lozer said:Hello Grumpy,

I've seen that your an engine guru and was wondering if you could point me in the right direction.

Im building a 383 out of my 89 l98 and i can either go with a 9.4:1 cr or a 10.5:1 cr depending on which pistions i use.

Specs are scap 9000 crank(400) with 5.7" scat rods.

pocket ported and polished 113 heads, lpe 219 cam and super ram intake.

Now the question is is that 1 point going to make this motor less reliable and is it worth the power difference? This motor is being used for auto x mainly.

Thanks in advance for any advice.

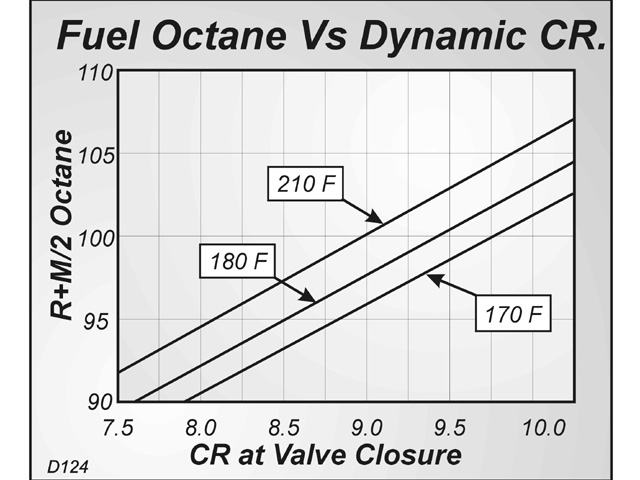

your potentially looking at a difference of about 3% more torque with the higher compression ratio and with that cam, if you can stay out of detonation ,

http://www.lingenfelter.com/mm5/merchan ... YQuVcocCjY

but with pump gas octane fuel the 9.4:1 ratios more likely to work the best in that application

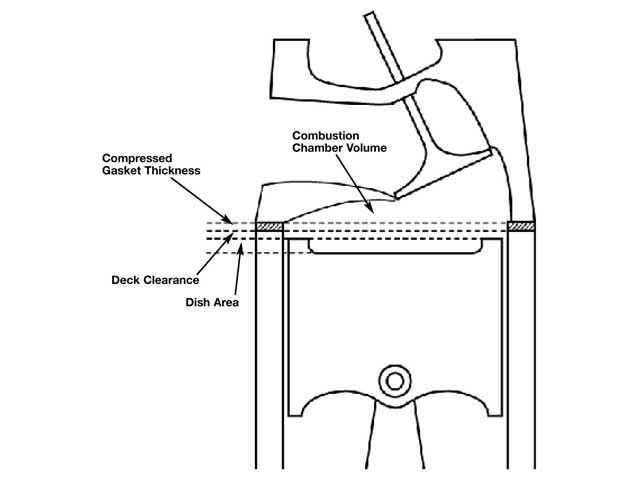

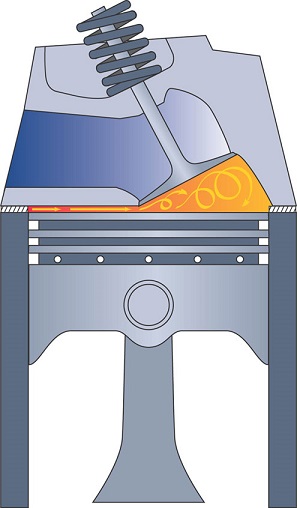

OK, first fact! the piston can,t compress anything until both valves fully seat, static compression is based on the volume compressed between the piston starting at bottom dead center and compressing everything into the combustion chamber , head gasket quench,volume, that remains when the pistons at TDC

valve seat and back face angles ,valve diameter and valve lift and duration effect the flow thru the curtain area

keep in mind that valve may be forced off its seat, too full lift and re-seating 50 plus TIMES A SECOND at near 5500 rpm, so theres very little TIME for gases to move through the very restrictive space between the valve seat and valve edge

Calculating the valve curtain area

The following equation mathematically defines the available flow area for any given valve diameter and lift value:

Area = valve diameter x 0.98 x 3.14 x valve lift

Where 3.14 = pi (π)

For a typical 2.02-inch intake valve at .500-inch lift, it calculates as follows:

Area = 2.02 x 0.98 x 3.14 x 0.500 = 3.107 square inches

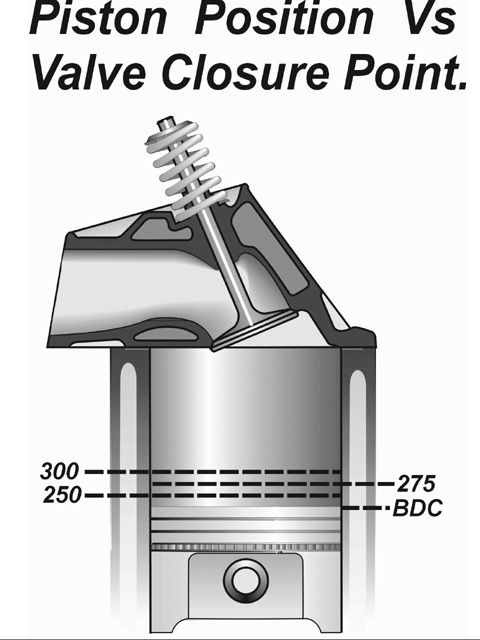

dynamic compression is the ONLY compression the engine ever sees or deals with, it measure compression from the time both valves seal the chamber,and that is always lower simply because the valves always seat after the piston is already moving upwards on the compression stroke.

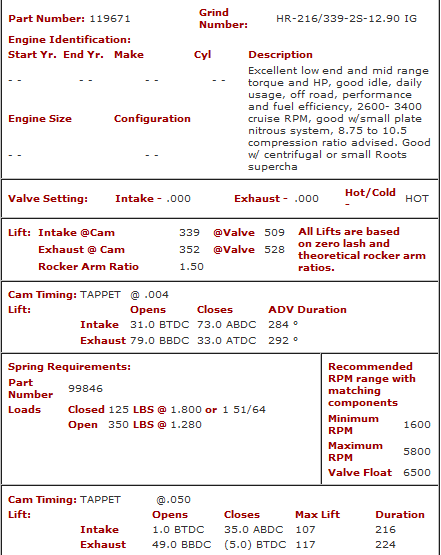

if we look at the crane cam I linked earlier you see the valves seat at about 75 degrees after bottom dead center

RELATED INFO YOU MIGHT NEED

viewtopic.php?f=55&t=2718&p=41142&hilit=octane+calculate#p41142

viewtopic.php?f=52&t=4299

RELATED INFO

viewtopic.php?f=52&t=727

viewtopic.php?f=52&t=4299

viewtopic.php?f=50&t=8960&p=31942&hilit=+octane+calculate#p31942

viewtopic.php?f=50&t=208&p=16848&hilit=+octane+calculate#p16848

viewtopic.php?f=44&t=6897&p=22516&hilit=+octane+calculate#p22516

viewtopic.php?f=52&t=4081&p=13146&hilit=+octane+calculate#p13146

Last edited by a moderator: