I can't but help, but remember a poem that I heard when I was younger, when I talk to some guys I know about the issues they have had while assembling an engine!

The Blind Men and the Elephant

John Godfrey Saxe (1816-1887)

It was six men of Indostan

To learning much inclined,

Who went to see the Elephant

(Though all of them were blind),

That each by observation

Might satisfy his mind.

It was six men of Indostan

To learning much inclined,

Who went to see the Elephant

(Though all of them were blind),

That each by observation

Might satisfy his mind.

The First approached the Elephant,

And happening to fall

Against his broad and sturdy side,

At once began to bawl:

"God bless me! but the Elephant

Is very like a WALL!"

The Second, feeling of the tusk,

Cried, "Ho, what have we here,

So very round and smooth and sharp?

To me 'tis mighty clear

This wonder of an Elephant

Is very like a SPEAR!"

The Third approached the animal,

And happening to take

The squirming trunk within his hands,

Thus boldly up and spake:

"I see," quoth he, "the Elephant

Is very like a SNAKE!"

The Fourth reached out an eager hand,

And felt about the knee

"What most this wondrous beast is like

Is mighty plain," quoth he:

"'Tis clear enough the Elephant

Is very like a TREE!"

The Fifth, who chanced to touch the ear,

Said: "E'en the blindest man

Can tell what this resembles most;

Deny the fact who can,

This marvel of an Elephant

Is very like a FAN!"

The Sixth no sooner had begun

About the beast to grope,

Than seizing on the swinging tail

That fell within his scope,

"I see," quoth he, "the Elephant

Is very like a ROPE!"

And so these men of Indostan

Disputed loud and long,

Each in his own opinion

Exceeding stiff and strong,

Though each was partly in the right,

And all were in the wrong!

now maybe I'm the one whos got the wrong concept, here,

but I learned early in the process ,

that making mistakes is both very expensive and wastes time,

Time and cash, you could better spend doing the job correctly AFTER asking someone with a great deal more experience for advice,

and that when your not sure, or might even vaguely suspect your NOT doing something correctly,

or your NOT getting the results you expect,.....

its best to STOP and ASK DETAILED QUESTIONS ,

and follow up those questions with a general question, like

" is there anything I might be over-looking or any bits of related info ,

Can, you can tell me about the tools or parts that might be useful to know about or use or suggest a better way too do this?"

I recently was asked to diagnose a problem that could have easily been avoided.

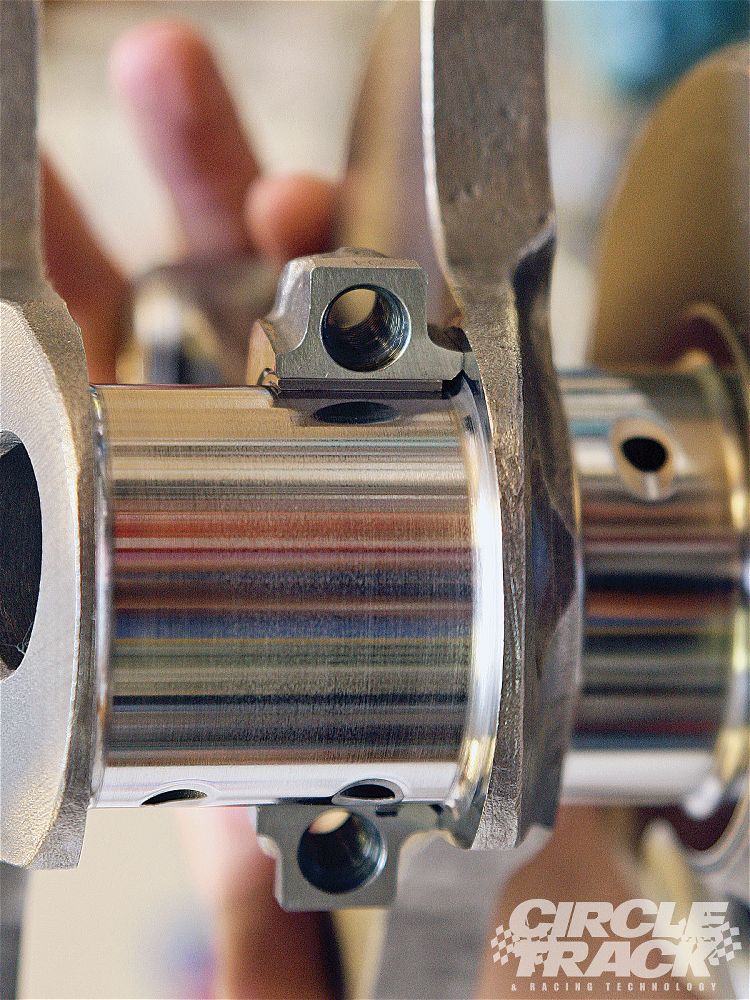

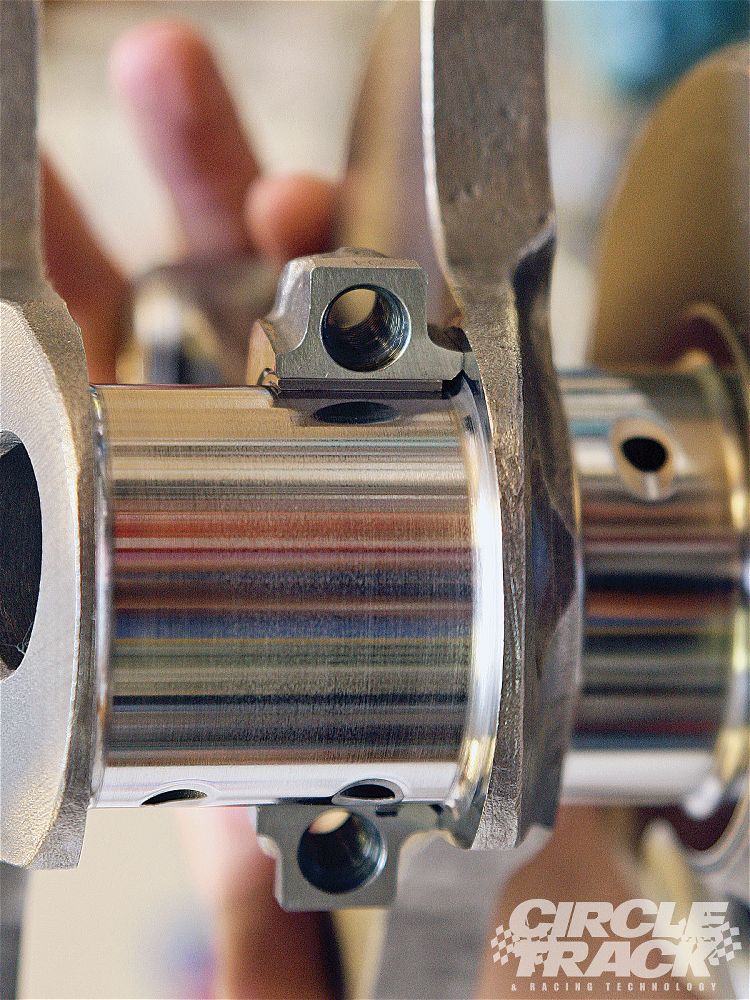

one of the neighbors kids (about mid 20s ) was assembling a 454 chevy hes installing in a dodge dart as the original engine is trash, during the engine assembly he found that he could not get it to easily rotate once he had installed 4 connecting rods.once his dad saw him using a long breaker bar on the crank to get it to rotate and almost tip over the engine stand he suggested I get a phone call. and yeah! he damaged the bearings but we managed to save the crank,(yes he needed to buy new bearings) because he had managed to install the connecting rods on a couple cylinders with the rods facing the wrong direction and with the pistons not having a dome that faces the outer block wall it was not obvious to him as it was his first engine build. now I can easily sympathize with the younger guy here , simply because I remember running into a similar issue when I was about 16 years old , and I foolishly also ruined a set of bearings , but my mentor at the time took the time to help dis-assemble and point out how I'd screwed up!

yeah! you tend to remember your own screw-ups but the key is in not repeating them and learning how to proceed correctly

http://garage.grumpysperformance.co...ting-resistance-to-look-for.11312/#post-51472

http://garage.grumpysperformance.co...tion-of-crank-durring-short-blk-assembly.852/

http://garage.grumpysperformance.com/index.php?threads/can-i-get-it-polished.9214/#post-43456

http://garage.grumpysperformance.co...earances-and-journal-surface.9955/#post-38385

http://forum.grumpysperformance.com/viewtopic.php?f=53&t=2726&p=7077&hilit=plastigauge#p7077

http://forum.grumpysperformance.com/viewtopic.php?f=59&t=1390&p=3073&hilit=precision#p3073

http://garage.grumpysperformance.co...-crane-and-engine-stand-mods-accesories.3724/

http://garage.grumpysperformance.com/index.php?threads/main-cap-fit-in-block.5945/#post-34251

it might also be a good place to mention a solid engine stand is a wise investment

HERES A PICTURE OF AN ENGINE STAND THATS OWNED BY A GUY THAT FEELS A FAR MORE RIGID STAND IS A BIGGER ADVANTAGE THAN HAVING IT FOLD UP SMALLER FOR EASY STORAGE, AND YES HAVING A SHOP WELDER IS A GREAT IDEA< AS IT GIVES YOU OPTIONS

The Blind Men and the Elephant

John Godfrey Saxe (1816-1887)

It was six men of Indostan

To learning much inclined,

Who went to see the Elephant

(Though all of them were blind),

That each by observation

Might satisfy his mind.

It was six men of Indostan

To learning much inclined,

Who went to see the Elephant

(Though all of them were blind),

That each by observation

Might satisfy his mind.

The First approached the Elephant,

And happening to fall

Against his broad and sturdy side,

At once began to bawl:

"God bless me! but the Elephant

Is very like a WALL!"

The Second, feeling of the tusk,

Cried, "Ho, what have we here,

So very round and smooth and sharp?

To me 'tis mighty clear

This wonder of an Elephant

Is very like a SPEAR!"

The Third approached the animal,

And happening to take

The squirming trunk within his hands,

Thus boldly up and spake:

"I see," quoth he, "the Elephant

Is very like a SNAKE!"

The Fourth reached out an eager hand,

And felt about the knee

"What most this wondrous beast is like

Is mighty plain," quoth he:

"'Tis clear enough the Elephant

Is very like a TREE!"

The Fifth, who chanced to touch the ear,

Said: "E'en the blindest man

Can tell what this resembles most;

Deny the fact who can,

This marvel of an Elephant

Is very like a FAN!"

The Sixth no sooner had begun

About the beast to grope,

Than seizing on the swinging tail

That fell within his scope,

"I see," quoth he, "the Elephant

Is very like a ROPE!"

And so these men of Indostan

Disputed loud and long,

Each in his own opinion

Exceeding stiff and strong,

Though each was partly in the right,

And all were in the wrong!

now maybe I'm the one whos got the wrong concept, here,

but I learned early in the process ,

that making mistakes is both very expensive and wastes time,

Time and cash, you could better spend doing the job correctly AFTER asking someone with a great deal more experience for advice,

and that when your not sure, or might even vaguely suspect your NOT doing something correctly,

or your NOT getting the results you expect,.....

its best to STOP and ASK DETAILED QUESTIONS ,

and follow up those questions with a general question, like

" is there anything I might be over-looking or any bits of related info ,

Can, you can tell me about the tools or parts that might be useful to know about or use or suggest a better way too do this?"

I recently was asked to diagnose a problem that could have easily been avoided.

one of the neighbors kids (about mid 20s ) was assembling a 454 chevy hes installing in a dodge dart as the original engine is trash, during the engine assembly he found that he could not get it to easily rotate once he had installed 4 connecting rods.once his dad saw him using a long breaker bar on the crank to get it to rotate and almost tip over the engine stand he suggested I get a phone call. and yeah! he damaged the bearings but we managed to save the crank,(yes he needed to buy new bearings) because he had managed to install the connecting rods on a couple cylinders with the rods facing the wrong direction and with the pistons not having a dome that faces the outer block wall it was not obvious to him as it was his first engine build. now I can easily sympathize with the younger guy here , simply because I remember running into a similar issue when I was about 16 years old , and I foolishly also ruined a set of bearings , but my mentor at the time took the time to help dis-assemble and point out how I'd screwed up!

yeah! you tend to remember your own screw-ups but the key is in not repeating them and learning how to proceed correctly

http://garage.grumpysperformance.co...ting-resistance-to-look-for.11312/#post-51472

http://garage.grumpysperformance.co...tion-of-crank-durring-short-blk-assembly.852/

http://garage.grumpysperformance.com/index.php?threads/can-i-get-it-polished.9214/#post-43456

http://garage.grumpysperformance.co...earances-and-journal-surface.9955/#post-38385

http://forum.grumpysperformance.com/viewtopic.php?f=53&t=2726&p=7077&hilit=plastigauge#p7077

http://forum.grumpysperformance.com/viewtopic.php?f=59&t=1390&p=3073&hilit=precision#p3073

http://garage.grumpysperformance.co...-crane-and-engine-stand-mods-accesories.3724/

http://garage.grumpysperformance.com/index.php?threads/main-cap-fit-in-block.5945/#post-34251

it might also be a good place to mention a solid engine stand is a wise investment

HERES A PICTURE OF AN ENGINE STAND THATS OWNED BY A GUY THAT FEELS A FAR MORE RIGID STAND IS A BIGGER ADVANTAGE THAN HAVING IT FOLD UP SMALLER FOR EASY STORAGE, AND YES HAVING A SHOP WELDER IS A GREAT IDEA< AS IT GIVES YOU OPTIONS

Last edited: