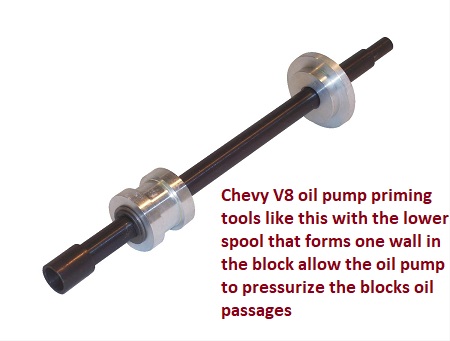

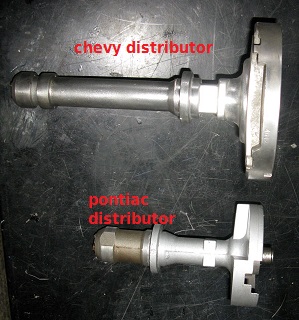

I got a Summit 901010 Oil Pump Primer for X-mas & it seems i've already broken it :lol: . Actually it appears that its missing a pin that holds the lower sleeve that slides over the tang that fits into the oil pump.

I got a stupid question though ... I know the upper blue piece fits over the distributor hole but what's the lower blue piece for above the sleeve?

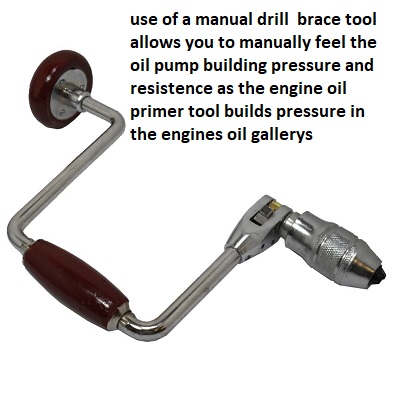

I assume it needs to spin clockwise & should probably take the valve covers off to make sure that the oils made it up to the top of the motor. Is it necessary to rotate the engine?

I got a stupid question though ... I know the upper blue piece fits over the distributor hole but what's the lower blue piece for above the sleeve?

I assume it needs to spin clockwise & should probably take the valve covers off to make sure that the oils made it up to the top of the motor. Is it necessary to rotate the engine?