These are not the typical wheels y'all would use.

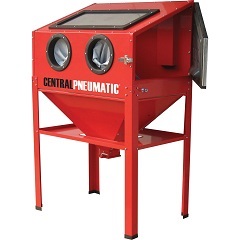

I've started the restoration of my artillery wheels. I have 10 or 12 of them. All but 2 need to be cleaned up, sanded, and painted. I know it's not a smart thing to do to sand blast them. Sand blasting would hurt the wood. I'm told to media blast them instead. So I went to Home Depot and they have a siphon tube used for media blasting but no media of any type. They didn't even know what I was talking about.

My question is, is it worth the expense? I looked up prices for media at the harbor freight site. My thought is that I would lose any media I used and that it would take a bunch to clean the wheels. No doubt I would save a lot of time but is it worth the expense? Would plastic or walnut media hurt the spokes?

Here's what I've done to the first wheel. All the wood sanding was done by hand. The metal was cleaned using a wire wheel on the outside edges and, believe it or not, a pocket knife between the spokes. The knife was quicker than the wire wheel.

I've started the restoration of my artillery wheels. I have 10 or 12 of them. All but 2 need to be cleaned up, sanded, and painted. I know it's not a smart thing to do to sand blast them. Sand blasting would hurt the wood. I'm told to media blast them instead. So I went to Home Depot and they have a siphon tube used for media blasting but no media of any type. They didn't even know what I was talking about.

My question is, is it worth the expense? I looked up prices for media at the harbor freight site. My thought is that I would lose any media I used and that it would take a bunch to clean the wheels. No doubt I would save a lot of time but is it worth the expense? Would plastic or walnut media hurt the spokes?

Here's what I've done to the first wheel. All the wood sanding was done by hand. The metal was cleaned using a wire wheel on the outside edges and, believe it or not, a pocket knife between the spokes. The knife was quicker than the wire wheel.