The oil filter fitting for the Mark V (left) differs from the standard Mark IV mount. They can't be confused.

The Mark V big-block requires oil system bypass valves to make it compatible with an engine-mounted oil filter system. Forget these bypass valves, and you can kiss your engine goodbye, as oil will not circulate properly through the engine.

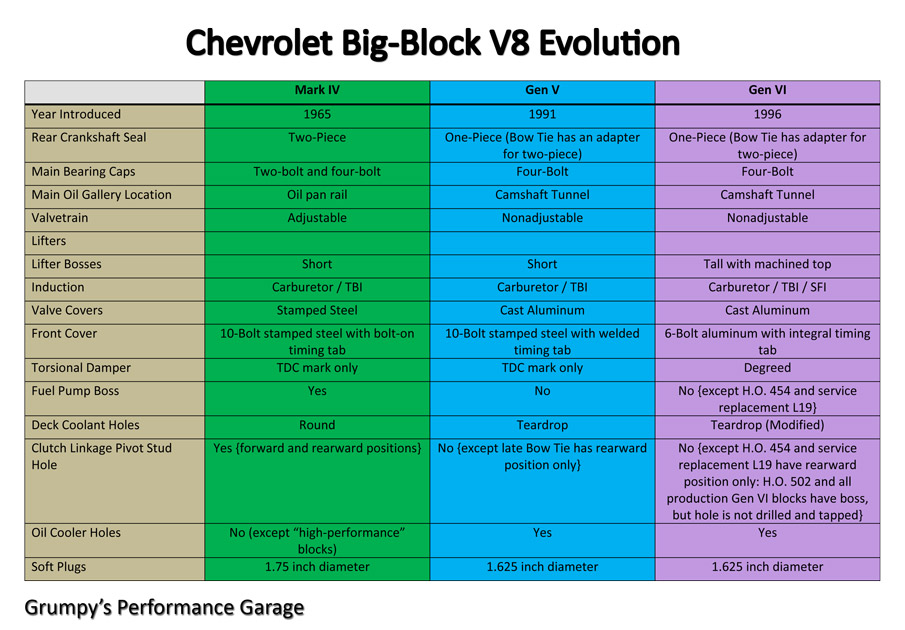

mark V (5) and mark VI (6) blocks have one piece rear seal cranks and this type oil filter boss above (later lower compression emission style truck engines)

mark IV (4) blocks have two piece rear seal cranks and this type oil filter boss above (the muscle car era engines)

1991-1997 BBC MARK V (above and below)

pressure is a measure of RESISTANCE to oil flow, if the pumps providing flow and yes that needs to be verified,

( because if the oil pump pick-up is less than a 1/4" off the oil pan floor flow is potentially restricted)

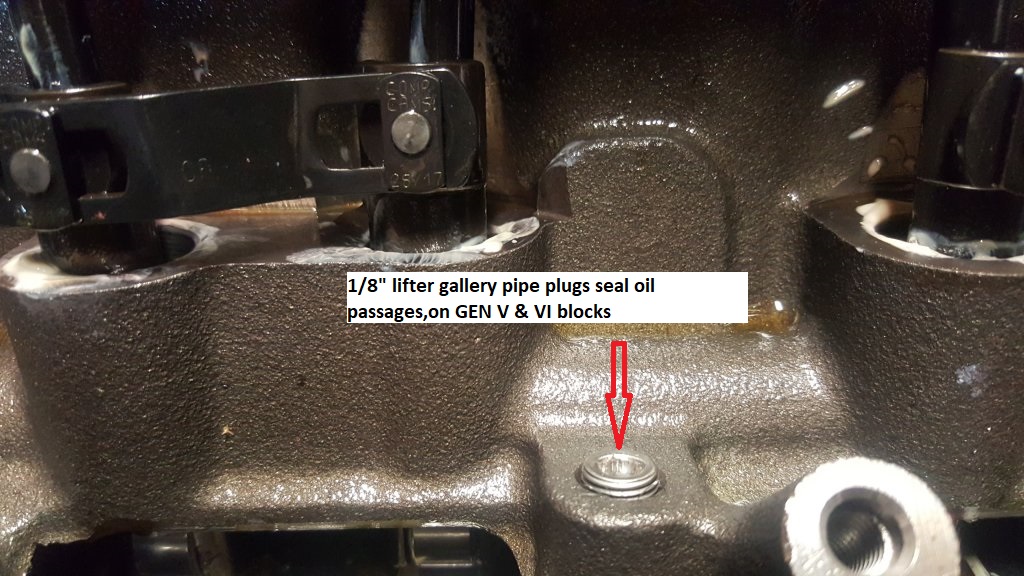

if your getting oil flow from the oil pump and no back pressure Id suggest checking the flow control valves, bearing clearances and oil passage plugs at the ends of the lifter gallery passages, any major open to flow oil passage results in very low oil pressure readings

http://garage.grumpysperformance.co...ark-v-bbc-engine-oil-system-differences.4576/

https://www.chevydiy.com/oil-lubrication-systems-guide-big-block-chevy-engines/

https://paceperformance.com/i-51345...ich-adapter-for-external-oil-cooler-only.html

Big Block Chevrolet Gen V and Gen VI Oiling SystemSolving the mystery of the Gen V and Gen VI Priority Main Oiling system

Priority Main Oiling System

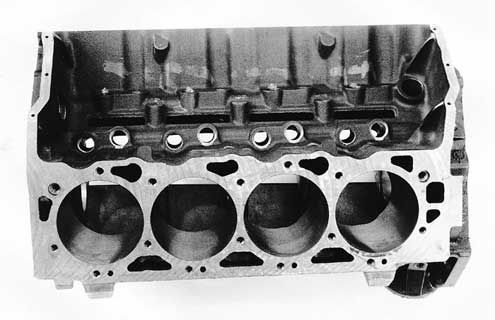

The Generation V and VI big block Chevrolet blocks feature a priority main oiling system where the main oil supply passage is located adjacent to the camshaft tunnel. Drilled passages which intersect this large oil tunnel carry oil directly to the main bearings. If you are facing the front of the block with the engine in the upright position, this main oil supply tunnel is located in the 2 o’clock position just below the right hand lifter oil supply line.

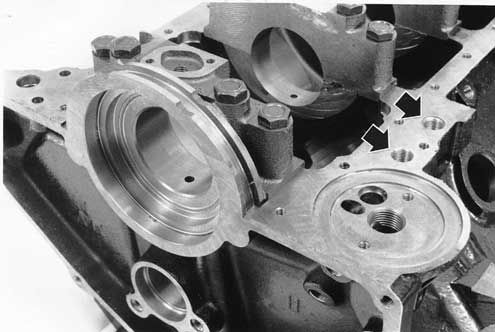

Oil Cooler Plumbing

Located along the oil pan rail just ahead of the oil filter pad are two drilled and tapped (3/8” NPT) oil passages for routing oil to an external oil cooler. The hole located closest to the oil filter pad (#2) is for the outgoing supply line to the oil cooler. The front passage (#1), which is farthest from the filter pad, is the return line from the oil cooler.

Careful examination reveals that these two passages intersect the same return line that feeds oil back to the main oil tunnel. This requires that a special fitting be used in the #2 supply line to prevent oil from short circuiting the oil cooler.

Part number SD1540 provides the necessary diverter basket to prevent the supply oil from entering the return line before going to the oil cooler. This fitting has a dash 10AN thread to allow the use of aftermarket components to plumb your external oil cooler. The front passage #1 will require a 3/8” NPT by dash 10AN adapter (#FCM2185), which is available from Scoggin-Dickey.

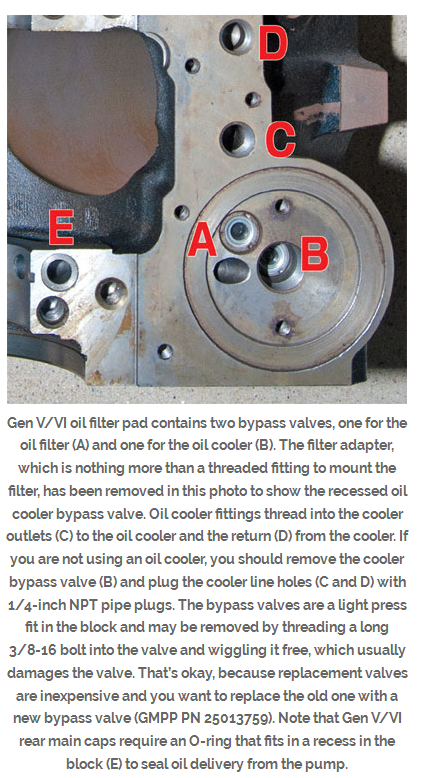

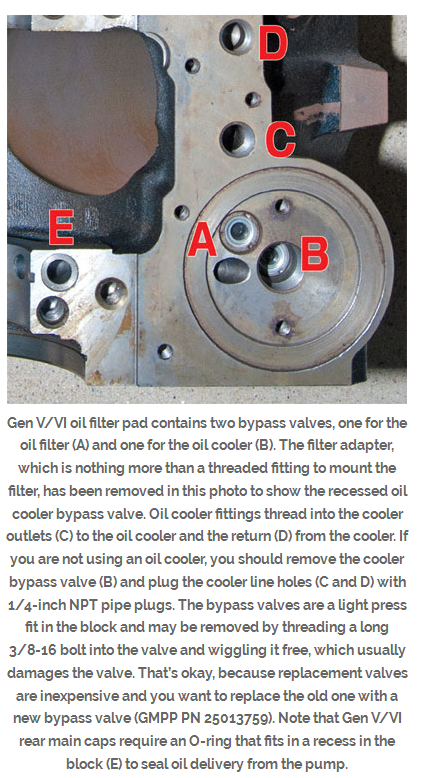

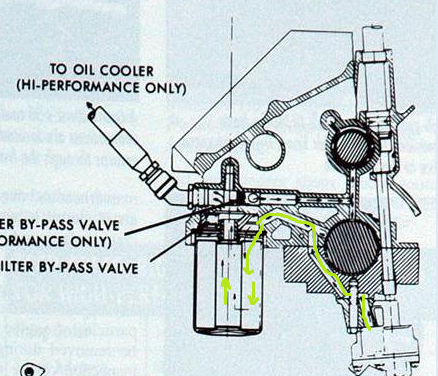

Understanding By-pass Valve Locations

Factory assembled 454, 502 engines and short blocks have two by-pass valves installed in the block. These factory installed by-pass valves (#25013759) will open at an 11 psi pressure differential. One by-pass valve is installed in the center hole on the oil filter pad (#4). This hole is the oil return passage from the oil filter. The second by-pass valve is installed in the adjacent hole (#3). The egg shaped hole (#5) is the high pressure oil supply passage from the oil pump.

For all racing application that will NOT use an oil cooler but will maintain the stock oil filter location, you must remove the center by-pass valve in location #4. Removing this valve eliminates three redundant right runs in the oil system. However, if you leave this by-pass in place the oil system will still function as it was intended, but a loss of oil pressure can result from the four right angle turns required for oil to return to the main oil tunnel.

If you intend to use a remote oil filter, a high pressure by-pass valve part number 25161284 must be installed in position #3. This valve will open at a 30 psi pressure differential. A plug will be installed in position #4 to prevent oil flow thru this passage. Oil should be returned to the block in the 3/8” hole located just able the oil filter pad. An oil filter block off plate kit (#SD3891) can be purchased from Scoggin-Dickey for Gen V and VI blocks to plumb your external oil filter.

If you intend to maintain the stock filter location and will use the factory provided oil cooler passages to install your oil cooler, then you must install two high pressure by-pass valves (#25161284). One will be installed in location #3 and the second in location #4.

with the revised MARK VI (6) the manual FUEL pump boss was reinstated

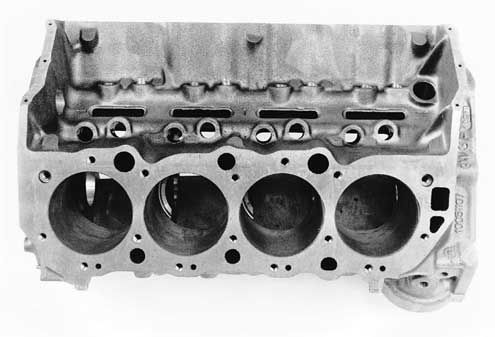

mark IV or common early BBC engine1965-1990 (These TWO PICTURES POSTED ABOVE)

if your looking for an oil pan Id suggest,you call these guys and ask for suggestions, prices and info, give them all the info you can and ask about header, frame, suspension, access/and clearance,problems, oil filter access/clearances, maximum crank stroke, etc.

Id suggest you select a 7-8 quart baffled design with no more than 8" depth on most cars and a 7" depth on low cars like corvettes

theres basically stock 4-5 quart oil pans that fit but they don,t provide ideal lubrication

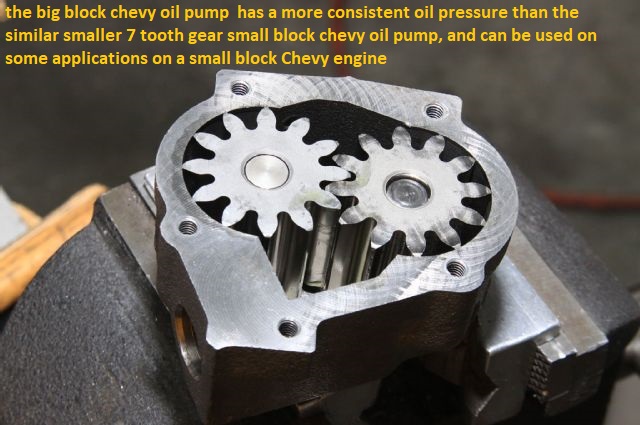

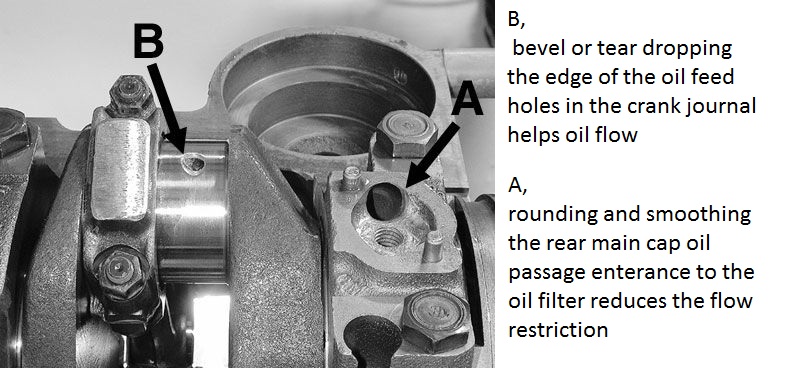

because of differences in the oil pumps and main cap designs and clearances its common that if you use a mark IV oil pump you'll need to clearance it like the pictures show to install it on a mark V-VI engine

greg_moreira posted this bit of info

"GenVI production block has advantages and disadvantages. Talking 454 block, not the 502.

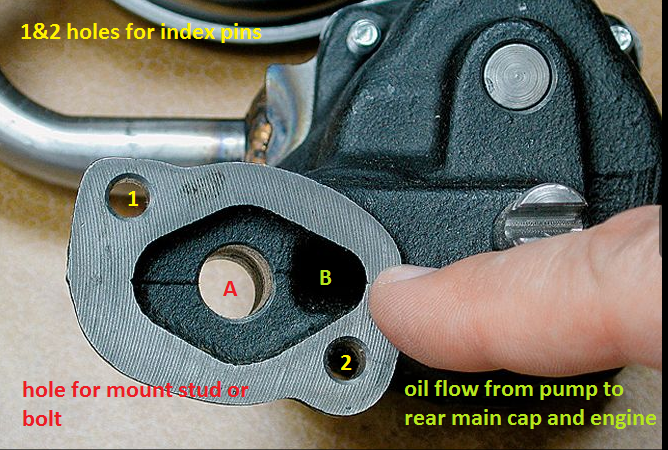

mounting the oil pump to the rear main cap

failure to use the correct oil pump,mounting stud, bolt or nut or carefully check clearances when mounting an oil pump can cause problems, AND THE HEIGHT OF THE MAIN CAPS AND OIL PUMP CASTINGS DO DIFFER, ESPECIALLY ON THE LATER BIG BLOCK VS THE EARLY BIG BLOCK COMPONENTS

BE 100% SURE that the oil pump bolt or STUD doesn,t protrude past the inner main cap surface , because if it bears on the rear main bearing shell it will almost always result in a quickly failed rear bearing[/b

ONE RATHER COMMON MISTAKE IS USING THE WRONG OIL PUMP STUD OR BOLT TO MOUNT THE OIL PUMP AS IF EITHER EXTENDS THRU THE REAR MAIN CAP SURFACE, IT CAN AND WILL BIND ON THE BEARING SHELL BACK SURFACE AND CAN LOCK OR RESTRICT, SMOOTH CRANK ROTATION.

STUDS ARE PREFERRED BECAUSE THEY GET THE THREADS THAT ENTER THE MAIN BEARING CAP COATED WITH THREAD LOCKER, LIQUID , THEN SCREWED IN TO THE MAIN CAP UNTIL THEY TOUCH THE BACK OF THE BEARING SHELL THEN BACKED OF 3/4 OF A TURN , THE OIL PUMP MOUNTED , AND THE WASHER AND FINE THREAD LOCKING NUT SECURED PER THE TORQUE SPECS.THIS INSURES THE STUD DOES NOT BEAR ON THE REAR BEARING SHELL , A BOLT WHEN TIGHTENED MUST BE TURNED DEEPER INTO THE THREADS IN THE REAR MAIN CAP, AND ITS MUCH HARDER TO PREVENT IT FROM BEARING OR CAUSING PRESSURE ON THE BACK OF THE BEARING SHELL IF ITS A BIT TOO LONG (A COMMON ISSUE, IN REBUILDS WHERE THE WRONG BOLTS USED.)

viewtopic.php?f=54&t=2187&p=5890#p5890

]yes the oil flows around the mounting stud,from oil pump to main cap to reach the engine oil passages, thru the oil filter

just keep in mind that you'll need to very carefully blend and smooth and carefully clean,the edges of the beveled area where the oil port feeds the bearing surface with some 600 grit sand paper so the oil flows well and theres no edges to cause bearing wear issues or crud left from the process that would get embedded in the bearings.

Advantage: revised oiling system, taller lifter bores adds lifter stability, one pc seal (although, can't really say I ever had 2pc seal leaks using modern seals), all are 4 bolt main

Disadvantages: thinner decks, thinner cylinder walls (cylinder prep is very important on these, absoluely have to plate hone), fewer pan choices, fewer crank choices, no fuel pump boss for mech pump on early blocks. I prefer to use head studs on a performance GenVI 454, but block has to be plate honed with studs installed. Might be able to go back and hit the cylinders with a couple passes if converting to studs, need to check with the machine shop on that. Not a necessity, more of a precaution.

502 block doesn't seem to have the same limits on cylinder walls or decks as the cylinders are siamesed and the head bolt holes are blind so not subject to corrosion. Totally different animal but GenVI Sportsman block is as beefy as they get: .400" cylinder walls at 4.500" bores, splayed main caps, siamese bores, thick decks, higher strength iron. This is where it gets crazy. Using the 800.00 finish machined block as a baseline, that's a pretty good deal, going rate around here is 1100.00-1200.00 for a finished block. I was able to get into the Sportsman block to build a 540" for 2200.00 finished. Crank/rods/pistons are a wash 496 or 540. You can see how it gets out of hand fast. From a performance standpoint, any of those

blocks you listed will do. Just take a good look at the head bolt holes on that GenVI, especially the ones where the dowels are located, as these have couple less threads. No biggie to fix those with a helicoil though if need be. Again, not a necessity just a precaution. "

related links and info

http://www.summitracing.com/parts/SUM-G3510X/

http://www.midwestmotorsportsinc.com/in ... parent=277

obviously you'll want to verify it fits before ordering

http://www.midwestmotorsportsinc.com/in ... parent=277

http://www.midwestmotorsportsinc.com/in ... parent=277

http://www.milodon.com/

http://www.cantonracingproducts.com/store/oilpans.html

http://moroso.com/catalog/categorybrows ... Code=11000

http://www.hamburgersperformance.com/

http://www.stefs.com/stefsindex.htm

Last edited by a moderator: