Hi I also wanted to ask here because after some research it seemed that here is some serious sBC oil system knowledge.

I seem to have a serious problem with oil pressure in my new SBC409. I have had experience in engine building, built 4 before and no problems whatsoever in any of these. I'm asking serious help

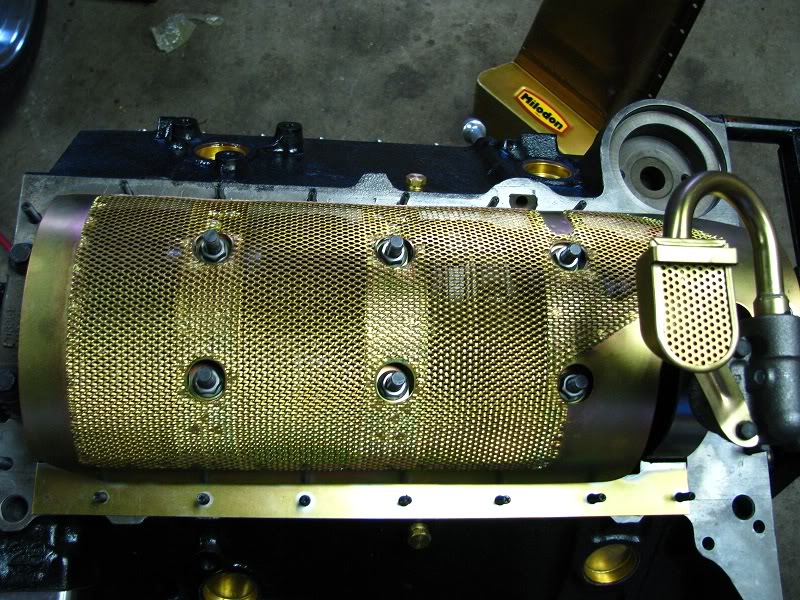

The engine was dynoed at 560hp/520tq, It has a small base circle mechanical roller camshaft (248/252@050"), 11,5 comression, forged parts, AFR210cc heads, stock block with 4-bolt aftermarket boillet caps, etc etc. oh Melling M55HV high volume pump too!

The problem with the oil pressure is that the pressure is constantly around 20psi below what it should be. Already in the dyno we saw this pressure drop and were cautious in running the engine. No problems arose, everything went as well as they could have gone. No problems whatsoever, except the constantly too low oil pressure. We even opened the oil filter and it was clean. No noises, nothing out of the ordinary, except more power than I anticipated and and too low oil pressure

We analysed the dynos oil pressure graph and came to a conclusion that the oil pump pressure relief valve must have been stuck of binding because we saw a bit erratic and too low pressure graph through RPM range. The pressure even got weaker when the RPMs went up:

Cold pressure at idle 40-50 PSI

hot pressure idle 15-20PSI

hot pressure 50PSI@4000RPM and dropping to 45PSI@6500RPM.....

After dyno I removed the pan, changed the pump, and started the engine... same problem with my in car mechanical gauge...

Cold pressure 45PSI@1500RPM (i'm used to seeing around 70PSI)

Hot pressure 50PSI@4000RPM (Again I'm used to seeing around 60PSI)

Now there is only one thing that I can think of but let's check the easy ones first:

All bearing clearances within spec (closer to upper limit)

All oil passage plugs in place and also the fron ones tapped for pipe plugs

Cam bearings cover the grooves in block

Oil pickup around 3/8 from pan bottom (Spec)

Center oil galley plug in front drilled for timig chain cooling (very small hole)

No outside oil leaks

Anything else???

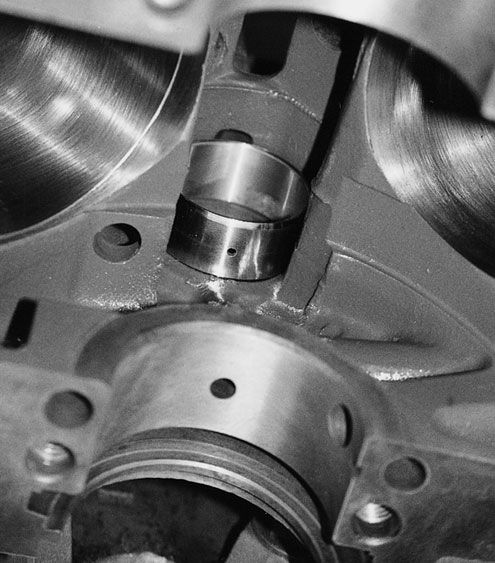

Now the only thing I can figure out is that the small Base circle cam brings the lifters too low in their bores and thus allows too much oil to enter the small holes that supply oil to the top end

Could it be this problem?

How can I tell if too much oil is getting to the top end?

I can't think of anything more, except that melling suplied me with 2 bad pumps...

So If you have had this problem and foud the reason please let me know.

I seem to have a serious problem with oil pressure in my new SBC409. I have had experience in engine building, built 4 before and no problems whatsoever in any of these. I'm asking serious help

The engine was dynoed at 560hp/520tq, It has a small base circle mechanical roller camshaft (248/252@050"), 11,5 comression, forged parts, AFR210cc heads, stock block with 4-bolt aftermarket boillet caps, etc etc. oh Melling M55HV high volume pump too!

The problem with the oil pressure is that the pressure is constantly around 20psi below what it should be. Already in the dyno we saw this pressure drop and were cautious in running the engine. No problems arose, everything went as well as they could have gone. No problems whatsoever, except the constantly too low oil pressure. We even opened the oil filter and it was clean. No noises, nothing out of the ordinary, except more power than I anticipated and and too low oil pressure

We analysed the dynos oil pressure graph and came to a conclusion that the oil pump pressure relief valve must have been stuck of binding because we saw a bit erratic and too low pressure graph through RPM range. The pressure even got weaker when the RPMs went up:

Cold pressure at idle 40-50 PSI

hot pressure idle 15-20PSI

hot pressure 50PSI@4000RPM and dropping to 45PSI@6500RPM.....

After dyno I removed the pan, changed the pump, and started the engine... same problem with my in car mechanical gauge...

Cold pressure 45PSI@1500RPM (i'm used to seeing around 70PSI)

Hot pressure 50PSI@4000RPM (Again I'm used to seeing around 60PSI)

Now there is only one thing that I can think of but let's check the easy ones first:

All bearing clearances within spec (closer to upper limit)

All oil passage plugs in place and also the fron ones tapped for pipe plugs

Cam bearings cover the grooves in block

Oil pickup around 3/8 from pan bottom (Spec)

Center oil galley plug in front drilled for timig chain cooling (very small hole)

No outside oil leaks

Anything else???

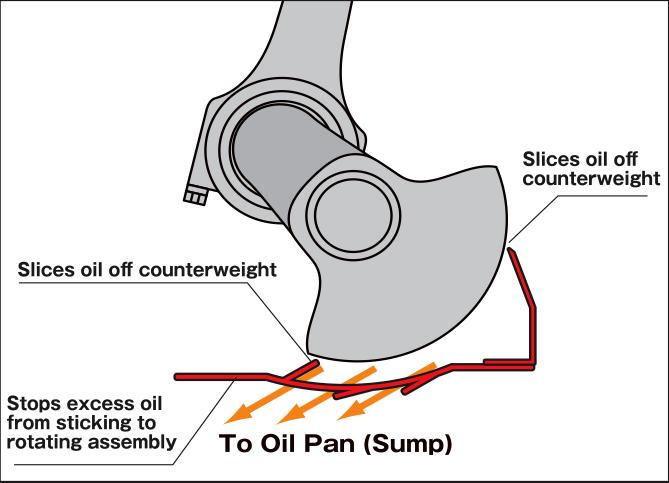

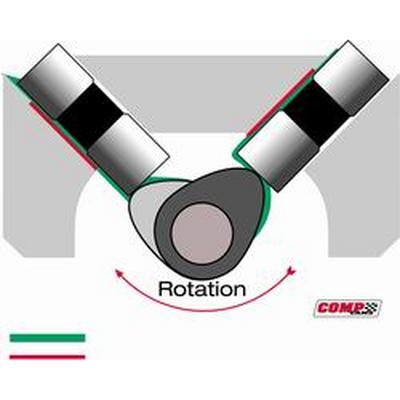

Now the only thing I can figure out is that the small Base circle cam brings the lifters too low in their bores and thus allows too much oil to enter the small holes that supply oil to the top end

Could it be this problem?

How can I tell if too much oil is getting to the top end?

I can't think of anything more, except that melling suplied me with 2 bad pumps...

So If you have had this problem and foud the reason please let me know.