nawlins-tim

Member

Grumpy I totally respect your decision making ability and auto knowledge so I figured I'd start this question with you. I have a new motor I'm building and a had a small "alignment pin" issue when I went to assemble some new heads on a freshly decked 400sbc block. Well I'm about 95% happy with the way the heads going on and I have this slight worry that I may have a leak of some kind. And by the way it's in my nature to think of the worst happening in everything I do.

My question is would a leak down test be worth while on a fresh motor that has not been started or broken in. I know I can physically do the test, but would the un-broken in ring be able to hold enough air preasure to tell me if my head gasket is in good shape. I would like to know now , before the engine is in the car, to find out IF in fact my head gasket has a good seal. And if you recommend this type of test, how much air preasure would you use? Thanks, Tim

My question is would a leak down test be worth while on a fresh motor that has not been started or broken in. I know I can physically do the test, but would the un-broken in ring be able to hold enough air preasure to tell me if my head gasket is in good shape. I would like to know now , before the engine is in the car, to find out IF in fact my head gasket has a good seal. And if you recommend this type of test, how much air preasure would you use? Thanks, Tim

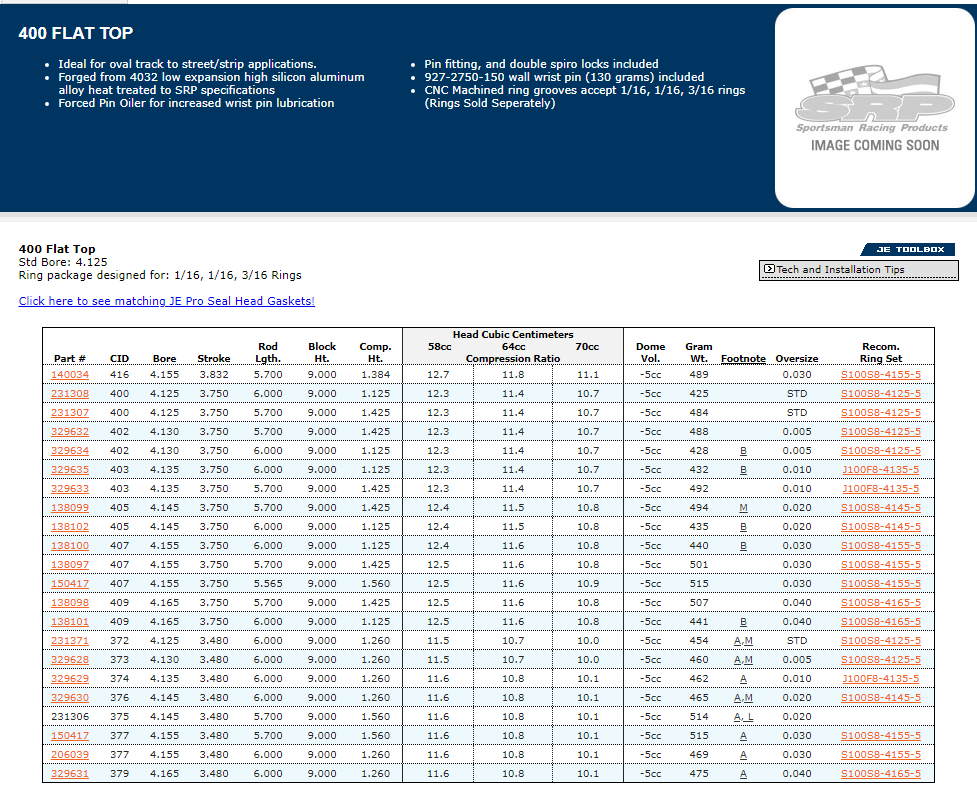

![img]](/proxy.php?image=http%3A%2F%2Fwww.grumpysperformance.com%2Fap18%2Fsrp400.png%2Fimg%5D&hash=7242359095b5915d1cad6acb6ae57c72)