Grumpy,

yesterday I jumped the A+B pin, let it sit 30 seconds, disconnected the IAC and started it up. I did not get a low idle, still had 800 and rising. I shut it down and restarted it with the connector off and still went from 800 to 1600 hot. It showed no codes even with the connector off. I rechecked the TPS it was .59 reset to .54 no change. Did the ECM take a dump? The car runs great other than the idle.

Grumpy,

I have had a problem since last fall but with the T5 swap hadn't got to it. I have asked on here several times and get no response other than the normal base idle and TPS adjustments. I have done that, checked with propane for leaks, swapped MAF relays, checked codes - none. The problem is (the engine starts right up but..cold idle is 800 and as the engine warms it go's up. When warm it is 1600 rpm. Throttle flaps are not sticking open, cleaned throttle body and idle speed motor. When I unplug the MAF it goes back to 800 and idles a bit rough though throttle remains crisp. I can reconnect the MAF connector with no change. The service engine light comes on and will remain this way until I disconnect the battery and clear the code. When I restart it it is right back to 1600 hot. What do you think???

WATCH THE VIDEO, READ THE LINKS

http://www.youtube.com/watch?v=9CPqbaSg ... re=related

http://tpiparts.net/90_92_speed_density_sensors/

http://tpiparts.net/85_89_maf_sensors/

viewtopic.php?f=2&t=3074&p=8144#p8144

viewtopic.php?f=32&t=6550

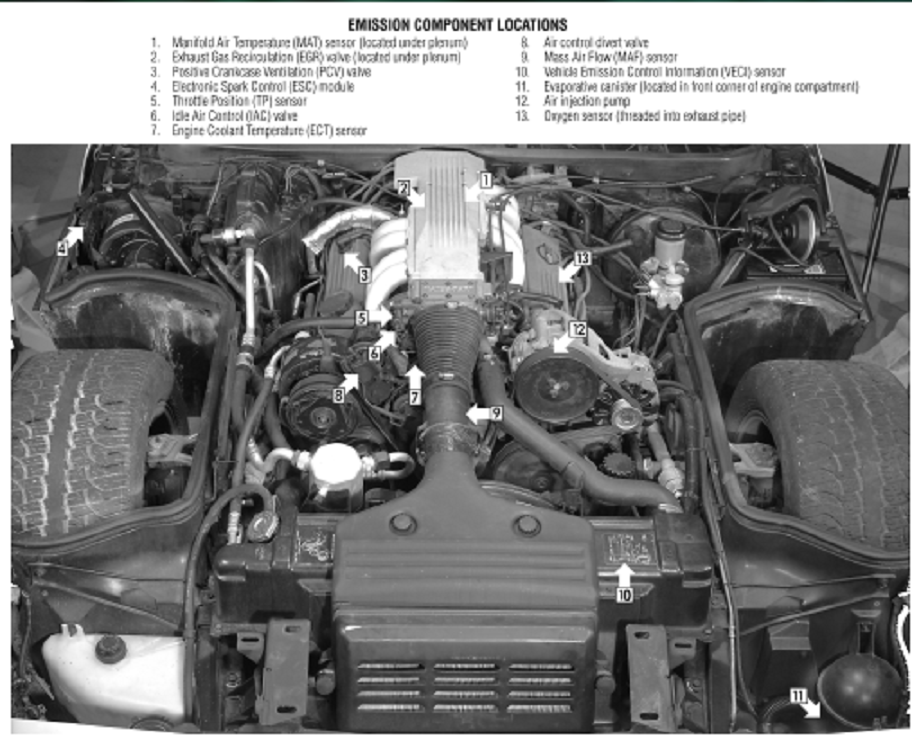

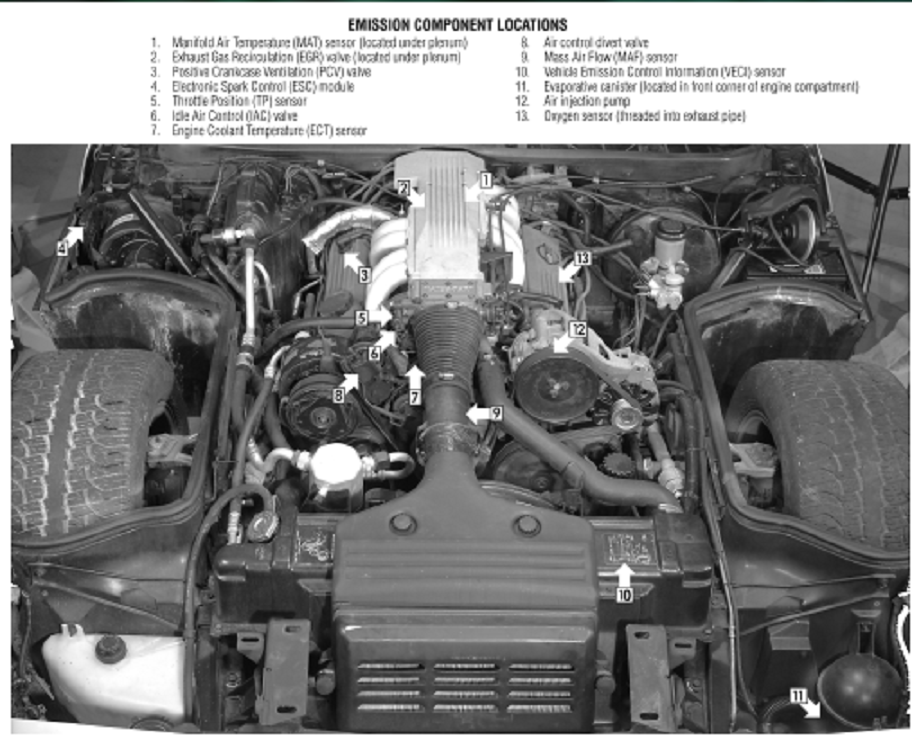

Id sure like to know the TROUBLE code your clearing, and it sounds like the IAC needs to be replaced or cleaned,or theres something keeping the throttle blades from closing but without more info Im guessing at this point without more info

always start with the basics and obvious potential sources,verify all sensors are connected,verify your ignition timing is correct, then,read thru these links and the sensor info near the end of the thread,

viewtopic.php?f=32&t=168

viewtopic.php?f=80&t=728&p=8392&hilit=sensor+location#p8392

Idle speed is speed is controlled by the ECM through the Idle Speed Control motor and is not adjustable. The minimum air rate is adjustable as follows.

1. Ground diagnostic terminal, turn ignition on, but do not start engine.

2. Wait 45 seconds for IAC to fully seat, then with ignition still on disconnect IAC connector.

3. Disconnect the distributor set timing connector.

4. Start engine and allow engine to go into "Closed Loop".

5. Remove ground from diagnostic terminal.

6. Adjust idle speed to specifications using throttle stop screw,

making sure the throttle blades move smoothly and don,t bind

7. Turn ignition off and reconnect IAC connector.

8. Adjust TPS voltage if necessary: With ignition "ON" use a scan tool or 3 jumper wires to adjust TPS sensor to correct voltage specification. Tighten screws, then recheck reading to insure adjustment has not changed.

9. Start engine and check for proper idle operation.

How To Adjust the Early C4 TPS and Idle Speed

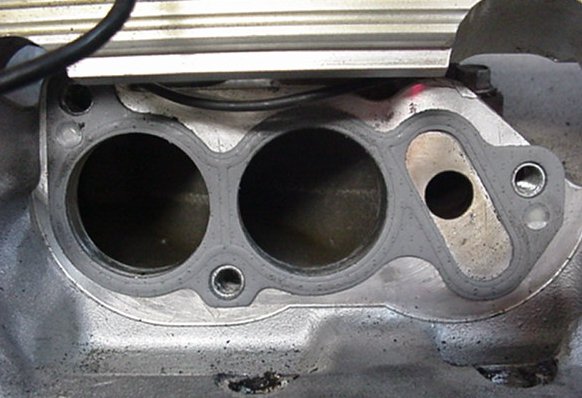

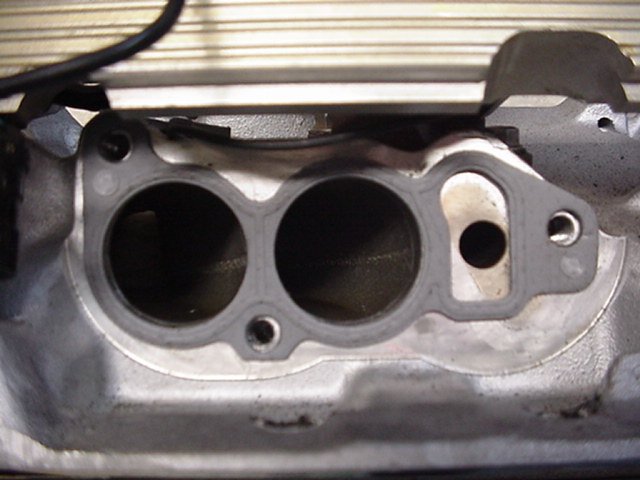

How to Adjust your Early C4 TPS and Idle Speed by Lars Grimsrud SVE Automotive Restoration Musclecar, Collector & Exotic Auto Repair & Restoration Broomfield, CO Rev. New 6-15-00 This tech paper will discuss the procedure for correct adjustment of the Minimum Idle Speed and for adjustment of the Throttle Position Switch (TPS) on the early C4 Corvette TPI systems. These steps apply specifically to the 1985 model year, and in general to other years. Later model years do not have adjustable TPS's. General Idle speed and off-idle throttle response on the early TPI systems is determined by correct adjustment of the minimum idle speed screw combined with a correct setting of the TPS. I've seen many of these cars that have had their idle speed "corrected" by well-intentioned mechanics and owners by simply screwing the minimum idle speed screw in a few turns. This really messes up the settings, and will not make your car perform properly. Doing a correct setup of the TPS is one of the easiest ways to make your car feel and respond better. To maximize the benefit of this procedure, I recommend that you first remove your Throttle Body (TB), disassemble it (it's incredible easy - there are a total of about 5 pieces in it...), clean the TB up really good with some spray carb cleaner, and put it back together. A nice clean TB will really put an edge on the performance improvement you will get by doing this procedure. The Service Manual has instructions for doing these operations, but the directions are scattered through several sections of the Manual. Here is the complete, step-by-step process for doing this (not including TB rebuild). All specs and steps are taken directly from the Manual (all 3 different sections), and this process is absolutely correct. Tools & Equipment You will need the following tools and equipment: 1. A set of Torx wrenches. You can buy a complete set in a nice, genuine plastic pouch at Sears. 2. A good digital voltmeter that will read voltages less than 1 volt. 3. A paper clip. 4. A small screwdriver. Procedure There are two electrical components on the TB that you will be working with: The TPS and the Idle Air Control Valve (IAC). Make sure that the connectors for these two components are easily accessible and that you can easily disconnect the IAC. You will also be playing with the diagnostic connector under the dash. Remove the cover (if it's still in place). Bend your paper clip into a "U" shape. You will be playing with the two top right hand terminals ("A" and "B") in the connector. First step is to set the minimum idle speed. If nobody has messed with this on your car before, the set screw will be covered by a pressed-in plug. It's located on the driver's side of the TB. Remove this plug if it's there. With the IAC connected and the ignition "OFF," stick the paper clip into the diagnostic connector from "A" to "B." This grounds the diagnostic lead. Turn the ignition to the "ON" position without starting the engine. Wait 30 seconds. Now, with the ignition still in the "ON" position, disconnect the IAC connector at the IAC. Remove the paper clip from the diagnostic connector. Start the engine and allow it to reach normal operating temperature. The idle speed will probably be really low, and you may have to coax the engine a bit with the gas pedal to keep it running for a while. If your car is an automatic, set the parking brake and put the transmission in "DRIVE." If your car is a manual, leave it in neutral. Adjust the idle speed screw to obtain 400 rpm in drive or 450 in neutral. Shut off the engine and re-connect the IAC. That's it for idle speed. Now on to the TPS. There are 3 wires stacked vertically on the TPS. You will need to be able to measure the voltage between the two top wires. You can either buy a special harness connector that breaks these wires out (from Mid America), or gently pierce the insulation of the wires with the pointy prongs on your volt meter. You can also stick a paper clip into each of the two top locations of the connector and clamp onto the paper clips to measure the voltage. Whatever is easiest for you. Turn the ignition to the "ON" position without starting the engine. Loosen the TPS Torx adjustment screws. Set your volt meter to a low scale DC volt setting that will accurately read less than 1 volt. Measure the voltage between the two top TPS wires. Adjust the TPS by rotating its position until you get a reading of .54 volts. Tighten the Torx screws and recheck the voltage. Re-adjust if necessary to make sure voltage is right at .54. Turn the ignition "OFF." You are now in perfect adjustment on idle speed and TPS output. Start the engine. It may take a few seconds for the car to "catch on" to its new settings. Questions, Comments & Technical Assistance If you have questions or comments regarding this article, or if you notice any errors that need to be corrected (which is quite possible since I'm writing this from memory...), please feel free to drop me an e-mail. Also, if you need any technical assistance or advice regarding this process, or other maintenance issues, feel free to contact me: lars.grimsrud@lmco.com "

IF ITS STILL TO HIGH<>>>Plug up every vacuum port except for the fuel pressure regulator, i.e. temporarily take every vacuum line off the manifold

except for the FPR and then run the engine. If things improve you probably have a leak somewhere. If it's still running rough, it could be in the manifold seal to the heads or something else. Also check to make sure your throttle body mounting bolts are tight.then let me know the results

yesterday I jumped the A+B pin, let it sit 30 seconds, disconnected the IAC and started it up. I did not get a low idle, still had 800 and rising. I shut it down and restarted it with the connector off and still went from 800 to 1600 hot. It showed no codes even with the connector off. I rechecked the TPS it was .59 reset to .54 no change. Did the ECM take a dump? The car runs great other than the idle.

Grumpy,

I have had a problem since last fall but with the T5 swap hadn't got to it. I have asked on here several times and get no response other than the normal base idle and TPS adjustments. I have done that, checked with propane for leaks, swapped MAF relays, checked codes - none. The problem is (the engine starts right up but..cold idle is 800 and as the engine warms it go's up. When warm it is 1600 rpm. Throttle flaps are not sticking open, cleaned throttle body and idle speed motor. When I unplug the MAF it goes back to 800 and idles a bit rough though throttle remains crisp. I can reconnect the MAF connector with no change. The service engine light comes on and will remain this way until I disconnect the battery and clear the code. When I restart it it is right back to 1600 hot. What do you think???

WATCH THE VIDEO, READ THE LINKS

http://www.youtube.com/watch?v=9CPqbaSg ... re=related

http://tpiparts.net/90_92_speed_density_sensors/

http://tpiparts.net/85_89_maf_sensors/

viewtopic.php?f=2&t=3074&p=8144#p8144

viewtopic.php?f=32&t=6550

Id sure like to know the TROUBLE code your clearing, and it sounds like the IAC needs to be replaced or cleaned,or theres something keeping the throttle blades from closing but without more info Im guessing at this point without more info

always start with the basics and obvious potential sources,verify all sensors are connected,verify your ignition timing is correct, then,read thru these links and the sensor info near the end of the thread,

viewtopic.php?f=32&t=168

viewtopic.php?f=80&t=728&p=8392&hilit=sensor+location#p8392

Idle speed is speed is controlled by the ECM through the Idle Speed Control motor and is not adjustable. The minimum air rate is adjustable as follows.

1. Ground diagnostic terminal, turn ignition on, but do not start engine.

2. Wait 45 seconds for IAC to fully seat, then with ignition still on disconnect IAC connector.

3. Disconnect the distributor set timing connector.

4. Start engine and allow engine to go into "Closed Loop".

5. Remove ground from diagnostic terminal.

6. Adjust idle speed to specifications using throttle stop screw,

making sure the throttle blades move smoothly and don,t bind

7. Turn ignition off and reconnect IAC connector.

8. Adjust TPS voltage if necessary: With ignition "ON" use a scan tool or 3 jumper wires to adjust TPS sensor to correct voltage specification. Tighten screws, then recheck reading to insure adjustment has not changed.

9. Start engine and check for proper idle operation.

How To Adjust the Early C4 TPS and Idle Speed

How to Adjust your Early C4 TPS and Idle Speed by Lars Grimsrud SVE Automotive Restoration Musclecar, Collector & Exotic Auto Repair & Restoration Broomfield, CO Rev. New 6-15-00 This tech paper will discuss the procedure for correct adjustment of the Minimum Idle Speed and for adjustment of the Throttle Position Switch (TPS) on the early C4 Corvette TPI systems. These steps apply specifically to the 1985 model year, and in general to other years. Later model years do not have adjustable TPS's. General Idle speed and off-idle throttle response on the early TPI systems is determined by correct adjustment of the minimum idle speed screw combined with a correct setting of the TPS. I've seen many of these cars that have had their idle speed "corrected" by well-intentioned mechanics and owners by simply screwing the minimum idle speed screw in a few turns. This really messes up the settings, and will not make your car perform properly. Doing a correct setup of the TPS is one of the easiest ways to make your car feel and respond better. To maximize the benefit of this procedure, I recommend that you first remove your Throttle Body (TB), disassemble it (it's incredible easy - there are a total of about 5 pieces in it...), clean the TB up really good with some spray carb cleaner, and put it back together. A nice clean TB will really put an edge on the performance improvement you will get by doing this procedure. The Service Manual has instructions for doing these operations, but the directions are scattered through several sections of the Manual. Here is the complete, step-by-step process for doing this (not including TB rebuild). All specs and steps are taken directly from the Manual (all 3 different sections), and this process is absolutely correct. Tools & Equipment You will need the following tools and equipment: 1. A set of Torx wrenches. You can buy a complete set in a nice, genuine plastic pouch at Sears. 2. A good digital voltmeter that will read voltages less than 1 volt. 3. A paper clip. 4. A small screwdriver. Procedure There are two electrical components on the TB that you will be working with: The TPS and the Idle Air Control Valve (IAC). Make sure that the connectors for these two components are easily accessible and that you can easily disconnect the IAC. You will also be playing with the diagnostic connector under the dash. Remove the cover (if it's still in place). Bend your paper clip into a "U" shape. You will be playing with the two top right hand terminals ("A" and "B") in the connector. First step is to set the minimum idle speed. If nobody has messed with this on your car before, the set screw will be covered by a pressed-in plug. It's located on the driver's side of the TB. Remove this plug if it's there. With the IAC connected and the ignition "OFF," stick the paper clip into the diagnostic connector from "A" to "B." This grounds the diagnostic lead. Turn the ignition to the "ON" position without starting the engine. Wait 30 seconds. Now, with the ignition still in the "ON" position, disconnect the IAC connector at the IAC. Remove the paper clip from the diagnostic connector. Start the engine and allow it to reach normal operating temperature. The idle speed will probably be really low, and you may have to coax the engine a bit with the gas pedal to keep it running for a while. If your car is an automatic, set the parking brake and put the transmission in "DRIVE." If your car is a manual, leave it in neutral. Adjust the idle speed screw to obtain 400 rpm in drive or 450 in neutral. Shut off the engine and re-connect the IAC. That's it for idle speed. Now on to the TPS. There are 3 wires stacked vertically on the TPS. You will need to be able to measure the voltage between the two top wires. You can either buy a special harness connector that breaks these wires out (from Mid America), or gently pierce the insulation of the wires with the pointy prongs on your volt meter. You can also stick a paper clip into each of the two top locations of the connector and clamp onto the paper clips to measure the voltage. Whatever is easiest for you. Turn the ignition to the "ON" position without starting the engine. Loosen the TPS Torx adjustment screws. Set your volt meter to a low scale DC volt setting that will accurately read less than 1 volt. Measure the voltage between the two top TPS wires. Adjust the TPS by rotating its position until you get a reading of .54 volts. Tighten the Torx screws and recheck the voltage. Re-adjust if necessary to make sure voltage is right at .54. Turn the ignition "OFF." You are now in perfect adjustment on idle speed and TPS output. Start the engine. It may take a few seconds for the car to "catch on" to its new settings. Questions, Comments & Technical Assistance If you have questions or comments regarding this article, or if you notice any errors that need to be corrected (which is quite possible since I'm writing this from memory...), please feel free to drop me an e-mail. Also, if you need any technical assistance or advice regarding this process, or other maintenance issues, feel free to contact me: lars.grimsrud@lmco.com "

IF ITS STILL TO HIGH<>>>Plug up every vacuum port except for the fuel pressure regulator, i.e. temporarily take every vacuum line off the manifold

except for the FPR and then run the engine. If things improve you probably have a leak somewhere. If it's still running rough, it could be in the manifold seal to the heads or something else. Also check to make sure your throttle body mounting bolts are tight.then let me know the results