- Home

- Forums

- Technical Articles/muscle cars

- Engine & transmission Swaps, related info

- Engine: Selection and Modification

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

need help with sbc

- Thread starter 383rookie

- Start date

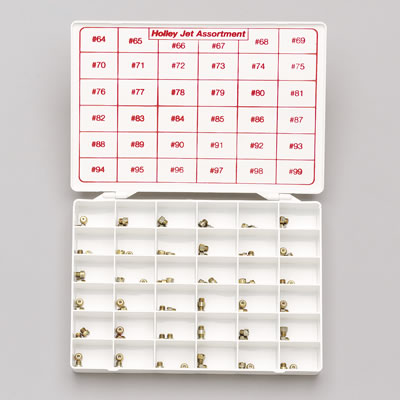

Id suggest starting by going 2 sizes SMALLER on the JETS

and verifying the float levels and fuel pressure at the carb inlet port is at 5.5 psi MAX, if its higher than that you need a return style fuel pressure regulator

get out a vacuum gauge and read the vacuum at idle and install a power valve thats as close as you can get too 1/2 the value, IE if the vacuum gauge reads lets say 16.6" youll want a 7.5-

power valve

viewtopic.php?f=55&t=211

viewtopic.php?f=55&t=635

and verifying the float levels and fuel pressure at the carb inlet port is at 5.5 psi MAX, if its higher than that you need a return style fuel pressure regulator

get out a vacuum gauge and read the vacuum at idle and install a power valve thats as close as you can get too 1/2 the value, IE if the vacuum gauge reads lets say 16.6" youll want a 7.5-

power valve

viewtopic.php?f=55&t=211

viewtopic.php?f=55&t=635

ok got it put back together and then it wouldnt idle( crank up and then shortly go down till she finally shut off) so i started looking at fuel related issues and found nothing so i pulled the valve covers and backed the rocker nuts off a bit and bam, we are running again. so now i guess i need to figure out why it did that first, then figure out my fuel issue( or cam issue). anyone have any idea why after about 5 days of this thing running flawlessly it would suddenly tighten its own rocker nuts down, or the best way to adjust while its running?

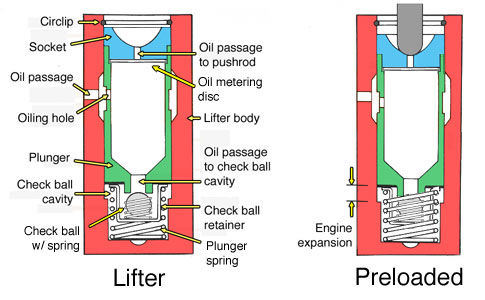

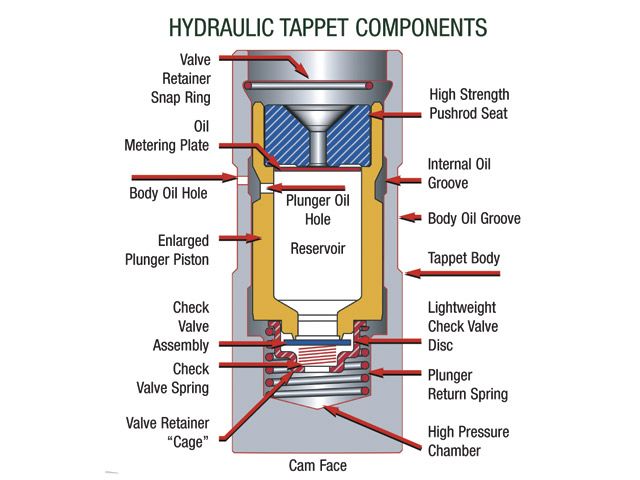

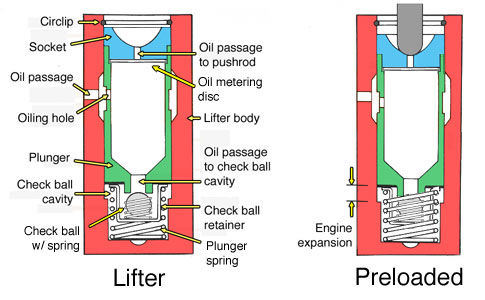

ok went to adjust the rockers and noticed that i am only getting oil on 2 of the rockers(through the pushrods) and they are clicking(loose) when i tighten them using my fingers just at the point where they stop clicking i loose my oil, so i try loosening the others and most all of them do the same. is it possible that my lfter are bad or am i not seeing things correctly?

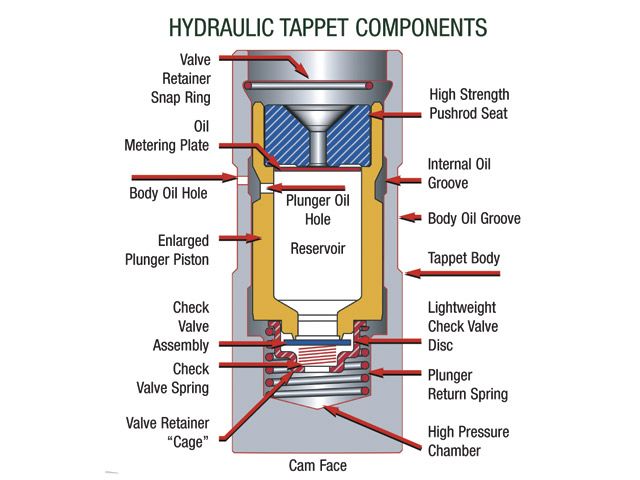

Assuming your using hydraulic lifters,you need to loosen any rocker to the point it clicks,at idle, noticeably, then slowly tighten the adjustment nut on the rocker just to the point the rocker stop clicking then add an additional 1/4 turn of pre-load, this allows the lifters push rod seat to move enough to depress , and force oil up the push-rods as the lobe rotated under the lifter

no its not supposed to stop oiling, do all the pushrods bleed oil if its clicking

sounds like somethings may be restricting oil flow, first check your dipstick oil level then check your oil pressure gauge. if your pans full the oil pump pick-up may have vibrated down to the oil pan floor restricting intake flow, the filter may be clogged or defective or the oil pump pick-up may have fallen off

read these

viewtopic.php?f=54&t=3834

viewtopic.php?f=27&t=1514&p=3464&hilit=+handy+tool#p3464

read these

viewtopic.php?f=54&t=3834

viewtopic.php?f=27&t=1514&p=3464&hilit=+handy+tool#p3464

Id throw a quart of MARVEL MYSTERY OIL into the engine, FIRST, its just good light weight machine oil with lots of crud solvents that many times will free up stuck or clogged lifters

http://www.marvelmysteryoil.com/

http://www.marvelmysteryoil.com/

I hope you correctly labeled EACH one and where it goes back into the block or theres a good chance youll screw up the cam, in the next hundred miles

even with roller lifters?grumpyvette said:I hope you correctly labeled EACH one and where it goes back into the block or theres a good chance youll screw up the cam, in the next hundred miles

383rookie said:even with roller lifters?grumpyvette said:I hope you correctly labeled EACH one and where it goes back into the block or theres a good chance youll screw up the cam, in the next hundred miles

good catch,your correct,

SORRY,I was answering 3 different posts and forgot that yours was a roller lifter

no, your probably ok with roller lifters,

its rare, but not unheard of for those to cause wear issues

you should be ok with either rocker ratio, theres not enough difference to worry about it