2Loose

reliable source of info

I originally built and put this truck on the road ten years ago. I put in a used '70 Olds 455 and it eventually developed problems and I had to pull it and rebuild it. But the original front steering setup I put on it had a bad bump steer problem that I had to resolve.

I had mounted a steering box 12" in front of the front axle. The drag link ran straight back to the steering arm from the pitman arm. It turned out that due to that setup, the arc of the end of the drag link at the steering arm was rather sharp, and a 2" upward movement in the axle resulted in an 1/8" forward movement in the steering arm, causing the truck to head into the oncoming traffic, the harder the bump the worse it got, definitely not a good thing!!!

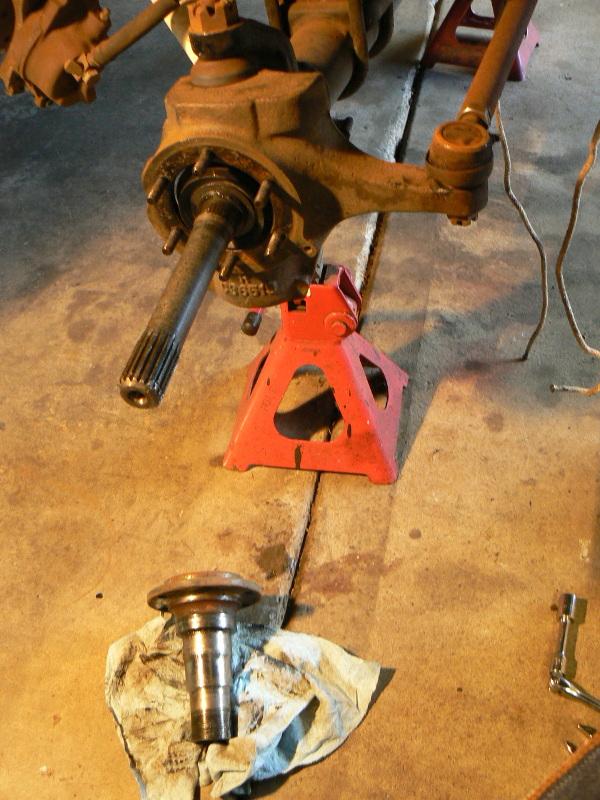

So I finally put the front end up on stands and pulled it apart....l

And fabricated a new steering arm to put on the right side steering knuckle of the front axle, converting it to a cross steer setup.....

I sent the right side steering knuckle to a machine shop to get it drilled and tapped accurately for the new steering arm (well, more accurately than I am capable of.....). While I am waiting for the machine shop, I notched the left side frame rail for clearance for the reoriented pitman arm and the ball joint nut:

I cut the original 12" long drag link in half and prepped the two pieces to insert and weld into a longer piece of heavy wall pipe. The final length will be around 36", exact length to be determined when the right side of the axle is back together with the new steering arm on it...

Our "Old Dudes Racing" shop has a Smithy, a small lathe and milling machine, very handy for jobs just like this one....

LINK: There's a whole bunch more pix and story here.....

Aloha,

Willy

I had mounted a steering box 12" in front of the front axle. The drag link ran straight back to the steering arm from the pitman arm. It turned out that due to that setup, the arc of the end of the drag link at the steering arm was rather sharp, and a 2" upward movement in the axle resulted in an 1/8" forward movement in the steering arm, causing the truck to head into the oncoming traffic, the harder the bump the worse it got, definitely not a good thing!!!

So I finally put the front end up on stands and pulled it apart....l

And fabricated a new steering arm to put on the right side steering knuckle of the front axle, converting it to a cross steer setup.....

I sent the right side steering knuckle to a machine shop to get it drilled and tapped accurately for the new steering arm (well, more accurately than I am capable of.....). While I am waiting for the machine shop, I notched the left side frame rail for clearance for the reoriented pitman arm and the ball joint nut:

I cut the original 12" long drag link in half and prepped the two pieces to insert and weld into a longer piece of heavy wall pipe. The final length will be around 36", exact length to be determined when the right side of the axle is back together with the new steering arm on it...

Our "Old Dudes Racing" shop has a Smithy, a small lathe and milling machine, very handy for jobs just like this one....

LINK: There's a whole bunch more pix and story here.....

Aloha,

Willy