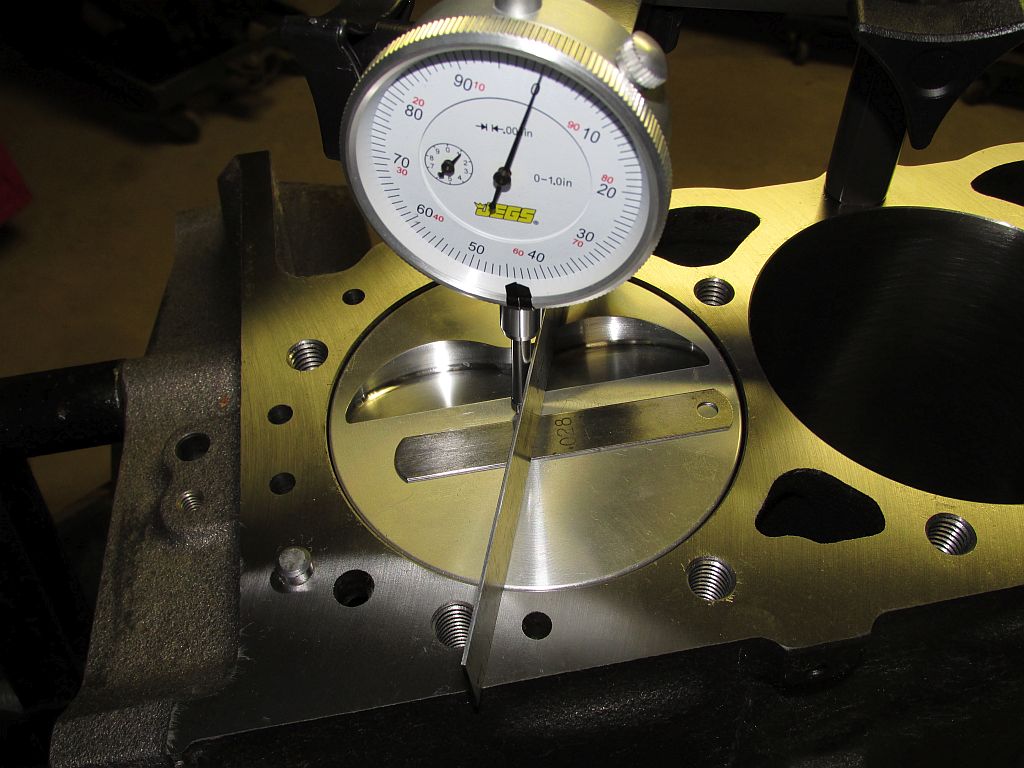

If you don't really have control over the main bearing oil clearance with the size of the main bearing bore, then what is the preferred size of the main bearing bore???

Should I have the DART SHP block line honed to obtain the preferred size or just measure to confirm the size is within manufacture's tolerances???

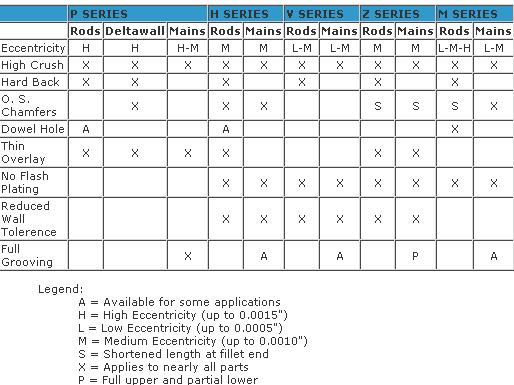

The Scat crank is Nitride hardened, so I'm reluctant to polish the crankshaft to gain any clearance. I can juggle my Std bearings to adjust for a few tenths, but if I need to gain additional .001", my only option for adjusting clearances is by using the bearing with additional .001" clearance.

Below is a quote from Dart about the size of main bearing bore when shipped.

"Main journals are finish line honed to the low to middle of the specification.

They should be measured for your preference. If you have need for a different

diameter you must realign hone this yourself."