thats a common question and if you think theres a need to start swapping carbs to get an answer you may be surprised at how simple it is to find the answer......carbs almost always make there best power if, the fuel pressures at between 4.5psi and 6 psi at the carb inlet,IF the fuel air ratio is between 12.4:1-12.8:1 and the vacuum in the plenum ,at wide open throttle at peak rpms is in the 1.0" of vacuum-to- 0.5" range.90% or more of selecting the correct carburetor for the application comes down to the ability of the guy using it to tune the carburetor you've selected, and set up the fuel system supplying it correctly.

you can get into the correct ball park range , for a performance 4 barrel carburetor by simply multiplying your engine displacement in cubic inches by 2.09, IE if you multiply 383 x 2.09=800 cfm

or 2.09x 454=950cfm.

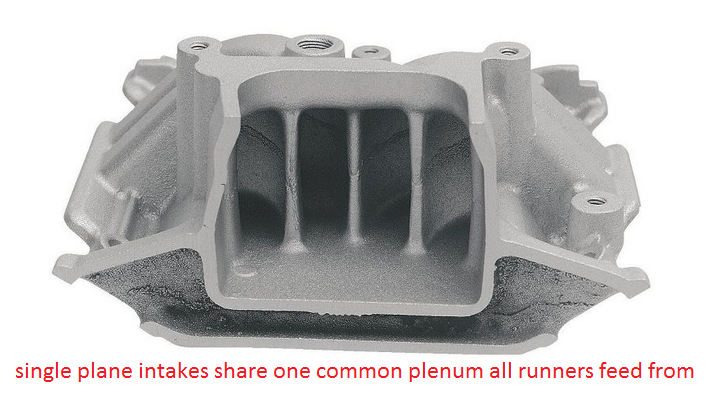

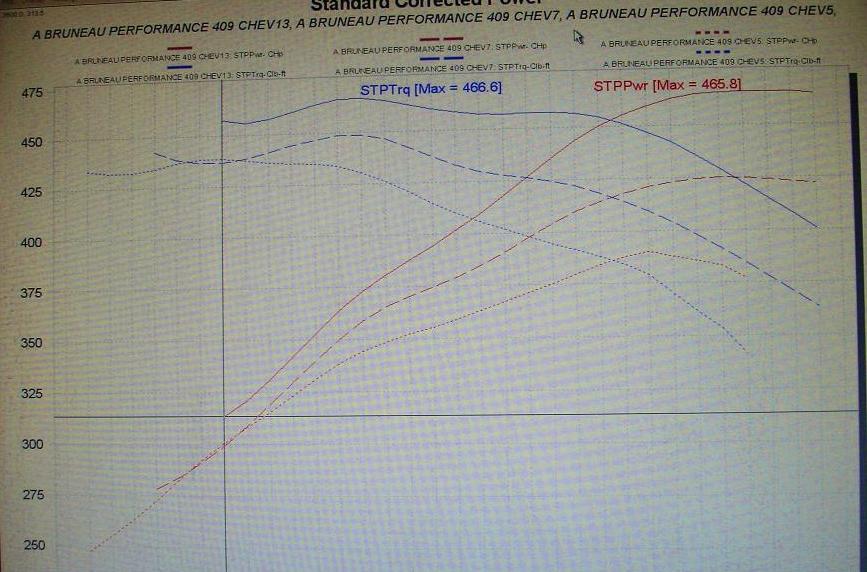

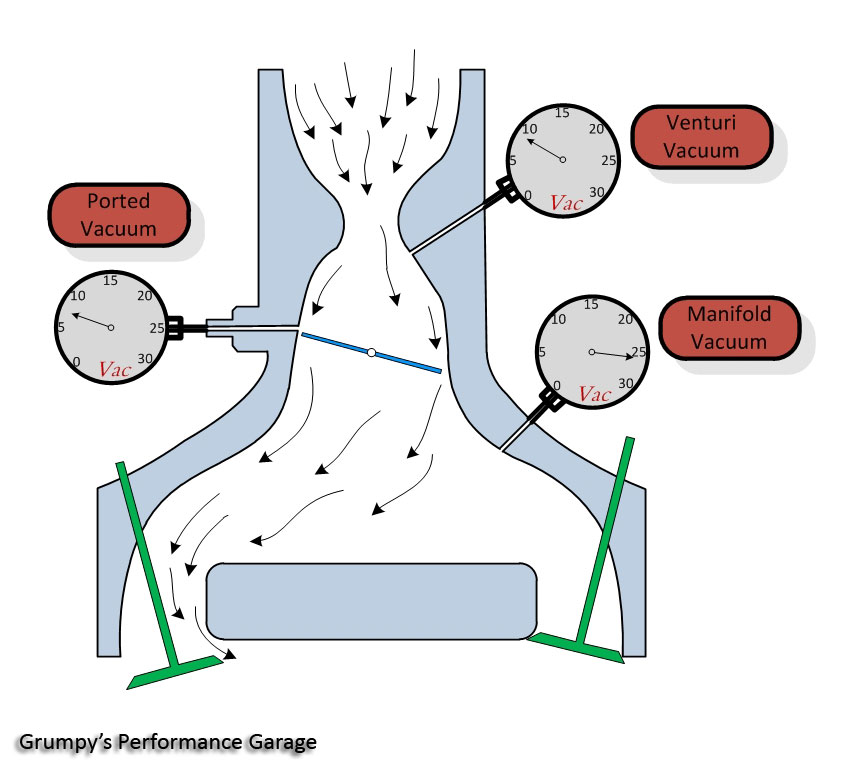

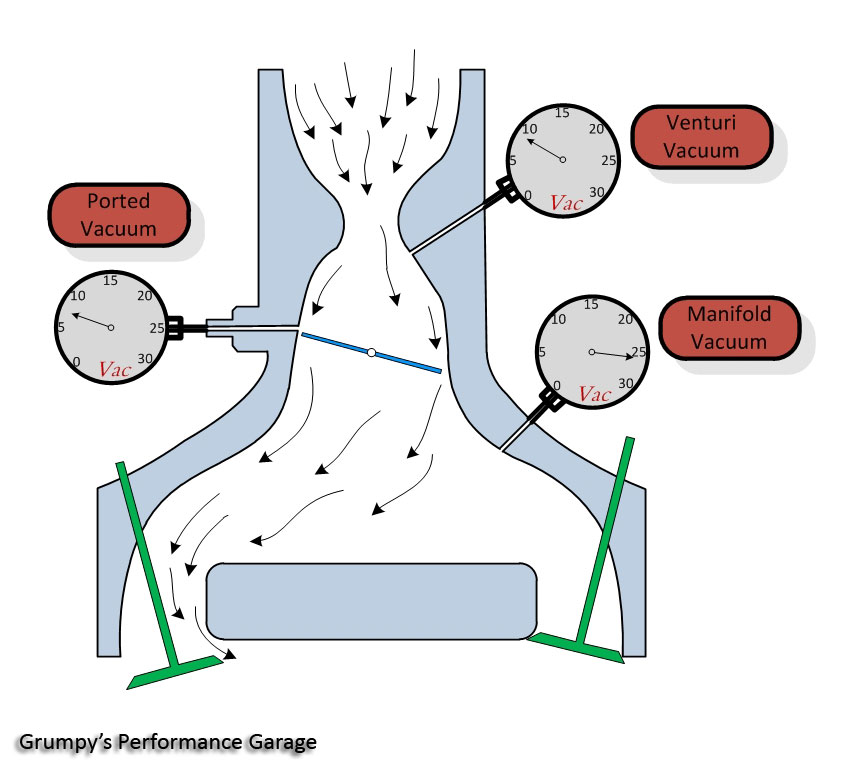

keep in mind your intake manifold design, exhaust scavenging, cylinder head design, your cam timing , lift /duration/LSA and compression ratio, all effect the results youll see!, and a good indication on any restriction to flow rates is to measure the plenum vacuum under the carburetor at wide open throttle and measure the air speeds in the intake runners, but remember if the intake runners are too small in cross sectional area,or restrictive adding plenum volume, is only marginally helpful.the short version,of how a carb works,is that air velocity in the carb is what allows fuel to flow from the fuel wells into the venturi area making the carb function as designed and it takes a minimal pressure and velocity difference to allow the carb to function efficiently.

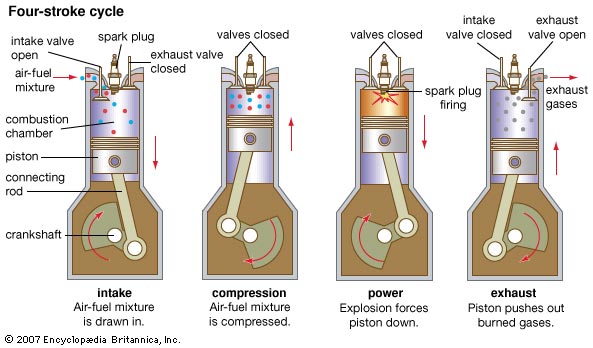

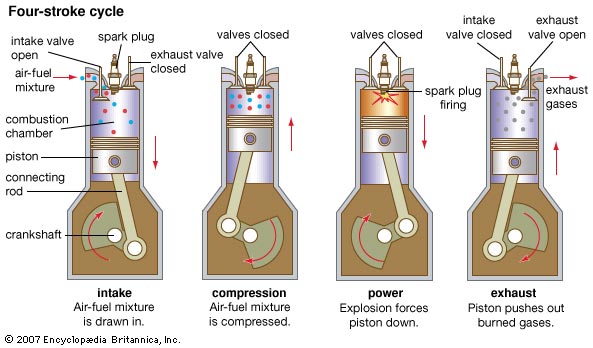

An engine, is basically an air pump, functioning on rapid increases in cylinder pressure.

Since the engine will flow a certain amount of air volume at a given RPM, use of a larger carburetor will cause a reduction in air velocity across the carbs venturi,s and a smaller carb tends to increase air velocity thus causing either a reduction in or increase in negative pressure in the venturies the airs drawn thru.

Too large a carburetor will have a reduced signal due to slower air velocity and tend to run LEAN, as its less able to instantly draw fuel thru the boosters, to small a carb restricts air flow near peak rpms..!

keep in mind if the exhaust system is not correctly scavenging the cylinders the intake is far less effective at filling the cylinders

(what goes in needs to be drawn out) and yes your almost certain to find most commercial headers are built with much shorter primary tubes than would be ideal.

YOULL FIND THESE LINKED CALCULATORS USEFUL

http://www.wallaceracing.com/runnertorquecalc.php

http://www.wallaceracing.com/lpv.php

http://www.wallaceracing.com/header_length.php

http://www.wallaceracing.com/max-rpm.php

viewtopic.php?f=55&t=858&p=3036&hilit=take+fast+ratio#p3036

http://www.wallaceracing.com/intake-runner-length.php

http://www.hipermath.com/engines/carburetor_cfm

viewtopic.php?f=55&t=1038&p=23653&hilit=test+mule#p23653

http://www.wallaceracing.com/header_length.php

http://www.wallaceracing.com/ca-calc.php

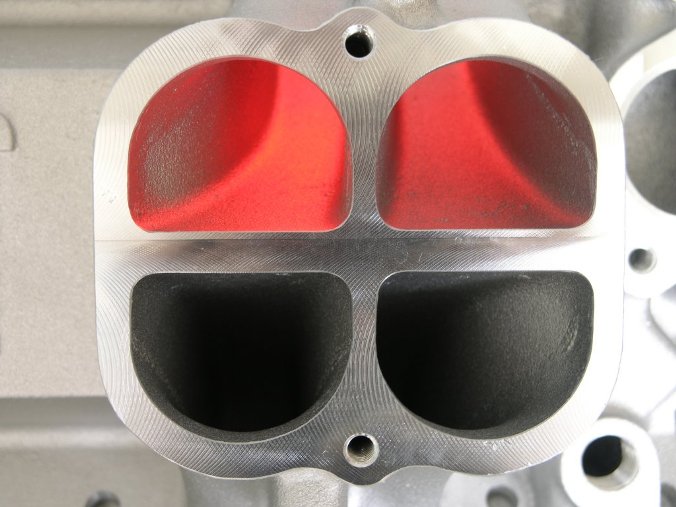

get the head intake port or intake runner to small in cross sectional area and you still get good torque and fast effective air flow port speeds but at some point the intake or heads become restrictive and power falls off as the rpms increase.

select a larger than ideal cylinder head port, larger than ideal intake manifold runner cross sectional area, and port air flow speeds drop off at lower rpms , which can noticeably reduce cylinder volumetric efficiency.

get the cam duration to short and power hits a air flow ceiling or flow limitation as the rpms increase and power is restricted.

select a cam thats got to much duration for the application and your valves close to late at lower rpms to effectively trap and compress the cylinder volume of fuel/air mix and low and mid rpm torque suffer as a result.

on any 383 sbc a good 750cfm vacuum secondary HOLLEY carburetor is going to be a decent choice, because its fairly easy to tune and theres a wide selection of power valves jets, squirters,accelerator pumps, pump cams, etc for it easily available, the fact is that a vacuum secondary carburetor is almost self adjusting to the flow required and you just need to adjust it so the fuel/air ratio stays in about the 13.5:1-14.5:1 range below about 2000rpm-3000rpm and slowly get richer too about the 12.5:1-13.2:1 range over about 3000rpm-5000rpm

you need to get the ignition timing curve correct and know how to read plugs and an infrared temp gun or fuel/air ratio meter, and a vacuum gauge can be very useful

viewtopic.php?f=55&t=109

viewtopic.php?f=55&t=635

viewtopic.php?f=55&t=211

viewtopic.php?f=55&t=1639

viewtopic.php?f=55&t=1790

/viewtopic.php?f=44&t=579&p=743&hilit=+infrared+tuning#p743

A bit of reading before making changes might help here

viewtopic.php?f=52&t=5078

viewtopic.php?f=52&t=727

viewtopic.php?f=71&t=1715

viewtopic.php?f=71&t=741

viewtopic.php?f=52&t=333

viewtopic.php?f=70&t=4683

viewtopic.php?f=70&t=1015

viewtopic.php?f=52&t=90

obviously carbs with vacuum secondaries self compensate to a large degree and will allow a larger than ideal carb to still function,and run just fine, on combos the calculators may indicate need a smaller carb, thats one factor in how you can get away with using an 850cfm carb on some hotter sbc combos on the street now theres dozens of calculators available that can calculate your displacement times the rpms etc. and give you an expected carb size,

example

http://users.erols.com/srweiss/calccarb.htm

we have all seen those formulas that allow you to calculate the required carb flow rates on an engine,

CFM = engine size (cid) x maximum RPM / 3456 x VE

So, assuming 6000 RPM and 85% VE: on a 383 cid engine

383 x 6000 / 3456 x .85 = 565 CFM.

Even at 90% VE, CFM = 598

At 90% VE and 7000 RPM, CFM = 680

that indicates 650 CFM is all a stout 383 will ever need. By going to a 750cfm, you give up some better peak hp and slightly reduced throttle response due to the larger primary bores.

the formula would be just fine if the engine was 100% efficient and port flow in and out of the cylinders was at a constant air speed and the valves were not a factor, but theres a 720 degree repetitive cycle and ports generally flow only about 1/3 of that time, now divide the flow into a plenum and swap which port is running a negative vs a positive pressure about 30-60 times every second and you find true flow efficiency drops to the point where you need a good deal more potential flow capacity to match the engines requirements.

ever think of what those flow numbers mean on cylinder head flow charts, if for example the heads flow 260cfm at .600 lift and youve got 8 cylinders, it sounds like youll need almost 2100cfm of flow to keep up, but because the port only flows when the valves open and the flow rate changes with piston speed,port inertia, cam timing and exhaust scavenging,intake plenum and runner design, port reversion rates, altitude,etc. a simple formula can,t give you more than a semi-accurate guess as to the engine requirements.

the best gauge IVE found is a vacuum gauge, if your pulling more than 1 psi of vacuum at WOT your more than likely going to benefit from a larger carb or a carb spacer or a different plenum design.

viewtopic.php?f=55&t=2994

viewtopic.php?f=55&t=4362

http://www.classictruckshop.com/clubs/e ... ac/uum.htm

but your engine may not be operating at the same volumetric efficiency levels your expecting and both your exhaust systems scavenging efficiency and your intakes flow characteristics can significantly change the expected results.

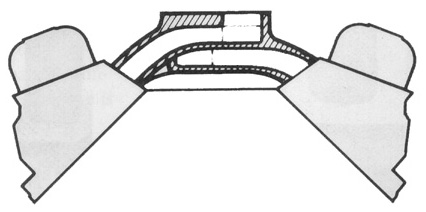

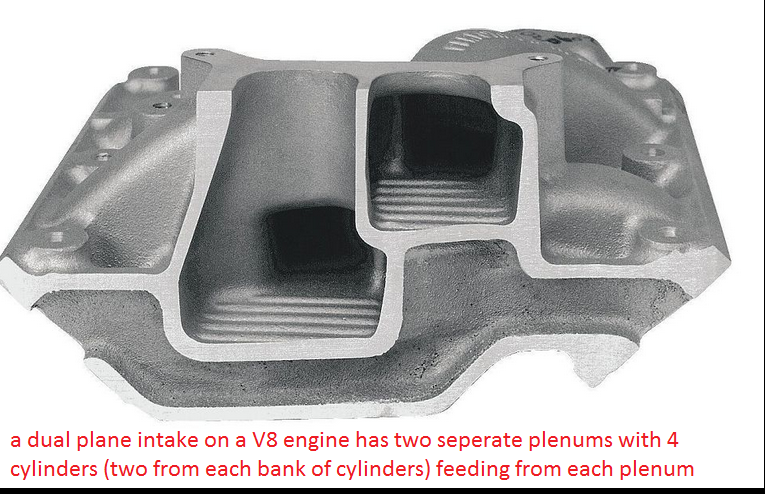

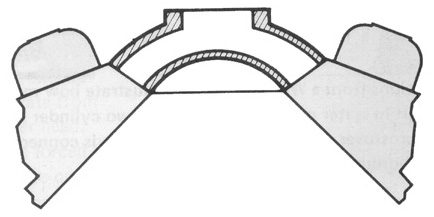

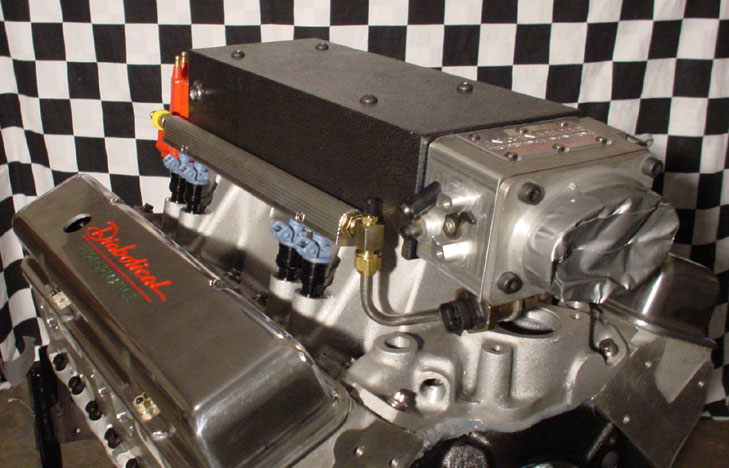

calculators will not generally compensate for factors like the differences between a dual plane and a single plane intake design ,nor will they give you a clue when you get into combos using a tunnel ram with dual quads or some other rather exotic intake or a really effective exhaust scavenging the cylinders at rates over 90% plus

but a simple vacuum gauge CONNECTED TO MANIFOLD VACUUM will be a surprisingly accurate tool providing you know how to use it.

you don,t need an expensive tool

http://www.harborfreight.com/cpi/ctaf/d ... mber=93547

and your tach. just hook the gauge to the intakes plenum CONNECTED TO MANIFOLD VACUUM and as your running at w.o.t thru the long back stretch on your track or running thru the lights at the end of the 1/4 mile have a friend keep a close eye on the vacuum gauge , Ive found that if it reads , in the 1"-0.5" range your generally in the ball park on carb size, BUT, if you reach 0.0 even before reaching peak power and rpms your carbs more than likely to large for the application

BTW remember those cheap crappy fuel filters I told you to never use?

well heres where they come in handy, you plug them into the rubber fuel line between the vacuum gauge and the intake plenum where they act like a pulse dampers making the vacuum needle stay a bit more steady and easier to read.

It should also be rather obvious that what goes in, needs to go out, a low restriction exhaust that reads lower than 1 psi MAX back pressure at high rpms will be required to maintain a full power curve

RELATED THREADS

viewtopic.php?f=55&t=444&p=5682&hilit=quads#p5682

viewtopic.php?f=55&t=211&p=6904&hilit=+vacuum+gauge#p6904

viewtopic.php?f=4&t=1337&p=2921&hilit=+vacuum+gauge#p2921

viewtopic.php?f=50&t=383&p=2301&hilit=+vacuum+gauge#p2301

viewtopic.php?f=70&t=202

viewtopic.php?f=44&t=392&p=5415#p5415

http://www.carcraft.com/techarticles/se ... index.html

viewtopic.php?f=56&t=495

http://users.erols.com/srweiss/calcdchg.htm

If you decide to go with dual quads, remember when you double the venturie area with two carbs youve effectively cut the depression, or flow thru each carb on the same engine about in half

4 barrel carbs are measured at 3", so a 500cfm carb that flows 500cfm at 3", paired with a second 500cfm rated carb would be flowing about 350cfm at 1/2 or 1.5" of depression giving the new twin carbs about 700cfm as a paired flow rate, obviously the true flow is determined by the true depression or vacuum under the venturies but the ratio will be similar

you can get into the correct ball park range , for a performance 4 barrel carburetor by simply multiplying your engine displacement in cubic inches by 2.09, IE if you multiply 383 x 2.09=800 cfm

or 2.09x 454=950cfm.

keep in mind your intake manifold design, exhaust scavenging, cylinder head design, your cam timing , lift /duration/LSA and compression ratio, all effect the results youll see!, and a good indication on any restriction to flow rates is to measure the plenum vacuum under the carburetor at wide open throttle and measure the air speeds in the intake runners, but remember if the intake runners are too small in cross sectional area,or restrictive adding plenum volume, is only marginally helpful.the short version,of how a carb works,is that air velocity in the carb is what allows fuel to flow from the fuel wells into the venturi area making the carb function as designed and it takes a minimal pressure and velocity difference to allow the carb to function efficiently.

An engine, is basically an air pump, functioning on rapid increases in cylinder pressure.

Since the engine will flow a certain amount of air volume at a given RPM, use of a larger carburetor will cause a reduction in air velocity across the carbs venturi,s and a smaller carb tends to increase air velocity thus causing either a reduction in or increase in negative pressure in the venturies the airs drawn thru.

Too large a carburetor will have a reduced signal due to slower air velocity and tend to run LEAN, as its less able to instantly draw fuel thru the boosters, to small a carb restricts air flow near peak rpms..!

keep in mind if the exhaust system is not correctly scavenging the cylinders the intake is far less effective at filling the cylinders

(what goes in needs to be drawn out) and yes your almost certain to find most commercial headers are built with much shorter primary tubes than would be ideal.

YOULL FIND THESE LINKED CALCULATORS USEFUL

http://www.wallaceracing.com/runnertorquecalc.php

http://www.wallaceracing.com/lpv.php

http://www.wallaceracing.com/header_length.php

http://www.wallaceracing.com/max-rpm.php

viewtopic.php?f=55&t=858&p=3036&hilit=take+fast+ratio#p3036

http://www.wallaceracing.com/intake-runner-length.php

http://www.hipermath.com/engines/carburetor_cfm

viewtopic.php?f=55&t=1038&p=23653&hilit=test+mule#p23653

http://www.wallaceracing.com/header_length.php

http://www.wallaceracing.com/ca-calc.php

get the head intake port or intake runner to small in cross sectional area and you still get good torque and fast effective air flow port speeds but at some point the intake or heads become restrictive and power falls off as the rpms increase.

select a larger than ideal cylinder head port, larger than ideal intake manifold runner cross sectional area, and port air flow speeds drop off at lower rpms , which can noticeably reduce cylinder volumetric efficiency.

get the cam duration to short and power hits a air flow ceiling or flow limitation as the rpms increase and power is restricted.

select a cam thats got to much duration for the application and your valves close to late at lower rpms to effectively trap and compress the cylinder volume of fuel/air mix and low and mid rpm torque suffer as a result.

on any 383 sbc a good 750cfm vacuum secondary HOLLEY carburetor is going to be a decent choice, because its fairly easy to tune and theres a wide selection of power valves jets, squirters,accelerator pumps, pump cams, etc for it easily available, the fact is that a vacuum secondary carburetor is almost self adjusting to the flow required and you just need to adjust it so the fuel/air ratio stays in about the 13.5:1-14.5:1 range below about 2000rpm-3000rpm and slowly get richer too about the 12.5:1-13.2:1 range over about 3000rpm-5000rpm

you need to get the ignition timing curve correct and know how to read plugs and an infrared temp gun or fuel/air ratio meter, and a vacuum gauge can be very useful

viewtopic.php?f=55&t=109

viewtopic.php?f=55&t=635

viewtopic.php?f=55&t=211

viewtopic.php?f=55&t=1639

viewtopic.php?f=55&t=1790

/viewtopic.php?f=44&t=579&p=743&hilit=+infrared+tuning#p743

A bit of reading before making changes might help here

viewtopic.php?f=52&t=5078

viewtopic.php?f=52&t=727

viewtopic.php?f=71&t=1715

viewtopic.php?f=71&t=741

viewtopic.php?f=52&t=333

viewtopic.php?f=70&t=4683

viewtopic.php?f=70&t=1015

viewtopic.php?f=52&t=90

obviously carbs with vacuum secondaries self compensate to a large degree and will allow a larger than ideal carb to still function,and run just fine, on combos the calculators may indicate need a smaller carb, thats one factor in how you can get away with using an 850cfm carb on some hotter sbc combos on the street now theres dozens of calculators available that can calculate your displacement times the rpms etc. and give you an expected carb size,

example

http://users.erols.com/srweiss/calccarb.htm

we have all seen those formulas that allow you to calculate the required carb flow rates on an engine,

CFM = engine size (cid) x maximum RPM / 3456 x VE

So, assuming 6000 RPM and 85% VE: on a 383 cid engine

383 x 6000 / 3456 x .85 = 565 CFM.

Even at 90% VE, CFM = 598

At 90% VE and 7000 RPM, CFM = 680

that indicates 650 CFM is all a stout 383 will ever need. By going to a 750cfm, you give up some better peak hp and slightly reduced throttle response due to the larger primary bores.

the formula would be just fine if the engine was 100% efficient and port flow in and out of the cylinders was at a constant air speed and the valves were not a factor, but theres a 720 degree repetitive cycle and ports generally flow only about 1/3 of that time, now divide the flow into a plenum and swap which port is running a negative vs a positive pressure about 30-60 times every second and you find true flow efficiency drops to the point where you need a good deal more potential flow capacity to match the engines requirements.

ever think of what those flow numbers mean on cylinder head flow charts, if for example the heads flow 260cfm at .600 lift and youve got 8 cylinders, it sounds like youll need almost 2100cfm of flow to keep up, but because the port only flows when the valves open and the flow rate changes with piston speed,port inertia, cam timing and exhaust scavenging,intake plenum and runner design, port reversion rates, altitude,etc. a simple formula can,t give you more than a semi-accurate guess as to the engine requirements.

the best gauge IVE found is a vacuum gauge, if your pulling more than 1 psi of vacuum at WOT your more than likely going to benefit from a larger carb or a carb spacer or a different plenum design.

viewtopic.php?f=55&t=2994

viewtopic.php?f=55&t=4362

http://www.classictruckshop.com/clubs/e ... ac/uum.htm

but your engine may not be operating at the same volumetric efficiency levels your expecting and both your exhaust systems scavenging efficiency and your intakes flow characteristics can significantly change the expected results.

calculators will not generally compensate for factors like the differences between a dual plane and a single plane intake design ,nor will they give you a clue when you get into combos using a tunnel ram with dual quads or some other rather exotic intake or a really effective exhaust scavenging the cylinders at rates over 90% plus

but a simple vacuum gauge CONNECTED TO MANIFOLD VACUUM will be a surprisingly accurate tool providing you know how to use it.

you don,t need an expensive tool

http://www.harborfreight.com/cpi/ctaf/d ... mber=93547

and your tach. just hook the gauge to the intakes plenum CONNECTED TO MANIFOLD VACUUM and as your running at w.o.t thru the long back stretch on your track or running thru the lights at the end of the 1/4 mile have a friend keep a close eye on the vacuum gauge , Ive found that if it reads , in the 1"-0.5" range your generally in the ball park on carb size, BUT, if you reach 0.0 even before reaching peak power and rpms your carbs more than likely to large for the application

BTW remember those cheap crappy fuel filters I told you to never use?

well heres where they come in handy, you plug them into the rubber fuel line between the vacuum gauge and the intake plenum where they act like a pulse dampers making the vacuum needle stay a bit more steady and easier to read.

It should also be rather obvious that what goes in, needs to go out, a low restriction exhaust that reads lower than 1 psi MAX back pressure at high rpms will be required to maintain a full power curve

RELATED THREADS

viewtopic.php?f=55&t=444&p=5682&hilit=quads#p5682

viewtopic.php?f=55&t=211&p=6904&hilit=+vacuum+gauge#p6904

viewtopic.php?f=4&t=1337&p=2921&hilit=+vacuum+gauge#p2921

viewtopic.php?f=50&t=383&p=2301&hilit=+vacuum+gauge#p2301

viewtopic.php?f=70&t=202

viewtopic.php?f=44&t=392&p=5415#p5415

http://www.carcraft.com/techarticles/se ... index.html

viewtopic.php?f=56&t=495

http://users.erols.com/srweiss/calcdchg.htm

If you decide to go with dual quads, remember when you double the venturie area with two carbs youve effectively cut the depression, or flow thru each carb on the same engine about in half

4 barrel carbs are measured at 3", so a 500cfm carb that flows 500cfm at 3", paired with a second 500cfm rated carb would be flowing about 350cfm at 1/2 or 1.5" of depression giving the new twin carbs about 700cfm as a paired flow rate, obviously the true flow is determined by the true depression or vacuum under the venturies but the ratio will be similar