NewbVetteGuy

Well-Known Member

Grumpy and Grumpites,

I appreciate all the help with my build so far; many of the variables in my build are slowly turning into constants and that's enabling me to model my build in a number of Engine simulation software packages and "make sure" before I begin purchasing things.

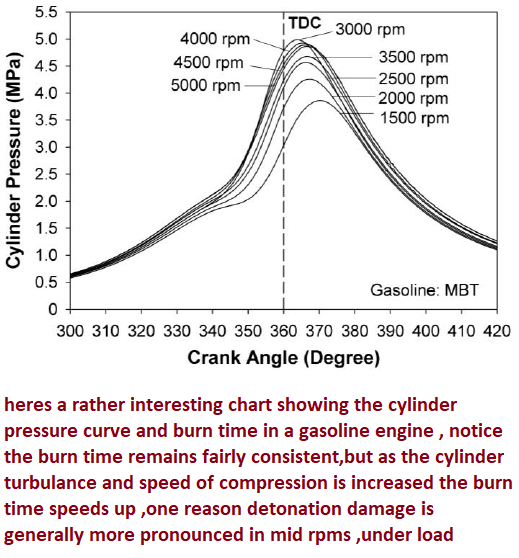

Here's my issue in large nutshell: I'm looking at a static CR of 10.2:1 with my Gen1 SBC 350 and aluminum heads. I'm doing a very torque-focused build with a reasonably small cam and a long-runner high flowing F.I.R.S.T. fuel injection (TPI on steroids) intake. As I model the combination in Desktop Dyno & PipeMax (an acquaintance modeled it in EA for me, too) I'm getting some slightly scary high cylinder pressure / trapped air estimates that make me think that near my torque peak RPM, I could very much be getting into a high risk of detonation.

Ask: Please review my situation and provide your appraisal of how much detonation risk I'm actually in and recommendations of how to best remediate it. I'd like recommendations that won't hurt fuel economy, ideally.

It's the stock 350, 2 piece rear mains, 4 bolt, L82 forged everything bottom end- never over bored never "refreshed" at all. 13,600 miles on it.

Bore: 4.0

Stroke: 3.48

Rod Length: 5.7"

Peak HP RPM: 5,500 (according to both Desktop Dyno and EA) -hp peak is pretty wide/flat from 5,500-6,200 in simulations

Peak Torque RPM: 4,500 according to Desktop Dyno, EA -and BadSS from the ThirdGen forums who has built some incredible FIRST intake-based engines; PipeMax is estimating a peak closer to 4,100

Static CR: 10.2:1

Pistons are 0.025" down the hole -estimated, not measured based upon other measurements from other 1979 L82 corvette engines

Felpro 0.015" gasket with 4.1" bore

5cc valve relief flat-top pistons

2.02" intake valve; 1.6" exhaust valve

Intake and Exhaust lift with 1.6ratio RRs: 0.600"

Duration @ 0.050" 227/232 (although my retrofit roller lifters have a 0.700" diameter wheel and the cam was rated for a 0.800" wheel so my actual duration @ 0.050" will be reduced by about 1 degree so closer to 226/231 effective)

Duration @ 0.006" / Advertised: 272/280

LSA: 110

ICL: 107

Exhaust: coated full length headers, 3" collectors, 3"-2 1/2" reducers, no cats, high flow mufflers; H-pipe within 20" of collectors (not yet sure about whether it's a tuned length or not; working on it...)

So if I used the internet calculator's "DCR" calculation (not dynamic but adjusted for the intake close event, anyway), I end up with a DCR of 8.256, rounded to 8.3.

Pipemax takes things a bit further and it has a calculation that can adjust that very simple, single variable (ICL event timing only) DCR calculation and adds to it valve lash (which can impact actual timing) and then helps to better estimate the amount of trapped air by adjusting for your Volumetric Efficiency at Torque Peak RPM. -Since BadSS modeled my engine with the first intake in EA, he came up with 110.5% VE @ 4,500 RPM. (The long-runner intake's tuned length is maximizing air velocity by using the reflected waves and can stuff more air into the cylinder than atmospheric pressure; if I get my exhaust properly tuned that will also help PULL the incoming air charge into the cylinder too.)

PipeMax then estimates then when adjusting for valve lash (which is essentially 0 with my hydraulic roller lifters) and volumetric efficiency, I would hit a DCR equivalent of 8.757... (obviously @ sea level but considering I live at sea level...)

This does not seem like a very safe DCR... Pipemax is pretty smart and converts this into a required octane of 95.8... (I can only regularly buy 92 octane in Washington State.)

I'm trying to figure out what I should do now...

I already plan to use a 3 row aluminum radiator and lower temp thermostat to try and keep engine temps lower. Roller lifters and roller rockers help a little bit with oil temps. I will definitely be using a Cold Air Intake and my intake does NOT have an exhaust cross over to worry about.

I'd really like solutions that don't hurt fuel economy; so running a fat AFR or pulling timing (particularly when my DCR peak is at 4,500 so pulling timing would hurt my torque throughout most of my curve) are probably my least favorite solutions.

I'm thinking that maybe I should polish the combustion chambers, pay attention to my spark plug temperature and I'm wondering what else... (Basically I need to gain 3.8 octane worth of detonation resistance somewhere...)

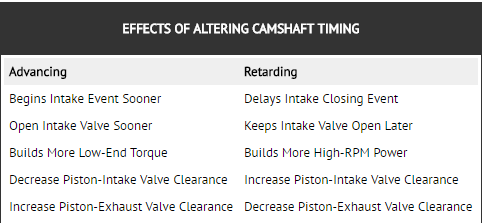

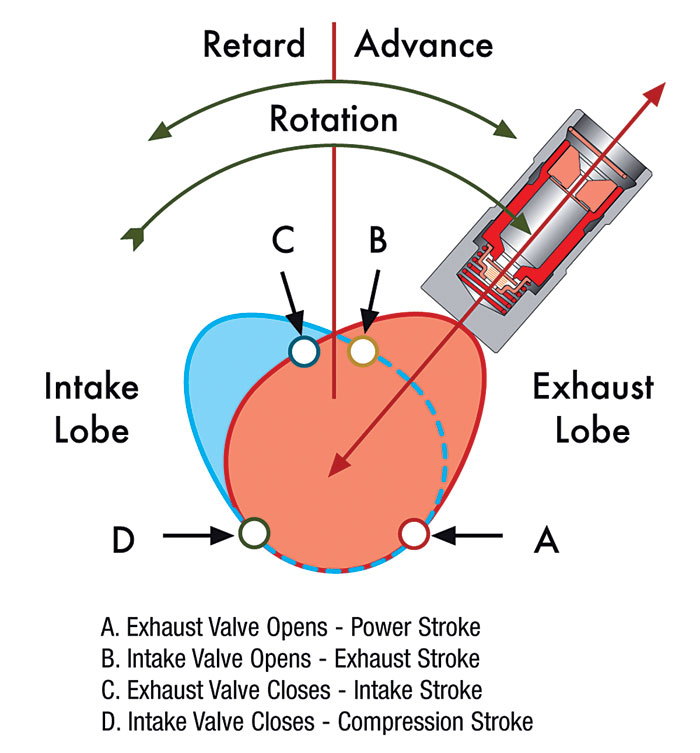

I was also thinking of retarding the cam by a few degrees and buying an adjustable timing chain and 2 piece cover- the cam has 3 degrees of advance built-in; I'd honestly prefer to just put the cam straight up either all the time or in summer when it gets hot rather than to pull timing.

I'm 90% certain my Holley EFI supports knock sensors so of course I could and should buy a filtered knock sensor and set it up to pull timing when necessary but I'd really like to put myself in a good situation to avoid having to have engine timing pulled.

Does anyone think going with a big baffled oil pan and a large oil filter with an oil filter heat sink on it would help get me a few more degrees and help with detonation risk? (Loved reading that thread here.)

I'm just not quite sure what it's going to take to get 3.8 octane points worth of detonation resistance.... -Should I just ask the CAM grinder to add another 5 degrees of duration to the intake and exhaust to bleed off more pressure?

Is 110.5% VE just a ridiculious number to even start with for an old SBC 350 with a FIRST intake? (If it is, then I'm probably worrying about nothing.)

Thanks for helping me think this through; I externally process information so even writing this out helps me to think through my options.

Adam

I appreciate all the help with my build so far; many of the variables in my build are slowly turning into constants and that's enabling me to model my build in a number of Engine simulation software packages and "make sure" before I begin purchasing things.

Here's my issue in large nutshell: I'm looking at a static CR of 10.2:1 with my Gen1 SBC 350 and aluminum heads. I'm doing a very torque-focused build with a reasonably small cam and a long-runner high flowing F.I.R.S.T. fuel injection (TPI on steroids) intake. As I model the combination in Desktop Dyno & PipeMax (an acquaintance modeled it in EA for me, too) I'm getting some slightly scary high cylinder pressure / trapped air estimates that make me think that near my torque peak RPM, I could very much be getting into a high risk of detonation.

Ask: Please review my situation and provide your appraisal of how much detonation risk I'm actually in and recommendations of how to best remediate it. I'd like recommendations that won't hurt fuel economy, ideally.

It's the stock 350, 2 piece rear mains, 4 bolt, L82 forged everything bottom end- never over bored never "refreshed" at all. 13,600 miles on it.

Bore: 4.0

Stroke: 3.48

Rod Length: 5.7"

Peak HP RPM: 5,500 (according to both Desktop Dyno and EA) -hp peak is pretty wide/flat from 5,500-6,200 in simulations

Peak Torque RPM: 4,500 according to Desktop Dyno, EA -and BadSS from the ThirdGen forums who has built some incredible FIRST intake-based engines; PipeMax is estimating a peak closer to 4,100

Static CR: 10.2:1

Pistons are 0.025" down the hole -estimated, not measured based upon other measurements from other 1979 L82 corvette engines

Felpro 0.015" gasket with 4.1" bore

5cc valve relief flat-top pistons

2.02" intake valve; 1.6" exhaust valve

Intake and Exhaust lift with 1.6ratio RRs: 0.600"

Duration @ 0.050" 227/232 (although my retrofit roller lifters have a 0.700" diameter wheel and the cam was rated for a 0.800" wheel so my actual duration @ 0.050" will be reduced by about 1 degree so closer to 226/231 effective)

Duration @ 0.006" / Advertised: 272/280

LSA: 110

ICL: 107

Exhaust: coated full length headers, 3" collectors, 3"-2 1/2" reducers, no cats, high flow mufflers; H-pipe within 20" of collectors (not yet sure about whether it's a tuned length or not; working on it...)

So if I used the internet calculator's "DCR" calculation (not dynamic but adjusted for the intake close event, anyway), I end up with a DCR of 8.256, rounded to 8.3.

Pipemax takes things a bit further and it has a calculation that can adjust that very simple, single variable (ICL event timing only) DCR calculation and adds to it valve lash (which can impact actual timing) and then helps to better estimate the amount of trapped air by adjusting for your Volumetric Efficiency at Torque Peak RPM. -Since BadSS modeled my engine with the first intake in EA, he came up with 110.5% VE @ 4,500 RPM. (The long-runner intake's tuned length is maximizing air velocity by using the reflected waves and can stuff more air into the cylinder than atmospheric pressure; if I get my exhaust properly tuned that will also help PULL the incoming air charge into the cylinder too.)

PipeMax then estimates then when adjusting for valve lash (which is essentially 0 with my hydraulic roller lifters) and volumetric efficiency, I would hit a DCR equivalent of 8.757... (obviously @ sea level but considering I live at sea level...)

This does not seem like a very safe DCR... Pipemax is pretty smart and converts this into a required octane of 95.8... (I can only regularly buy 92 octane in Washington State.)

I'm trying to figure out what I should do now...

I already plan to use a 3 row aluminum radiator and lower temp thermostat to try and keep engine temps lower. Roller lifters and roller rockers help a little bit with oil temps. I will definitely be using a Cold Air Intake and my intake does NOT have an exhaust cross over to worry about.

I'd really like solutions that don't hurt fuel economy; so running a fat AFR or pulling timing (particularly when my DCR peak is at 4,500 so pulling timing would hurt my torque throughout most of my curve) are probably my least favorite solutions.

I'm thinking that maybe I should polish the combustion chambers, pay attention to my spark plug temperature and I'm wondering what else... (Basically I need to gain 3.8 octane worth of detonation resistance somewhere...)

I was also thinking of retarding the cam by a few degrees and buying an adjustable timing chain and 2 piece cover- the cam has 3 degrees of advance built-in; I'd honestly prefer to just put the cam straight up either all the time or in summer when it gets hot rather than to pull timing.

I'm 90% certain my Holley EFI supports knock sensors so of course I could and should buy a filtered knock sensor and set it up to pull timing when necessary but I'd really like to put myself in a good situation to avoid having to have engine timing pulled.

Does anyone think going with a big baffled oil pan and a large oil filter with an oil filter heat sink on it would help get me a few more degrees and help with detonation risk? (Loved reading that thread here.)

I'm just not quite sure what it's going to take to get 3.8 octane points worth of detonation resistance.... -Should I just ask the CAM grinder to add another 5 degrees of duration to the intake and exhaust to bleed off more pressure?

Is 110.5% VE just a ridiculious number to even start with for an old SBC 350 with a FIRST intake? (If it is, then I'm probably worrying about nothing.)

Thanks for helping me think this through; I externally process information so even writing this out helps me to think through my options.

Adam