if the oil pumps hitting the oil pan interior, find out where its hitting

most oil pumps are of similar depth, but different brands of oil pump pick-ups vary a great deal in design and lateral clearance against the pans interior vertical walls,

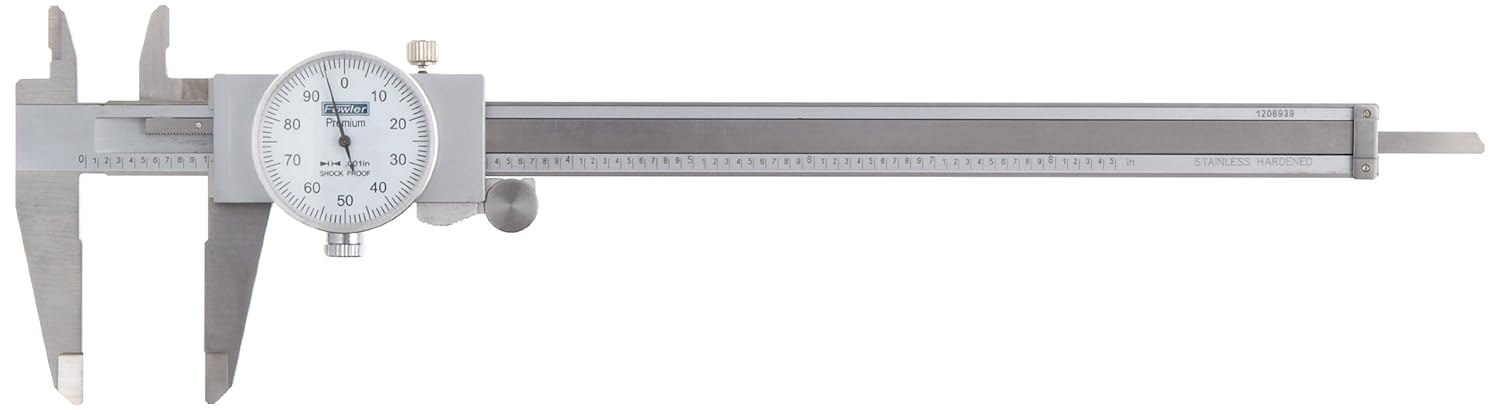

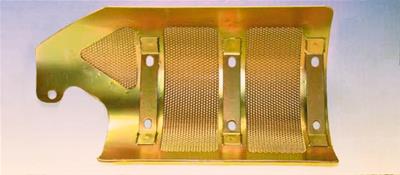

you can add a windage screen and oil control baffles if you have a mig/tig welder , a decent 12" caliper, some masking tape and cardboard to use as a pattern, and test fitting the cardboard/taped parts, and basic welding skills, once you fabricate the steel parts required, very easily

but you might want to just buy a new aftermarket oil pan already modified if you don't feel up to the challenge of custom fabrication,

well designed oil control baffles do help keep the oil pump pick-up covered in oil,

especially under hard acceleration, hard breaking and hard turns, all those momentary lapses in full oil pressure, to the bearings that the oil pump pick-up being momentarily uncovered, thus sucking air vs oil, that a non-baffled oil pan sees,

tends to result in, more accelerated bearing wear, but unless consistent and frequent, those dips in oil flow rate/pressure are rarely critical on a street car that rarely sees consistent abuse at high stress and high rpms.

The question comes up rather frequently when I suggest buying or modifying oil pans as to "WHY BOTHER?" well its simply the fact that most stock oil pans were designed simply to be the cheapest to manufacture component that would function on an engine that would rarely be spinning over 3500rpm...

garage.grumpysperformance.com

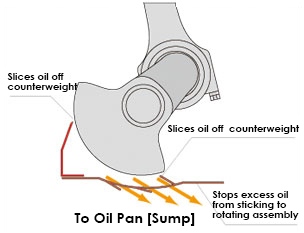

"OK GRUMPYVETTE< I have dumb question? What is a windage tray and whats it for?" windage trays don,t provide a huge boost in horse power, the purpose is mostly in providing much improved oil control, thus they can, if properly designed provide a much more consistent oil supply, and enhanced...

garage.grumpysperformance.com

heres a short list REMEMBER the object or goal in building and maintaining the lubrication system is too maintain a 100% dependable pressurized cooling flow of lubricant to the bearings, rockers ,valves etc. your most important tool, is your ability to think about how things are supposed to...

garage.grumpysperformance.com