I thought this was rather interesting

There are gaskets made specifically for this swap. Use other gaskets at you're own risk- these are what you want (from a V/R press release, presumably prior to the Gen 6 engine release):

General Motors 7.4L Head Gasket

Issue:

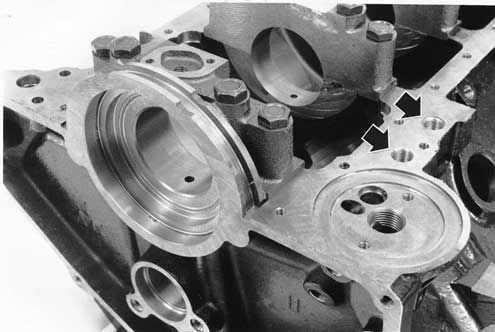

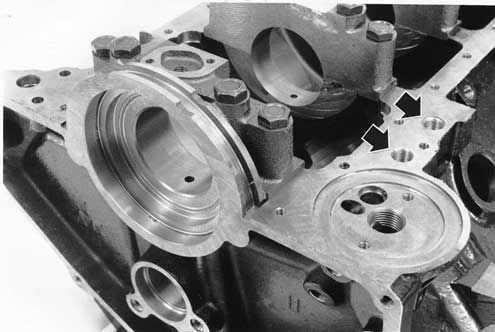

General Motors (GM) 7.4L (454 CID) engines use two types of engine blocks: the Mark IV and Mark V. The Mark IV is found on 7.4L engines in model years from 1965 to 1990, and the Mark V is found on 7.4L engines in model years from 1991 and newer.

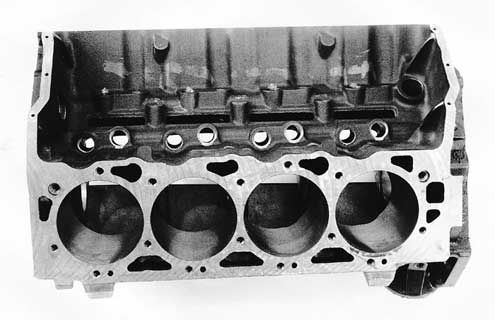

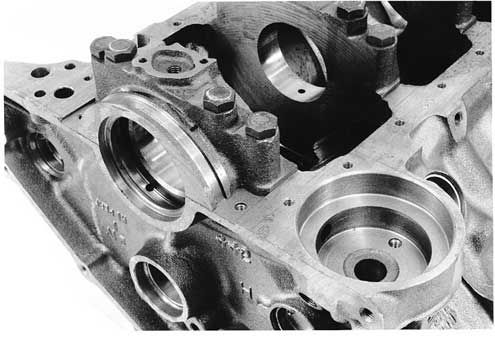

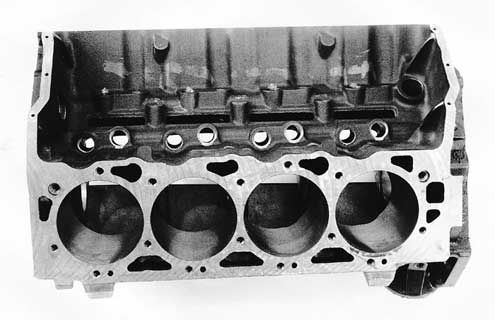

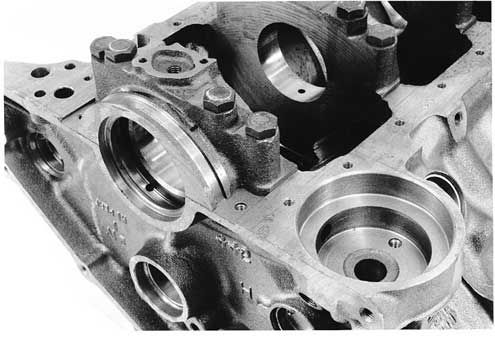

Often, installers will attempt to adapt a Mark IVcylinder head for a Mark V block. This conversion can be made if attention is paid to the coolant circulation. Mark IV and Mark V have different coolant flows and were originally designed for different head gaskets. If the conversion is not performed correctly, the engine will overheat, causing premature engine wear and damage.

Resolution:

Victor Reinz has designed two Nitroseal® head gaskets to specifically allow for this conversion. The installation requires Victor Reinz part number 4918 be installed on the right cylinder bank to maintain proper coolant circulation, and part number 4923 to be installed on the left cylinder bank for the correct coolant flow.

Application:

Victor Reinz part numbers 4918(right bank) and 4923 (left bank) are available for GM 7.4L (454 CID)

engines.

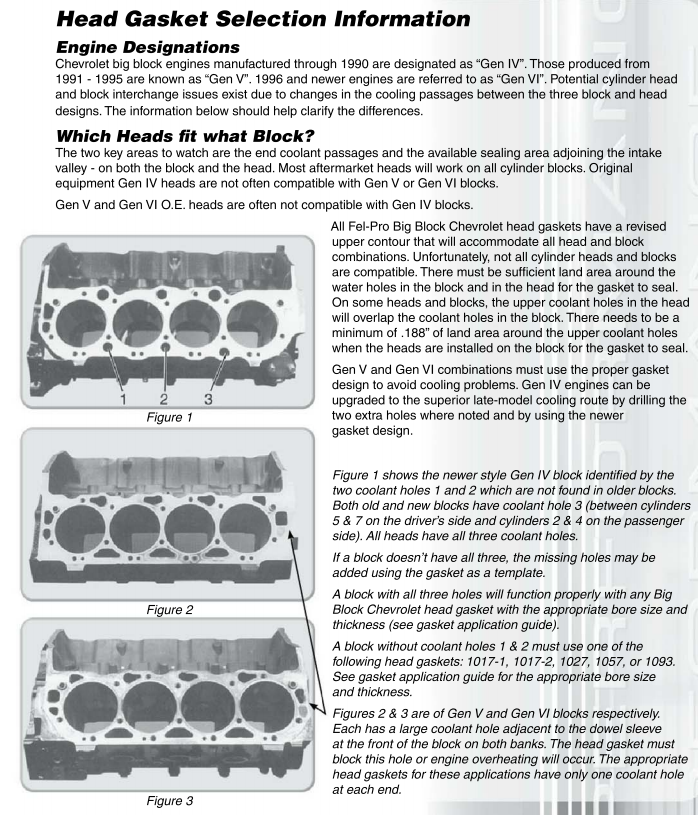

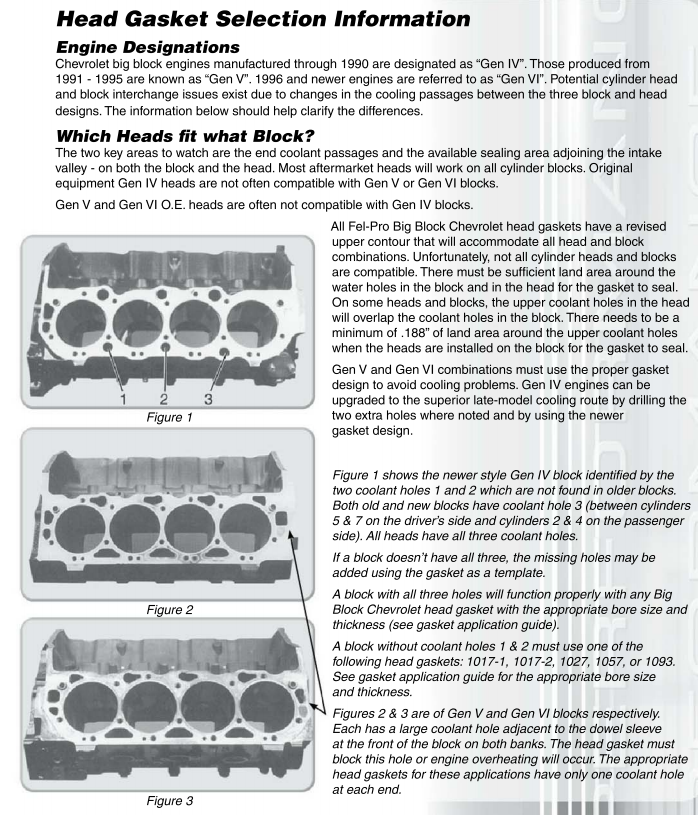

mark iv blocks

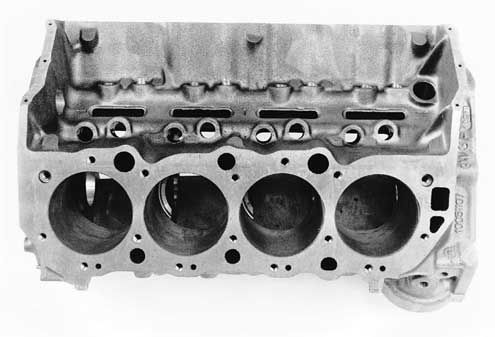

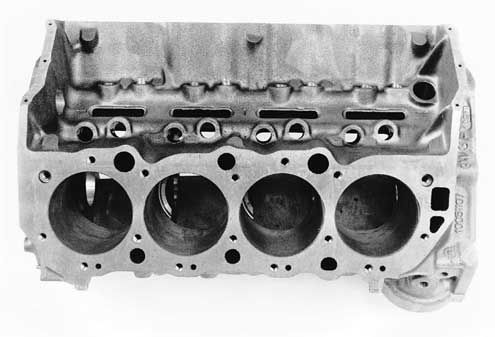

mark v blocks

(keep in mind that ALL '91 and later Gen.V and Gen.VI big blocks come with 4-bolt main caps. The two-bolt big blocks are no longer in production

MANY BUT NOT ALL aftermarket head designs have been modified to work on both the early MARK IV 1965-90 and later MARK V & VI blocks 1991-later.)

BTW, , on BIG BLOCKS the oil pumps and oil filter adapters are different due to the block oil filter recess and rear seals being different

GEN 4 or MARK IV

GEN V and VI

http://www.cxracing.com/mm5/merchant.mv ... _Code=TOCH

much better match to a 496 BBC

https://www.carid.com/weiand/8-71-s...MIhuaYkZ2m3AIVC7XACh0IKA_UEAQYBSABEgK_kPD_BwE

https://www.procharger.com/automoti...eted/gm-carbureted-aftermarket-efi/sbbb-chevy

https://www.procharger.com/automoti...t-efi/sbbb-chevy#/p-1x-and-d-1x-superchargers

https://www.holley.com/products/int...MIgbncx6Cm3AIVFrbACh13kQbIEAQYBCABEgJwy_D_BwE

https://www.powerperformancenews.com/tech/grade-on-a-curve-choosing-the-right-supercharger/

http://www.superchargersonline.com/index.php?main_page=page&id=53

https://www.jegs.com/s/tech-article...chargers+-+Blowers+-+Roots+Type+-+Centrifugal

http://www.superchevy.com/how-to/engines-drivetrain/0610ch-superchargers/

https://www.carthrottle.com/post/what-do-supercharger-capacity-ratings-actually-mean/

jackie schmidt said:The article is not on the Internet yet, so no link.

But what they did was take a big block out of a 90 one ton truck, did nothing to it but ad a mild hydraulic cam, (529 lift, 226/234 at .050),and some Race Rite Aluminum Heads. They kept the cast crank, the powdered metal rods, and cast pistons. They did regap the rings to keep them from closing.

Added....... Two turbos, 76 mm models from CXRacing, that would allow up to 29 pounds of boost blowing through a modified 850 Holley.

They tested first with no turbos, just the heads and cam. It made 442 HP at 5200, and 477 ft lbs of torque at 3900. Not bad for about 8 to 1 compression.

With the turbos, starting at 7 pounds of boost, the Hp went to 607, and torque at 667.

8.3 pounds of boost yielded 657 HP,

11psi went to 730, and 16.4 psi yielded 869 HP,

and then 958 HP at 19.2 psi. Torque was at 1032 ft lbs.

They then went to racing gas, and

finally hit 1237 HP and 1322 ft lbs of torque at just over 29 psi of boost.

They flogged the devil out of this "junk yard" engine, and the cast crank, cast pistons, and stock rods never gave up.

It's a pretty good read, this article is keeping with their "Blue Collar" 454 builds.

Everybody is always taking about just pulling a 5.3 LS out of a junker and stacking on some turbos. Well, this shows what a basic Rat Motor is capable of using the same guidelines.

I kinda wish they would have left the peanut port heads on, just to see what could be had. But they didn't.

There are gaskets made specifically for this swap. Use other gaskets at you're own risk- these are what you want (from a V/R press release, presumably prior to the Gen 6 engine release):

General Motors 7.4L Head Gasket

Issue:

General Motors (GM) 7.4L (454 CID) engines use two types of engine blocks: the Mark IV and Mark V. The Mark IV is found on 7.4L engines in model years from 1965 to 1990, and the Mark V is found on 7.4L engines in model years from 1991 and newer.

Often, installers will attempt to adapt a Mark IVcylinder head for a Mark V block. This conversion can be made if attention is paid to the coolant circulation. Mark IV and Mark V have different coolant flows and were originally designed for different head gaskets. If the conversion is not performed correctly, the engine will overheat, causing premature engine wear and damage.

Resolution:

Victor Reinz has designed two Nitroseal® head gaskets to specifically allow for this conversion. The installation requires Victor Reinz part number 4918 be installed on the right cylinder bank to maintain proper coolant circulation, and part number 4923 to be installed on the left cylinder bank for the correct coolant flow.

Application:

Victor Reinz part numbers 4918(right bank) and 4923 (left bank) are available for GM 7.4L (454 CID)

engines.

mark iv blocks

mark v blocks

(keep in mind that ALL '91 and later Gen.V and Gen.VI big blocks come with 4-bolt main caps. The two-bolt big blocks are no longer in production

MANY BUT NOT ALL aftermarket head designs have been modified to work on both the early MARK IV 1965-90 and later MARK V & VI blocks 1991-later.)

BTW, , on BIG BLOCKS the oil pumps and oil filter adapters are different due to the block oil filter recess and rear seals being different

GEN 4 or MARK IV

GEN V and VI

http://www.cxracing.com/mm5/merchant.mv ... _Code=TOCH

much better match to a 496 BBC

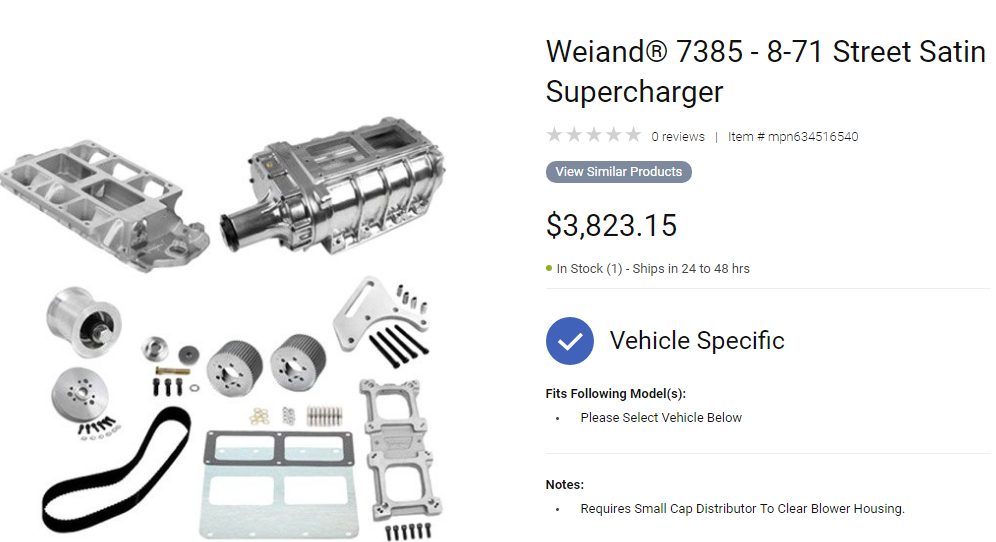

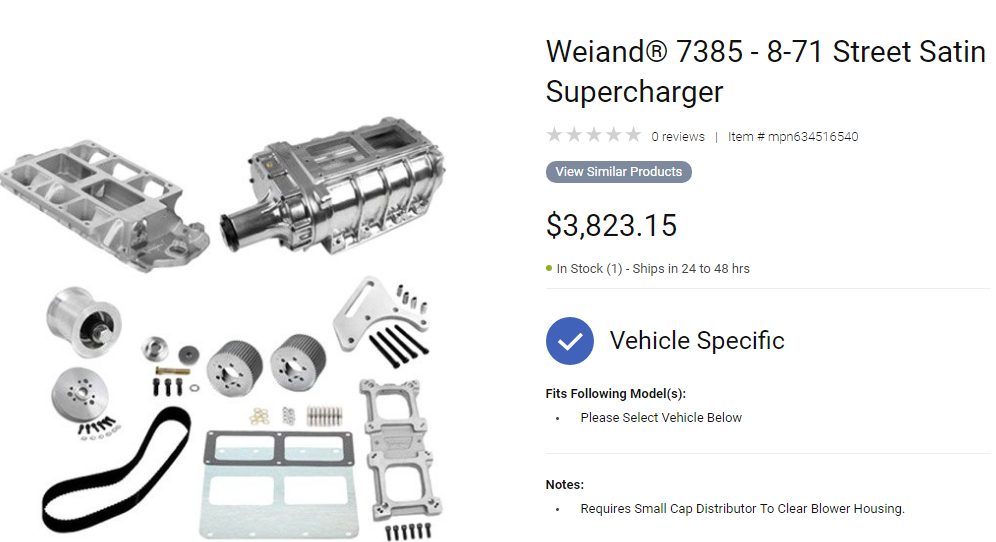

https://www.carid.com/weiand/8-71-s...MIhuaYkZ2m3AIVC7XACh0IKA_UEAQYBSABEgK_kPD_BwE

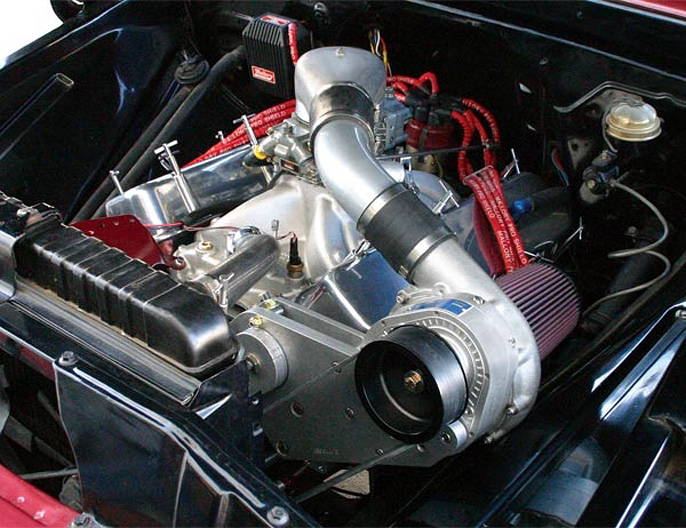

https://www.procharger.com/automoti...eted/gm-carbureted-aftermarket-efi/sbbb-chevy

https://www.procharger.com/automoti...t-efi/sbbb-chevy#/p-1x-and-d-1x-superchargers

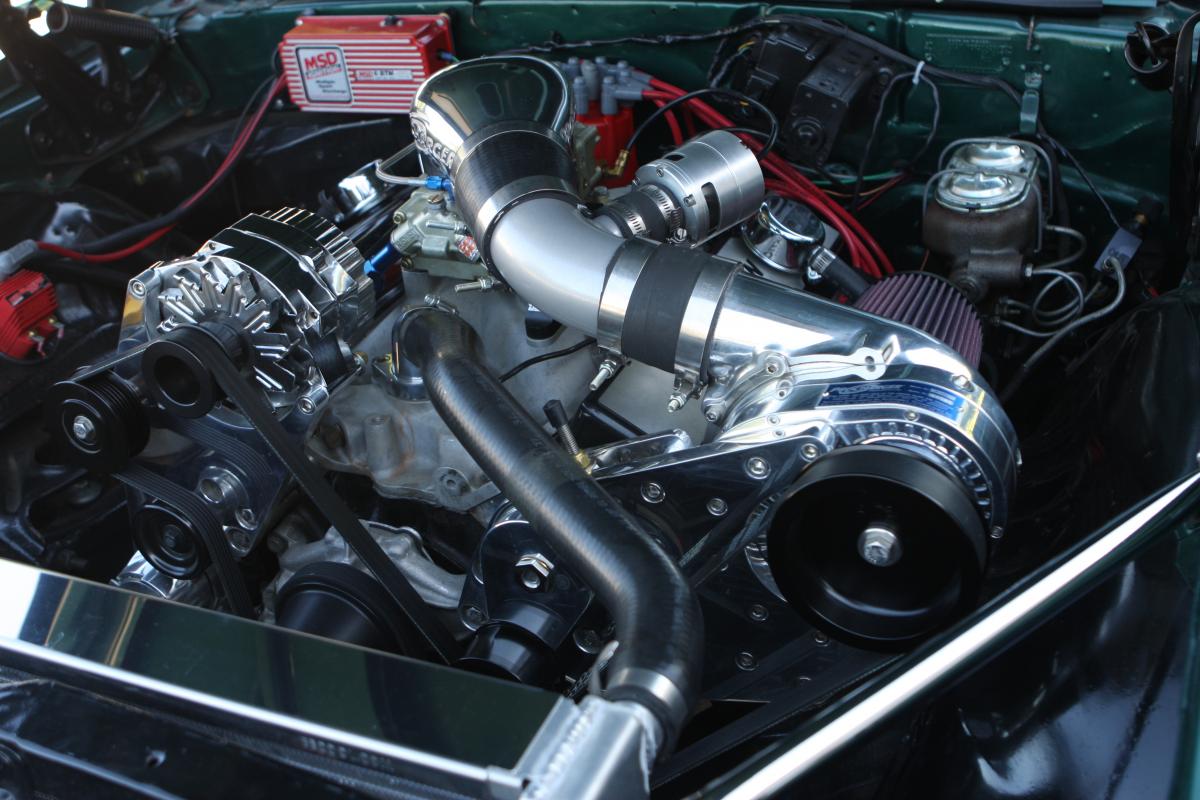

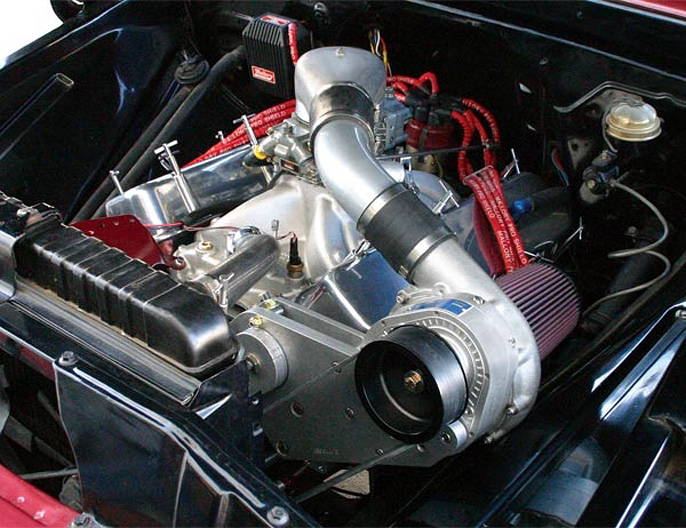

an even better option in my opinion , requiring less hood clearance, would be a centrifugal supercharger with inter-cooler ( inter-cooler not shown in this picture) and a throttle body and direct port injection is also an option.The numbers related to these blower sizes, such as 142, 177, and 256, relate to the amount of air in cubic inches that is pumped by the blower in one blower revolution. The 6-71 and 8-71 designations refer to the original GMC diesel engines. Table 2 shows the amount of air per blower revolution the Weiand blowers pump.

TABLE 2: Supercharger Volumes

Supercharger Type Approximate CID or

Air Per Revolution

Pro-Street 142 142

Pro-Street 177 177

Pro-Street 256 256

Weiand 6-71 411

Weiand 8-71 436

Weiand 10-71 469

Weiand 12-71 497

Weiand 14-71 522

In selecting the proper supercharger for your application, you also need to take into consideration how you plan to drive your vehicle and the approximate boost level desired. How you plan to drive your vehicle is important because you can set up your blower to be more efficient at high engine speeds or more efficient at low engine speeds, or you can arrange for the best compromise for the full engine rpm range.

To run boost levels from 6 to 10 pounds we recommend the following:

Forged blower pistons with a static compression ratio of 7.5:1

For maximum boost and horsepower applications (12 pounds or more), we recommend the following engine specifications:

- Steel crankshaft

- Four bolt main caps

- Steel harmonic dampener

- Stainless steel valves

- Three angle valve job

- More aggressive camshaft

- Roller rockers

- Ported and polished heads

- Steel rods with good rod bolts

- Chromoly push rods

- High output ignition

- Weiand high flow water pump (cast iron or aluminum available - see our complete water pump section for applications)

- Minimum of a 2-1/2" diameter dual exhaust with headers. Recommended primary tube diameters and collector sizes are:

- Small Blocks: 1-5/8" to 1-3/4" with 3" collectors

- Big Blocks: 1-7/8" to 2' with 3-1/2" collectors

- High quality forged or billet crankshaft

- Four bolt main caps with quality bolts or studs

- Steel harmonic balancer or crank hub

- High quality steel rods (H or I beam)

- Forged blower pistons

- O-ringing the block (mandatory)

- Severe duty stainless steel valves or iconel

- Fully ported and polished heads

- Solid or roller cam designed for high boost

- Roller rockers

- Chromoly push rods

- High output ignition management system or magneto

- Blueprinted carburetors or fuel injection

- High octane race fuel (112+ rating)

- Minimum of a 3" diameter dual exhaust with free flowing street/race mufflers and large tube headers.

- Recommended primary tube diameters and collector sizes are:

- Small Blocks: 1-7/8" to 2" with 3-1/2" collectors Big Blocks: 2-1/8" to 2-1/4", with 4" collectors

- Maximum effective compression ratio on gas not to exceed 24:1

- It's important to realize that there are no hard and fast rules and the suggestions made here are general in nature.

https://www.holley.com/products/int...MIgbncx6Cm3AIVFrbACh13kQbIEAQYBCABEgJwy_D_BwE

https://www.powerperformancenews.com/tech/grade-on-a-curve-choosing-the-right-supercharger/

http://www.superchargersonline.com/index.php?main_page=page&id=53

https://www.jegs.com/s/tech-article...chargers+-+Blowers+-+Roots+Type+-+Centrifugal

http://www.superchevy.com/how-to/engines-drivetrain/0610ch-superchargers/

https://www.carthrottle.com/post/what-do-supercharger-capacity-ratings-actually-mean/

Last edited by a moderator: