RSB said:Hi All,

My newly-acquired vette with a 350 occasionally has a slight ticking noise that I haven't been able to identify. At first I thought it sounded like an exhaust leak but I don't think so. I finally decided to pull the valve covers and have a look. I have no history on this motor so I don't know how it was built.

Of the valves that are closed, I notice the rockers are loose and I can wiggle them around. Does this indicate I have solid lifters (or very poorly-adjusted hydraulics)? I have only ever worked with hydraulic lifter setups.

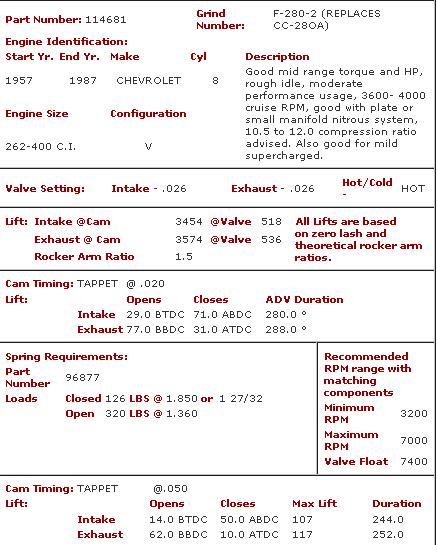

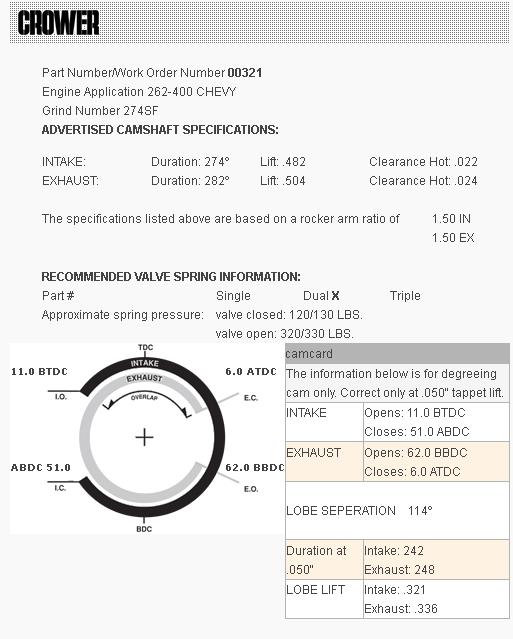

So if I'm dealing with a solid lifter setup, does the ticking noise even indicate a problem or are they normally noisy? Also, how do I know the specs for what the intake/exhaust clearance should be given I don't know what cam I have? The rockers are stamped with 1.50.

I don't plan to take any action until I understand more about what I'm dealing with.

Here is a pic.

Any tips would be greatly appreciated.

Thanks!

first I think that youll find the two different color roller rockers most likely indicate a MIXED ratio set, Id check, you may find one sets 1.5 and the other color is 1.6:1

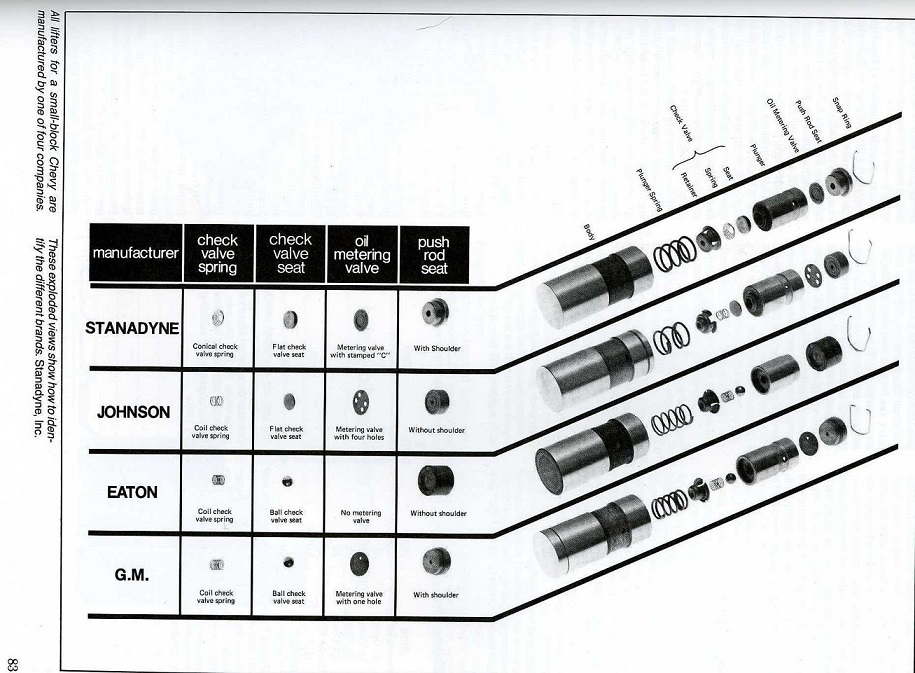

next on a loose rocker place the push rod on the rocker tip and try to depress it, with your palm, if it hydraulic it will probably move down .050-.080 before it seats a solid lifter won,t move, a hydraulic lifter looks different in about 90% of the cases get a strong light and look thru the cylinder head push rod holes at the clips in the lifter

read this

http://garage.grumpysperformance.com/index.php?threads/junk-hydraulic-lifters-mystery-solved.12263/

READ these links. it may help

viewtopic.php?f=52&t=10431&p=43419&hilit=solid+hydraulic+lifters#p43419

viewtopic.php?f=44&t=10554&p=44954&hilit=+adjusting+valves#p44954

viewtopic.php?f=52&t=196

viewtopic.php?f=52&t=181

viewtopic.php?f=55&t=464

http://www.cranecams.com/bulletins_listview.php?s_id=7

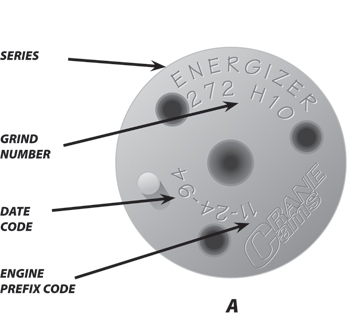

most manufacturers IDENTIFY OR mark cams under the timing gear mount surface

personally if it was my new car, Id spend the 1-2 hours to pull the water pump and front cover and timing chain and get the numbers off the cam so I knew what I was dealing with, as the 1-2 hours spent and the minimal cost and a few gaskets is a very good investment, in returned info of what your dealing with.

IF you can,t tell that way (UNLIKELY) ID pull the intake and distributor and find out by pulling and examining a few lifters (just be aware the lifter removed to examine MUST go back on the SAME CAM lobe they were removed from)

the only logical reason to have a mixed set of the exact same ratio is several previous rockers failed, and a second set was purchased for replacement parts (people don,t generally spend well over $200 just to alternate colors on parts you can,t see with the valve covers installed.

there are a few mixed color sets but most SBC ROLLER ROCKERS FOR 23 DEGREE HEADS, are either mix ratio or mixed off-set, most are uniform in color

as to the lifters theres a few odd ones, (like the RHOADS FAST BLEED HYDRAULICS, and similar high rpm hydraulics)

that don,t follow these basic guide lines but probably 90% do

Last edited by a moderator: