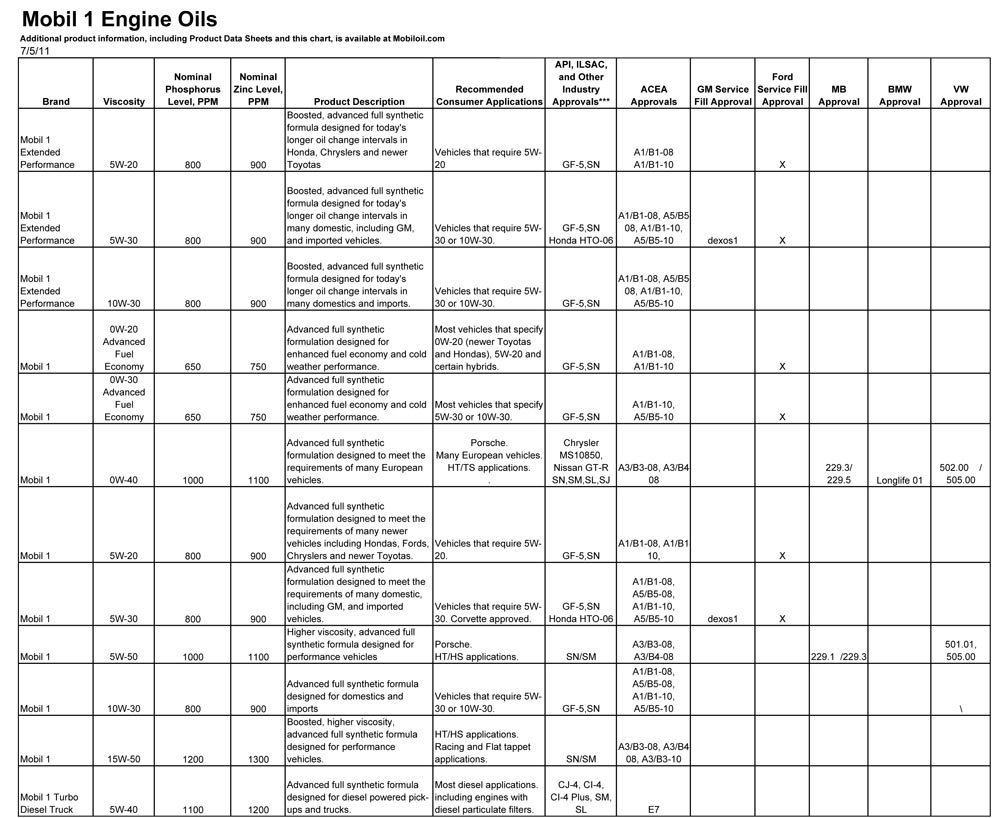

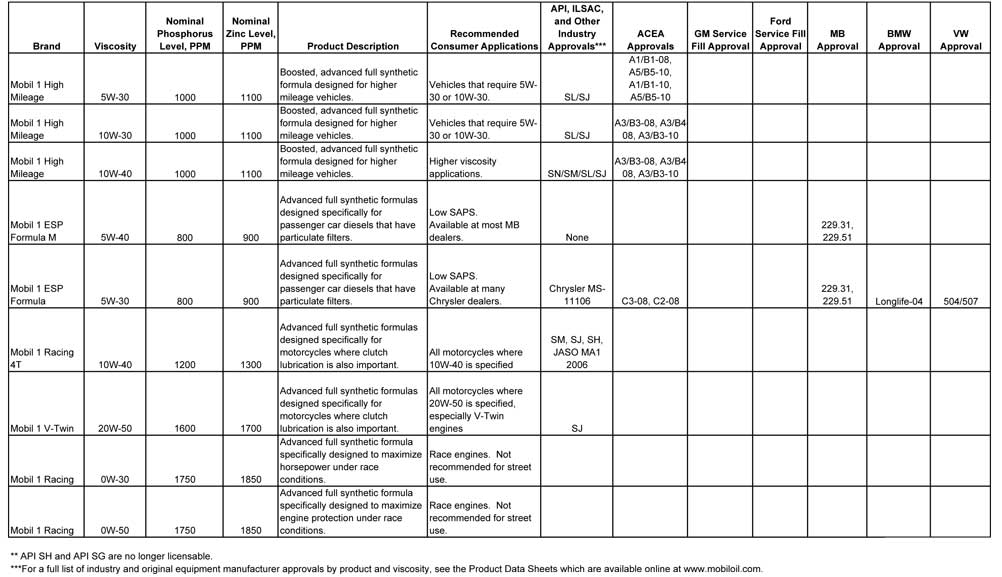

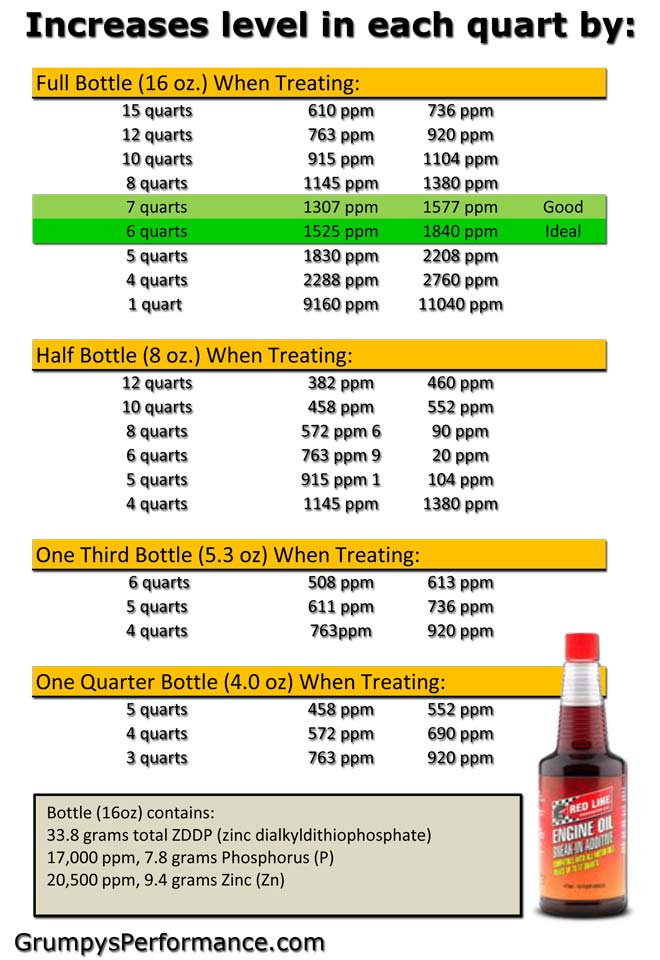

most of the more modern oil formulas designed for modern engines with roller cams and catalytic converters have a good deal less ZINC that the older formulations designed for the pre- catalytic converter/ emission testing, and flat tappet cam engines of the muscle car era so they have less ability to lubricate the cam lifter lobe contact area, ZINC was used in the older formulas as it provided extra wear resistance, but over time it tends to reduce the catalytic converter efficiency.All current engine oils have an additive called ZDDP (Zinc DialkylDithioPhosphate) for wear protection. theres several reasons you might want to run synthetic oils but the modern dino oils are a huge improvement over previous blends in some areas. In general, heavy duty engine oils (truck oils like Mobil Delvac) have a higher level of ZDDP. Automotive engine oils generally have a lower level of ZDDP to protect catalytic systems.

a MINIMUM level of ZDDP of 1800PPM is suggested for use with flat tappet cams and lifters AS IS breaking the cam in with a MOLY based assembly lube and an oil having that minimum ZDDP level

synthetic oils have a higher temp limitation and can last longer between oil changes, but SOME modern formulations were not formulated for the older flat tappet cam and lifter friction levels

now if I was swapping to a synthetic oil with a flat tappet cam ID verify with the manufacturer that it would provide the required lubrication or ID either use a ZDDP additive, as the combo would provide some extra wear protection because the current oil formulas were not designed for flat tappet cams, or ID used a 50%/50% mix of DIESEL engine OIL with its higher Zddp and a synthetic oil

[

this might help

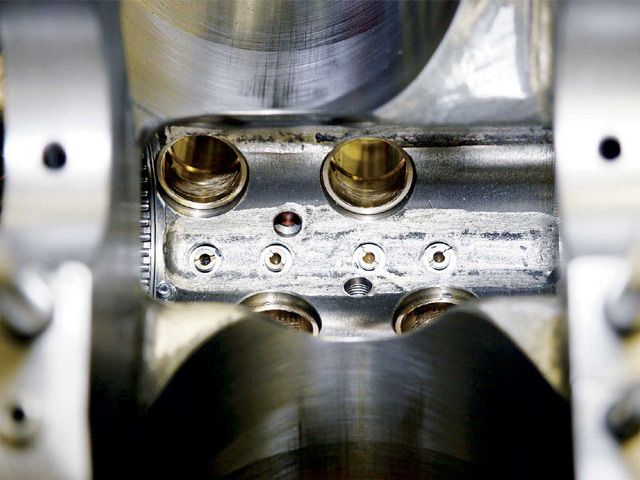

The camshaft had an

as-cast Brinell hardness in the range of 331 to 364. The camshaft was.heated to 1600°F (871°C) in 20 minutes in an electric furnace. The furnace temperature was then raised to 1640°F (893°C) and held at that temperature for 80 minutes. Subsequently, the temperature in the furnace was cooled to.400°F (204°C) in one and a half hours. The camshaft was then taken out of .the furnace and allowed to air cool. The hardness of the camshaft thus heat treated was in the range of

311 to 321 BHN.

this is HARDER AND MORE WEAR RESISTANT THAN THE LIFTER BASE BY DESIGN

viewtopic.php?f=52&t=6237&p=32472&hilit=lifter+spin#p32472

viewtopic.php?f=54&t=4793&p=13273&hilit=lifter+spin#p13273

http://www.hotrod.com/articles/best-tips-breaking-new-camshaft/

very good

very very good

viewtopic.php?f=54&t=2102

http://www.pqiamerica.com/apiserviceclass.htm

there ARE ZDDP additives available, that will allow use of the newer oils in older flat tappet cam engines during the critical cam break-in process

READ THE LINKED INFO

http://motorcycleinfo.calsci.com/API.html

GREASE - Multi-purpose lithium-based grease

M -Molybdenum disulfide grease with at least 3% moly content

MP - Molybdenum disulfide paste with at least 40% moly content

hand coat or brush on moly paste on cam lobes and lifter bases and rocker balls on stock rockers and coat crank journals and you form a protective barrier that can stand 550F temps and well over 400,000 psi pressure which the parts it is on seldom can tolerate, yes having a quality oil with ZDDP sure helps but MOLY provides excellent protection as long as theres a cooling flow of oil in the 200F-300f temp range flowing over the surface the molys embedded in

States of Lubrication

HYDRODYNAMIC LUBRICATION

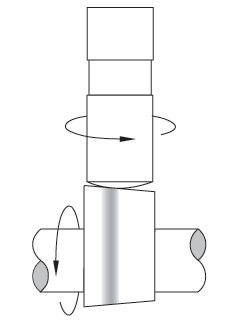

The design of oil is to produce a film of oil between two mating surfaces which gives you the best protection against wear. As the image below shows, oil flows, and creates a hydraulic pressure (elasto-hydrodynamic lubrication,EHL) between the two surfaces. Now under perfect conditions this type of lubrication will not allow wear. But in reality, this is not always the case.This takes us to the next state of lubrication.

hydrodynamic lubrication

MIXED FILM LUBRICATION

This is where lubrication is marginal. Under load conditions oil is squeezed under pressure. For example, during accelleration of an engine, you step on the gas and the engine dumps fuel, in turn the force is increased against the rod bearings, pushing (or squeezing) on the hydrodynamic oil creating a marginal lubrication condition. This is under normal use. But what happens to oil when it is under extreme pressure created by abuse or just a heavy foot? Follow me to the next state of lubrication.

mixed_film_lubrication

BOUNDARY LUBRICATION

This is where lubrication is dependant on antiwear additives. What happens here, is lubrication can be put under so much pressure, and is momentarily squeezed out to such a point that if oil didn't have any antiwear additives, you would be metal to metal. This is the last line of defense for lubrication to protect your equipment. A common place where you see a lot of high levels of barrier lubricant is in gear lubes. Ever wonder what that rotten smell was? Yep, high levels of zinc, and phosphorus. These are the two most used antiwear wear additives used in oils today.

boundary_lubrication

A lot of aftermarket additives use zinc and phosphorus for extra protection. The problem is, when you overload an oil with this type of additive, your oxidation levels tend to increase, causing an attack on the base oil, which in turn can cause an increase of viscosity, (thicken the oil) .This is why it is important not to play home chemist and blend in aftermarket additives that are not designed to be in the oil to start with.

So, as you can see, viscosity of the oil isn't the only important factor. Like building a house, you want a good foundation or base. Then you would use a quality product to build with. In this case, a good base oil is a start, then with good additives you achieve a good lubricant. Is zinc and phosphorus the only barrier additives available? No, there are more. Follow me to a barrier lubricant that has been around for a long time and has proven out for many years...

Molybdenum Disulfide

Molybdenum is a very hard metal with a number of industrial uses:

It is combined with chromium in steel to make the steel harder and more resistant to bending. Most of the bicycle frames produced today use chromium and molybdenum steel. Because the steel is so much harder, the manufacturers can use less, thereby making the frame lighter.

Molybdenum Disulfide (Moly) has been used for decades in lubricating pastes and greases because it is slippery and forms a protective coating on metal parts:

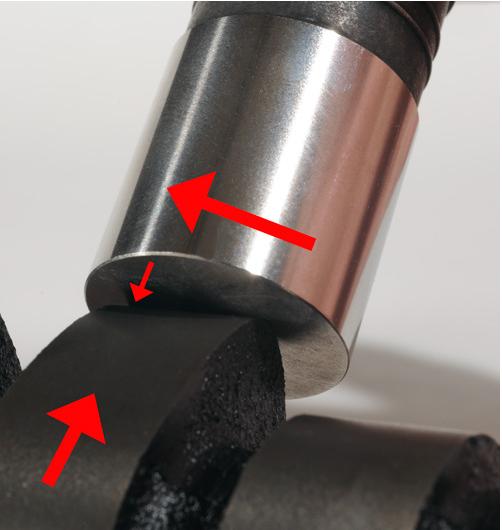

Single Molecule of MolyMoly exists as microscopic hexagonal crystal platelets Several molecules make up one of these platelets. A single molecule of Moly contains two sulfur atoms and one molybdenum atom. Moly platelets are attracted to metal surfaces. This attraction and the force of moving engine parts rubbing across one another provide the necessary thermochemical reaction necessary for Moly to form an overlapping protective coating like armor on all of your engine parts. This protective armor coating has a number of properties that are very beneficial for your engine.

The Moly platelets that make up the protective layers on your engine surfaces slide across one another very easily. Instead of metal rubbing against metal, you have Moly platelets moving across one another protecting and lubricating the metal engine parts.

This coating effectively fills in the microscopic pores that cover the surface of all engine parts, making them smoother. This feature is important in providing an effective seal on the combustion chamber. By filling in the craters and pores Moly improves this seal allowing for more efficient combustion and engine performance.

This overlapping coating of Moly also gives protection against loading (perpendicular) forces. These forces occur on the bearings, and lifters. The high pressures that occur between these moving parts tend to squeeze normal lubricants out.

squeeze

Eventually, there is metal to metal contact, which damages these moving parts and creates large amounts of heat. Fortunately, this is not the case with some lubricants.The layer of moly that forms on these moving surfaces can withstand pressures of 500,000 psi, without being squeezed out.

nosqueeze

Engineers and scientists have tried for years to use Moly in motor oils but they had been unsuccessful because they could not find a way to keep Moly in suspension. Once Moly was put into suspension it would gradually settle out. It was easy to see it come out of suspension because a black sludge would collect on the bottom of the oil containers. In engines it would settle to the bottom of the crankcase or clog oil pathways and filters.

Engineers have overcome these obstacles. They have developed a process that keeps Moly in suspension and isn't filtered out. Since that time the product has undergone extensive independent testing in labs and in the field for many years to insure that the product stands up to the rigorous needs of today's engines. With the plating action of Moly reducing friction which reduces heat, this helps keep rings free from carbon buildup, prevents blow-by, decreases emission, and extends oil life.

ZDDP: What does it mean to me?

View the printable pdf version

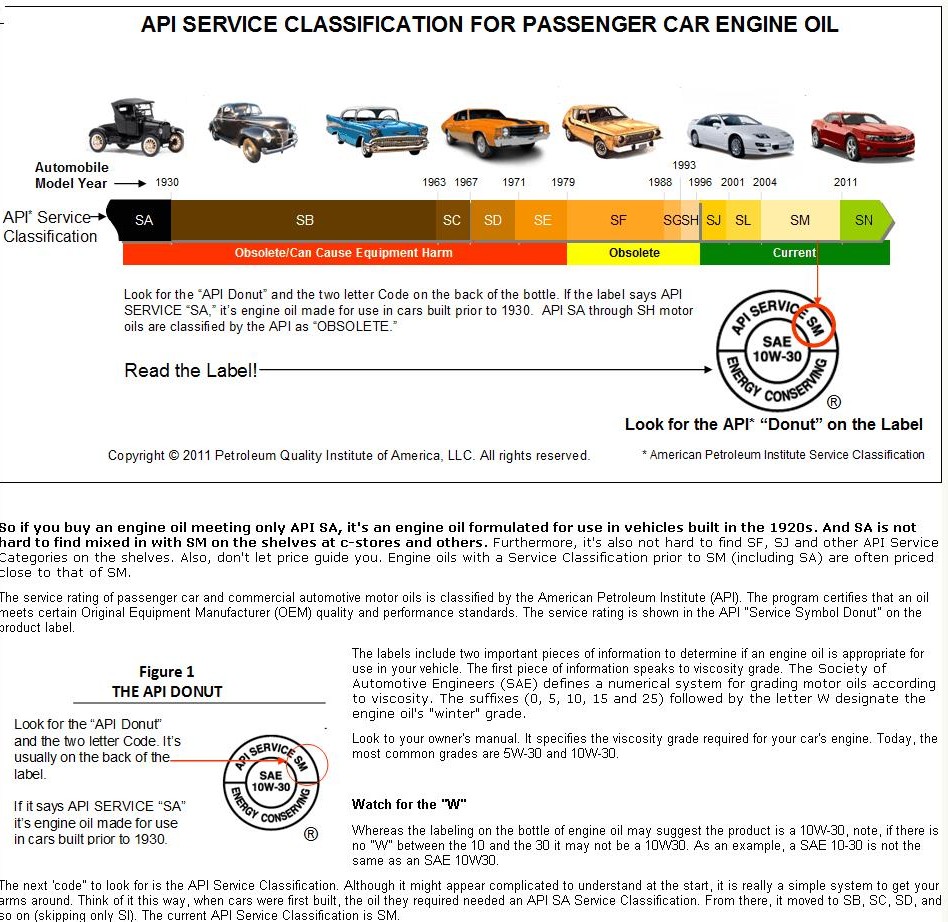

Oil is killing our cars!†warns Keith Ansell, President of Foreign Parts Positively. “Be aware that ‘New and Improved,’ or even the ‘standard products’ we have been using for many years, are destroying our cars. It isn’t the same stuff we were getting even a year ago.â€

Although a bit of a sensationalist, Keith is not completely out of line and he isn’t the only Internet auto expert touting the effects of the industry required ZDDP (zinc dialkyl dithiophosphate) decrease in motor oil.

Twelve years ago, the maximum ZDDP level in passenger car motor oil was 1600ppm. Over the years, the EPA has slowly decreased the allowed amount to today’s range of 600-800ppm. ZDDP’s primary purpose is to prevent wear in high friction areas of the engine such as camshafts, connecting rods and lifters, which is probably why Keith is so concerned about its decline.

Less ZDDP = More engine wear?

The reduction of ZDDP in motor oils has caused many issues in flat tappet engines and a big stir in the classic car forum. Most V-8 engines in the muscle car era (cars built before 1975) came standard with a flat tappet camshaft and no catalytic converter. The flat tappet is, for the most part, flat on the bottom. Flat tappet cams are under a lot of pressure and require an extra oil additive for tight tolerances. Oil is the only thing between the lifter and camshaft lobe preventing them from welding each other together. Without sufficient lubrication during break-in and over long-term use, cams can suffer pitting, uneven lobes and severe wear patterns. So, in high performance or classic cars, opt for heavy-duty, performance or racing oils with higher levels of ZDDP that will provide flat tappet cams with anti-scuffing, anti-wear and oxidation inhibition.

Ok, so what about your basic passenger car? In the last decade or so, car manufacturers switched to more reliable, efficient roller camshafts for mass production. Because roller cams don’t require the same level of zinc protection as flat tappet cams, passenger car engines can afford a decrease in ZDDP. In fact, less ZDDP could actually be a good thing. Phosphorous—one of the main ingredients—is a poison to catalytic converters (fitted in most passenger cars since the mid-70s). Excessive ZDDP content will bond to the metal catalyst beads inside the converter rendering it useless as a pollution control device. See why the EPA wants to regulate the life requirement of the catalyst?

In order to meet API SM specifications, oil manufacturers must decrease ZDDP. Today’s modern passenger car oils contain other dedicated antioxidants to make up for the loss of ZDDP and resulting in a better overall product for consumers.

To sum up, less ZDDP is suitable for vehicles with roller cams and catalytic converters and bad for vehicles with flat tappet cams and no cat.

How can BG help?

BG MOA® uses a combination of additives that improve oil s ability to withstand breakdown due to combustion byproducts, increased temperatures and loads, and frictional wear. And unlike many other oil additives, BG MOA® does not fully rely on ZDDP as its sole anti-wear additive and antioxidant. BG MOA® relies on its proprietary additives for extra wear protection and oxidation stability under severe condition like that of engines with flat tappet cams. For cars with catalytic converters, BG MOA® only contains ZDDP to a similar concentration as a typical base engine oil, which is not enough to ruffle a cat s fur.

If the cat already stinks, it doesnt necessarily mean its poisoned by ZDDP. Chances are hydrocarbon deposits from combustion have plugged it up. And a dirty cat can pump noxious gases into the air and reduce engine performance. For extra protection of the catalytic converter and oxygen sensor, pour in a can of BG 44K® in the fuel tank every 7,500 miles. BG 44K® is proven to restore converter efficiency and remove deposits from the oxygen sensor ultimately restoring power and performance.

So the next time you hear someone like Keith yelling, an Oil is killing our cars! recommend BG MOA® for superior lubrication and wear protection of the engines moving parts even flat tappet cams.

AMSOIL RACING - 3200PPM

CASTROL GTX - 1900PPM

BRAD PENN RACING OIL-2100-2500PPM

REDLINE - 2200-3000PPM

MOBIL - 2500-2900PPM

VALVOLINE DURABLEND 2600PPM

very good

very very good

read the links

viewtopic.php?f=52&t=282&p=345#p345

viewtopic.php?f=54&t=150

viewtopic.php?f=54&t=1334

viewtopic.php?f=54&t=615

viewtopic.php?f=54&t=296