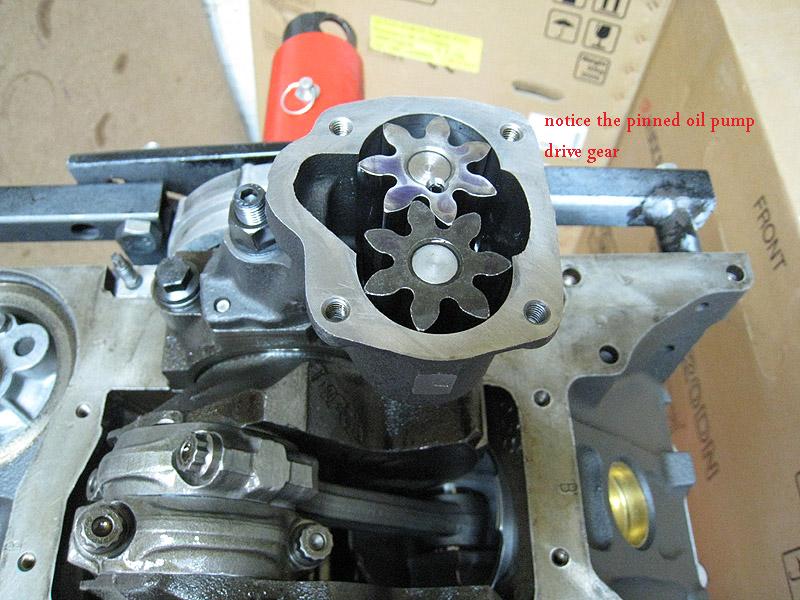

I've bought a Canton RR oil pan (part nr. 15-240M) for my vette but I received a pick-up

for high voulme oil pump with it.

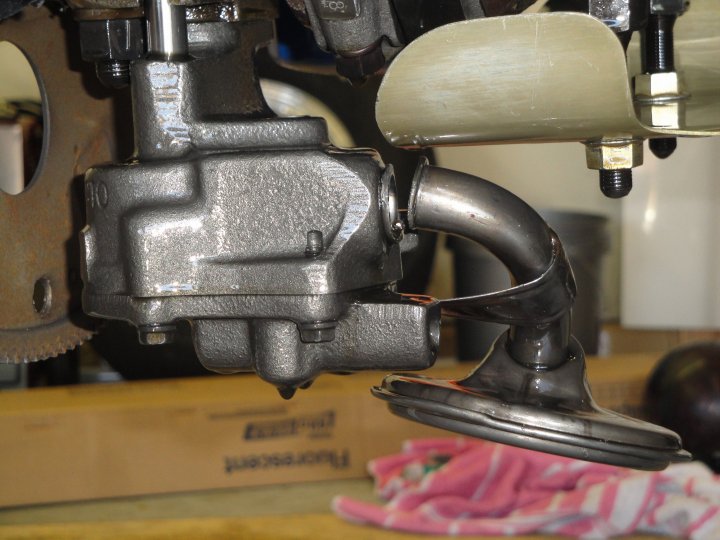

I think that I'll stick with stock oil pump for now, so my question is, can I use stock pump and

stock pick-up with this pan?

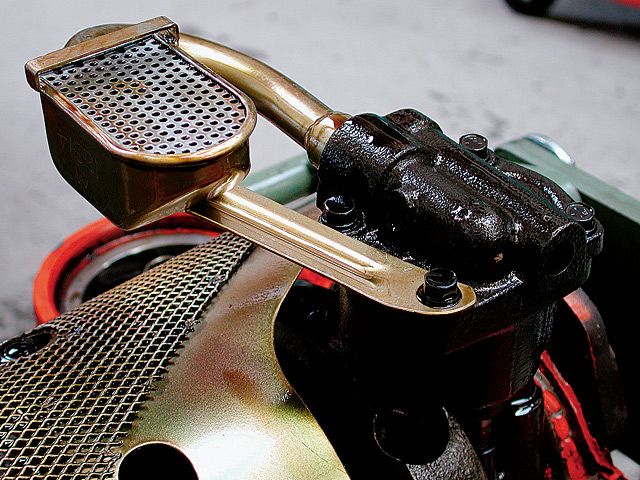

I know that pickup height from the bottom is most important, but I'm asking this question because

stock pickup is round style and the one that I received with the pan is square and looks completely

different.

Or do you think that buying a new melling m-select 10550 HV oil pump would be a good idea?

I've read through a lot of web pages and opinions vary. Some say that HV pump will heat up the oil,

cause foaming, even oil starvation, and most important that it will kill distributor or cam gears prematurely.

Before my rebuild, I had good oil pressures, but when fully heated, it would go as low as ~10 PSI at idle (900 rpm).

I'm affraid that after rebuild, and I'll be using stock crank that will be only polished and std/std bearings, my pressure

could be a bit lower (due to a little more clearances from polishing).

What would be your choice?

My engine will be street/road race driven and I like to drive it hard, so engine sees a lot of abusing.

It should be arround 400 crank HP and 6500 rpm red line.

Engine combo is:

- stock crank - polished

- std/std bearings

- forged SCAT rods

- forged SRP pistons

- Canton 15-240M oil pan

- ??? oil pump

- LS style hyd. roller lifters

- 1.6 RR's, pro-magnums

- CC's XR288HR cam 236/242 @.050"

- #113 heads ported, 2.02/1.60 valves

- ported superram

for high voulme oil pump with it.

I think that I'll stick with stock oil pump for now, so my question is, can I use stock pump and

stock pick-up with this pan?

I know that pickup height from the bottom is most important, but I'm asking this question because

stock pickup is round style and the one that I received with the pan is square and looks completely

different.

Or do you think that buying a new melling m-select 10550 HV oil pump would be a good idea?

I've read through a lot of web pages and opinions vary. Some say that HV pump will heat up the oil,

cause foaming, even oil starvation, and most important that it will kill distributor or cam gears prematurely.

Before my rebuild, I had good oil pressures, but when fully heated, it would go as low as ~10 PSI at idle (900 rpm).

I'm affraid that after rebuild, and I'll be using stock crank that will be only polished and std/std bearings, my pressure

could be a bit lower (due to a little more clearances from polishing).

What would be your choice?

My engine will be street/road race driven and I like to drive it hard, so engine sees a lot of abusing.

It should be arround 400 crank HP and 6500 rpm red line.

Engine combo is:

- stock crank - polished

- std/std bearings

- forged SCAT rods

- forged SRP pistons

- Canton 15-240M oil pan

- ??? oil pump

- LS style hyd. roller lifters

- 1.6 RR's, pro-magnums

- CC's XR288HR cam 236/242 @.050"

- #113 heads ported, 2.02/1.60 valves

- ported superram