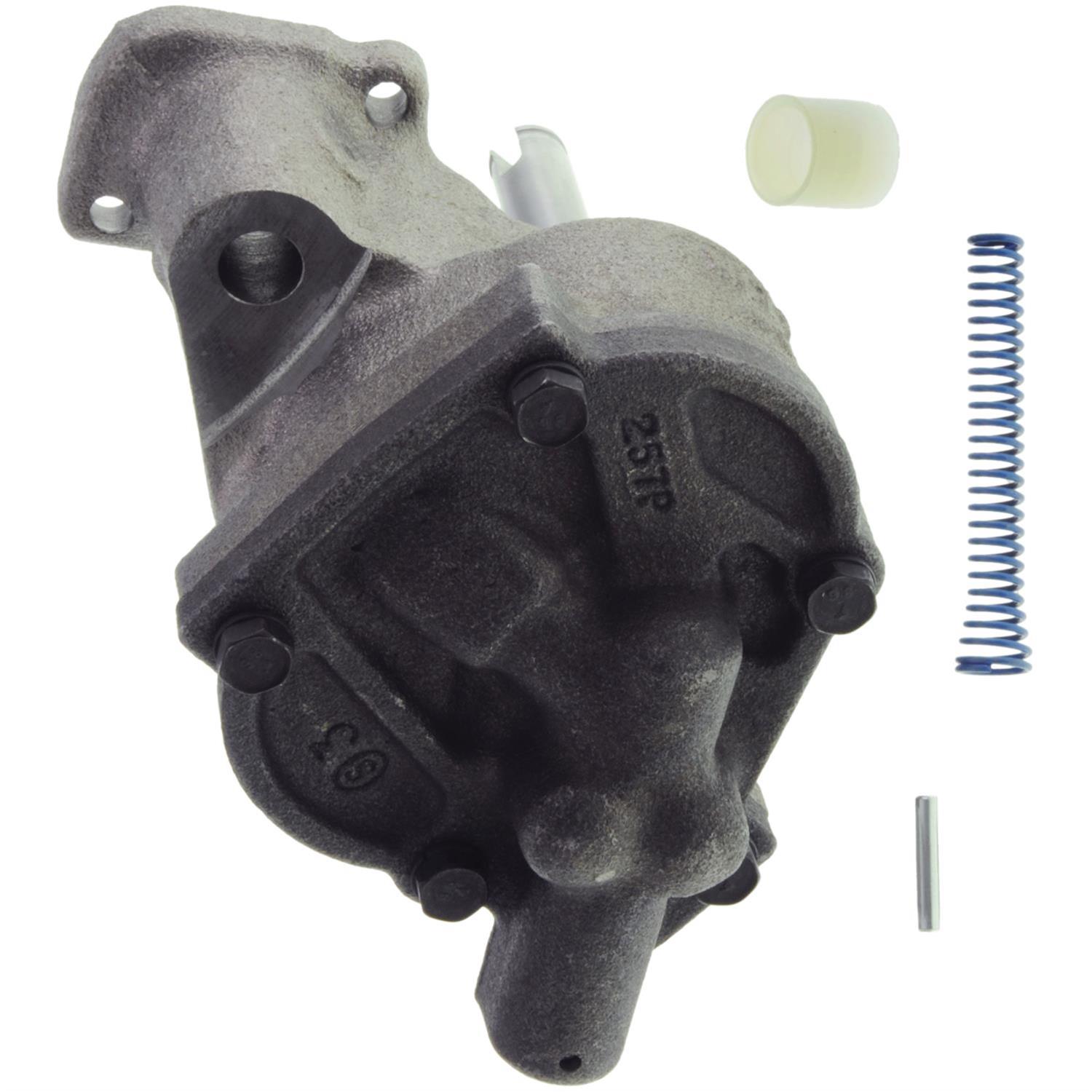

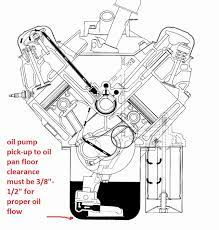

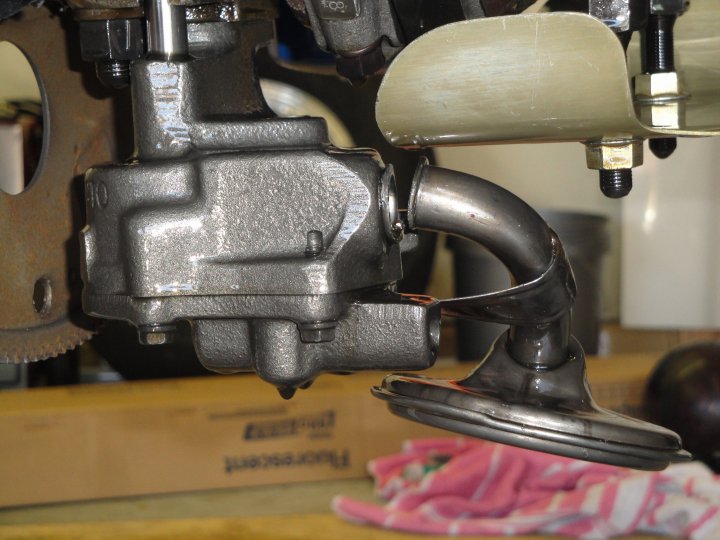

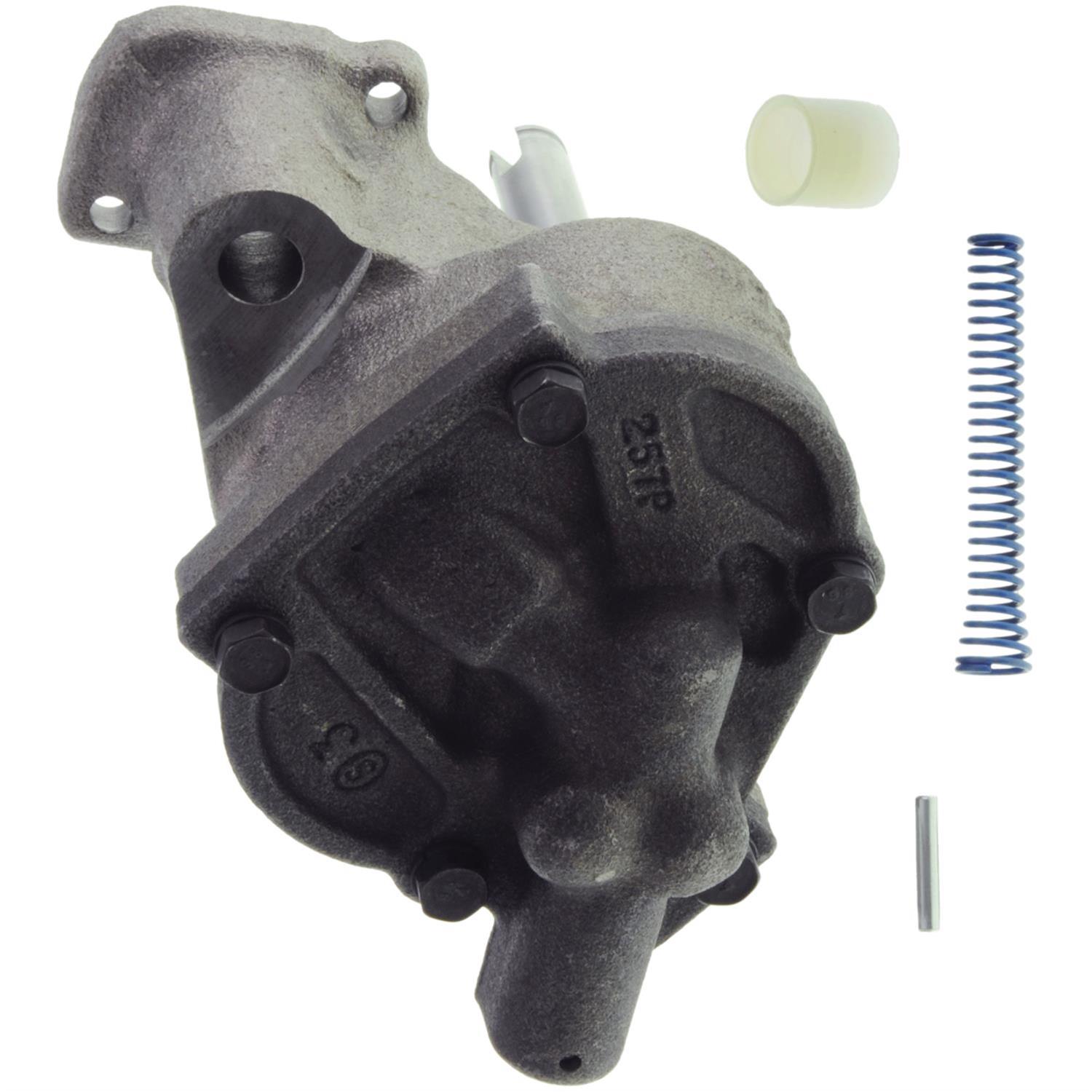

use this oil pump(link below) in most stock SBC builds, as it produces a 10% increase in oil volume and standard pressure which is just fine , but obviously check your bearing clearances and oil pump to oil pan floor clearances and braze the CORRECT MATCHING pick-up to the pump, and I'd also suggest if you have the room, for clearance that you look into one of the less expensive 7 quart baffled oil pans as they provide a good deal more potential protection and durability to your bearings longevity.

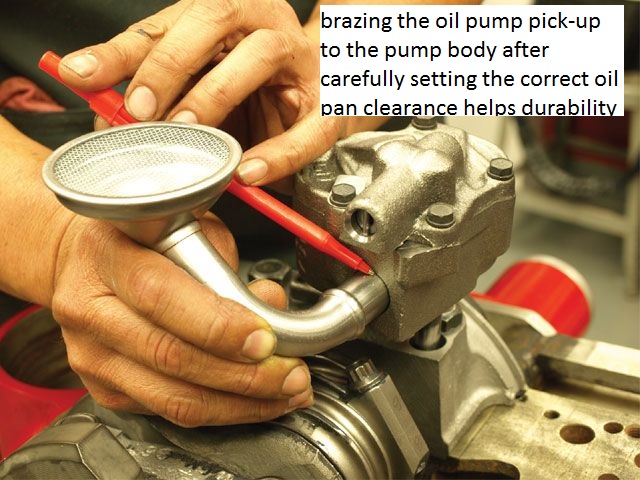

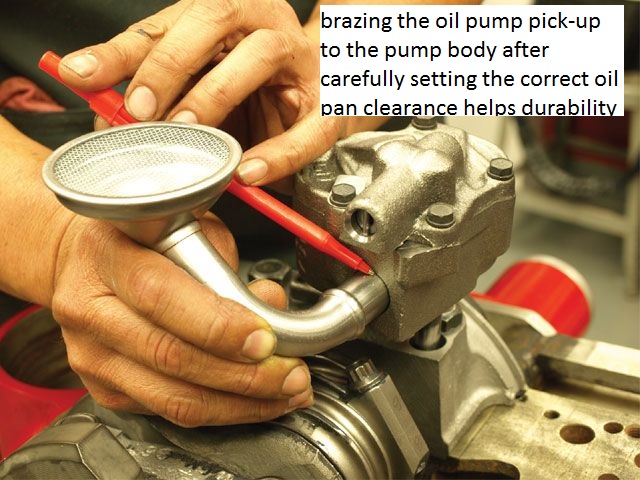

be very sure you verify the oil pump pick-up to oil pan floor clearance, and braze the pick-up to the pump body.

brazing may be a bit weaker than TIG welding in theory, but I found its (brazing) much less likely to crack over time,

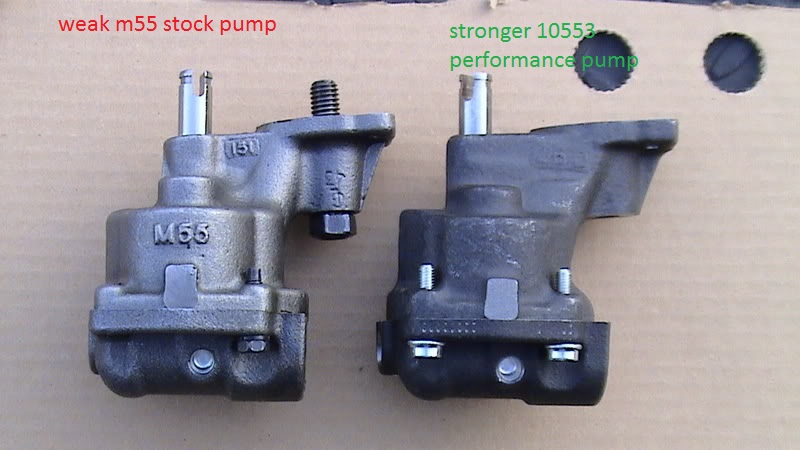

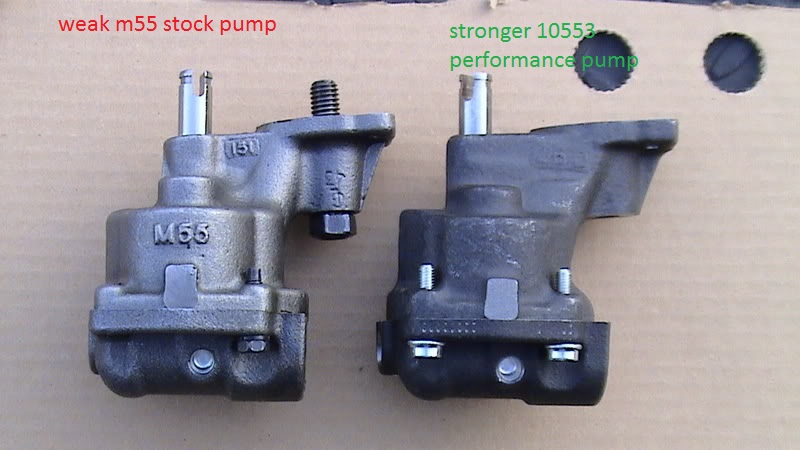

yes there's less expensive oil pumps that will work,

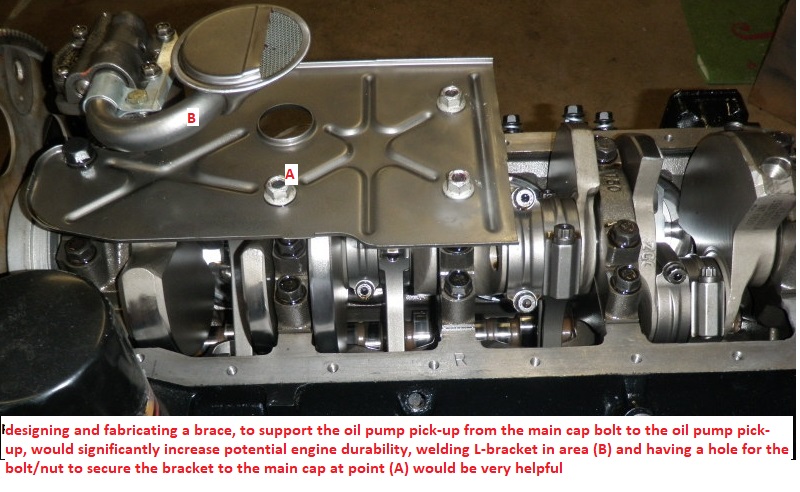

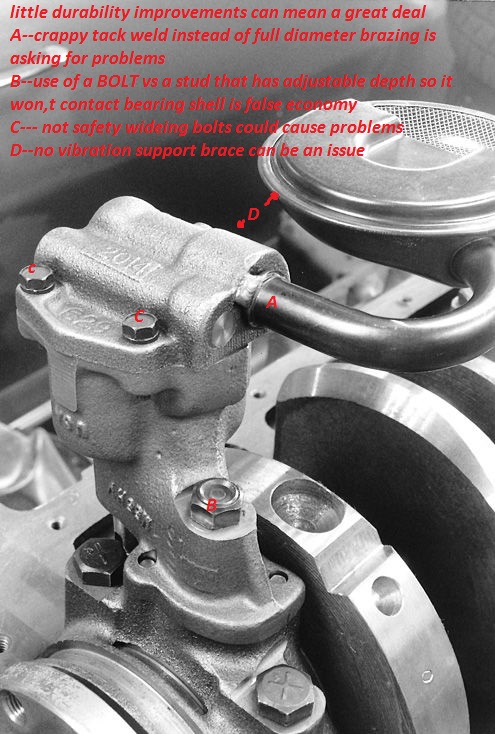

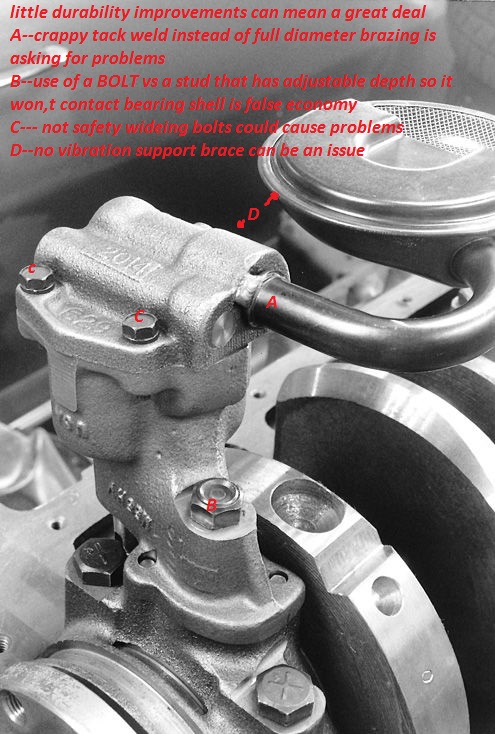

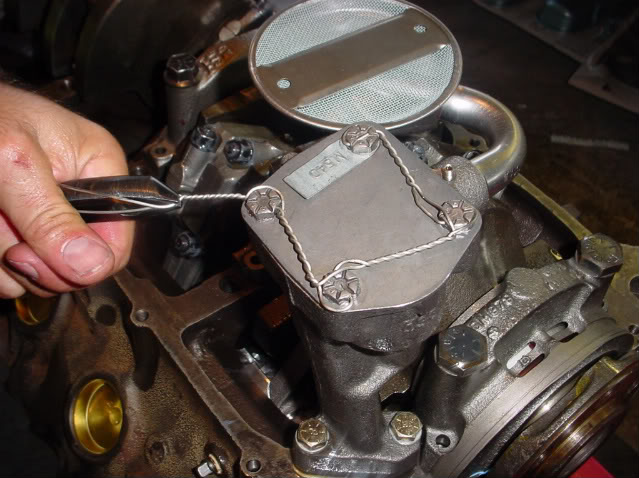

and use of safety wire on the oil pump bolts, and welding/brazing the pick-up to the pump and use of a brace bracket ,

sure wont hurt either

but that's a good value, in a well made pump.

WATCH VIDEO, get the oil pump pickup to oil pan floor clearance correct and for darn sure braze or tig weld the pick-up to the pump once the clearance is verified

you have three rather commonly available sources for decent reasonably priced oil pumps ,

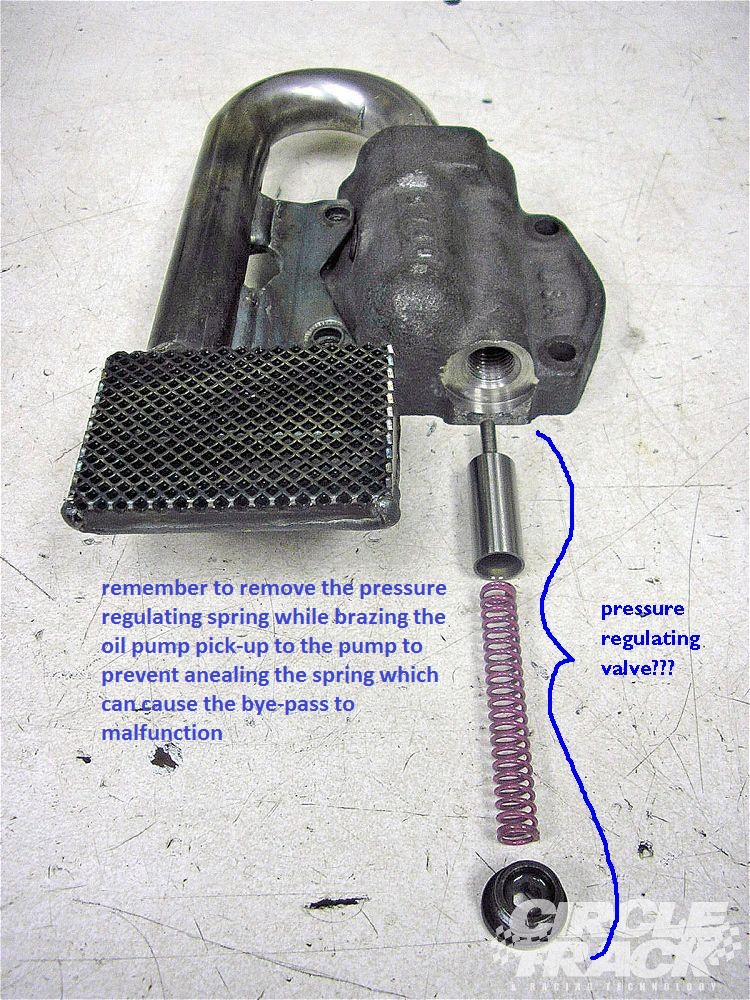

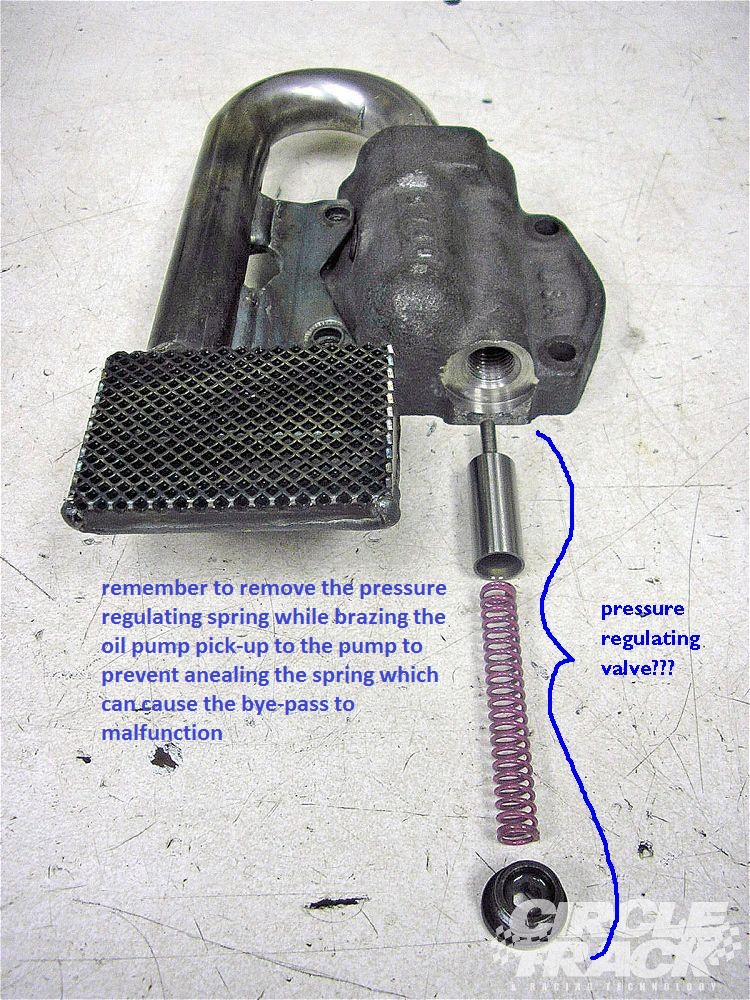

yes I would remove the pressure relief spring temporarily while brazing the pick-up to the oil pump.

brazing a oil pump pick-up to the pump as proven to be more durable than tig or mig welding on most pumps ,

as brazing is less prone to cracking from constant vibration, if done correctly

Melling,

www.summitracing.com

www.summitracing.com

www.summitracing.com

www.summitracing.com

milodon

https://www.jegs.com/i/Milodon/697/18732/10002/-1

and

moroso,

www.summitracing.com

www.summitracing.com

I generally prefer moroso, or milodon, but all three options will work,

If I was assembling that engine, Id suggest, you want to buy and use a big chevy,

block standard volume and standard pressure oil pump.

obviously you need to verify pick-up to oil an floor clearances ,

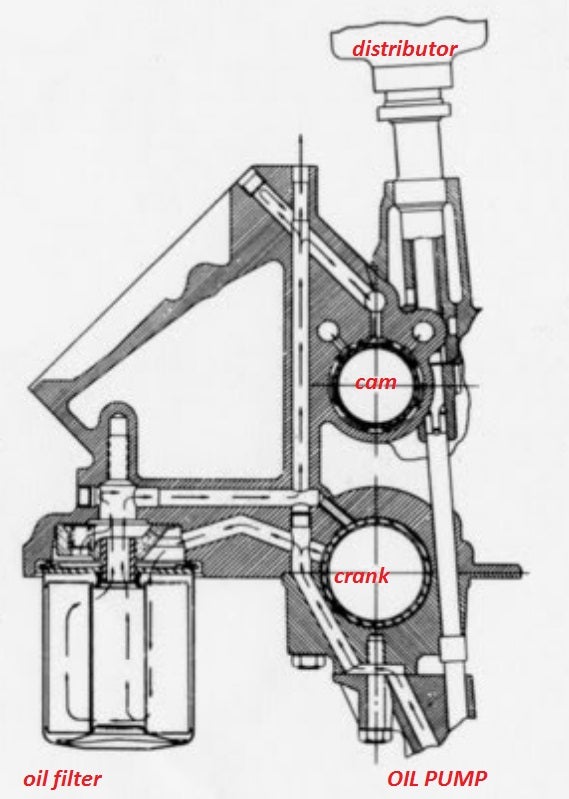

and oil pump drive shaft, to the seated distributor shaft ,

clearances during the installation process.

measure accurately then order the correct matching oil pump pick-up

https://www.jegs.com/p/Speedmaster/Speedmaster-Oil-Pump-Pickup-Tubes/3151009/10002/-1

https://www.speedwaymotors.com/shop/speedway-oil-pump-pickup-tubes~8207-10191-4770-10-599-30999

https://www.jegs.com/c/Oil-System_Oil-Pumps-Pickups/10453/10002/-1

https://www.cnc-motorsports.com/engine-parts/oil-system-components/pickup-tubes

https://www.jegs.com/vpt/Melling/En...MI2sHX-KiH4gIVDSsMCh22AgQ_EAMYASAAEgJziPD_BwE

https://www.jegs.com/p/Moroso/Moros...MIn46_96mH4gIVgo7ICh1ebwxQEAAYASAAEgItx_D_BwE

https://www.melling.com/product/oil-pump-screens/

https://www.enginelabs.com/news/video-how-to-moroso-performance-explains-oil-pump-pickup-clearance/

first choice

http://www.summitracing.com/parts/mel-10552/overview/ SBC

or

http://www.jegs.com/i/Melling/689/10778C/10002/-1 BBC

its not that difficult to remove the oil pan, replace the gasket with a new one piece synthetic one and cure that leak,

most guys can do that in a single afternoon with the car up on 4 12 ton jack stands rather easily.

be aware that the crank counter weights rotated to the correct location makes removing the oil pan a bit easier.

it might be a great opportunity to swap to a higher capacity baffled oil pan.

obviously youll want to carefully research the correct oil pan for your engine and chassis before purchasing one

https://www.summitracing.com/parts/ctr-15-240/overview/make/chevrolet/model/corvette

7" deep

https://www.cantonracingproducts.com/cgi-bin/commerce.cgi?preadd=action&key=11-102

6.5" deep

https://www.carid.com/moroso/oil-pa...MIraOQn-602QIVBJ7ACh2mTwt4EAQYAyABEgJZWfD_BwE

7" deep

theres lots of 8" and 8.25" deep corvette oil pans but they don,t last too long with speed bumps and raised manhole cover rims

https://www.summitracing.com/parts/...MIytnIx-y02QIVHrjACh35mQ-OEAQYASABEgJnZvD_BwE

http://garage.grumpysperformance.co...etic-oil-cause-leaky-gaskets.2725/#post-13817

http://garage.grumpysperformance.com/index.php?threads/under-car-safety.26/page-4#post-69999

http://garage.grumpysperformance.co...-pan-gasket-still-small-leak.3084/#post-11971

http://www.onallcylinders.com/2014/10/23/oil-well-choosing-proper-pressure-volume-oil-pump/

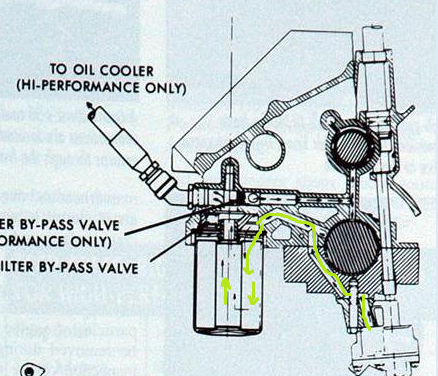

keep in mind swapping to a heavier rated oil pump spring does not increase oil pressure, oil pressure is the result of the resistance to oil flow volume through the bearing clearances, increasing the oil spring pressure in the oil pump only results in limiting the max oil pressure, the pumps resistance to its produced oil volume pumped through those bearing clearances, reaches, before the oil pressure relief valve opens to limit the max oil pressure

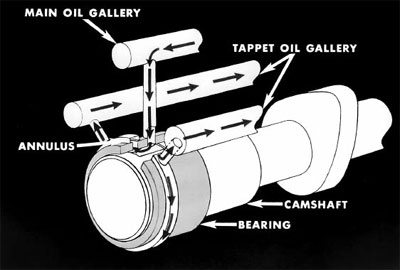

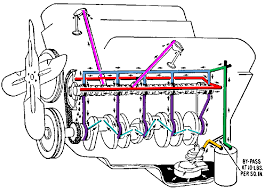

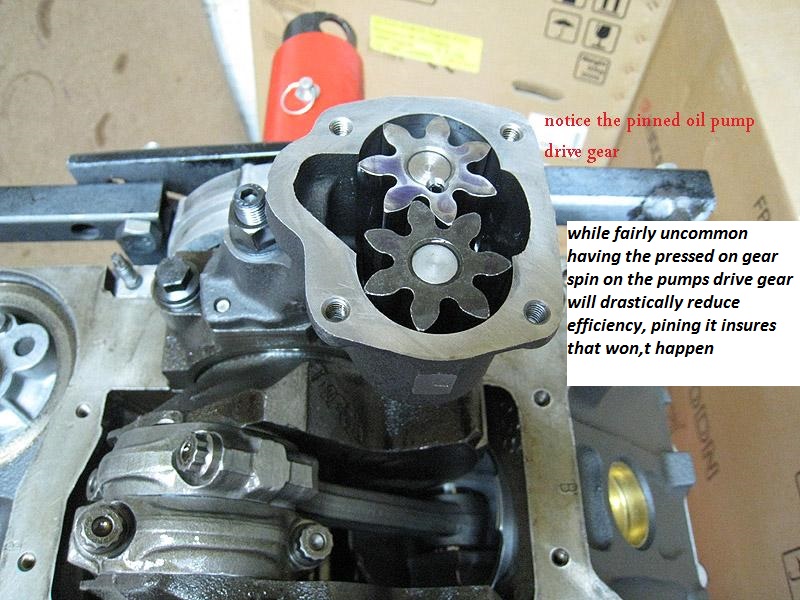

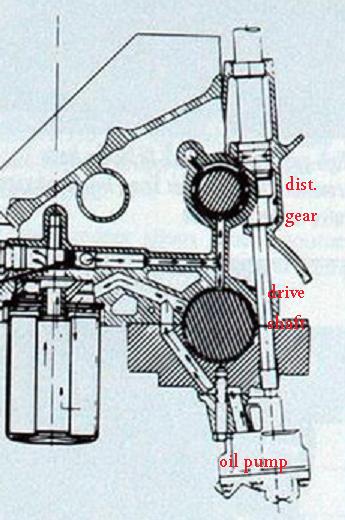

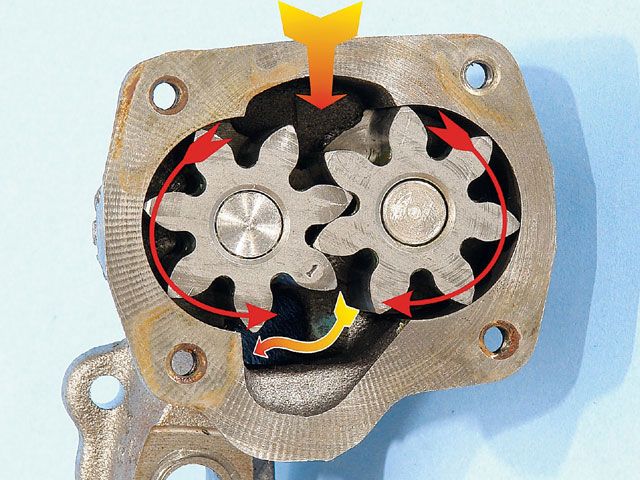

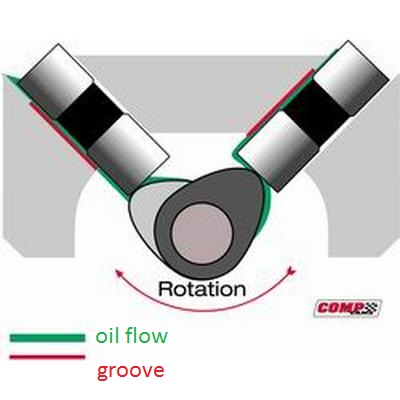

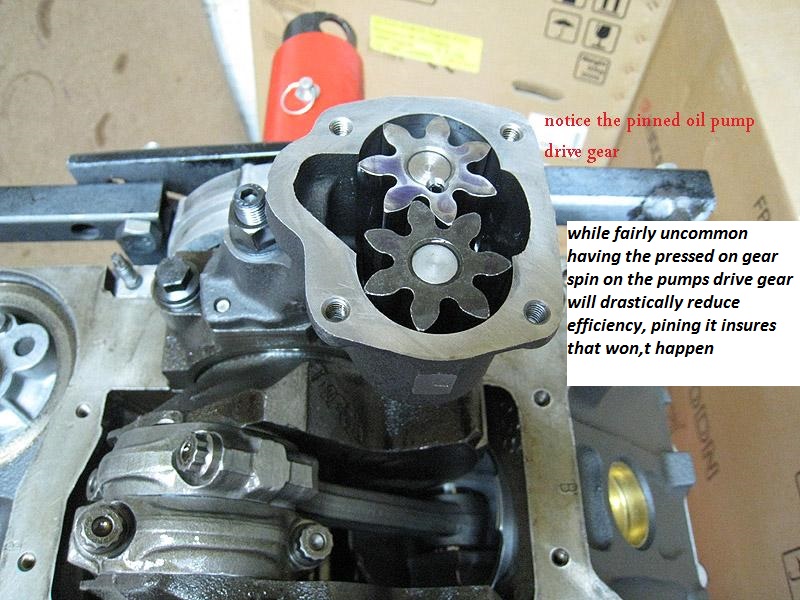

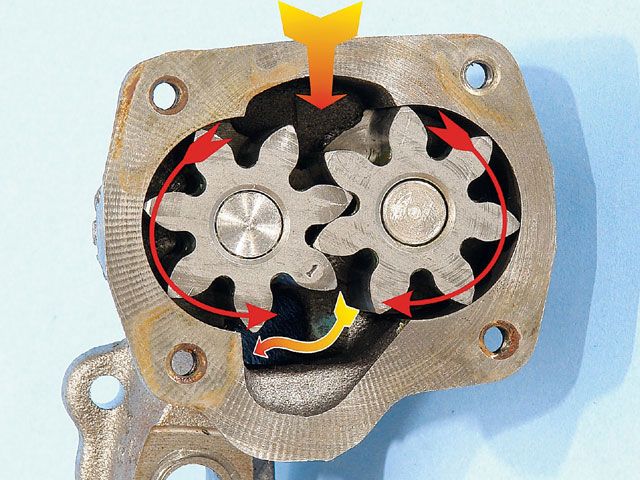

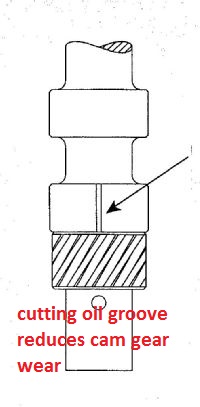

keep in mind the oil pump gears spin at 1/2 engine rpm as they are driven by the distributor gear. on the cam shaft

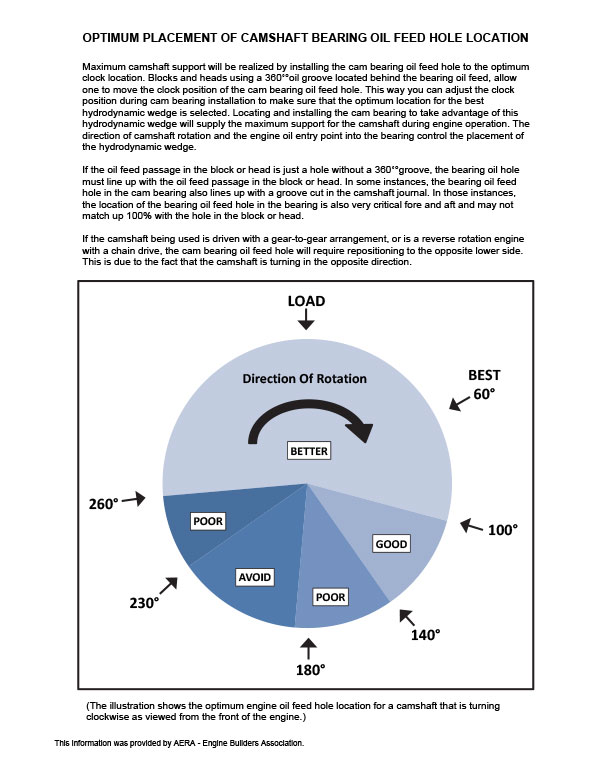

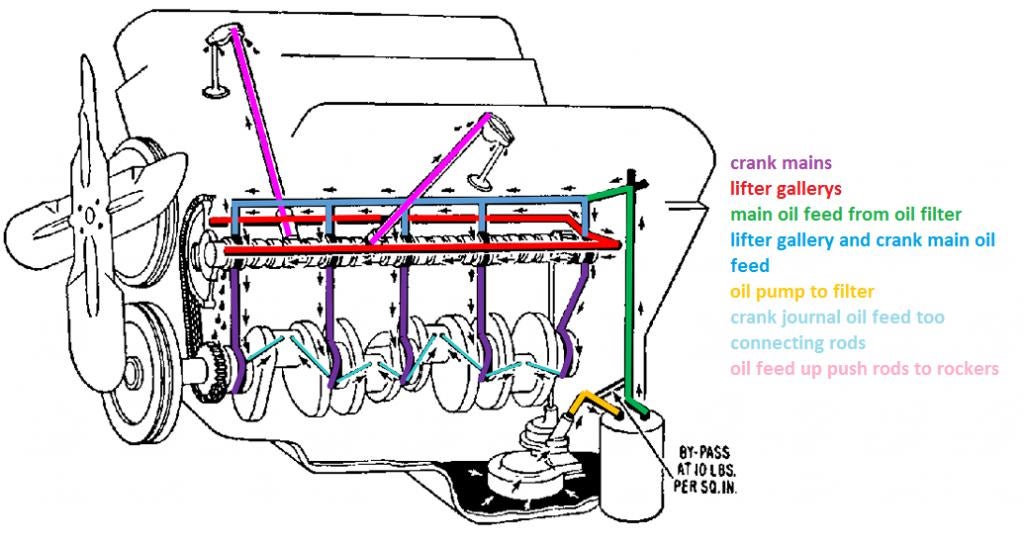

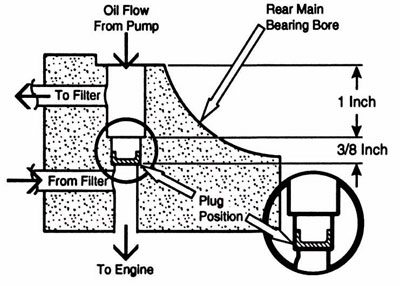

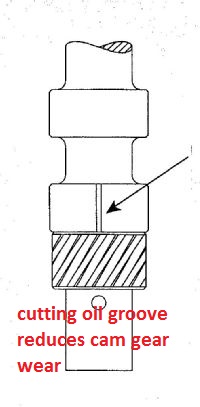

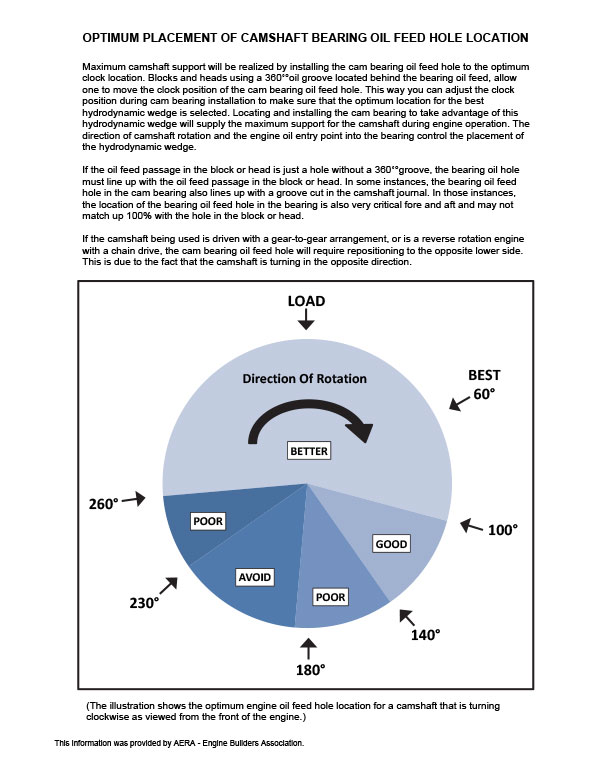

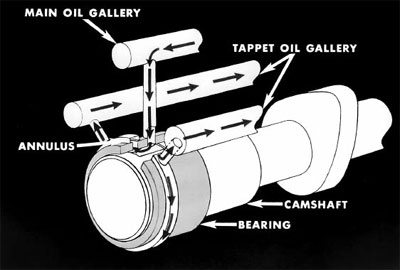

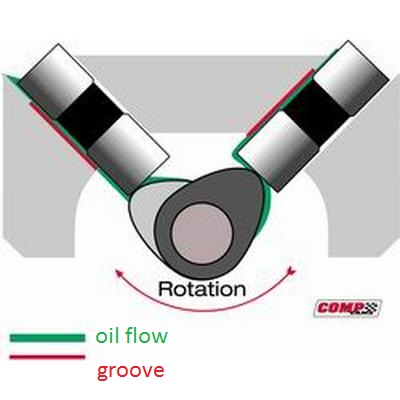

obviously the small groove is intended to flow extra oil volume to the rear vertical thrust bearing surfaces

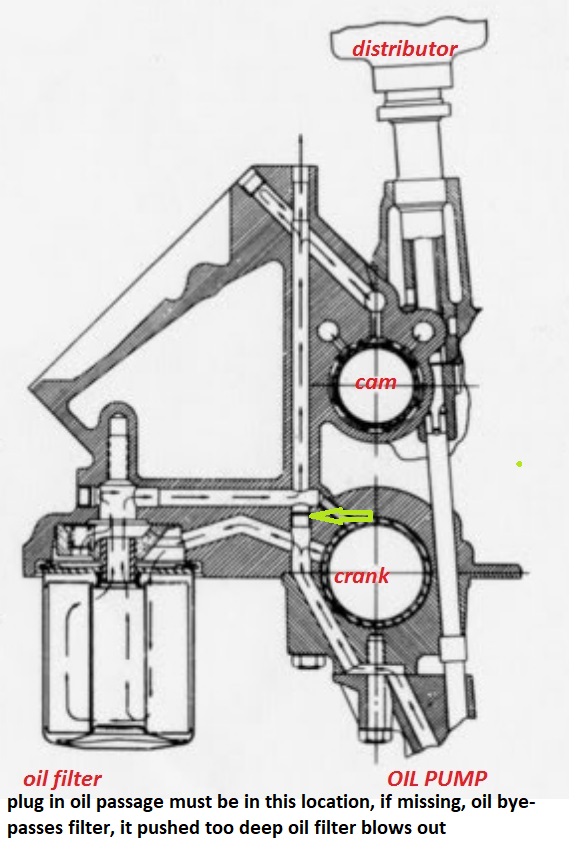

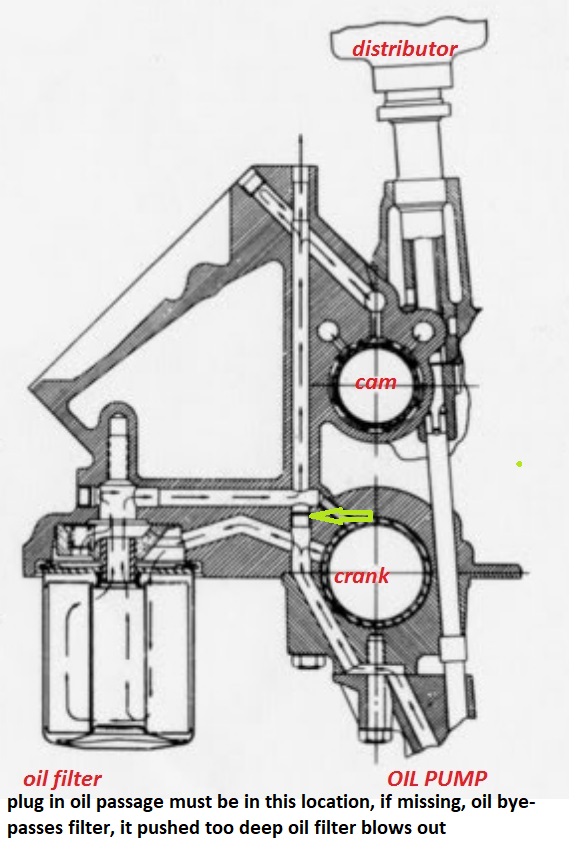

If your not getting oil to the rockers but have 65 psi as the engine idles,

Id suspect either the cam bearings (especially the rear cam bearing or the oil passage plugs under the timing chain are incorrectly installed

http://www.mellingselectperformance.com/Products/Cast-Iron-Oil-Pumps

second choice

http://www.summitracing.com/parts/mil-18750/overview/ SBC

related threads you should read

http://garage.grumpysperformance.co...ibutors-wont-seat-on-intake.12538/#post-63636

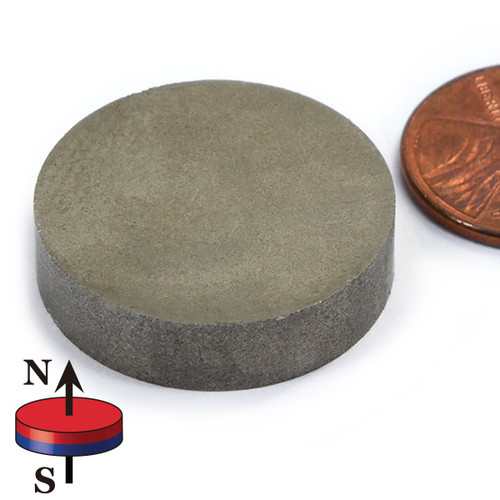

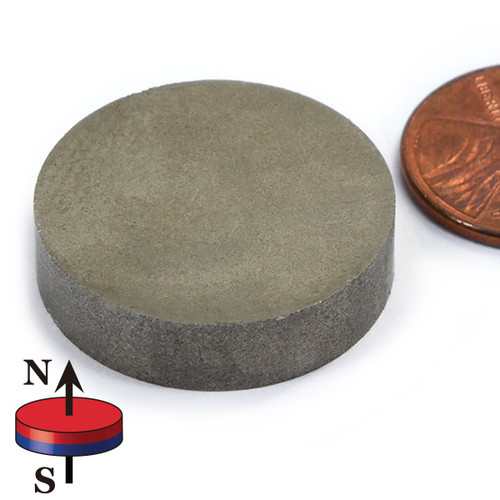

use proper oil and filters and damn surely use high temp magnets to trap fine metallic abrasive crud

www.magnet4sale.com

http://www.enginebuildermag.com/Article ... pumps.aspx

www.magnet4sale.com

http://www.enginebuildermag.com/Article ... pumps.aspx

http://garage.grumpysperformance.com/index.php?threads/sbc-oil-pump-noise.14582/

http://www.aa1car.com/library/2005/us020516.htm

http://www.moroso.com/catalog/pdf/Oil_Pumps_106.pdf

http://www.milodon.com/oil-system/oil-pumps.asp

http://www.melling.com/Info/TechTipVideos.aspx

there are oil pump testers available commercially or if your mechanically inclined you can fabricate one with reasonable care, after a bit of measuring and purchasing a gauge

http://cvrproducts.com/oil-pressure-test-kit/

Melling 55070

70 psi, Steel, Pink, Pins, Chevy, Small Block, Kit

Melling 77070

Oil Pump Springs, 70 psi, Steel, Pink, Pins, Chevy, Big Block, Kit

Melling 55058

Oil Pump Springs, 58 psi, Steel, Yellow, Pins, Chevy, Small Block, Kit

Melling 55078

Oil Pump Springs, 78 psi, Steel, Green, Pins, Chevy, Small Block, Kit

Melling 77060

Oil Pump Springs, 60 psi, Steel, Black, Pins, Chevy, Big Block, Kit

Melling 55049

Oil Pump Springs, 49 psi, Steel, Green, Pins, Chevy, Small Block, Kit

Melling 77052

Oil Pump Springs, 52 psi, Steel, Purple, Pins, Chevy, Big Block, Kit

Melling 7770M

Oil Pump Springs, 70 psi, Steel, Pink, Chevy, Big Block, Set of 5

Melling 5556F

Oil Pump Springs, 55 psi of Force, Steel, Chevy, Small Block, Set of 5

Melling 5570F

Oil Pump Springs, 70 psi, Steel, Pink, Chevy, Small Block, Set of 5

Melling 7760M

Oil Pump Springs, 60 psi, Steel, Black, Chevy, Big Block, Set of 5

Melling 7752M

Oil Pump Springs, 52 psi, Steel, Purple, Chevy, Big Block, Set of 5

the idea that you can 'pump the pan dry" with a high volume oil pump, in a properly set up chevy engine has been proven false dozens of times, thats a myth that myth been repeated for decades and the reason its gained its supposed verification as fact is simply that guys install a high voluum oil pump in the same engine that they just removed a stock oil pump from and find that they reve the engine and the oil pressure starts to go up then tops out or even drops off , the instant and wrong conclusion drawn is that the high voluum oil pump sucked the oil pan dry, but what really happened in almost every case was a bit simpler.

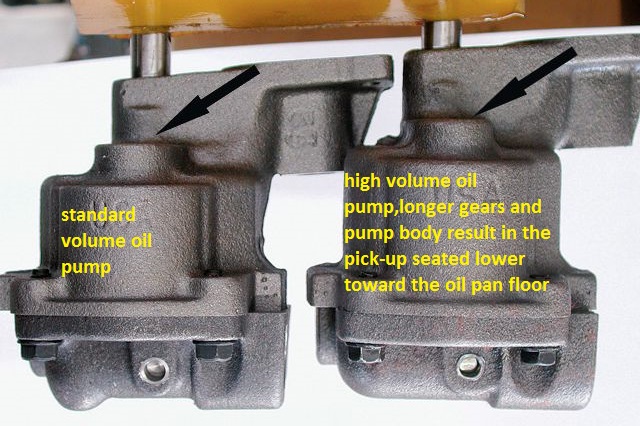

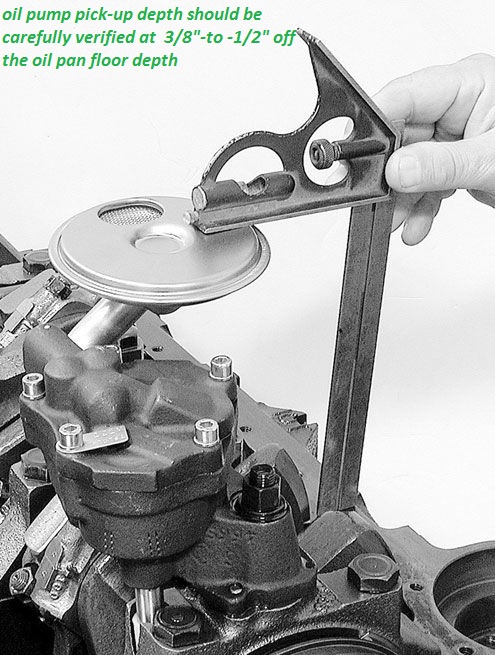

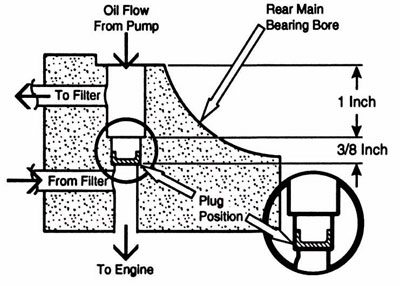

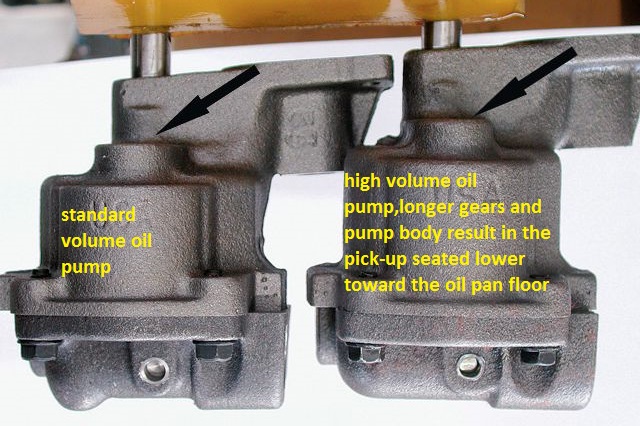

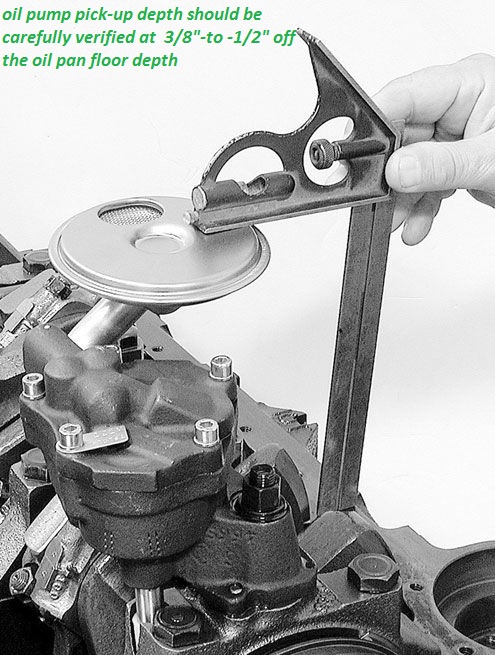

high volume oil pumps have a longer body that moves the oil pump pick-up closer to the oil pan floor and if the clearance is not checked and corrected to maintain the required 3/8"-1/2" minimum clearance it severely restricts the flow into the oil pump and pressure drops of as a result of the restriction on the intake side of the oil pump pick-up.

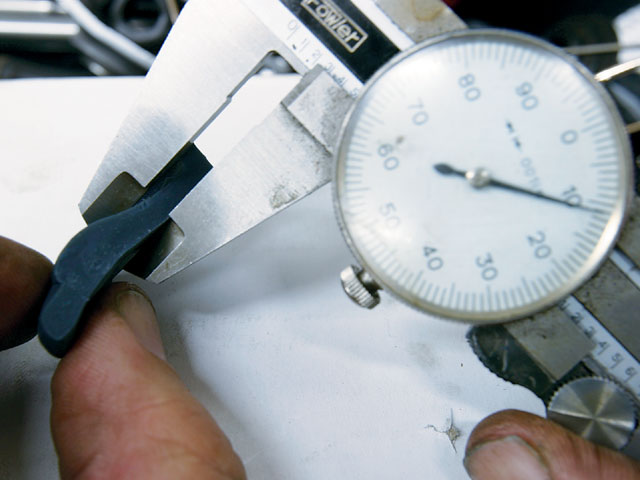

this is a fairly easy to problem too prevent ,during assembly with careful measuring, and a bit of clay,to check clearance, before you braze the pick-up to the oil pump, especially if you braze a 1/2" nut to the lower surface of the oil pump pick up to prevent it from vibrating down close to the oil pan floor should it come loose and if you weld braces to prevent its movement after carefully measuring the correct clearance.

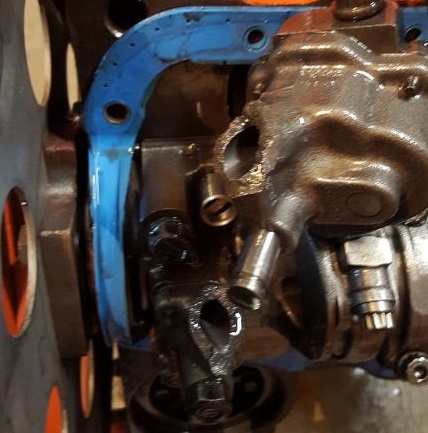

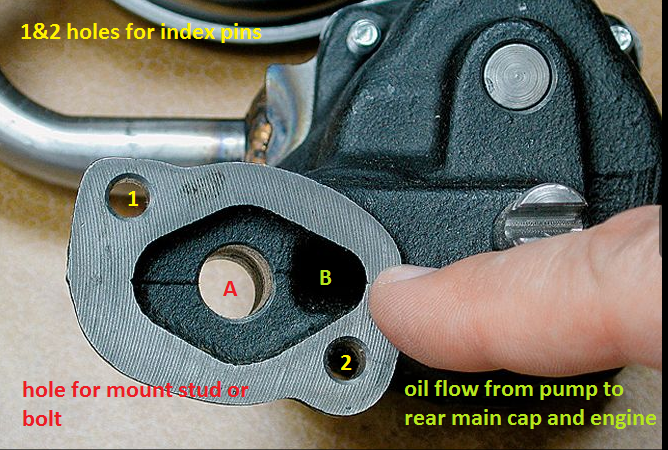

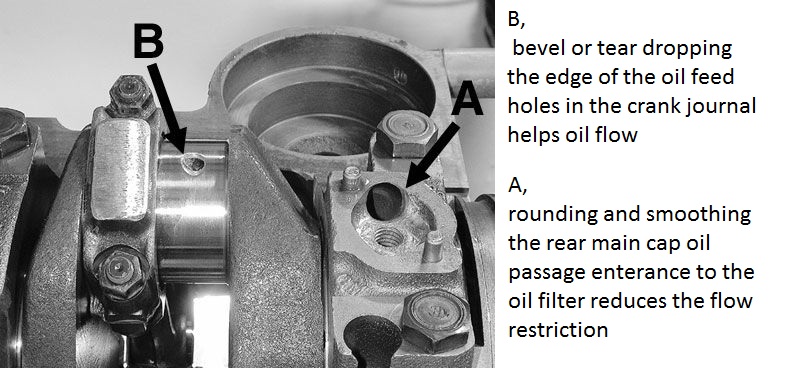

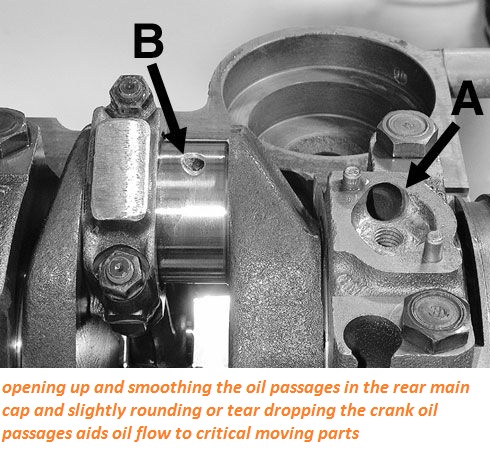

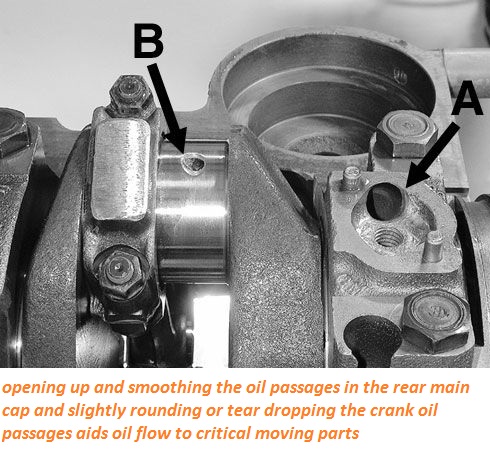

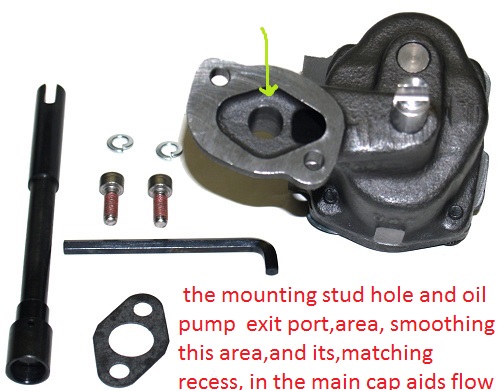

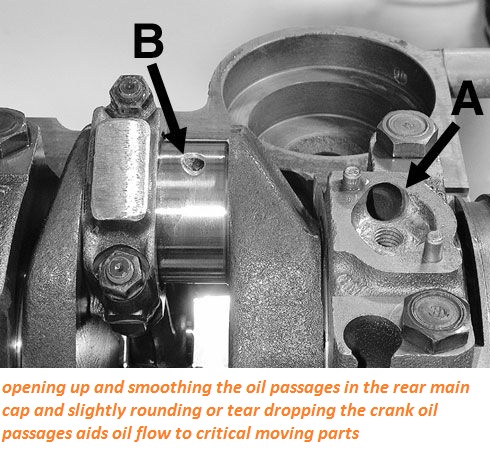

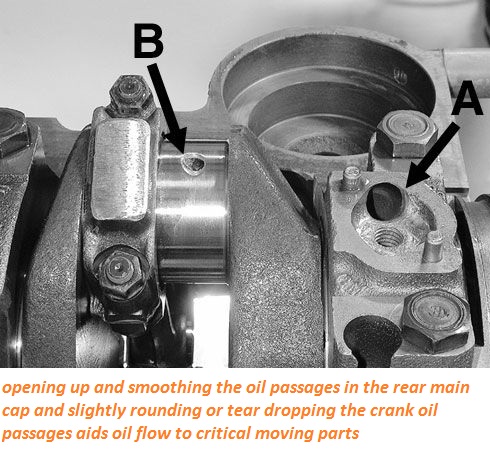

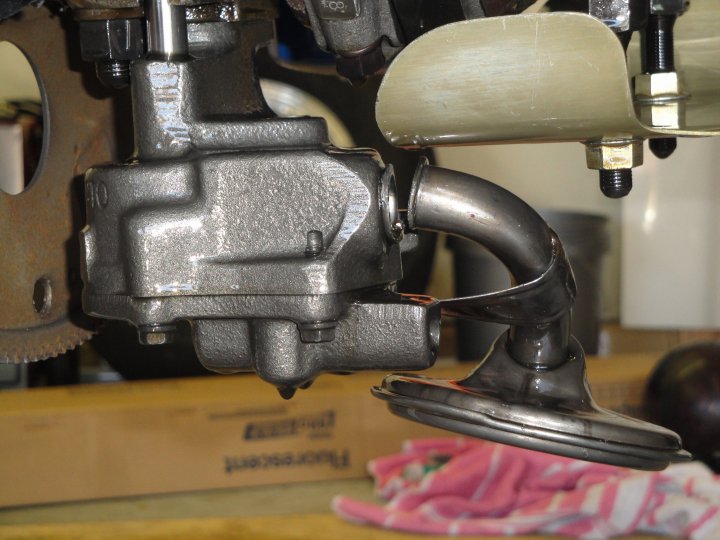

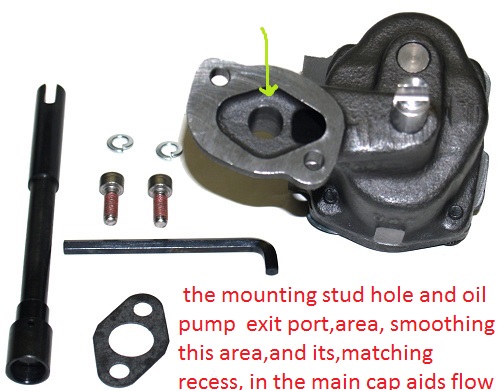

opening and smoothing the recessed area and porting the oil passage entrance reduces the restriction to oil flow

notice the open slot between the rear main cap supporting the oil pump and bearing shell support and the area supporting the rear main seal, this prevents PRESSURIZED oil from the bearings reaching the rear main seal.

the as cast recess in the rear main cap where the oil pump mounts can be rather restrictive and shallow, and if your replacing a missing main cap , with one from a different block you'll very likely be required to have the block?cap too be line honed to get the correct alignment and fit clearances for the crank shaft

Chevrolet Performance 14091563

Left (Driver Side) Dipstick Plug

Chevrolet Performance 9421743

Right (Passenger Side) Dipstick Plug

http://www.hotrod.com/articles/ccrp-0911-small-block-chevy-oil-pumps/

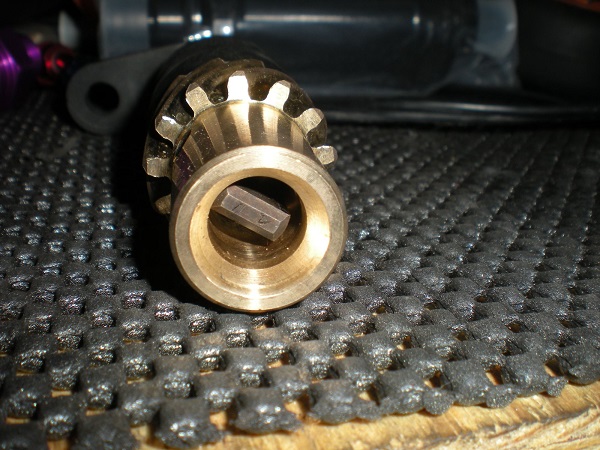

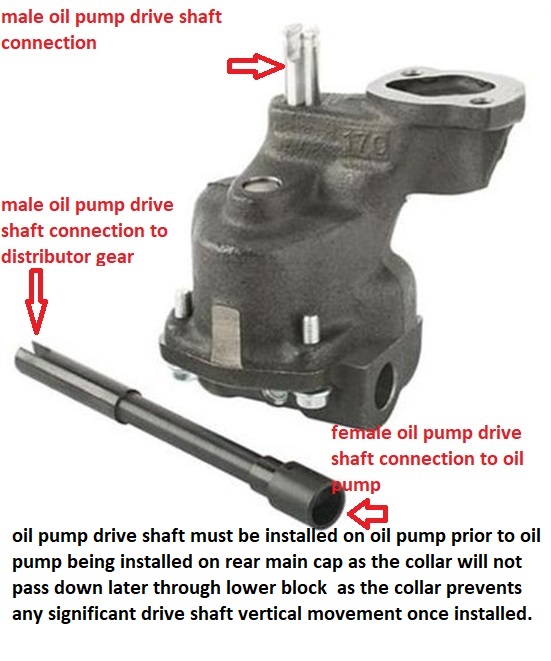

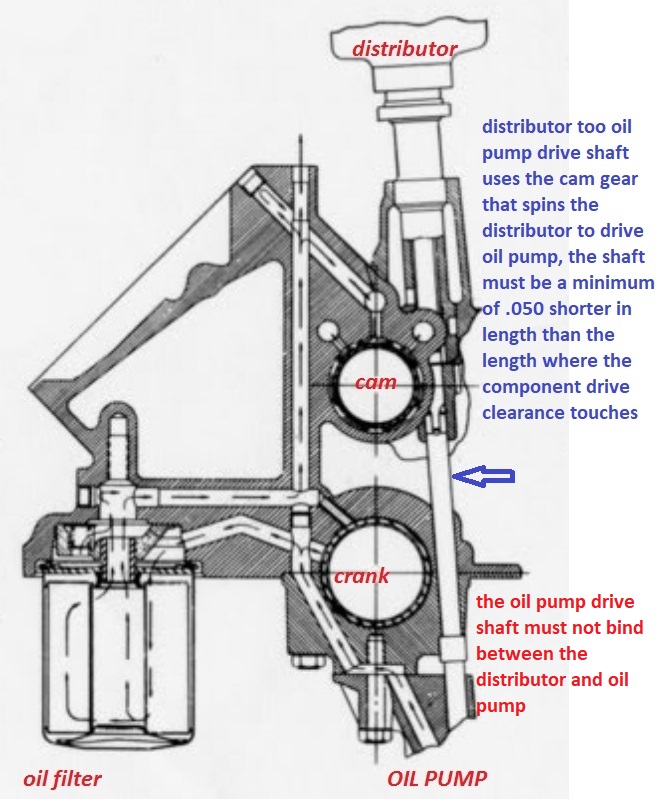

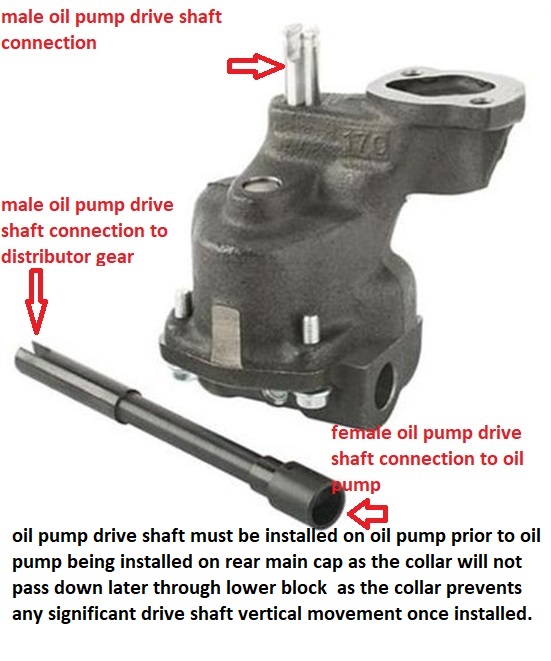

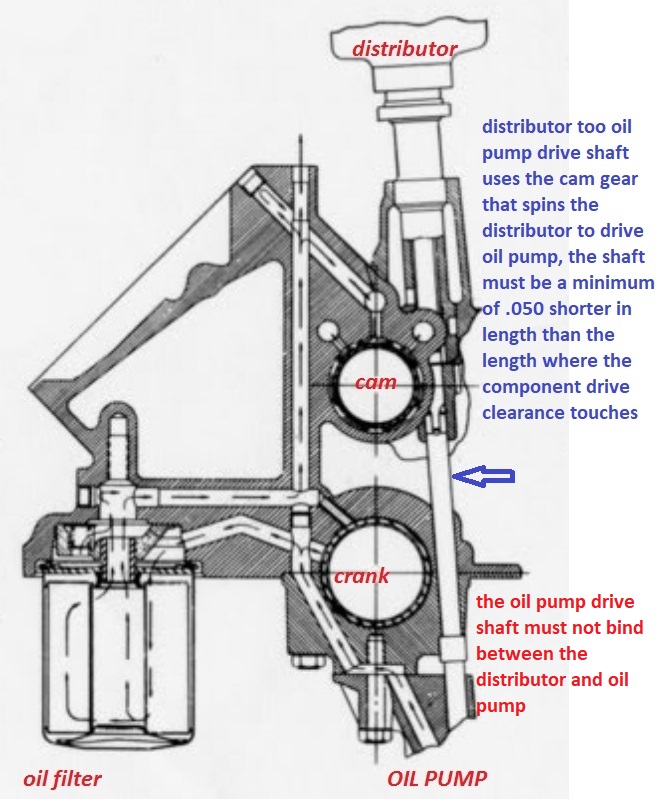

Ive seen this frequently, and almost always its a case where if you measure carefully, youll almost surely find,

the oil pump drive shaft is bottoming out solidly between the oil pump and the distributor gear is binding,

so the distributor is not firmly seated against the intake manifold surface.

the oil pump drive shaft length MUST BE about .050 SHORTER than the distance it would take to firmly seat it inside the distributor drive gear, the cam has a gear that spins the distributor and the oil pump drive shaft is driven by that distributor gear in the lower distributor that extends down to the oil pump drive.

this gear must not bind on the distributor too oil pump drive shaft when the distributor is seated firmly on the intake manifold and clamped into place there must be about .050 clearance minimum

related threads you should really read

http://garage.grumpysperformance.com/index.php?threads/oil-pump-drive-shafts.123/

http://garage.grumpysperformance.co...ibutors-wont-seat-on-intake.12538/#post-63636

http://garage.grumpysperformance.com/index.php?threads/oil-pump-drive-shafts.123/#post-19025

http://garage.grumpysperformance.co...ing-an-oil-pump-pick-up-tube.1800/#post-43110

http://garage.grumpysperformance.com/index.php?threads/distributor-gear-wear.1701/#post-4160

http://garage.grumpysperformance.co...butor-clamp-that-just-won-t-clamp-firmly.871/

http://garage.grumpysperformance.co...-allows-the-distrib-to-turn-even-tighten.873/

http://garage.grumpysperformance.com/index.php?threads/setting-timing-question.1411/#post-3131

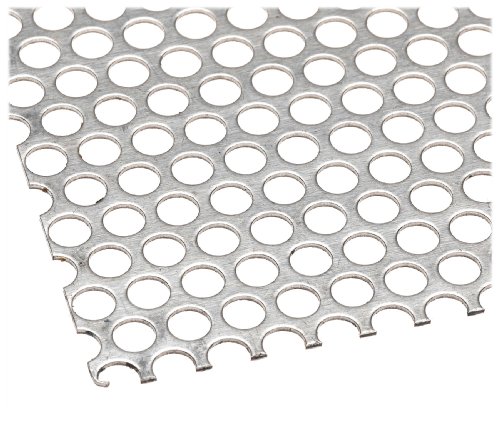

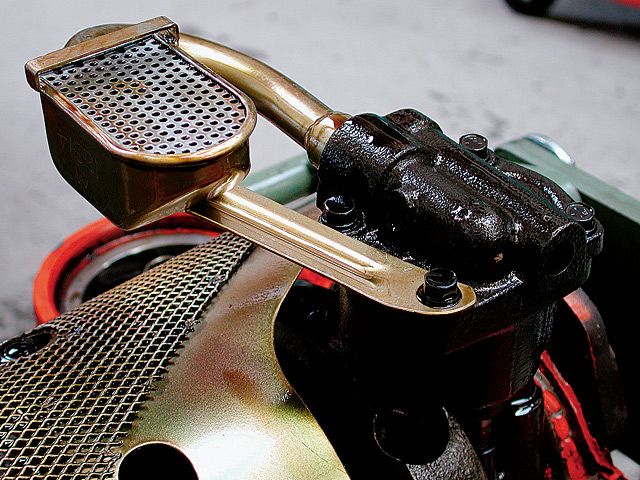

ADDING A WELL DESIGNED WINDAGE SCREEN SPEEDS OIL RETURN SPEEDS . AND EFFICIENCY TO THE ENGINE SUMP

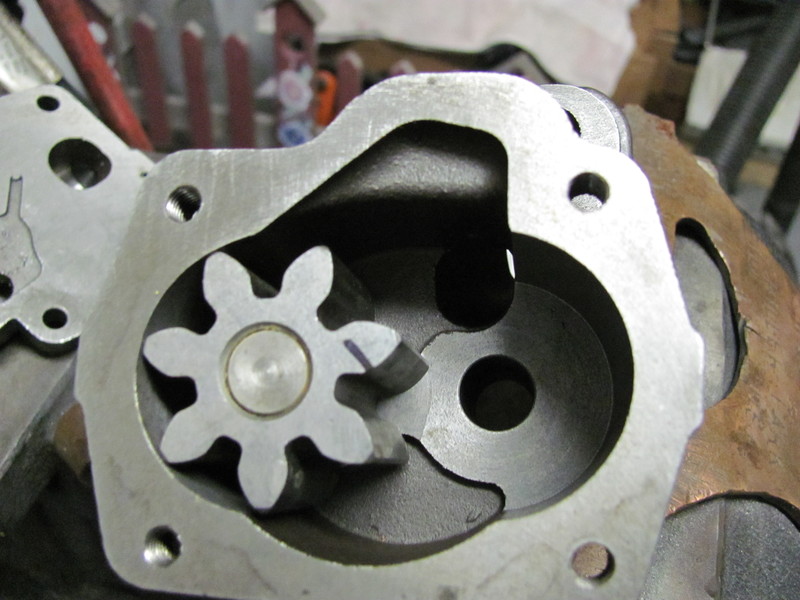

your typical small block oil pump has a 4 bolt cover, a 5/8" pick-up tube diameter and the pick-up presses into the cover , it has the smaller 7 tooth gears, and because the pick-up tube presses into the cover swapping from a standard to a high volume pump, with its longer impeller and hoseing casting, tends to move the pick-up about 1/4" closer to the oil pan floor

http://www.mellingselectperformance.com ... -Oil-Pumps

while your checking put some modeling clay under both pick-ups and see the effective clearance difference then see if the old pump clears the problem, in an ideal world the pick-up to pan floor clearance is a minimum of 3/8" and 1/2" is ideal

OIL PUMP MODS

http://www.corvette-restoration.com/res ... ancing.htm

http://www.corvette-restoration.com/res ... lation.htm

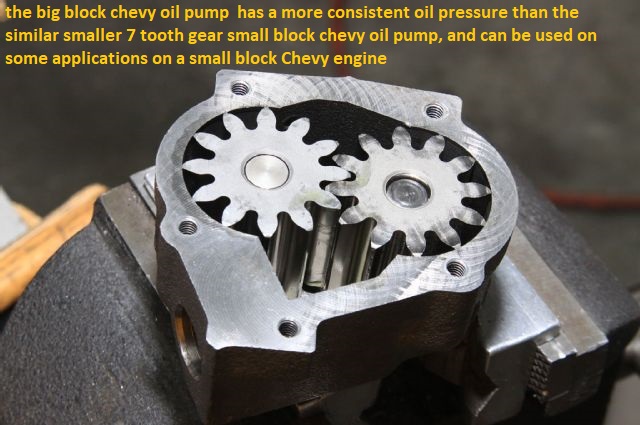

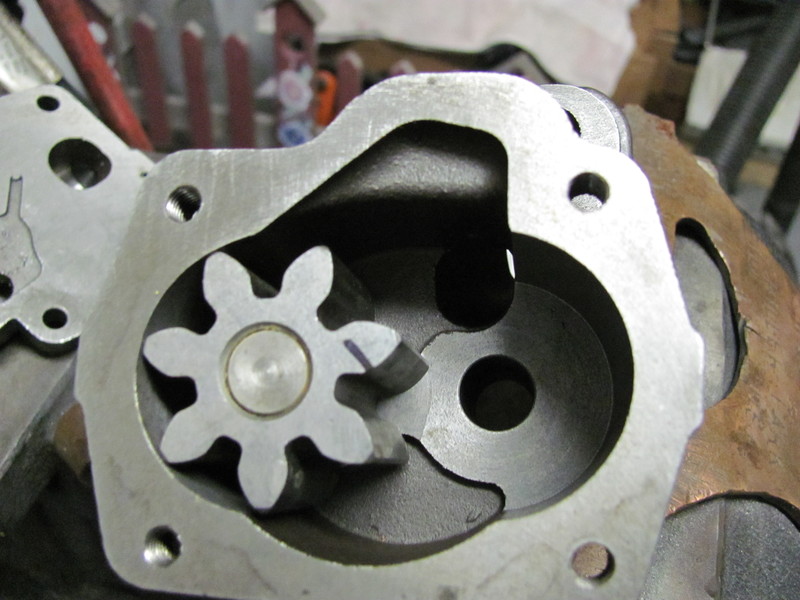

small block pumps have 7 tooth gears and 4 bolt covers and don,t provide the smooth oil flow rates the 12 tooth, and 5 bolt cover big block gear pumps provide

big block vs small block chevy oil pump

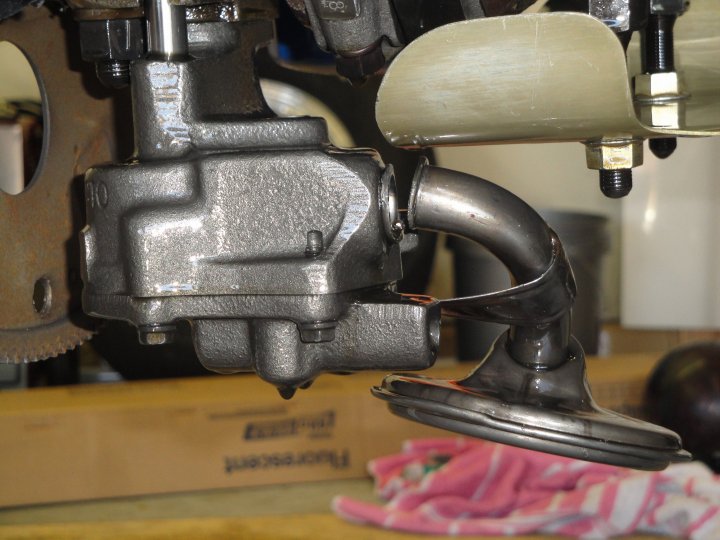

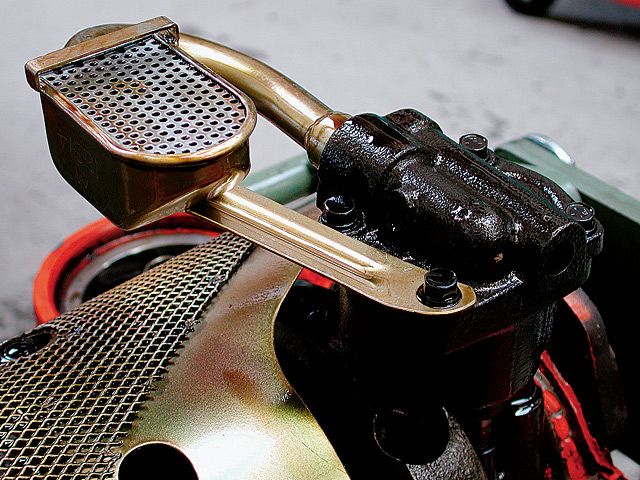

the standard big block chevy oil pump has a 3/4" oil pump pick-up that is inserted in the main pump body, NOT THE 5 BOLT LOWER COVER

your typical small block oil pump has a 4 bolt cover, a 5/8" pick-up tube diameter and the pick-up presses into the cover , it has the smaller 7 tooth gears, and because the pick-up tube presses into the cover swapping from a standard to a high volume pump, with its longer impeller and hoseing casting, tends to move the pick-up about 1/4" closer to the oil pan floor

your typical big block oil pump has a 5 bolt cover, a 3/4" pick-up tube diameter and the pick-up presses into the pump body , it has the larger more efficient 12 tooth gears and in many cases can be mounted on a small block, but its usually not required

BIG BLOCK CHEVY 5 BOLT cover pump

the standard SMALL block chevy oil pump has a 5/8" oil pump pick-up that is inserted in the lower oil pump 4 bolt lower gear cover

SBC 4 BOLT COVER OIL PUMP

SBC pumps have 7 tooth gears and BBC pumps generally have 12 tooth gears making the flow more consistent

a well supported oil pump pick-up tends to cause far fewer issues than one that cab flex and vibrate as metal fatigue can eventually cause them to break

http://www.mellingselectperformance.com/Products/Cast-Iron-Oil-Pumps

BRAZING IS ALWAYS A GOOD IDEA,(just be sure to remove the bye-pass circuite parts and verify function when reinstalled)

vibration can and does occasionally cause pick-up failures

Tig welding is OK, BRAZING the pick-up once youve determined the correct oil pan floor clearance is PREFERRED

ITS always a good idea to verify the oil pan floor to oil pump pick-up clearance and to braze the pick-up to the oil pump, to reduce the potential for it to come loose.

yes you can MIG ,TIG or TORCH WELD the pick-up but I found BRAZING works the best and is less likely to warp or crack the pump or pick-up

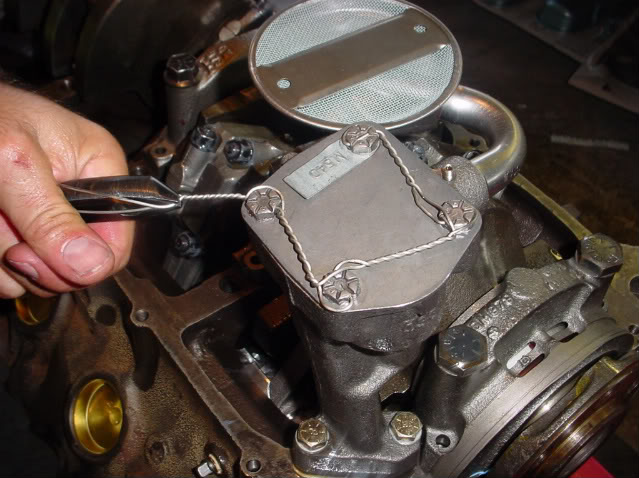

"how in hell do those twisty, safety wire pliers work?"

well a video should be helpful here! Id also point out that you can buy the wire in several diameters and the thicker sizes are far more difficult to use, home depot sells the 22 gauge and 18 gauge, the 22-24 gauge is what youll use far more commonly, as its much easier to use,both stainless (PREFERED) and galvanized are used, and will work on 95% of the applications on a car your likely to use.

using anti-seize paste on bolt or stud threads helps prevent future problems

using safety wire pliers

www.jegs.com

www.jegs.com

bracing the oil pump with a milodon vibration brace can increase durability

MORE USEFUL INFO

BE 100% SURE that the oil pump bolt or STUD doesn,t protrude past the inner main cap surface , because if it bears on the rear main bearing shell it will almost always result in a quickly failed rear bearing

http://www.islandblue.com/store/product ... -ASSORTED/

TO FUNCTION CORRECTLY THE OIL PUMP PICK UP MUST BE MOUNTED AT BETWEEN 3/8" and 1/2" FROM THE OIL PAN FLOOR,CHECK CAREFULLY WITH CLAY and a DIAL CALIPER ,BEFORE BRAZING OR TIG WELDING THE PUMP PICK-UP TO THE PUMP BODY , ONE OF THE MOST COMMON MISTAKES IS INSTALLING A HIGH VOLUME OIL PUMP AND NOT CAREFULLY VERIFYING THE OIL PUMP PICK-UP TO OIL PAN FLOOR CLEARANCE IS IN TH 3/8"-1/2" RANGE WITH THE PAN INSTALLED OR FORGETTING TO BRAZE THE PICK-UP AND ADDING A BRACE TO KEEP IT FROM MOVING, FAILURE TO DO THAT CAN FREQUENTLY RESULT IN LOWER OIL PRESSURE AS THE RPMS INCREASE BECAUSE THE OIL PUMP CAN,T GET ENOUGH OIL INTO THE PUMP THRU THE RESTRICTED OPEN AREA BELOW THE OIL PUMP PICK-UP...FREQUENT WRONGLY DIAGNOSED AS THE PUMP, PUMPING THE PAN DRY, WHICH IS NOT THE CAUSE

place the clay under the pick-up and temporarily mount the oil pan, then remove it and check the compressed clay, get this correct or youll have oil pressure and flow issues

THIS LOOKS like it might be exactly what I buy at my local miller welding supply dealer for brazing/silver soldering, oil pump pick-up tubes to oil pumps, I doubt youll have any issues using it for that application,

but the last time I purchased it it was priced at $6 a stick, or just over $107 for a pack of 20 sticks

and IM fairly sure it said #15 on the package...luckily you seldom require more than about 1/2 a stick to braze an oil pump pick-up onto an oil pump

btw if your curious as too the reference to PLASTIC timing gears, they DO cause problems and should be replaced, because not only will the chain stretch and slip eventually, the nylon debris will clog the oil pump pick-up over time, remember the oil pump pick-up would need to allow the nylon trash to go through the gears and into the oil pump, main cap and only then enter the oil filter.

BE DAMN SURE THE OIL PUMP PICK-UP HAS A LAGER SCREEN SURFACE AREA

http://garage.grumpysperformance.com/index.php?threads/timing-chains-stretch.5734/#post-17492

http://garage.grumpysperformance.co...oil-passages-and-improved-oil-flow-mods.3834/

http://www.harrisproductsgroup.com/en/P ... lv-15.aspx

http://store.cyberweld.com/tubrrodsi15s ... productads

http://www.harrisproductsgroup.com/en/P ... azing.aspx

and I have used a propane torch in the past but my ox-acetolene torch works much better

HARRIS AND VICTOR are the torch brands I prefer

or silver solder rods for the torch

I don't see how anyone serious in this hobby does not have a TIG welder and/or oxy-acetylene torch welder , or at least a decent MIG and/or oxy-acetylene torch welder

and a drill press and hydraulic press

Ive always found the best results from keeping the low rpm pressure , in the 15psi-20psi at hot idle and no more than 65psi at high rpms,is really useful, the voluum required depends on the way the engines clearances and oil systems designed or modified ,voluum/viscosity/clearances in the approximately stock range works fine in most .

I like high voluum pumps but I certainly don,t use them IF the engines nearly stock as the standard Z28 SBC pump works fine

"the standard volume pump gears are about 1.2" long the high volume pump gears are about 1.5 inches long (depends on manufacturer)

heres the discriptions right from chevy

12555884

SBC Oil Pump, High Pressure Z28/LT1. Production high-pressure oil pump with 1.20" gears.

Will produce 60-70 psi oil pressure. Does not include screen. The pickup tube dia. is 5/8" for this pump.

62.17

the true high volume pumps like this below are not necessary UNTILL you've done extensive mods that require the extra oil flow volume

14044872

SBC Oil Pump, High-Volume. This high-volume pump has1.50" long gears.

It has approximately 25% more capacity than a production pump at standard pressure. Does not include screen."

viewtopic.php?f=54&t=2187

keep in mind, most bbc pumps have 5 bolts in the cover and the pump body is where the pick-up tube installs

keep in mind, most sbc pumps have 4 bolts in the cover and the pump cover is where the pick-up tube installs

http://www.speedwaymotors.com/Oil-Pump- ... GoogleBase

http://www.youtube.com/watch?v=KOIhaI3e ... r_embedded

http://books.google.com/books?id=GUC52- ... t&resnum=3

use the correct tool to seat the oil pump pick-up using a wrench and hammer often distorts the tube

https://www.summitracing.com/parts/mel-mcat-75

https://www.summitracing.com/parts/mel-mcat-62

http://www.chevyhiperformance.com/techa ... index.html

heres some decent designed oil pans for bbc and SBC, naturally you need to verify if they work in your application

http://www.moroso.com/catalog/categoryd ... code=11330

btw, Ive built SBC engine with standard oil pumps, and big block oil pumps, in the past, and while I have experience doing it both ways and setting engines up with clearances both on the tighter side of the range with the standard oil pumps and a bit looser with the 5 bolt big block pumps, theres a system that needs to be used , not just an oil pump you stick in an engine, generally if you opt to install the larger big block 5 bolt oil pump theres a reason, and you do mods that require the extra oil flow rates., things like larger auxiliary outside mount oil coolers ,come to mind.

https://stellartechnical.com/products/sil-fos-15-brazing-rods?variant=5368214126619&utm_medium=cpc&utm_source=google&utm_campaign=Google Shopping&gclid=Cj0KCQjwp4j6BRCRARIsAGq4yMHcjgBKY6oe0p7-knvvNsXU2lpl33Pi1KGgn6RxyRb5n4t4lgGI7hEaAqrKEALw_wcB

https://stellartechnical.com/products/sil-fos-15-brazing-rods?variant=5368214126619&utm_medium=cpc&utm_source=google&utm_campaign=Google Shopping&gclid=Cj0KCQjwp4j6BRCRARIsAGq4yMHcjgBKY6oe0p7-knvvNsXU2lpl33Pi1KGgn6RxyRb5n4t4lgGI7hEaAqrKEALw_wcB

or lets go the cheaper route,

you clamp the oil pump body minus the gears and base plate (which you remove temporarily) in a vise with the tube entrance facing vertically, and a short section of soft pine 2x4 under the pump body , if you support the pump body underneath with a section of soft wood 2 x 4 and cushion the vise jaws and clamped between two sections of 1/2" plywood to cushion the vice jaws you find a crows foot open end wrench, or the correct tool, that clamps to the pick-up, that slides over the oil pump pick-up tube but not over the ridge, in the tube that in theory prevents you from inserting the tube too deeply into the pump body. can be use to efficiently tap the tube into the pump body.

failure to use the wood as a vise jaw cushion, binding the drive shaft, marring the mount surface or over tightening the vise will sometimes damage the pump, so be cautious, use your common sense, and treat the pump as the fairly fragile piece of precision casting that it is!

be aware that some pick-ups will extent too far into the pump body if inserted up to the full depth so verify internal pump gear clearance and smooth function,before brazing the pick-up tube into place

use a 8" extension and the crows foot wrench and a rubber mallet to seat the pick-up tube into the pump body, then temporarily mount the oil pump and place a lump of modeling clay on the pick-up body lower surface and install the oil pan for a second to compress the clay giving you the distance between the oil pump pick-up and the oil pan floor, adjust it until the distance is approximately 3/8"-1/2"

once that distance is correct BRAZE the pickup to the pump body AFTER temporarily removing the bye-pass spring so it won,t get annealed, and its a very good idea to use the type of pick-up that has both the feed tube and the screened suction section braced to the pump body, so they don,t crack from vibration and metal fatigue.

Id also point out that a few of the oil pump pick up designs available , have tubes that can be pressed into the pump body far enough to contact the gears, if pounded into the pump to the swagged ring on the mount tube, it makes a good deal more sense to radias the exit port and insert the pick-up only to the point the exit tort radias reaches it and after careful measuring and removing the spring assembly to BRAZE the pick up to the pump body. It also helps to weld in a vibration brace.

LIKE THESE

if you use a non-supported pick-up like this one below, its far more likely to break

once that's done you clean lube and re-install the pump components and verify clearances, and the gears spin freely with out binding, don,t forget to use some MOLY assembly lube, or VASOLINE on the gears to assure it primes quickly.

BTW if you have a sudden drop in oil pressure on any engine with no other symptoms, you might want to replace the oil filter and check oil levels before you panic as its not uncommon for some brands of oil filters to fail internally

YOU NEVER want to bolt the pump body to the rear main cap and beat the pick-up into the pump body as that will result in un- acceptable stress on the cast pump body which CAN RESULT IN A TOTAL PUMP FAILURE

brazing the oil pump pick-up tube to the pump body after carefully checking clearances will usually prevent the oil pump pick-up from vibrating loose over time

BRAZING the pick-up to the pump is a good idea but remember to remove the pressure regulator valve first and oil and replace it after the pumps cooled

http://www.youtube.com/watch?v=KOIhaI3e ... r_embedded

this is a factory produced hamberger oil pan but its a decent example of what can be fabricated

TEL: (562) 921-0404

http://www.hamburgersperformance.com/

other options

http://www.stefs.com/products/oilpans/supergascompstreetpans.htm

http://www.kevkoracing.com/wetsump_chevy.htm

http://www.moroso.com/catalog/categorydisplay.asp?catcode=11330

use this oil pump(link below) in most stock SBC builds, as it produces a 10% increase in oil volume and standard pressure which is just fine , but obviously check your bearing clearances and oil pump to oil pan floor clearances and braze the CORRECT MATCHING pick-up to the pump, and I'd also suggest if you have the room, for clearance that you look into one of the less expensive 7 quart baffled oil pans as they provide a good deal more potential protection and durability to your bearings longevity.

be very sure you verify the oil pump pick-up to oil pan floor clearance, and braze the pick-up to the pump body.

brazing may be a bit weaker than TIG welding in theory, but I found its (brazing) much less likely to crack over time,

yes there's less expensive oil pumps that will work,

and use of safety wire on the oil pump bolts, and welding/brazing the pick-up to the pump and use of a brace bracket ,

sure wont hurt either

but that's a good value, in a well made pump.

WATCH VIDEO, get the oil pump pickup to oil pan floor clearance correct and for darn sure braze or tig weld the pick-up to the pump once the clearance is verified

you have three rather commonly available sources for decent reasonably priced oil pumps ,

yes I would remove the pressure relief spring temporarily while brazing the pick-up to the oil pump.

Testing High Volume Vs Standard Chevy Oil Pumps

after reading all the posted info , you would more than likely avoid or skip the related links, so I posted them at the beginning so you at least realize, theres much more and useful info available https://www.cpperformance.com/products/Engine_Parts/valve-spring-oiler.htm btw if you don,t want...

garage.grumpysperformance.com

brazing a oil pump pick-up to the pump as proven to be more durable than tig or mig welding on most pumps ,

as brazing is less prone to cracking from constant vibration, if done correctly

Melling,

CHEVROLET Melling 10774 Melling Performance Oil Pumps | Summit Racing

Free Shipping - Melling Performance Oil Pumps with qualifying orders of $109. Shop Oil Pumps at Summit Racing.

Melling M-77 Melling Oil Pumps | Summit Racing

Free Shipping - Melling Oil Pumps with qualifying orders of $109. Shop Oil Pumps at Summit Racing.

milodon

https://www.jegs.com/i/Milodon/697/18732/10002/-1

and

moroso,

CHEVROLET Moroso 22150 Moroso Racing Oil Pumps | Summit Racing

Free Shipping - Moroso Racing Oil Pumps with qualifying orders of $109. Shop Oil Pumps at Summit Racing.

I generally prefer moroso, or milodon, but all three options will work,

If I was assembling that engine, Id suggest, you want to buy and use a big chevy,

block standard volume and standard pressure oil pump.

obviously you need to verify pick-up to oil an floor clearances ,

and oil pump drive shaft, to the seated distributor shaft ,

clearances during the installation process.

oil pump mods & related info

https://www.summitracing.com/search?SortBy=BestKeywordMatch&SortOrder=Ascending&keyword=3%2F4%22%20tube%20oil%20pump%20pickups https://www.jegs.com/webapp/wcs/stores/servlet/SearchResultsPageCmd?q=big+block+chevy+oil+pumps&storeId=10001&catalogId=10002&langId=-1...

garage.grumpysperformance.com

https://www.jegs.com/p/Speedmaster/Speedmaster-Oil-Pump-Pickup-Tubes/3151009/10002/-1

https://www.speedwaymotors.com/shop/speedway-oil-pump-pickup-tubes~8207-10191-4770-10-599-30999

https://www.jegs.com/c/Oil-System_Oil-Pumps-Pickups/10453/10002/-1

https://www.cnc-motorsports.com/engine-parts/oil-system-components/pickup-tubes

https://www.jegs.com/vpt/Melling/En...MI2sHX-KiH4gIVDSsMCh22AgQ_EAMYASAAEgJziPD_BwE

https://www.jegs.com/p/Moroso/Moros...MIn46_96mH4gIVgo7ICh1ebwxQEAAYASAAEgItx_D_BwE

https://www.melling.com/product/oil-pump-screens/

https://www.enginelabs.com/news/video-how-to-moroso-performance-explains-oil-pump-pickup-clearance/

first choice

http://www.summitracing.com/parts/mel-10552/overview/ SBC

or

http://www.jegs.com/i/Melling/689/10778C/10002/-1 BBC

its not that difficult to remove the oil pan, replace the gasket with a new one piece synthetic one and cure that leak,

most guys can do that in a single afternoon with the car up on 4 12 ton jack stands rather easily.

be aware that the crank counter weights rotated to the correct location makes removing the oil pan a bit easier.

it might be a great opportunity to swap to a higher capacity baffled oil pan.

obviously youll want to carefully research the correct oil pan for your engine and chassis before purchasing one

https://www.summitracing.com/parts/ctr-15-240/overview/make/chevrolet/model/corvette

7" deep

https://www.cantonracingproducts.com/cgi-bin/commerce.cgi?preadd=action&key=11-102

6.5" deep

https://www.carid.com/moroso/oil-pa...MIraOQn-602QIVBJ7ACh2mTwt4EAQYAyABEgJZWfD_BwE

7" deep

theres lots of 8" and 8.25" deep corvette oil pans but they don,t last too long with speed bumps and raised manhole cover rims

https://www.summitracing.com/parts/...MIytnIx-y02QIVHrjACh35mQ-OEAQYASABEgJnZvD_BwE

http://garage.grumpysperformance.co...etic-oil-cause-leaky-gaskets.2725/#post-13817

http://garage.grumpysperformance.com/index.php?threads/under-car-safety.26/page-4#post-69999

http://garage.grumpysperformance.co...-pan-gasket-still-small-leak.3084/#post-11971

http://www.onallcylinders.com/2014/10/23/oil-well-choosing-proper-pressure-volume-oil-pump/

keep in mind swapping to a heavier rated oil pump spring does not increase oil pressure, oil pressure is the result of the resistance to oil flow volume through the bearing clearances, increasing the oil spring pressure in the oil pump only results in limiting the max oil pressure, the pumps resistance to its produced oil volume pumped through those bearing clearances, reaches, before the oil pressure relief valve opens to limit the max oil pressure

keep in mind the oil pump gears spin at 1/2 engine rpm as they are driven by the distributor gear. on the cam shaft

obviously the small groove is intended to flow extra oil volume to the rear vertical thrust bearing surfaces

If your not getting oil to the rockers but have 65 psi as the engine idles,

Id suspect either the cam bearings (especially the rear cam bearing or the oil passage plugs under the timing chain are incorrectly installed

http://www.mellingselectperformance.com/Products/Cast-Iron-Oil-Pumps

second choice

http://www.summitracing.com/parts/mil-18750/overview/ SBC

related threads you should read

http://garage.grumpysperformance.co...ibutors-wont-seat-on-intake.12538/#post-63636

use proper oil and filters and damn surely use high temp magnets to trap fine metallic abrasive crud

SmCo 13.8 LB Pull Disk Magnet Dia 1x1/4" Samarium Cobalt 608 F Working Temperature

CMS Magnetics offers the best samarium cobalt 1x1/4" magnets online at at www.magnet4sale.com. Buy now from CMS Magnetics to get the best quality SmCo Magnets.

www.magnet4sale.com

www.magnet4sale.com

http://garage.grumpysperformance.com/index.php?threads/sbc-oil-pump-noise.14582/

http://www.aa1car.com/library/2005/us020516.htm

http://www.moroso.com/catalog/pdf/Oil_Pumps_106.pdf

http://www.milodon.com/oil-system/oil-pumps.asp

http://www.melling.com/Info/TechTipVideos.aspx

there are oil pump testers available commercially or if your mechanically inclined you can fabricate one with reasonable care, after a bit of measuring and purchasing a gauge

http://cvrproducts.com/oil-pressure-test-kit/

Melling 55070

70 psi, Steel, Pink, Pins, Chevy, Small Block, Kit

Melling 77070

Oil Pump Springs, 70 psi, Steel, Pink, Pins, Chevy, Big Block, Kit

Melling 55058

Oil Pump Springs, 58 psi, Steel, Yellow, Pins, Chevy, Small Block, Kit

Melling 55078

Oil Pump Springs, 78 psi, Steel, Green, Pins, Chevy, Small Block, Kit

Melling 77060

Oil Pump Springs, 60 psi, Steel, Black, Pins, Chevy, Big Block, Kit

Melling 55049

Oil Pump Springs, 49 psi, Steel, Green, Pins, Chevy, Small Block, Kit

Melling 77052

Oil Pump Springs, 52 psi, Steel, Purple, Pins, Chevy, Big Block, Kit

Melling 7770M

Oil Pump Springs, 70 psi, Steel, Pink, Chevy, Big Block, Set of 5

Melling 5556F

Oil Pump Springs, 55 psi of Force, Steel, Chevy, Small Block, Set of 5

Melling 5570F

Oil Pump Springs, 70 psi, Steel, Pink, Chevy, Small Block, Set of 5

Melling 7760M

Oil Pump Springs, 60 psi, Steel, Black, Chevy, Big Block, Set of 5

Melling 7752M

Oil Pump Springs, 52 psi, Steel, Purple, Chevy, Big Block, Set of 5

the idea that you can 'pump the pan dry" with a high volume oil pump, in a properly set up chevy engine has been proven false dozens of times, thats a myth that myth been repeated for decades and the reason its gained its supposed verification as fact is simply that guys install a high voluum oil pump in the same engine that they just removed a stock oil pump from and find that they reve the engine and the oil pressure starts to go up then tops out or even drops off , the instant and wrong conclusion drawn is that the high voluum oil pump sucked the oil pan dry, but what really happened in almost every case was a bit simpler.

high volume oil pumps have a longer body that moves the oil pump pick-up closer to the oil pan floor and if the clearance is not checked and corrected to maintain the required 3/8"-1/2" minimum clearance it severely restricts the flow into the oil pump and pressure drops of as a result of the restriction on the intake side of the oil pump pick-up.

this is a fairly easy to problem too prevent ,during assembly with careful measuring, and a bit of clay,to check clearance, before you braze the pick-up to the oil pump, especially if you braze a 1/2" nut to the lower surface of the oil pump pick up to prevent it from vibrating down close to the oil pan floor should it come loose and if you weld braces to prevent its movement after carefully measuring the correct clearance.

opening and smoothing the recessed area and porting the oil passage entrance reduces the restriction to oil flow

notice the open slot between the rear main cap supporting the oil pump and bearing shell support and the area supporting the rear main seal, this prevents PRESSURIZED oil from the bearings reaching the rear main seal.

the as cast recess in the rear main cap where the oil pump mounts can be rather restrictive and shallow, and if your replacing a missing main cap , with one from a different block you'll very likely be required to have the block?cap too be line honed to get the correct alignment and fit clearances for the crank shaft

Chevrolet Performance 14091563

Left (Driver Side) Dipstick Plug

Chevrolet Performance 9421743

Right (Passenger Side) Dipstick Plug

http://www.hotrod.com/articles/ccrp-0911-small-block-chevy-oil-pumps/

grumpy, no mater how hard I tighten the distributor clamp on my intake manifold,

I will almost enviably, find its moved and will require re-timing. any ideas?

Ive seen this frequently, and almost always its a case where if you measure carefully, youll almost surely find,

the oil pump drive shaft is bottoming out solidly between the oil pump and the distributor gear is binding,

so the distributor is not firmly seated against the intake manifold surface.

the oil pump drive shaft length MUST BE about .050 SHORTER than the distance it would take to firmly seat it inside the distributor drive gear, the cam has a gear that spins the distributor and the oil pump drive shaft is driven by that distributor gear in the lower distributor that extends down to the oil pump drive.

this gear must not bind on the distributor too oil pump drive shaft when the distributor is seated firmly on the intake manifold and clamped into place there must be about .050 clearance minimum

related threads you should really read

http://garage.grumpysperformance.com/index.php?threads/oil-pump-drive-shafts.123/

http://garage.grumpysperformance.co...ibutors-wont-seat-on-intake.12538/#post-63636

http://garage.grumpysperformance.com/index.php?threads/oil-pump-drive-shafts.123/#post-19025

http://garage.grumpysperformance.co...ing-an-oil-pump-pick-up-tube.1800/#post-43110

http://garage.grumpysperformance.com/index.php?threads/distributor-gear-wear.1701/#post-4160

http://garage.grumpysperformance.co...butor-clamp-that-just-won-t-clamp-firmly.871/

http://garage.grumpysperformance.co...-allows-the-distrib-to-turn-even-tighten.873/

http://garage.grumpysperformance.com/index.php?threads/setting-timing-question.1411/#post-3131

ADDING A WELL DESIGNED WINDAGE SCREEN SPEEDS OIL RETURN SPEEDS . AND EFFICIENCY TO THE ENGINE SUMP

your typical small block oil pump has a 4 bolt cover, a 5/8" pick-up tube diameter and the pick-up presses into the cover , it has the smaller 7 tooth gears, and because the pick-up tube presses into the cover swapping from a standard to a high volume pump, with its longer impeller and hoseing casting, tends to move the pick-up about 1/4" closer to the oil pan floor

http://www.mellingselectperformance.com ... -Oil-Pumps

while your checking put some modeling clay under both pick-ups and see the effective clearance difference then see if the old pump clears the problem, in an ideal world the pick-up to pan floor clearance is a minimum of 3/8" and 1/2" is ideal

OIL PUMP MODS

http://www.corvette-restoration.com/res ... ancing.htm

http://www.corvette-restoration.com/res ... lation.htm

small block pumps have 7 tooth gears and 4 bolt covers and don,t provide the smooth oil flow rates the 12 tooth, and 5 bolt cover big block gear pumps provide

big block vs small block chevy oil pump

the standard big block chevy oil pump has a 3/4" oil pump pick-up that is inserted in the main pump body, NOT THE 5 BOLT LOWER COVER

your typical small block oil pump has a 4 bolt cover, a 5/8" pick-up tube diameter and the pick-up presses into the cover , it has the smaller 7 tooth gears, and because the pick-up tube presses into the cover swapping from a standard to a high volume pump, with its longer impeller and hoseing casting, tends to move the pick-up about 1/4" closer to the oil pan floor

your typical big block oil pump has a 5 bolt cover, a 3/4" pick-up tube diameter and the pick-up presses into the pump body , it has the larger more efficient 12 tooth gears and in many cases can be mounted on a small block, but its usually not required

BIG BLOCK CHEVY 5 BOLT cover pump

the standard SMALL block chevy oil pump has a 5/8" oil pump pick-up that is inserted in the lower oil pump 4 bolt lower gear cover

SBC 4 BOLT COVER OIL PUMP

SBC pumps have 7 tooth gears and BBC pumps generally have 12 tooth gears making the flow more consistent

a well supported oil pump pick-up tends to cause far fewer issues than one that cab flex and vibrate as metal fatigue can eventually cause them to break

http://www.mellingselectperformance.com/Products/Cast-Iron-Oil-Pumps

BRAZING IS ALWAYS A GOOD IDEA,(just be sure to remove the bye-pass circuite parts and verify function when reinstalled)

vibration can and does occasionally cause pick-up failures

Tig welding is OK, BRAZING the pick-up once youve determined the correct oil pan floor clearance is PREFERRED

ITS always a good idea to verify the oil pan floor to oil pump pick-up clearance and to braze the pick-up to the oil pump, to reduce the potential for it to come loose.

yes you can MIG ,TIG or TORCH WELD the pick-up but I found BRAZING works the best and is less likely to warp or crack the pump or pick-up

"how in hell do those twisty, safety wire pliers work?"

well a video should be helpful here! Id also point out that you can buy the wire in several diameters and the thicker sizes are far more difficult to use, home depot sells the 22 gauge and 18 gauge, the 22-24 gauge is what youll use far more commonly, as its much easier to use,both stainless (PREFERED) and galvanized are used, and will work on 95% of the applications on a car your likely to use.

using anti-seize paste on bolt or stud threads helps prevent future problems

using safety wire pliers

JEGS 502080: Oil Pump Pickup for Small Block Chevy - JEGS

Get the Best Performance with JEGS Oil Pump Pickup for Small Block Chevy 502080 parts at JEGS. Shop Now at the Guaranteed Lowest Price!

bracing the oil pump with a milodon vibration brace can increase durability

MORE USEFUL INFO

BE 100% SURE that the oil pump bolt or STUD doesn,t protrude past the inner main cap surface , because if it bears on the rear main bearing shell it will almost always result in a quickly failed rear bearing

http://www.islandblue.com/store/product ... -ASSORTED/

TO FUNCTION CORRECTLY THE OIL PUMP PICK UP MUST BE MOUNTED AT BETWEEN 3/8" and 1/2" FROM THE OIL PAN FLOOR,CHECK CAREFULLY WITH CLAY and a DIAL CALIPER ,BEFORE BRAZING OR TIG WELDING THE PUMP PICK-UP TO THE PUMP BODY , ONE OF THE MOST COMMON MISTAKES IS INSTALLING A HIGH VOLUME OIL PUMP AND NOT CAREFULLY VERIFYING THE OIL PUMP PICK-UP TO OIL PAN FLOOR CLEARANCE IS IN TH 3/8"-1/2" RANGE WITH THE PAN INSTALLED OR FORGETTING TO BRAZE THE PICK-UP AND ADDING A BRACE TO KEEP IT FROM MOVING, FAILURE TO DO THAT CAN FREQUENTLY RESULT IN LOWER OIL PRESSURE AS THE RPMS INCREASE BECAUSE THE OIL PUMP CAN,T GET ENOUGH OIL INTO THE PUMP THRU THE RESTRICTED OPEN AREA BELOW THE OIL PUMP PICK-UP...FREQUENT WRONGLY DIAGNOSED AS THE PUMP, PUMPING THE PAN DRY, WHICH IS NOT THE CAUSE

place the clay under the pick-up and temporarily mount the oil pan, then remove it and check the compressed clay, get this correct or youll have oil pressure and flow issues

THIS LOOKS like it might be exactly what I buy at my local miller welding supply dealer for brazing/silver soldering, oil pump pick-up tubes to oil pumps, I doubt youll have any issues using it for that application,

but the last time I purchased it it was priced at $6 a stick, or just over $107 for a pack of 20 sticks

and IM fairly sure it said #15 on the package...luckily you seldom require more than about 1/2 a stick to braze an oil pump pick-up onto an oil pump

btw if your curious as too the reference to PLASTIC timing gears, they DO cause problems and should be replaced, because not only will the chain stretch and slip eventually, the nylon debris will clog the oil pump pick-up over time, remember the oil pump pick-up would need to allow the nylon trash to go through the gears and into the oil pump, main cap and only then enter the oil filter.

BE DAMN SURE THE OIL PUMP PICK-UP HAS A LAGER SCREEN SURFACE AREA

http://garage.grumpysperformance.com/index.php?threads/timing-chains-stretch.5734/#post-17492

http://garage.grumpysperformance.co...oil-passages-and-improved-oil-flow-mods.3834/

http://www.harrisproductsgroup.com/en/P ... lv-15.aspx

http://store.cyberweld.com/tubrrodsi15s ... productads

http://www.harrisproductsgroup.com/en/P ... azing.aspx

and I have used a propane torch in the past but my ox-acetolene torch works much better

HARRIS AND VICTOR are the torch brands I prefer

or silver solder rods for the torch

I don't see how anyone serious in this hobby does not have a TIG welder and/or oxy-acetylene torch welder , or at least a decent MIG and/or oxy-acetylene torch welder

and a drill press and hydraulic press

Ive always found the best results from keeping the low rpm pressure , in the 15psi-20psi at hot idle and no more than 65psi at high rpms,is really useful, the voluum required depends on the way the engines clearances and oil systems designed or modified ,voluum/viscosity/clearances in the approximately stock range works fine in most .

I like high voluum pumps but I certainly don,t use them IF the engines nearly stock as the standard Z28 SBC pump works fine

"the standard volume pump gears are about 1.2" long the high volume pump gears are about 1.5 inches long (depends on manufacturer)

heres the discriptions right from chevy

12555884

SBC Oil Pump, High Pressure Z28/LT1. Production high-pressure oil pump with 1.20" gears.

Will produce 60-70 psi oil pressure. Does not include screen. The pickup tube dia. is 5/8" for this pump.

62.17

the true high volume pumps like this below are not necessary UNTILL you've done extensive mods that require the extra oil flow volume

14044872

SBC Oil Pump, High-Volume. This high-volume pump has1.50" long gears.

It has approximately 25% more capacity than a production pump at standard pressure. Does not include screen."

viewtopic.php?f=54&t=2187

keep in mind, most bbc pumps have 5 bolts in the cover and the pump body is where the pick-up tube installs

keep in mind, most sbc pumps have 4 bolts in the cover and the pump cover is where the pick-up tube installs

http://www.speedwaymotors.com/Oil-Pump- ... GoogleBase

http://www.youtube.com/watch?v=KOIhaI3e ... r_embedded

http://books.google.com/books?id=GUC52- ... t&resnum=3

use the correct tool to seat the oil pump pick-up using a wrench and hammer often distorts the tube

https://www.summitracing.com/parts/mel-mcat-75

https://www.summitracing.com/parts/mel-mcat-62

http://www.chevyhiperformance.com/techa ... index.html

heres some decent designed oil pans for bbc and SBC, naturally you need to verify if they work in your application

http://www.moroso.com/catalog/categoryd ... code=11330

btw, Ive built SBC engine with standard oil pumps, and big block oil pumps, in the past, and while I have experience doing it both ways and setting engines up with clearances both on the tighter side of the range with the standard oil pumps and a bit looser with the 5 bolt big block pumps, theres a system that needs to be used , not just an oil pump you stick in an engine, generally if you opt to install the larger big block 5 bolt oil pump theres a reason, and you do mods that require the extra oil flow rates., things like larger auxiliary outside mount oil coolers ,come to mind.

or lets go the cheaper route,

you clamp the oil pump body minus the gears and base plate (which you remove temporarily) in a vise with the tube entrance facing vertically, and a short section of soft pine 2x4 under the pump body , if you support the pump body underneath with a section of soft wood 2 x 4 and cushion the vise jaws and clamped between two sections of 1/2" plywood to cushion the vice jaws you find a crows foot open end wrench, or the correct tool, that clamps to the pick-up, that slides over the oil pump pick-up tube but not over the ridge, in the tube that in theory prevents you from inserting the tube too deeply into the pump body. can be use to efficiently tap the tube into the pump body.

failure to use the wood as a vise jaw cushion, binding the drive shaft, marring the mount surface or over tightening the vise will sometimes damage the pump, so be cautious, use your common sense, and treat the pump as the fairly fragile piece of precision casting that it is!

be aware that some pick-ups will extent too far into the pump body if inserted up to the full depth so verify internal pump gear clearance and smooth function,before brazing the pick-up tube into place

use a 8" extension and the crows foot wrench and a rubber mallet to seat the pick-up tube into the pump body, then temporarily mount the oil pump and place a lump of modeling clay on the pick-up body lower surface and install the oil pan for a second to compress the clay giving you the distance between the oil pump pick-up and the oil pan floor, adjust it until the distance is approximately 3/8"-1/2"

once that distance is correct BRAZE the pickup to the pump body AFTER temporarily removing the bye-pass spring so it won,t get annealed, and its a very good idea to use the type of pick-up that has both the feed tube and the screened suction section braced to the pump body, so they don,t crack from vibration and metal fatigue.

Id also point out that a few of the oil pump pick up designs available , have tubes that can be pressed into the pump body far enough to contact the gears, if pounded into the pump to the swagged ring on the mount tube, it makes a good deal more sense to radias the exit port and insert the pick-up only to the point the exit tort radias reaches it and after careful measuring and removing the spring assembly to BRAZE the pick up to the pump body. It also helps to weld in a vibration brace.

LIKE THESE

if you use a non-supported pick-up like this one below, its far more likely to break

once that's done you clean lube and re-install the pump components and verify clearances, and the gears spin freely with out binding, don,t forget to use some MOLY assembly lube, or VASOLINE on the gears to assure it primes quickly.

BTW if you have a sudden drop in oil pressure on any engine with no other symptoms, you might want to replace the oil filter and check oil levels before you panic as its not uncommon for some brands of oil filters to fail internally

YOU NEVER want to bolt the pump body to the rear main cap and beat the pick-up into the pump body as that will result in un- acceptable stress on the cast pump body which CAN RESULT IN A TOTAL PUMP FAILURE

brazing the oil pump pick-up tube to the pump body after carefully checking clearances will usually prevent the oil pump pick-up from vibrating loose over time

BRAZING the pick-up to the pump is a good idea but remember to remove the pressure regulator valve first and oil and replace it after the pumps cooled

http://www.youtube.com/watch?v=KOIhaI3e ... r_embedded

this is a factory produced hamberger oil pan but its a decent example of what can be fabricated

TEL: (562) 921-0404

http://www.hamburgersperformance.com/

other options

http://www.stefs.com/products/oilpans/supergascompstreetpans.htm

http://www.kevkoracing.com/wetsump_chevy.htm

http://www.moroso.com/catalog/categorydisplay.asp?catcode=11330

Last edited by a moderator: