underpressure

Member

Hi Folks, this is the parts list for my current build.

350 chevy 4 bolt block bored to 4.030

scat ultralight crank stroked to 3.562 producing 363 c.i.

crower titanium rods, length 5.950

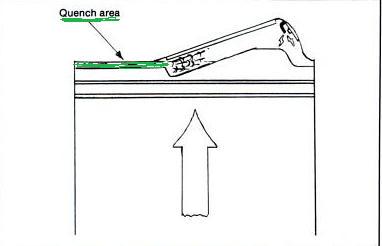

mahle flat top pistons w/ 5cc valve reliefs

afr 195 eliminator heads 65cc pocket w/ 2.05 i.v. 1.65 e.v.

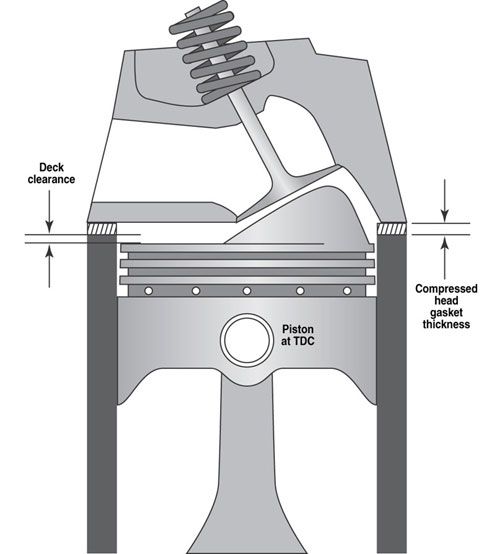

crane 1.5 roller rockers. fel-pro head gaskets .041 thick

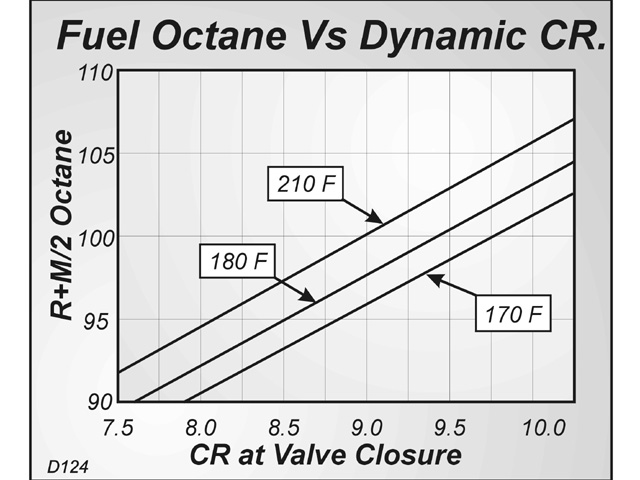

compression comes in right @ 10.46

the headers are ceramic coated block hugger 2 1/2'' & 1 5/8''

fuel supply is a edelbrock pro-flo 2 victor jr style manifold,

the electronics i'm using is the fast e-z efi multi port with 35lb injectors.

I'm planning on bolting this into a 3100lb 66' stingray coupe,

the car has a richmond 6 speed close ratio road race trans with a 2.77 1st and .62 overdrive. rear diff is 3.73 with a 25'' tall tire.

Opperating range 1800-6300 rpm.

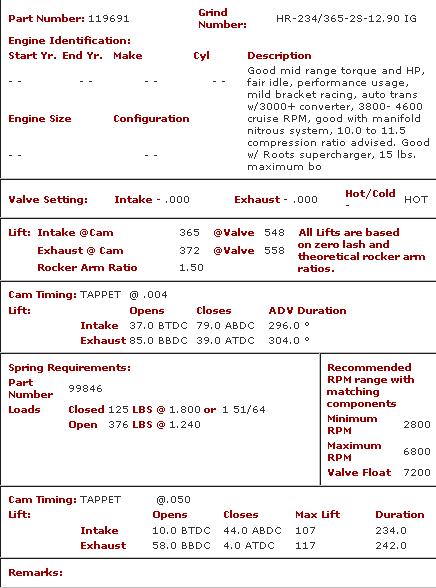

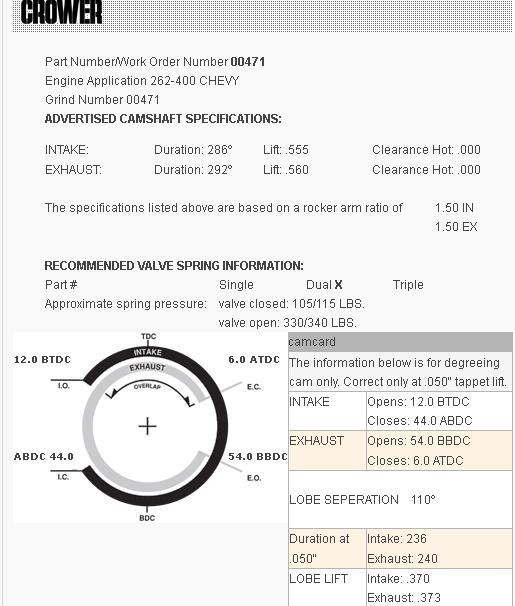

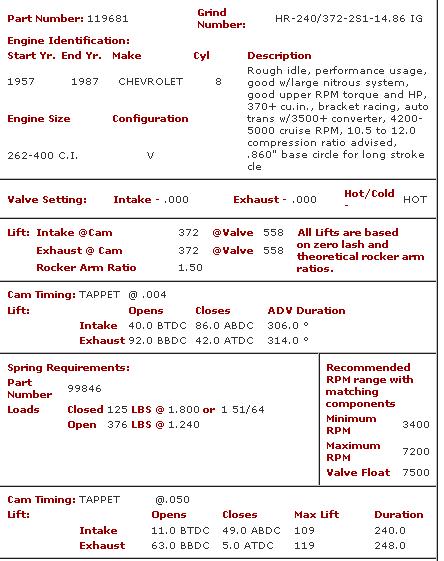

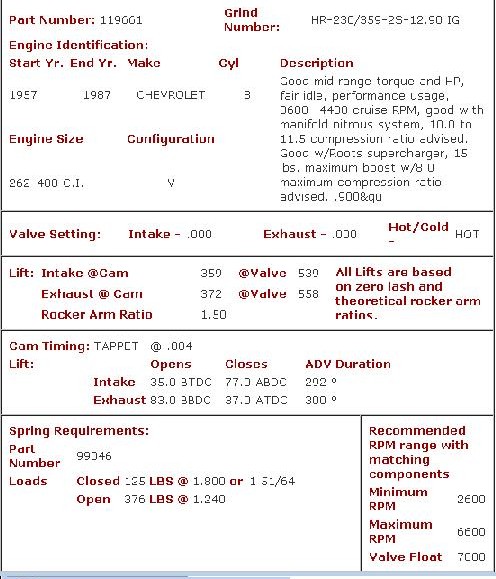

Now we get around to the camshaft......any body got a bottle!

I should first outline the usage for the car, basically it's going to be for weekend trips and an occasional industrial parking lot flogging! I'm also looking to get some kind of mileage out of it, and make good power, so i'm not trying to achieve max dyno numbers, just want good power and instant rev's. still torn between a solid roller and a "short travel" hydraulic roller, just to keep the oil in the pan in high rpm's. It's similar to the 96' Lt4 but with more c.i., superior electronics, more injector, and better heads.

Well Folks...that pretty much sums it up! So if there's anybody that

would like to trade this for a new LS7?....oh sure! or can help me with some cam knowledge i surely would appreciate it! Thanks'.

Underpressure.

350 chevy 4 bolt block bored to 4.030

scat ultralight crank stroked to 3.562 producing 363 c.i.

crower titanium rods, length 5.950

mahle flat top pistons w/ 5cc valve reliefs

afr 195 eliminator heads 65cc pocket w/ 2.05 i.v. 1.65 e.v.

crane 1.5 roller rockers. fel-pro head gaskets .041 thick

compression comes in right @ 10.46

the headers are ceramic coated block hugger 2 1/2'' & 1 5/8''

fuel supply is a edelbrock pro-flo 2 victor jr style manifold,

the electronics i'm using is the fast e-z efi multi port with 35lb injectors.

I'm planning on bolting this into a 3100lb 66' stingray coupe,

the car has a richmond 6 speed close ratio road race trans with a 2.77 1st and .62 overdrive. rear diff is 3.73 with a 25'' tall tire.

Opperating range 1800-6300 rpm.

Now we get around to the camshaft......any body got a bottle!

I should first outline the usage for the car, basically it's going to be for weekend trips and an occasional industrial parking lot flogging! I'm also looking to get some kind of mileage out of it, and make good power, so i'm not trying to achieve max dyno numbers, just want good power and instant rev's. still torn between a solid roller and a "short travel" hydraulic roller, just to keep the oil in the pan in high rpm's. It's similar to the 96' Lt4 but with more c.i., superior electronics, more injector, and better heads.

Well Folks...that pretty much sums it up! So if there's anybody that

would like to trade this for a new LS7?....oh sure! or can help me with some cam knowledge i surely would appreciate it! Thanks'.

Underpressure.