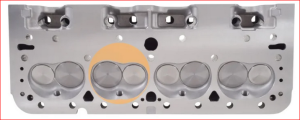

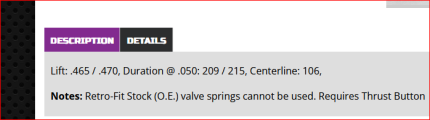

Looking to upgrade my camshaft to a retro roller. Stock 350 out of a 1982 corvette with throttle body’s. I want a grind with high torque off or near idle that will have good vacuum. Street not race. Can anyone give me an idear what to look for. I was told no more than 112 lsa for vacuum but the rest is beyond my experience. One profile was howard 110315-12. The other Melling 22135. Trying to keep it just above stock. The heads are brodix 180 cc 64 cambers. Not winding it any more than 5000rpms. Bottom end is stock all rebuilt.

Thanks Kevin

Thanks Kevin