https://www.chevydiy.com/ultimate-guide-building-chevy-big-blocks-cylinder-blocks-instruction/

Ultimate Guide to Building Chevy-Big Blocks: Cylinder Blocks Instruction

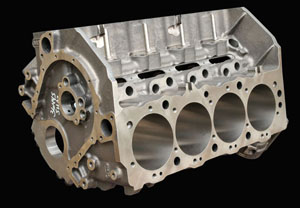

These big chunks of iron or aluminum are indeed the building blocks upon which your entire engine is crafted. Like a raw canvas or flawless piece of marble awaiting the master’s touch, the block is only as good as the casting itself.

Oil passages, lifter bores, and dozens of bolt-hole locations all factor into what makes a good block for a true highperformance or racing big-block Chevy. Most of these machining operations have been handled at the factory, and more often than not, they are going to be right on the money. When it comes time to select your block, you want to start with the right casting for your projected power level, and then find the best machine shop to bring everything to spec.

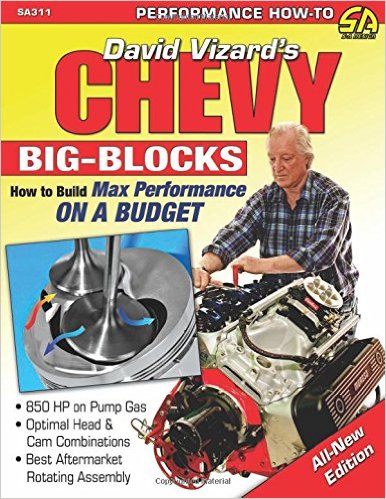

This Tech Tip is From the Full Book “HOW TO BUILD KILLER BIG-BLOCK CHEVY ENGINES“. For a comprehensive guide on this entire subject you can visit this link:

This Tech Tip is From the Full Book “HOW TO BUILD KILLER BIG-BLOCK CHEVY ENGINES“. For a comprehensive guide on this entire subject you can visit this link:

LEARN MORE ABOUT THIS BOOK HERE

SHARE THIS ARTICLE: Please feel free to share this post on Facebook / Twitter / Google+ or any automotive Forums or blogs you read. You can use the social sharing buttons to the left, or copy and paste the website link:

https://www.chevydiy.com/ultimate-guide-building-chevy-big-blocks-cylinder-blocks-instruction/

Block Selection

The first decision you need to make when it comes to selecting a block for your bruiser is whether to start with a factory production or aftermarket block. For the vast majority of people, the decision is an easy one: you plan to use a stock block, whether it’s one you already own or plan to purchase at the right price. There’s nothing really wrong with a stock block engine. It’s just that the beefier aftermarket or Bowtie blocks have advanced features (such as siamesed bores that can safely be bored to 4.600 inches or more) that contribute to greater power potential.

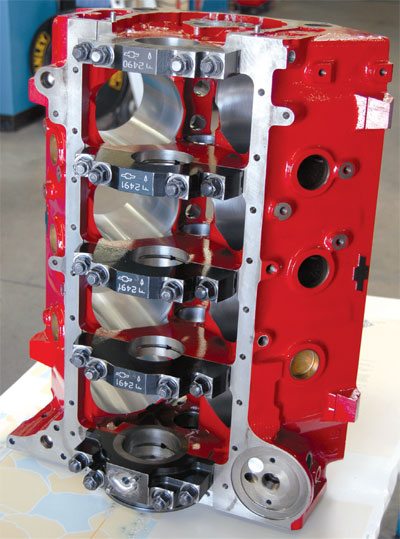

Gen VI Bowtie block with splayed bolt billet steel main caps. (Photo Courtesy GMPP)

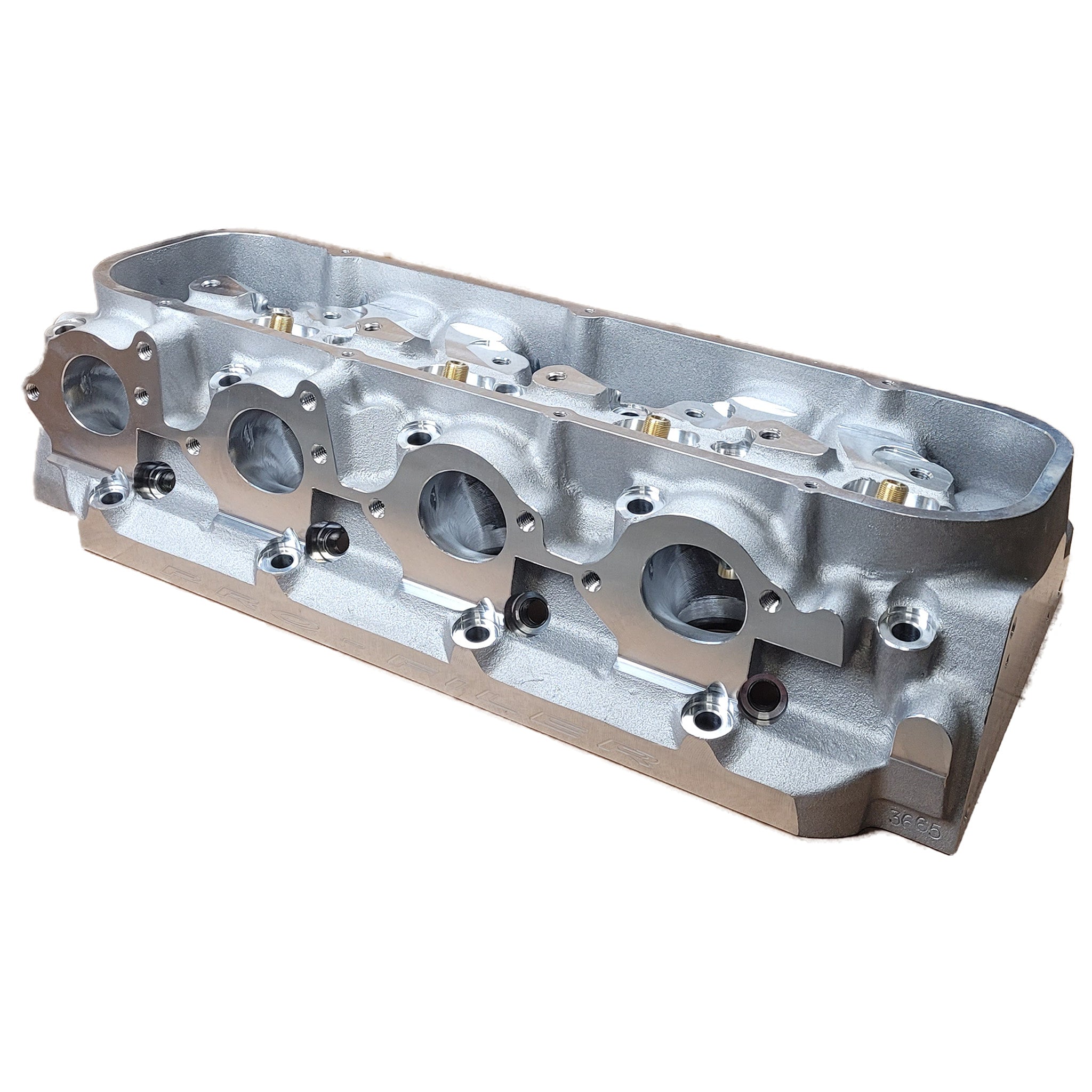

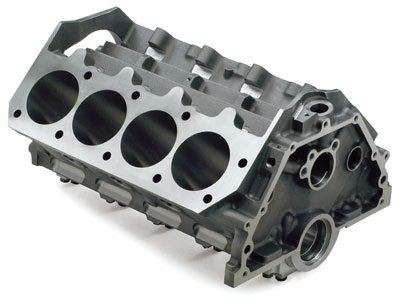

This cutaway of a Merlin III block shows the beefy cylinder walls made possible with siamesed bores. This allows much larger bore sizes than stock 454 blocks and the thick cylinder walls promote better ring seal. Also note the additional head-bolt bosses in the lifter valley, which give extra clamping power for a better head gasket seal. (Photo Courtesy World Products)

Here are the basics: if you plan to produce up to 650 hp (normally aspirated or “all motor” as the sport compact guys say) on the street or 750 hp on race gas, you can definitely get there with a stock-block four-bolt main engine. I limit power levels to 600 hp with a two-bolt main block. For higher power requirements, the aftermarket blocks start to look a lot better.

Let’s look at some examples: say your target power level is 750 hp. You can get there with a stock block 467-ci engine (4.250-inch bore plus .060-inch overbore, and 4.000-inch-stroke crank), but to produce 1.602 hp per cubic inch may require better flowing CNC-ported cylinder heads, a larger camshaft, a full kickout oil pan and matching pump, and other such tricks to produce the power needed. And, you probably have to spin the engine up to about 8,000 rpm, which puts additional wear and stress on all components, especially the valvetrain.

But a 565-ci engine (4.600-inch bore x 4.250-inch stroke) only needs to make 1.327 hp per cubic inch. And you can easily get there by using less expensive heads and a typical high-performance oiling system. You make the power at a lower RPM, which eases wear and tear and takes less of a toll on the valvetrain. And the real kicker is how, when you decide to “step it up” to the next class, bracket, or you just want to go faster, the same parts you needed just to qualify with a 467 really wake up that 565.

Maximum Bore Sizes

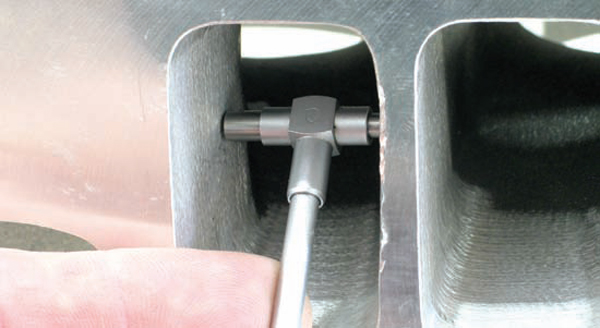

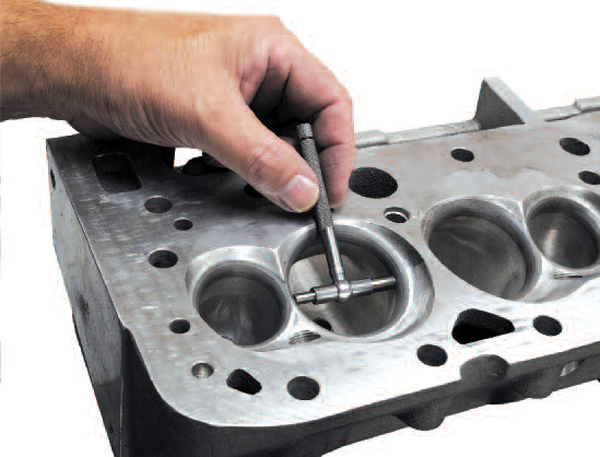

When overboring your block, the best way to determine the maximum safe bore size is to use a sonic wall thickness tester, a very expensive piece of equipment that most high-end machine shops will have on hand. The minimum safe wall thickness is .200 inch, but you are better off with a slightly smaller bore (and thus thicker cylinder walls) if the engine will be used on the street or for endurance racing applications such as off-shore boat racing. Most production blocks will easily accommodate overbores of .030-inch or .060-inch as long as there is no evidence of extreme core shift. The best indicator of core shift during the casting process is to look at the lifter bore bosses: the lifter bores should be well centered in their bosses. If there is no visible core shift in the lifter bosses, many 454-based engines are bored to +.100-inch (yielding a bore size of 4.350 inches), and some brave souls have gone as far as +.125-inch, although that is usually best left to drag-race-only applications using some form of block filler in the water jackets to support the resulting thin cylinder walls.

502 engine blocks (8.2 cast on sides of block) will safely tolerate a 4.500-inch bore, which is only .034-inch over their 4.466-inch bore size as produced. The cylinder wall thickness of Bowtie and aftermarket blocks with siamesed bores has varied considerably over the years, but most can safely tolerate bores to 4.600 inches and some are rated up to 4.625 inches. For the amount of money being invested in an engine of that nature, you are best advised to have the cylinder walls sonically checked and hold to the minimum wall thickness of .200 inch.

Stock Blocks

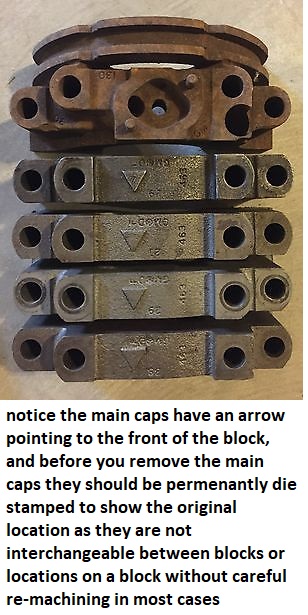

When I refer to stock blocks, I’m talking about original-equipment cylinder blocks found in cars or trucks, as opposed to the Bowtie blocks, which, even though they are “Genuine GM Parts,” were never available in a production vehicle. Always inspect a used engine for damage that is unrepairable, like cracks or excessive overboring, as well as flaws that can be fixed at additional expense, like stripped bolt-holes, main bore misalignment, and uneven deck surfaces.

Aftermarket blocks, like this Dart Big M cast-iron block, may cost more than stock blocks initially but can save you money in the long run as you search for more horsepower.

Original ZL-1 aluminum blocks are scarce as hen’s teeth, but you can buy a brandnew version from GMPP (PN 12370850) with the Mark IV–style two-piece rear main seal. PN 88958696 comes with the Gen V/VI–style one-piece rear main seal. (Photo Courtesy GMPP)

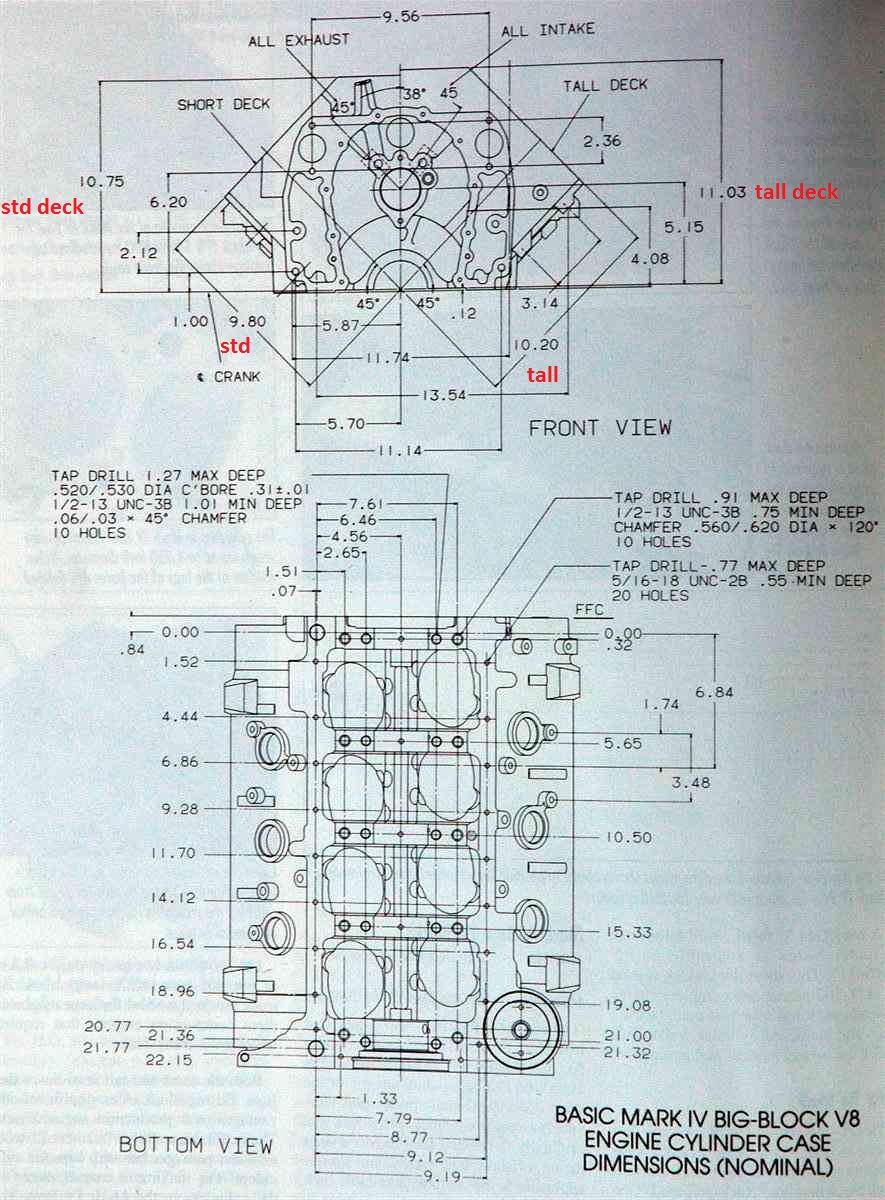

A. Here are the specifications of the front of the block:

B. Main Bore: 2.937 to 2.938 inches

C. Main Caps: (five) two- or four-bolt, 7/16-14 bolt holes

D. Cam Bore: 2.140 inches (number-1), 2.130 inches (number-2 and number-5), 2.120 inches (number-3 and number-4); cam bearing inside diameter: 1.950 inches

E. Crankshaft-to-Camshaft Centerline: 5.152 inches

F. Deck Height: 9.800 inches (standard), 10.200 inches (tall-deck Marine, Truck, and some High Performance)

G. Timing Cover Rail: ten 1/4-20 boltholes (Mark IV, Gen V), two .250-inch alignment dowels G. Water Pump Pads: 3/8-16 bolt-holes, two each side

H. Accessory/Motor Mount Pads: 7/16-14 bolt-holes, two each side

A. Here are the specifications of the front of the block:

B. Main Bore: 2.937 to 2.938 inches

C. Main Caps: (five) two- or four-bolt, 7/16-14 bolt holes

D. Cam Bore: 2.140 inches (number-1), 2.130 inches (number-2 and number-5), 2.120 inches (number-3 and number-4); cam bearing inside diameter: 1.950 inches

E. Crankshaft-to-Camshaft Centerline: 5.152 inches

F. Deck Height: 9.800 inches (standard), 10.200 inches (tall-deck Marine, Truck, and some High Performance)

G. Timing Cover Rail: ten 1/4-20 boltholes (Mark IV, Gen V), two .250-inch alignment dowels G. Water Pump Pads: 3/8-16 bolt-holes, two each side

H. Accessory/Motor Mount Pads: 7/16-14 bolt-holes, two each side

All stock blocks are cast iron except the rare ZL-1 aluminum block, which saw limited production in 1969. It’s a pretty safe bet that all of these jewels are well accounted for, and your chances of stumbling across one in some salvage yard are fairly slim.

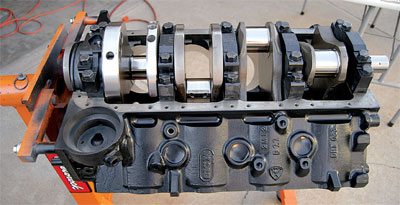

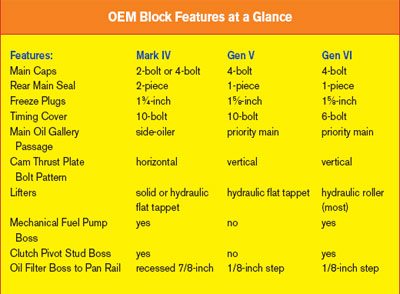

Mark IV Blocks

Stock blocks produced from 1965 to 1990 are the original Mark IV design, and were available with either two- or four-bolt main caps, and in three bore sizes (four, if you count the 366T talldeck truck blocks with their miniscule 3.935-inch bores, but I’m not counting them because they are totally unsuitable for any performance big-block buildup). The 396 had a bore of 4.094 inches, the 402 was slightly larger at 4.125 inches, and 427s and 454s share a 4.250-inch bore. All else being equal, there is no reason to start with any stock block other than the larger 4.250-inch-bore blocks.

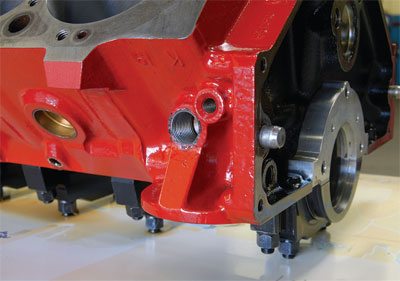

Muscle-car era Mark IV blocks with four-bolt mains were drilled and tapped for oil cooler fittings just above the oil filter mount. Note the 1/8-inch NPT pipe plugs just above the oil pan rail. These are where the main oil gallery was crossdrilled to feed the main bearings.

Standard big-block deck height is 9.800 inches from the crank centerline to the deck surface, and tall-deck blocks like this one measure 10.200 inches. You can easily spot a tall-deck block by looking at the distance from the top water pump bolt-hole to the deck surface. With a standard-height block, the top of the water pump is nearly even with the deck, but a tall-deck block has .400 inch more material, about the same amount as the diameter of the 3/8-16 bolt-hole. Also, most tall-deck Mark IV blocks have a 1/8-inch NPT oil gallery tap in front of the manifold end rail, as shown here.

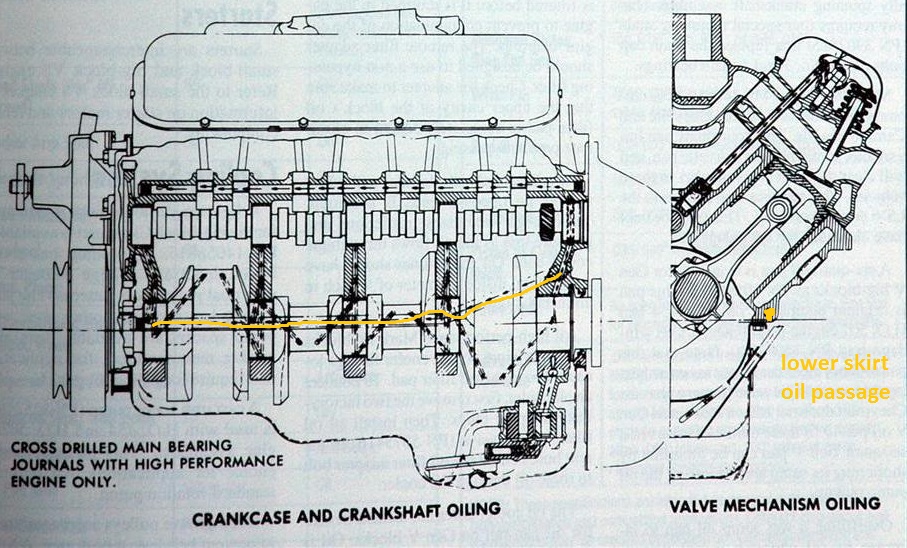

Very early Mark IV blocks had a couple of peculiarities you should be aware of. First, 1965 and 1966 blocks used a grooved rear cam bearing with a matching groove in the rear camshaft journal. This groove was designed to supply oil to the lifters, and if a non-grooved bearing or cam is used, there is no oil supply to the passenger-side lifters—this is not good. Second, all Mark IVs through 1967 used the 1950s-era oil canister with an oil filter cartridge inside. The 1968-andlater engines got the traditional spin-on oil filters that we all enjoy changing to this day.

Gen V and Gen VI Blocks

In 1991, General Motors changed several important design features of the Mark IV big-block with the introduction of the Gen V engine, most notably the addition of a one-piece rear main oil seal, and different coolant core passages in the deck surface of the block and heads. Gen V and Gen VI blocks are easy to spot in the wrecking yard; they all have a revised front core that features a distinctive continuous machined boss for the front cover, water pump, and front accessory mounting bosses, giving the appearance of having a frame around the front timing cover. All production engines were fuel injected by this time, so the mechanical fuel pump boss was also eliminated. Most of us “old timers” initially viewed this version of the big-block as something of a disappointment. The supply of good crankshafts, oil pans, and cylinder heads would no longer fit, which limited its performance potential.

Those performance challenges were addressed by a responsive aftermarket parts industry, and soon we had a choice of high-performance cylinder heads designed to work with either Mark IV or Gen V deck surfaces (with the appropriate head gasket for the block being used), two-piece seal adapters allowing the use of traditional Mark IV crankshafts, and performance oil pans designed for the wider rear main cap with its one-piece seal on the Gen V block.

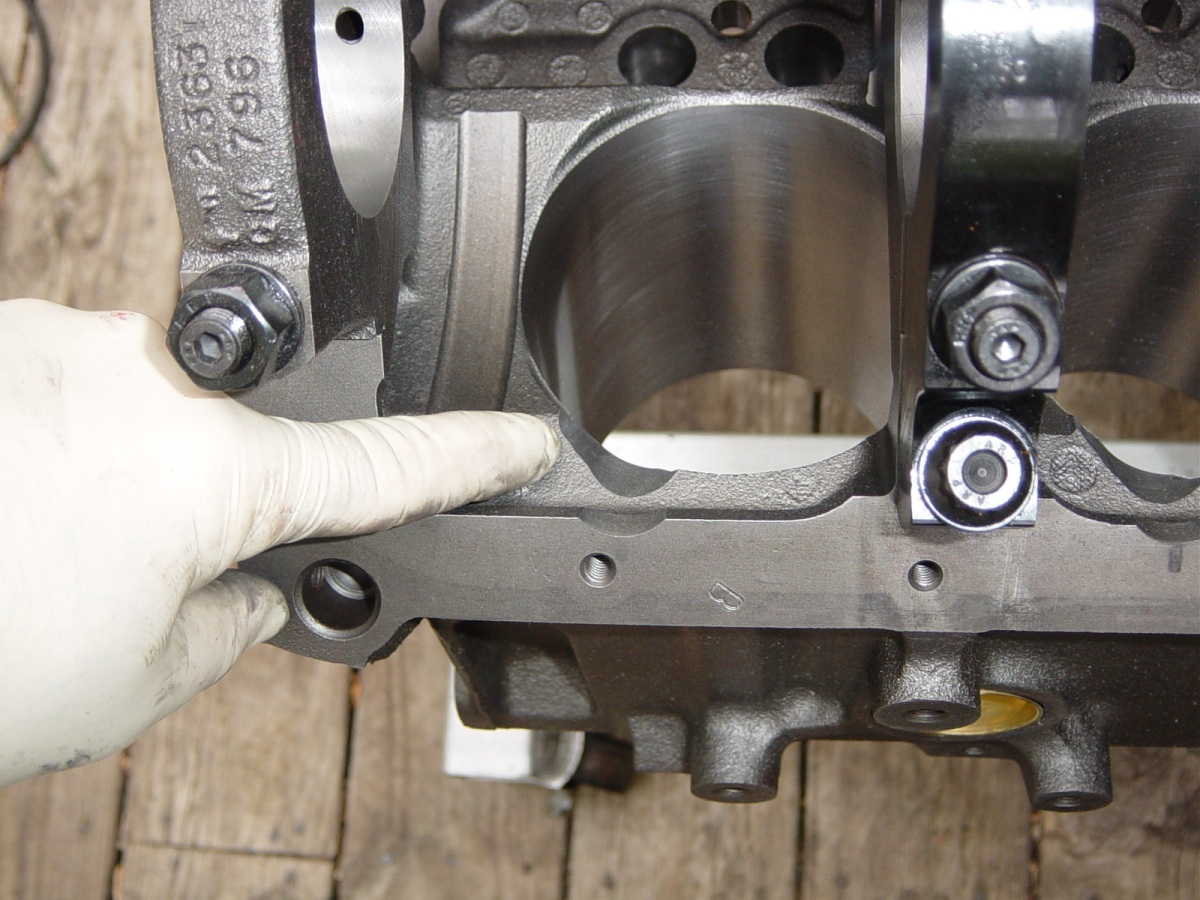

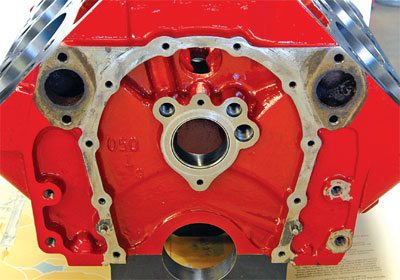

All Gen V and Gen VI blocks came with four-bolt main caps, like this Gen VI 502 block. Gen V/VI main caps are about .200 inch taller than Mark IV caps, and require different bolts or studs. This block has been drilled and tapped to accept a standard 10-bolt front cover; stock timing cover had six bolts.

Gen V and Gen VI blocks feature a priority main oil gallery that runs parallel to the lifter supply oil passage on the left of the block. It is the larger hole at the 3 o’clock position next to the cam bore. The two lifter oil galleries are above the cam bore at the 10 and 2 o’clock positions.

Gen V/VI blocks have an abbreviated oil filter mounting pad with a 1-inch-wide reinforcing rib. The filter sealing surface is nearly flush with the oil pan rail, while it is recessed by 7/8 inch on Mark IV blocks.

502 blocks can easily be identified by the “8.2” designation cast into the side of the block. They feature siamesed cylinder barrels and the finished bore size is 4.466 inches. They can safely be bored to 4.500.

With this kind of parts availability, there’s no reason not to consider a Gen V or Gen VI block as a good starting point for your project engine, with a few caveats. For one thing, production-line Gen V blocks have no provision for mechanical fuel pumps or traditional clutch linkage. These obstacles can be overcome by using an electric fuel pump and hydraulic clutch linkage, but you have to factor in these additional expenses and see how they compare to simply buying a block that has the features you need in the first place. Also, consider the limited cylinder head availability for the Gen V deck surface. There were very few factory performance heads made for this engine family, and these were mostly for the over-thecounter 502 HO engine. The production Gen V heads were all low-performance “peanut” port heads designed to produce good low-end grunt for the truck applications these engines were used in.

There is a good assortment of aftermarket cylinder heads, both cast iron and aluminum, that work on the Gen V, but you have to factor in the additional cost of these premium parts. One often overlooked difference between the Mark IV and Gen V engines is that the taller rear main cap bolts required for the Gen V’s one-piece rear main seal interferes with the original Mark IV oil pump. Gen V and Gen VI engines require matching oil pumps, along with a heavy-duty oil pump driveshaft like GM PN 3865886. On the plus side, all Gen V and Gen VI blocks were fitted with four-bolt main caps.

In 1996, the Gen VI was introduced with additional changes. Probably the easiest feature to spot when trolling for blocks at the salvage yard is the six-bolt composite or aluminum front timing cover. Both the Mark IV and the Gen V used stamped steel front covers with 10 bolt holes. If the cover is missing, just look for the six-bolt pattern, compared to the 10-bolt pattern used on all Mark IV-style engines, including Bowtie and aftermarket blocks. Gen VI blocks also benefit from the reintroduction of the mechanical fuel pump boss and clutch pivot stud boss.

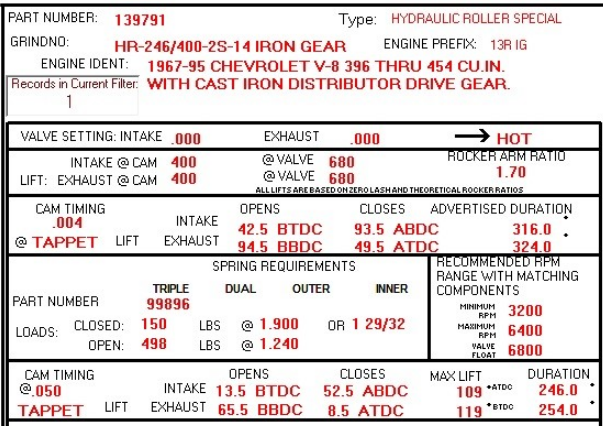

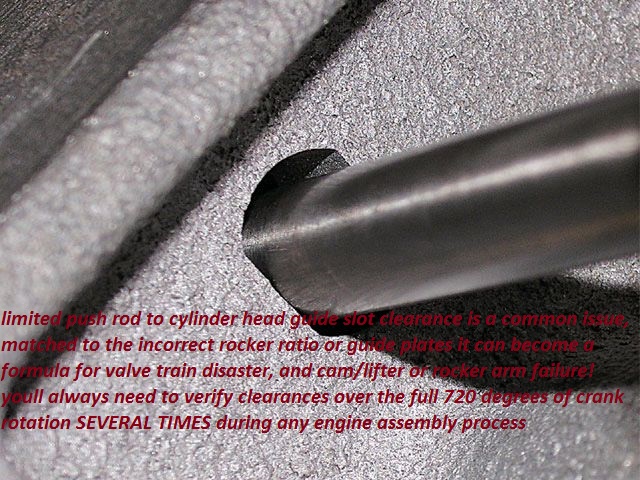

Production Gen VI blocks still have the large water passage and core holes in the deck surface, again requiring the use of Gen V or Gen VI cylinder heads or aftermarket heads designed to fit either the Mark IV or Gen V/VI blocks. Other refinements to the Gen VI include bosses in the lifter valley for the factory hydraulic roller lifter retainer, commonly called a “spider,” although not all Gen VI blocks have this feature. This can be important if your plans call for the use of a hydraulic roller lifter camshaft, because the cost of the lifters is quite a bit more than the cost of the camshaft. If your core engine includes the original GM roller lifters, they may be reused (unlike conventional flat-tappet lifters) as long as they are in good condition, although the stock lifter and guide arrangement is limited to valve lifts of around .600 inch.

If your block does not have the factory roller lifter alignment bosses, there are aftermarket roller lifters available with self-aligning tie bars so you can still use a hydraulic or mechanical roller cam. If you use tie-bar roller lifters, the taller lifter bores require roller lifters that are .300-inch taller than Mark IV lifters, and they are readily available from most cam companies.

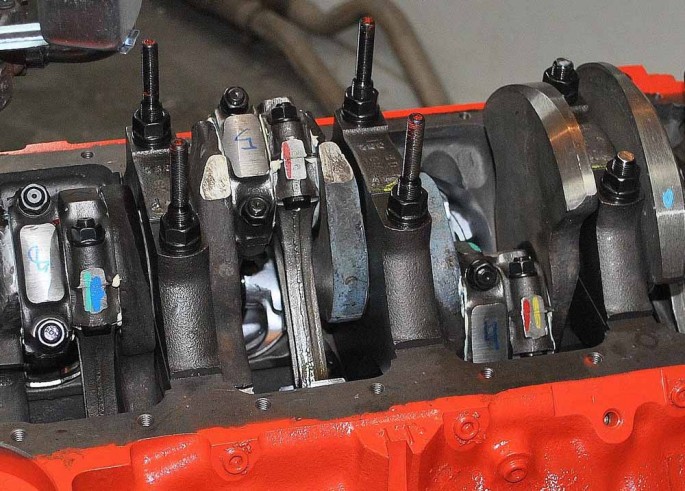

Gen V and Gen VI blocks feature a priority main oil gallery that runs parallel to the lifter-supply oil passage on the left (driver’s) side of the block. This feature has two advantages: first, oil from the oil pump goes directly to the main bearings (after being filtered, of course) then on to the lifters and cam bearings; and second, relocating the oil gallery from the driver’s-side oil pan rail (Mark IV location) means there is no chance of breaking into this passage when grinding the block for additional connecting rod clearance, or when fitting the block with splayed-bolt main bearing caps. This feature has proven to be so popular that it is now standard on most aftermarket cylinder blocks, as well as Gen V/VI blocks.

There is one more OEM block that was found in the last production bigblock engines used in trucks from 2001 to 2006, and that is the 8.1L (496 ci). While General Motors is nearly mute about this engine, you could call it the Gen VII big-block, because it has substantial differences from all other big-blocks. It uses entirely different symmetrical-port cylinder heads, which are bolted to the block with 18 head bolts instead of the usual 16 found on Mark IV and Gen V/VI production blocks. And no, the 18-bolt pattern is not the same as the Bowtie or aftermarket 18-bolt pattern, both of which use two additional bosses in the lifter valley. This engine, designated the “Vortec 8100” or RPO L18, has a tall-deck block with a 4.25-inch bore and a cast crankshaft with a 4.37-inch stroke. It is fully computercontrolled, and features a distributorless coil-near-plug ignition system and multipoint electronic fuel injection (EFI). It relies upon crankshaft and camshaft position sensors, and has redesigned water pump and coolant passages.

In short, it is a unique animal in the big-block jungle, and very few other bigblock performance parts fit. It does have both early- and late-model-style motor mount bosses, meaning it bolts into any engine compartment originally designed for the big-block, but its tall-deck design and different accessory mounting locations likely require some surgery with a cutting torch. There are aftermarket sources for powertrain control modules, if you really want to tackle something different in the world of big-block engine swaps. The block is readily identifiable by the “8.1” designation cast into the sides of the block.

Another block of considerable interest to hot rodders is the 502, sometimes referred to as the 8.2 liter, which is easily identified by the large “8.2” designation cast in the sides of the block. The 502 was never installed in production vehicles, though many were used by the marine industry, especially Mercury Marine. It features siamesed cylinder barrels and a finished bore size of 4.466 inches. They can safely be bored to 4.500 inches, which, even with the stock 454/502’s 4-inch-stroke crank, yields a displacement of 509 ci. Drop in a 4.250-inchstroke crank, and you’re looking at 540 cubes (actually 540.7, but everyone calls them 540s). This makes the 502-ci block an ideal start for a moderately high horsepower street, marine, or drag race engine, but remember that it is basically a production-line block and does not tolerate large overbores. It is not the same casting as the factory-produced highperformance Bowtie blocks. These blocks are available from GMPP (PN 19170540).

General Motors Performance Parts Blocks

While never installed in production vehicles, General Motors Performance Parts (GMPP) offers several replacement four-bolt main blocks suitable for performance applications. PN 19170538 is a non-siamesed-bore block with a 4.250- inch bore that is a hybrid of the original Mark IV and the newer Gen V/VI designs. Because it is a production-based block, bore size should be limited to 4.310 inches. Like all Gen V/VI blocks, it has a one-piece rear main seal and must be used with a Gen V/VI crankshaft or adapted to the older two-piece rear main seal for use with Mark IV cranks. It is machined for the Gen VI 6-bolt front cover, but there is adequate material to drill and tap the block for use with traditional 10-bolt covers, if desired.

GMPP block PN 19170538 is used in the 454 HO short block. This production-based non-siamesedbore block with a 4.250-inch bore is a hybrid of the original Mark IV and the newer Gen V/VI designs. (Photo Courtesy GMPP)

This block features traditional Mark IV features such as a machined fuel pump pad, clutch pivot stud bosses, and deck coolant passages that have been designed to seal properly with either Mark IV or Gen V/VI cylinder heads. It incorporates many of the Gen VI block’s desirable features such as provisions for hydraulic roller lifters, redesigned priority main oil passages, and the standard Gen VI oil filter mount with oil cooler fittings in the pan rail surface. This block is used in the ZZ427, the 454 HO, and the ZZ454 crate engines offered by GMPP.

PN 19170540 shares the same traits as the PN 19170538 block, but has siamesed 4.466-inch bores that may be increased to a maximum bore size of 4.500 inches. This is the block that General Motors uses for all of its 502-ci crate engines, including the ZZ502.

Bowtie Blocks

Beginning in the 1980s, Chevrolet rewarded its legion of Pro Stock and other big-block racers with the introduction of the Bowtie blocks, which have substantial improvements over regular production-line blocks in terms of strength and potential bore sizes. The most notable of all these features was the introduction of siamesed bores, which have no water passageways between the individual cylinder barrels. The thickness of the cylinder barrels was increased enough to accept 4.500-inch and larger bores while still retaining a wall thickness of .200 inch or more. There have been many versions of the Bowtie blocks, in Mark IV, Gen V, and Gen VI configurations, so the maximum bore size varies with the individual block casting number. Many can be safely bored to 4.600 inches.

Mark IV Bowtie blocks still used the original oil passage design, which I like to call side-oilers (not to be confused with Fords of the same name), since the main oil gallery is a drilled passage along the left side of the block just above the pan rail surface. Gen V and Gen VI Bowtie and production blocks feature a priority main oiling system, in which the main journals receive the oil before the lifter bores, ensuring that the most critical components in the engine are the first stop on the oil supply route.

You can easily identify the difference between the side-oilers and the priority main blocks by looking for the four 1/8-inch national pipe thread (NPT) plugs along the bottom left side of Mark IV blocks. These plugs cover the opening where the factory drilled intersecting holes to feed the main bearings from the main oil gallery. This applies to production blocks, as well as the Bowtie blocks, so it is one more quick and easy way to distinguish Mark IV blocks from Gen V/ VI blocks.

Another major benefit of all Bowtie blocks is the extra-thick deck surface with blind cylinder head-bolt holes. The thicker-than-stock decks are more stable under high loads, such as ultra-highcompression ratios, nitrous, or supercharged applications. Any time power production goes up, the load on the cylinder head and block junction surface increases, and the thicker decks are simply more stable and provide a better clamping force for the head gaskets. The blind head-bolt holes require no thread sealant, and positively eliminate the ageold problem of engine coolant leaking into the engine through the head-bolt bores in the head. Most Bowtie blocks also feature additional head-bolt bosses in the lifter valley, providing six-bolt clamping around every bore for superior gasket seal. Compare this with the smallblock, which has five bolts per cylinder, and Ford/Chrysler designs, which must get by with only four per hole. Those poor non-Chevy guys…

General Motors didn’t stop there: Bowtie blocks have been beefed up in the main webs as well, some more than others. There are short-deck (9.8-inch) and tall-deck (10.2-inch) versions of the Bowtie blocks, and some feature splayed bolts on the center three main bearing caps for additional crankshaft support. This little luxury item won’t add any performance to your basic 600- to 800- hp big-block, but it gives peace of mind when power levels exceed 900 hp.

GMPP Drag Race Competition Engine Blocks

GMPP Drag Race Competition Engine Blocks

GM Performance Parts currently offers two versions of this exotic iron block engineered to meet the specific needs of NHRA Pro Stock drag racers. Both are short-deck, semi-finished blocks with 4.900-inch bore spacing (4.840 inches is stock), and they are the spec blocks required by NHRA for GM competitors. They are supplied without head-bolt holes or lifter bores, allowing customization by the individual race teams to suit their needs. They may be machined to locate the starter on the left, allowing the use of oil pans with a full-length kick-out on the right side. The distributor-hole location has been moved to behind the lifter valley bulkhead and requires the use of special Drag Race Competition Engine (DRCE) camshafts. Side-motor mount pads have been eliminated, requiring the use of race-style front and rear motor plates.

The DRCE 2 (PN 24502572) is cast from traditional gray iron and comes with a 9.525-inch deck height that may safely be machined to 9.000 inches.

How do you know it’s a Bowtie block? Well, you can carry this book around with you and check the casting numbers listed on pages 25–27, or, even easier, look for the prominent Bowtie logo cast into the side of the block.

Most Bowtie blocks feature splayed-bolt main caps on the three center mains for added bottom-end strength.

Gen V and Gen VI Bowtie blocks have been available with both the productionstyle one-piece rear main seal and with a two-piece adapter and Mark IV–style rear main cap for use with traditional Mark IV cranks and oil pans. Unlike their production counterparts, Gen V and Gen VI Bowtie blocks have small round coolant passages in the deck surface, and they accept all design cylinder heads, including traditional Mark IV heads. (Photo Courtesy GMPP)

DRCE 2 block (PN 24502572) for Pro Stock competition comes without head bolt-holes or lifter bores. It features a Chevy/Pontiac/Oldsmobile bellhousing bolt pattern and in-block distributor-hole location. Pro Stock racers use dry sump oiling systems and front-drive distributors, so this hole is usually blocked off. (Photo Courtesy GMPP)

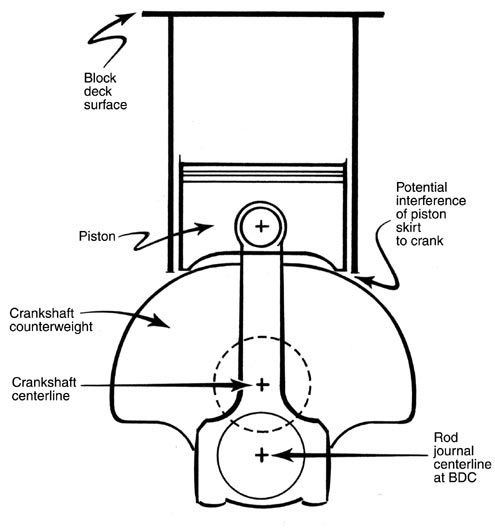

The camshaft bore is raised to 5.750 inches (stock is 5.152 inches) and the semi-finished 4.500-inch bores may be enlarged to 4.700 inches. The oil pan rails are spread .400 inch per side.

The DRCE 3 block (PN 25534406) is cast from compacted graphite iron for its superior strength and resistance to bore distortion. The 9.250-inch deck height may be reduced to 9.000 inches and the cam bore has been raised to 7.067 inches. The semi-finished 4.590-inch bores can be bored to 4.700 inches and the oil pan rails are spread to 12 inches. Main bores are 2.500 inches (409 Chevy) and they accept a special nine-journal camshaft with 60-mm bearings.

Aftermarket Blocks

Aftermarket blocks are standard fare for most serious big-blocks built these days, not only for extreme competition but for high-end street and weekly bracket racers as well. They are available in cast iron, cast aluminum, and fully machined billet aluminum configurations. Most follow the Mark IV blueprint and accept original equipment–spec parts such as cylinder heads, oil pans, starters, and water pumps, but there are also “mutant” variety blocks with specialized features such as spread oil pan rails for long-stroke clearance, raised cam bore locations, and spread-bore blocks with a bore spacing of 4.900, 5.000, 5.200 inches or more (stock bore spacing is 4.840 inches).

Brodix, Inc.

Long known as a leader in the field of high-performance and racing aluminum cylinder heads, Brodix also manufactures A-356 virgin aluminum blocks for the big-block Chevy in a variety of stock-replacement or custom configurations. They feature splayed billet main caps made of 1044 steel and coated with black oxide, and additional head bolt lugs in the deck area provide additional head gasket clamping. The main bulkheads have been strengthened and the lifter valley includes reinforcing ribs to prevent flex under high-power, high-load conditions. The lifter oil gallery is easily restricted from the front using Brodix oil restrictors (available separately), and a plug kit is provided with these blocks.

The 8B 2000A block is available in short-deck (9.800 inches) or tall-deck (10.200 inches) versions, and is a direct replacement for conventional Mark IV blocks with 4.840-inch bore spacing and standard cam location. It accepts either stock or stroker oil pans. The cast-iron sleeves, available in two bore sizes (4.480 or 4.590 inches), are retained by 1/4-inch registers, and may be bored up to 4.600 inches (small-bore sleeves are available on request).

The 8B 2000C block features a .400- inch raised cam location and your choice of 9.800-, 10.200-, or 10.700-inch deck heights. The 8B 2100C block adds your choice of 11.100- or 11.200-inch deck heights, and the 8B 2200C block can be had in 11.500- or 11.625-inch deck heights.

The 8B 2000 series blocks may be ordered with conventional big-block Babbitt cam bearings, 50-mm roller bearings, 55-mm roller bearings, or 60-mm Babbitt bearings. Lifter bores are standard Chevrolet (.842 inch) or Chrysler (.903 inch) with larger sizes available. Stroke clearance is 4.750 inches with standard cam location blocks and 5.000 inches with the raised-cam blocks (additional machining required).

If a mountain motor Rat is in your sights, you want to take a good look at Brodix’s fully CNC machined 5000 series aluminum blocks with 5.000-inch bore spacing. These blocks feature a 1.000-inch raised cam location and your choice of cam bearing and lifter sizes. Deck heights are 11.200 or 11.625 inches, and all are designed for dry sump oiling systems. Bore size as delivered is 4.585 inches, and the thick wall sleeves allow bore sizes up to 4.700 inches, which, combined with a 5.000-inch-stroke crank, gets you 694 ci of tire-frying power! Of course, Brodix also manufactures 5.000-inch bore space spread port cylinder heads that are the perfect match for these blocks.

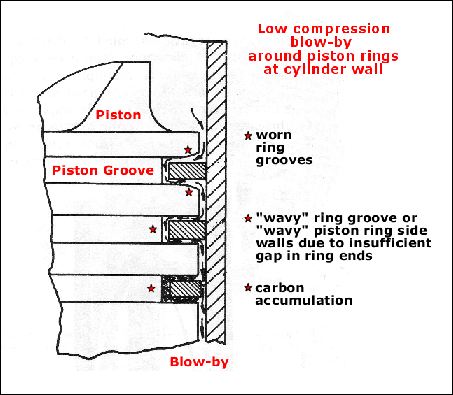

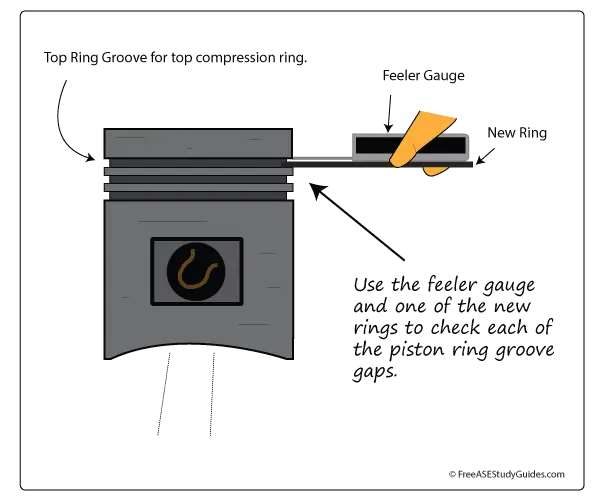

CN Blocks

CN Blocks produces fully CNC machined aluminum blocks whittled out of a solid chunk of forged aluminum. According to CN Blocks, its billet aluminum blocks have more than 36-percenthigher tensile strength than a cast 356 aluminum block, with a yield strength that is 66 percent greater than cast blocks. As a result of the greater material strength of the billet aluminum, you can expect less cylinder liner distortion and a better piston ring seal, reducing blow-by and producing more force on the crankshaft and improved horsepower.

Brodix 8B 2000C tall-deck block. (Photo Courtesy Brodix)

Brodix 8B 5000C tall-deck block featuring 5.0-inch bore spacing and a 1-inch raised cam bore. (Photo Courtesy Brodix)

Obviously, the cost to produce a 100-percent CNC-machined block is far higher than traditional cast-aluminum blocks, but many top racers in the IHRA Pro Stock and Pro Mod ranks rely on these whittled aluminum gems when the need for maximum performance outweighs capital expenditure concerns. Most of these blocks are available as either “dry” or “wet” blocks. Dry blocks have no coolant passages and are used only for drag racing where the short running time does not require coolant circulation. You can custom order a block from CN Blocks to just about any specs you provide, but the following are some of its standard offerings.

A splayed-bolt main cap block is available in four configurations: a traditional Mark IV replacement-style block with standard 4.840-inch bore spacing, 9.8-inch deck height, and stock cam location; a tall-deck (10.2 inches) block with raised cam; a 4.900-inch-bore-spacing block with raised cam; and a 5.000-inchbore- spacing block with raised cam location.

Cross Bolt blocks are intended for serious blower racers utilizing big-block Chevy-based engines. All five aluminum main caps are cross-bolted using 9/16- inch tool steel main studs and 1/2-inch side bolts; a custom Keith Black (KB) Olds or CN Blocks wide oil pan must be used with these blocks. Cam bearing sizes are standard BBC, 2.125 inches (460 Ford), 55 mm, 60 mm, or 65 mm. You also have your choice of lifter bores: .842, .904, .936, 1.00, or 1.062 inches. Blocks may be ordered with or without a distributor hole for racers who use a dry sump oil system and front-drive distributor.

The 1040Y can be used as a replacement block for KB Olds or Arias New Century blocks, and the 1041Y raises the cam .400 inch for larger cam cores and better pushrod geometry. The 1050Y and 1070Y feature 5.000-inch bore spacing, and the 1050Y features spread .160-inch mains and a +.400-inch-high cam. The 1070Y raises the cam +1.0 inch, and these blocks allow you to use bores of 4.600 to 4.750 inches. Dual starter bosses allow the use of full kick-out oil pans with leftmounted starters.

Dart Machinery

Founded by Richard Maskin, one of NHRA Pro Stock’s pioneers, Dart has been making outstanding blocks for Rat racers for years. Most Dart blocks for big-block Chevy engines are patterned after the Mark IV block, but are designed for hardcore racing, addressing all the weaknesses of the factory castings. Extra-thick decks, siamesed bores, enlarged water jackets, priority main oiling, four-bolt main caps, and finished main bearing bores and cam tunnels make it easier to build superior racing and performance engines.

The Big M block is available with deck heights of 9.800 and 10.200 inches, and bore sizes of 4.250, 4.500, and 4.600 inches. The priority main oil system features a stepped main oil gallery (9/16 to 1/2 to 7/16 inch) to increase the flow of oil to the crank at high engine speed (RPM), and the front oil crossover eliminates internal oil leaks around the distributor shaft. There are two slotted head stud bosses on both sides of the lifter valley so you can use studs instead of hardto- install bolts to take the place of the “missing” head bolts.

For mountain motor addicts, CN Blocks makes a series of 5.300-inch-bore-space billet aluminum blocks. These blocks are designed for a minimum bore size of 5.000 inches, yielding displacements in excess of 900 ci. The 5300 series features a 1.917-inch raised cam bore machined for 65- or 70-mm cam bearings and they may be ordered with head-bolt patterns to fit Alan Johnson, Sonny’s GM Hemi, or Sonny’s GM Wedge 5.3-inch cylinder heads. (Photo Courtesy CN Blocks)

CN Blocks’ Cross Bolt billet aluminum blocks are intended for serious blower racers who need the ultimate in bottomend strength. They are available with standard 4.840- or 5.000-inch bore spacing and cam bore locations up to +1.000-inch raised. (Photo Courtesy CN Blocks)

The Dart Big M Sportsman block is available with deck heights of 9.800 and 10.200 inches, and is fitted with ductile iron fourbolt main bearing caps. (Photo Courtesy Dart Machinery)

Manufactured from virgin C355-T61 aerospace aluminum alloy, Dart’s Aluminum Big M block is a conventional Mark IV configuration that retains all production dimensions for compatibility with standard components. (Photo Courtesy Dart Machinery)

Dart’s Race Series tall-deck block is available with deck heights up to 11.100 inches. (Photo Courtesy Dart Machinery)

Most big-block Chevys used in racing cars are mounted with a 1/4-inch-thick mid-plate between the engine block and the transmission, and require longerthan- stock bellhousing dowel pins. The stock diameter is .619 to .621 inch, and some racers try to use common 5/8-inch (.625-inch) dowels. That’s going to require a pretty big hammer, and may damage the block from the excessive force needed to drive them in. These dowel pins from Brodix and Speedway Motors (PN 91025840) are the correct diameter and are long enough for use with motor plates.

Big Ms are fitted with billet-steel fourbolt main caps for ultimate bottom-end strength, and they are machined on precision CNC equipment to ensure quality and to eliminate the need for additional machining. Another nice feature is the use of coated cam bearings, which have an annular groove on the back side and three oil holes to better lubricate the cam journals. The Big M Sportsman block was designed to be an even more affordable version of the Big M block, and is fitted with ductile iron four-bolt main bearing caps. All other features of the Big M are retained in the Big M Sportsman blocks.

The Dart Race Series block is for racers wanting to build real mountain motors—up to 763 ci—and it offers crank-to-deck dimensions of 10.600 and 11.100 inches, nearly 1 inch taller than the factory tall-deck block. The camshaft is raised .600 inch above the stock location for improved connecting rod clearance with stroker cranks, and the block is available with either 4.840- (standard big-block) or 4.900-inch bore spacing. The oil pan rails are spread to increase clearance for the connecting rods and crankshaft counterweights, and it can be ordered with various lifter locations and provisions for symmetrical or siamesedport cylinder heads. You can specify 2.125-inch (standard), 55-mm, or 60-mm roller cam bearings, and the lifter bosses can be machined to accommodate a variety of valve layouts with a choice of .842- (standard Chevrolet), .904-, .937-, or 1.063-inch-diameter lifters, with bushings for either standard tie-bar or keyed lifters. This is a good foundation for one very serious racing engine.

Dart also makes lightweight (140- pound) aluminum blocks that feature extra strengthening in critical areas, increased displacement capacity, true priority main oiling, and precision CNC machining. Dart’s Aluminum Big M block is a conventional Mark IV configuration that retains all production dimensions for compatibility with standard components. It is manufactured from virgin C355-T61 aerospace aluminum alloy and machined in-house to ensure absolute quality. Dart aluminum blocks feature ductile iron sleeves with extra-thick walls to promote excellent ring seal. Reinforcing ribs strengthen the lifter valley and bellhousing flange, and inboard head stud bosses provide additional head gasket sealing. The priority main oiling system delivers oil directly to the crankshaft bearings to enhance reliability at high engine speeds. These blocks include coated cam bearings, freeze plugs, and dowels.

Donovan Engineering

Donovan Engineering has been making aluminum racing engine blocks for more than 30 years, and each Donovan block is cast from strontium-modified B356 alloy with a special heat treat. These blocks may be ordered with full-water jackets, half-water jackets, or solid for drag racing use only.

Merlin III cast-iron blocks are available in 9.800- and 10.200-inch versions, and can be ordered with nodular iron or billet steel splayed-bolt main caps. All versions include priority main oiling, expanded water jackets for improved cooling of the siamesed bores, and .600-inch-thick decks with blind tapped bolt-holes. (Photo Courtesy World Products)

Cast from 357-A6 aluminum, Merlin X alloy blocks feature horizontal reinforcing ribs along the sides of the block and cross ribs in the lifter valley to stiffen the engine. (Photo Courtesy World Products)

The standard Donovan block weighs 140 pounds and is a traditional Mark IV replacement with oil filter and fuel pump bosses, standard motor mount and cam locations, and a custom 3/8-inch-wider oil pan rail. It is available in any deck height up to 10.300 inches, and with stock 4.840-inch bore spacing or custom 4.900- or 5.000-inch bore spacing. Chevy lifter bores (.842 inch) are standard, but any lifter bore diameter may be specified. For you marine types, you can even order the block anodized for corrosion resistance.

If you’re headed for the mountains, you can specify one of Donovan’s raised-cam blocks with options of .400- or 1.0-inch raised-cam location, 4.840- or 5.000-inch bore spacing, and deck heights up to 12.000 inches. These blocks all feature a 3/4-inch wider-than-stock oil pan rail to clear long strokes. Weight is up to 180 pounds, depending on the deck height and water jacket configuration desired.

Merlin (World Products)

As one of Bill Mitchell’s innovative companies, World Products has been producing its Merlin line of big-block Chevy engine blocks for years. They also follow the original Mark IV pattern in terms of parts fitment, and accept Mark IV spec cranks, heads, cams, oil pans, timing covers, etc. World’s current version of the Merlin block is the Merlin III, easily identified by the name cast in 1-inch-tall letters on the front of the block.

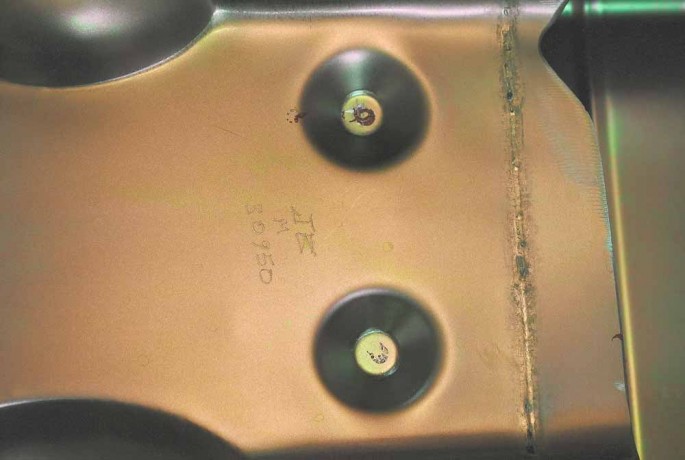

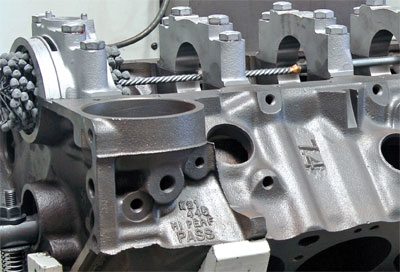

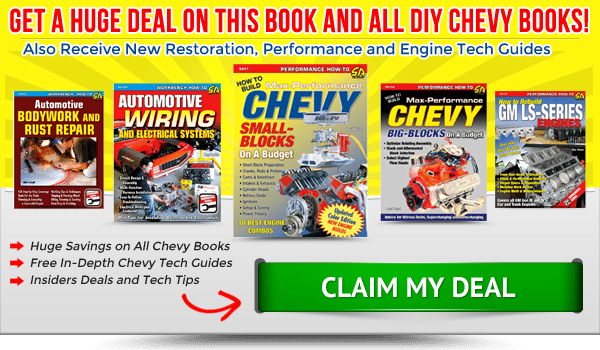

This 454 block has the last three digits of the casting number, 445, repeated on the block just above the oil filter mount, along with the date code K 2 1, plus the words “Hi Perf” and “PASS.” The “7.4” between the two freeze plug holes tell us it’s 454 (7.4 liters) with an original bore size of 4.250 inches. K 2 1 indicates that it was cast on November 2 in 1981 (K = November, 2 = day of the month, 1 = the last digit of the decade). How do you know it’s 1981 from the single digit “1”? In 1971 Chevy had not yet started using the metric designation 7.4, and by 1991 it would have been a Gen V block, which you can tell it’s not from the recessed oil filter boss and the 1-3/4-inch freeze plug bores. “Hi Perf” and “PASS” means it could be either a two- or four-bolt main block; you just have to look to see which one it is. Nearly all big-blocks have both Hi Perf and PASS cast into them, so ignore that.

Merlin III blocks are available in 9.800- and 10.200-inch (tall deck) versions, and can be ordered with nodular iron or billet steel splayed-bolt main caps. All versions include priority main oiling, expanded water jackets for improved cooling of the siamesed bores, and .600-inch-thick decks with blind tapped bolt-holes to prevent coolant leakage. The bottom end accepts standard Mark IV oil pans, and the crankcase has been clearanced to accept strokes up to 4.375 inches (up to 4.750 inches in the tall-deck blocks). The blocks are available in three bore sizes: 4.240, 4.490, and 4.590 inches, allowing you to finish hone the bores to your specs. Maximum bore size is 4.625 inches, and the minimum cylinder wall thickness is .240 inch at 4.600 inches.

World also sells its blocks fully raceprepped to your specifications, with finished bores and deck heights, cam bearings installed, etc., allowing you to do a fit-check and assemble the short block with no further machining required. Merlin blocks come with indexed stock location and diameter (.8437 inch) lifter bores. Approximate weight of these sturdy iron blocks is 270 pounds.

If an aluminum block is what you want, the Merlin X offers all the same features of the Merlin series in a 140-pound package. Cast from 357-A6 aluminum, these alloy blocks feature horizontal reinforcing ribs along the sides of the block and cross ribs in the lifter valley to stiffen the engine. Recommended maximum bore size is 4.600 inches, due to the use of cast-iron sleeves. The lubrication system features an integral boss for front-feed and a boss for rear scavenge. The rear main cap has provisions for a wet sump pump, and the block is also drilled for dry sump valley scavenge lines with cross-feed lines between left and right lifter oil galleries. The splayed-bolt main caps are made of 1045 alloy steel, attached with premium APR main studs and bolts.

Block Casting Dates

Big-block casting dates are generally located on the rear ledge of the block on the passenger side, although occasionally you find these dates on the driver’s side or even on the side of the block near the freeze plugs. The code is a simple alphanumeric code such as “C 12 7.” The first letter stands for the month of the year (A = January, B = February, etc.), so C would be March. The second numeral is the day of the month, and the last is the year of the decade. Which decade is not always clear, though it’s pretty easy to decipher for the big-block Chevy.

Early Mark IV–style big-blocks were not produced until 1965, and by 1975 they were only found in trucks. By the late 1970s, big-blocks had the displacement in liters cast into the sides of the block, for instance, 7.0 (427 ci), 7.4 (454 ci), or 8.2 (502 ci), so the decade your block was produced is usually pretty easy to decipher. Gen V blocks were only produced from 1991 through 1996, and Gen VI blocks from 1996 to 2000.

Going back to our mystery “C 12 7” code, the block was cast (not necessarily assembled until later) on March 12 of some year ending in “7.” If it were 1967, the block would accept an old-style canister oil filter housing, and might be a 396 (4.094-inch bore) or 427 (4.250-inch bore). If it were 1977, it would be 454 truck block with a 4.250-inch bore. By the 1980s, big-blocks had the engine size (in liters) cast into the side of the block, so a 1987 block from a truck would have “7.4” cast in. Simple, no?

Written by Tom Dufur and Posted with Permission of CarTechBooks

![7620_2[583x].jpg](/proxy.php?image=http%3A%2F%2Fwww.grumpysperformance.com%2Fjuly2017%2F7620_2%5B583x%5D.jpg&hash=5931892943d24f9505466692c10aa541)