You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Oil Pump shaft?

- Thread starter mtrhead

- Start date

For the price, it would an easy choice for me to purchase a shaft with a steel collar. I purchased a Melling

10552 pump. It has only 10% over volume, standard pressure and it comes with a drive shaft. Melling

must of thought it was important.

A Melling shaft is only $9.

http://www.summitracing.com/parts/MEL-IS-55E/?rtype=10

Keep us posted, I'm also building a Dart SHP motor.

viewtopic.php?f=69&t=3814

10552 pump. It has only 10% over volume, standard pressure and it comes with a drive shaft. Melling

must of thought it was important.

A Melling shaft is only $9.

http://www.summitracing.com/parts/MEL-IS-55E/?rtype=10

Keep us posted, I'm also building a Dart SHP motor.

viewtopic.php?f=69&t=3814

Attachments

the aftermarket drive shafts are held to a much higher strength tolerance, and a steel collar and and the reduced mid section are both good features, for the very low price Id strongly suggest pitching the stock drive shaft in the dumpster

be sure you select the correct oil pump drive shaft

SB - is a bit shorter about 5.75"

BB - is a bit longer about - 6.50" or so

there are several other length sold by various manufacturers

there should be about .050 vertical movement, of the oil pump oi,l pump drive shaft between the oil pump and lower distributor gear with the manifold and distributor seated correctly

Id point out up front that oil pressure on the gauge is the result of the resistance the engines clearances cause to oil flow rates,and the viscosity and temperature of the oil.

if your having any problem, maintaining oil pressure you can either increase the flow rate , of viscosity of the oil used or decrease the engines clearances, increasing the oil flow or viscosity is treating a symptom, decreasing the clearances is treating the problem,both approaches will work if done correctly withing reasonable limits and both approaches have points in their favor, and potential problems, IF THE CORRECT PARTS ARE USED, but controlling the oil flow is key to success. a standard z28 sbc oil pump will provide enough oil for most applications

example of (engine building" vs parts assembly)

Id bet 80% or more of the people assembling parts have never checked most component clearances ,

except in most cases for ring end gap and bearing to crank journal, as thats almost mandatory.

things like,

piston to the cylinder head (quench)

piston to valve,

rocker slot to rocker stud,

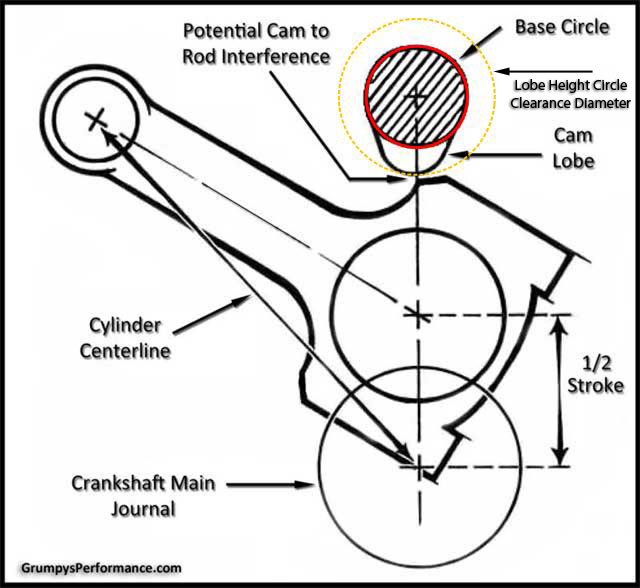

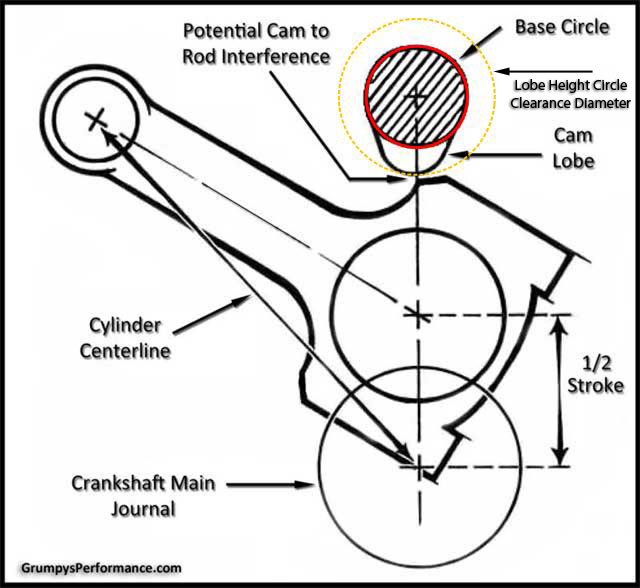

connecting rod to cam lobe,

connecting rod to block skirt,

piston skirt to crank counterweight,

cam button to the timing cover,

spring bind height,

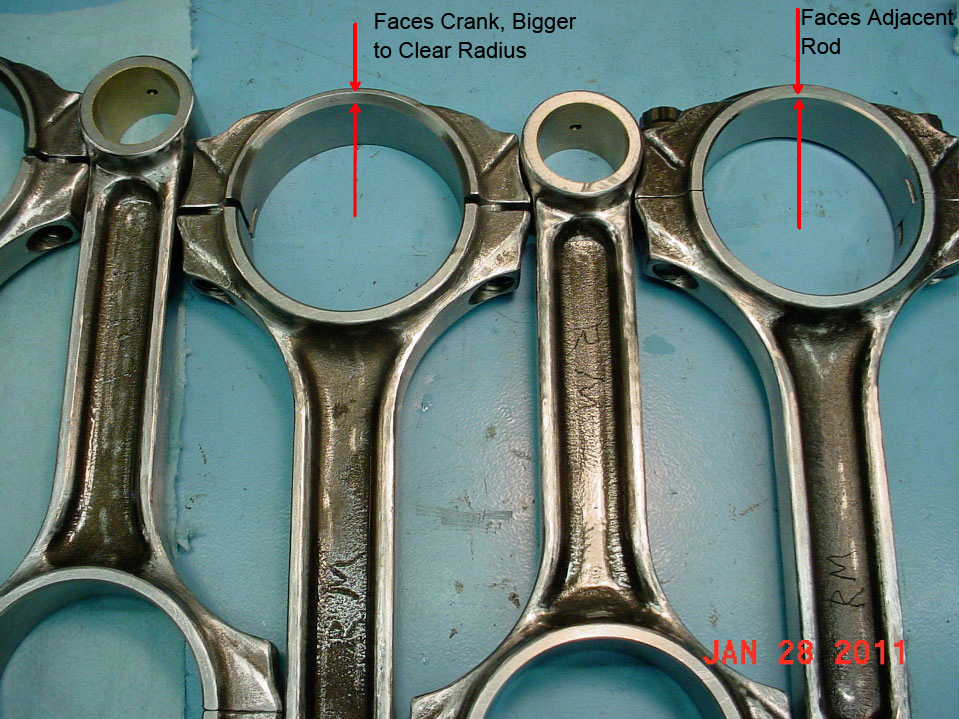

rod side clearance,

thrust bearing clearance,

ring end gap and piston slot back clearance on rings.

piston to bore clearance.

pushrod to the cylinder head, or guide plate,

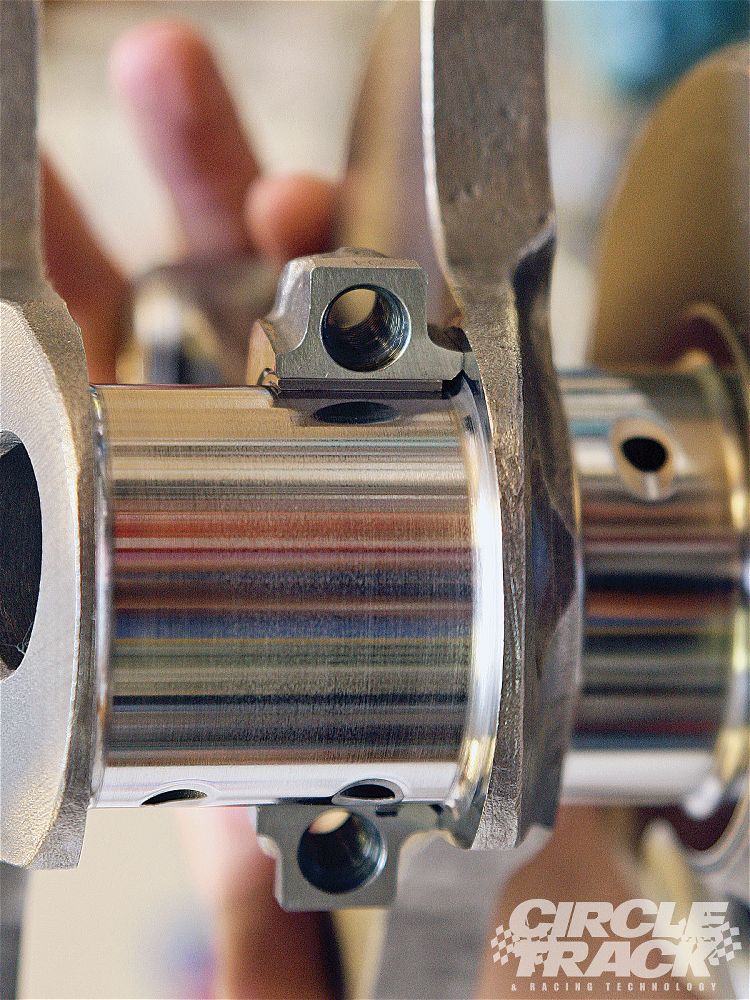

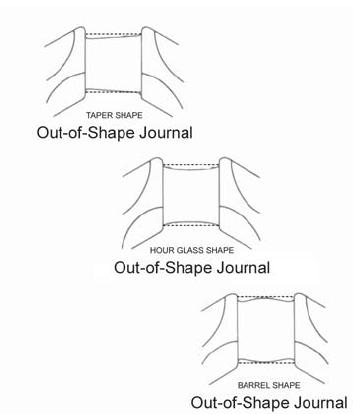

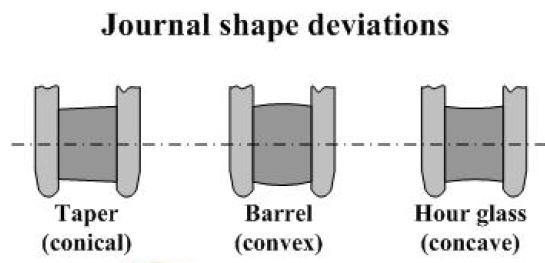

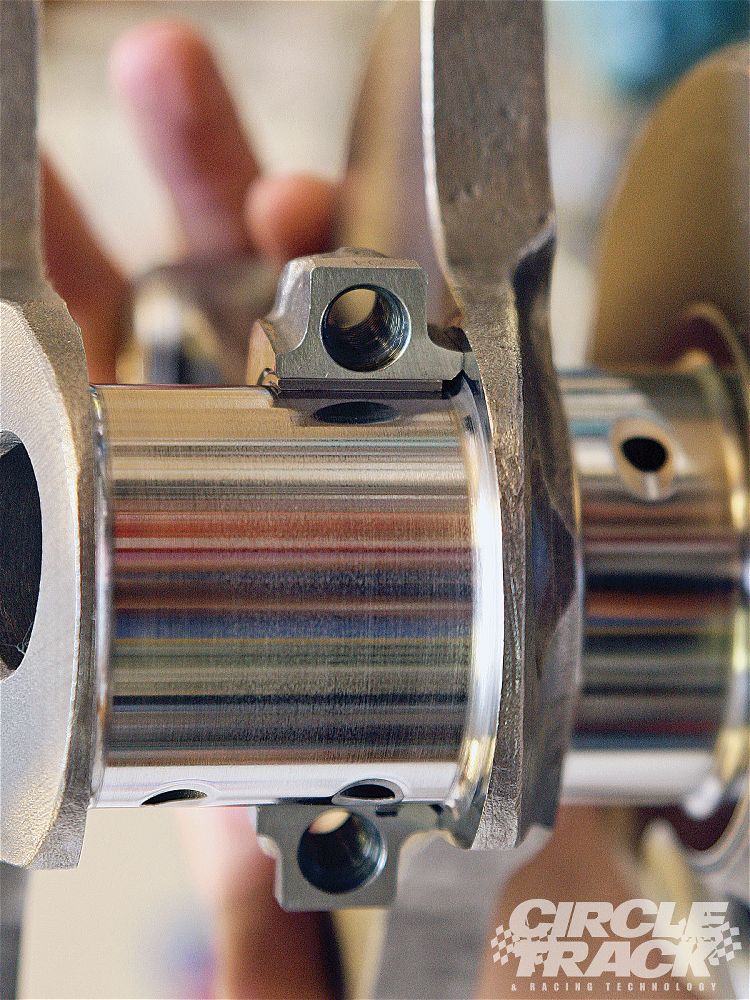

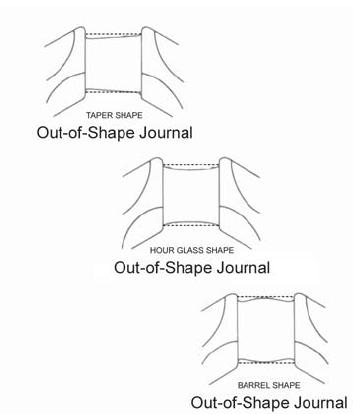

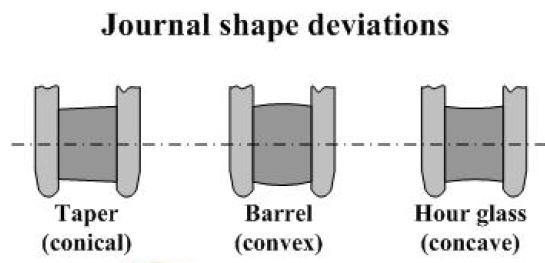

crank journal taper and concentricity and surface smoothness

cylinder head surface and not being warped

cleaning out all the threaded holes with a tap.

sonic testing bore walls

having the block , crank and heads checked for micro-cracks

verifying the oil pump drive shaft has about .050 clearance with the distributor fully seated,

replace and shim distributor gear with new cam installation

verify oil pump relief spring function, test to ensure it opens at no higher than 70 psi

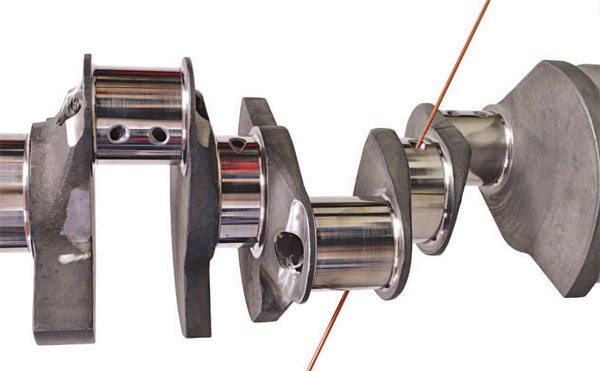

checking for crank straitness.

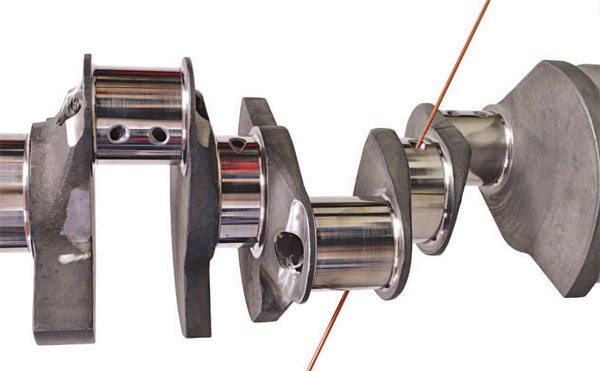

verify crank journal to counter weight junction has consistent radias

verify head gasket opening is at least .030 larger than bore diameter all the way around bore circumference

verifying main cap concentricity and shoulder depth.

verify pushrod length and valve train geometry.

timing chain slack, and/or lack of clearance to the timing cover.

verify theres no crud inside push rods or block oil passages.

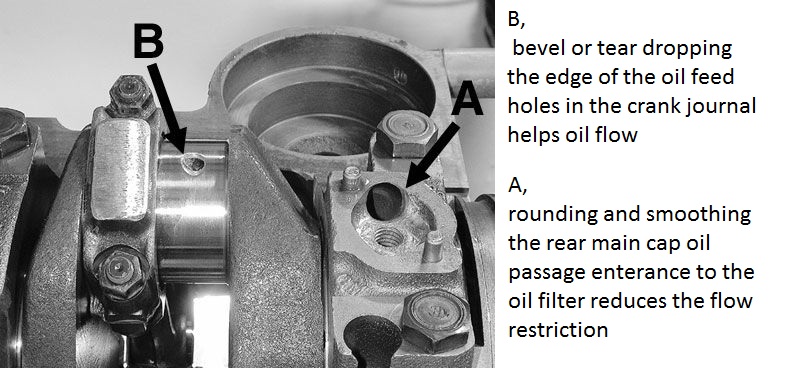

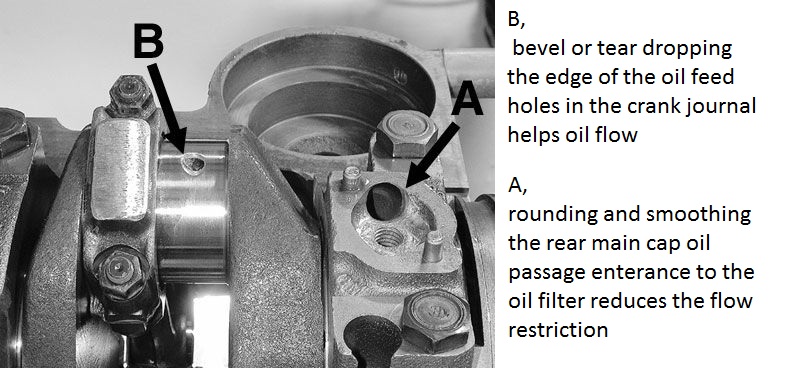

verify the block oil passages and bearing oil holes align properly (correct and bevel as required)

MEASURE CAREFULLY

notice how the rod bolts come close to the cam bearings as the pistons reach top dead canter in the bores

reading links and sub-links will take days ,

but it's sure to save you hundreds of dollars ,

and weeks of wasted effort.

http://garage.grumpysperformance.com/index.php?threads/bearing-clearances.2726/

http://garage.grumpysperformance.co...tion-of-crank-durring-short-blk-assembly.852/

http://garage.grumpysperformance.com/index.php?threads/another-rings-end-gap-question.14994/

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/

http://garage.grumpysperformance.co...alves-and-polishing-combustion-chambers.2630/

http://garage.grumpysperformance.com/index.php?threads/valve-train-clearances-and-problems.528/

http://garage.grumpysperformance.com/index.php?threads/checking-piston-to-valve-clearances.399/

http://garage.grumpysperformance.com/index.php?threads/cam-bearing-install-tools-install-info.1479/

http://garage.grumpysperformance.com/index.php?threads/rocker-push-rod-wear-issues.9815/

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

http://garage.grumpysperformance.com/index.php?threads/cylinder-head-resurfacing.15767/

http://garage.grumpysperformance.co...ng-and-basic-piston-ring-info-youll-need.509/

http://garage.grumpysperformance.com/index.php?threads/engine-assembly-tips.4294/

read the linked info

https://www.onedirt.com/tech/engine...fusion-out-of-distributor-gear-compatibility/

ok, If your going to run a big block oil pump,in a 400 sbc, the drive shaft running the oil pump is NOT necessarily shorter, it depends on the oil pump that's being used.

but in a 400 block it will need a narrowed waist area to bypass the 400 sbc larger diam. main bearing so the

ARP part # 134-7901 is used, there should be .050 minimum vertical slack/clearance once the oil pump drive shaft and distributor are assembled, obviously best verified with the engine on the engine stand and the oil pan removed with the intake and distributor temporarily assembled. a high capacity baffle oil pan equipped with a windage screen is highly advised, and verifying that the oil pump pick-up is correctly clearanced and brazed into place is mandatory

notice the welded tabs bracing the oil pump pick-up and that big block pumps have 5 cover screws unlike the small block pump with its 4 screw cover

read these

http://www.jegs.com/i/ARP/070/134-7901/10002/-1

the milodon 18770 pump is used

http://www.jegs.com/i/Milodon/697/18770/10002/-1

the 3/4" oil pan pick up that fits your oil pan is used

http://www.milodon.com/oil-pans/circle- ... -chevy.asp

example

#31504 oil pan

LATE MODEL & SPRINT -

COMPETITION SERIES, 7" DEEP

Designed for Dirt or Asphalt racing in Late Models, Modifieds, Sprint Cars that don't use a stock cross member location. The highly effective tray door system and the quick release windage tray assembly that is fastened into the pan provide 100% oil control at all times. This results in consistent oil pressure both in and out of the corners, as well as increases power output. Accepts stock large diameter flywheels. A sealed, dirt proof, screw in style dipstick and temperature sender bung are also welded into the pan.

Pan will fit a 4" stroke crank and Carillo or Eagle style rod.

Pan Capacity is 7 Quarts Plus Filter -

12" Sump Length, 7" Sump Depth

Left Hand, without dipstick 31504

Left Hand, with dipstick 31525

Oil Pump and Pick-Up Required:

Pickup with Milodon 18770 or Melling M99HV 18305

Pickup with Milodon 18750 or Melling M55HV / 10550 18306

Oil Pump 18750

Pump Drive Shaft 23050

Oil Pan Gasket 40100

Oil Pan Gasket, 1 piece, 41000

Rear Pan Baffle 32500

Oil Pan Bolts, vibration resistant 85000

related info, you'll want to read thru

viewtopic.php?f=54&t=1800

viewtopic.php?f=54&t=2187

viewtopic.php?f=54&t=2080

viewtopic.php?f=60&t=1948&p=5176&hilit=braze#p5176

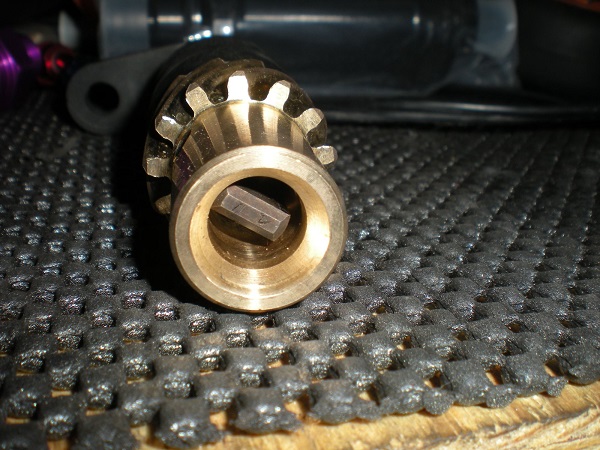

keep in mind the sbc oil pump has 7 tooth gears and the big block pumps have 12 teeth making the oil flow smoother and less pulsed, plus having larger gears they tend to supply more oil at lower rpms

look closely and youll see the big block oil pump has a 5 bolt lower cover and the oil pump pick-up with its 3/4" feed seats into the main pump casting while the small block oil pump has a 4 bolt cover and the sbc oil pump pick-up with its 5/8" feed seats into the pumps cover plate

look at the picture below, the restrictive stock O.E.M. pickup if placed to close to the oil pan floor becomes a HUGE restriction to oil flow rates

as many of you gentlemen know MELLING CHANGED the casting on their standard M55 high volume oil pumps making them weaker and thinner

like the thin casting on the left

like the thin casting on the left

but I understand that it caused a good deal of bad press and they are currently changing back to the thicker castings, but theres still thousands of the thin casting pumps in inventory that should not be use in high performance applications

did you replace the oil pump drive shaft?

theres three common lengths in those oil pump drive shafts

theres a difference in length between the drive shaft used for a common sbc oil pump,

the drive shaft used for a BIG BLOCK oil pump in a SMALL BLOCK APPLICATION,

and a BIG BLOCK oil pump drive shaft length

all can be placed in a small block,or a big block but only the correct length will function in each application

theres a difference between the sbc and bbc drive shaft designs so don,t mix them up

theres MARK IV and MARK V BBC oil pump drive shafts that differ also

theres both BBC and SBC oil pump drives and a less common oil pump drive shaft designed for using a BBC oil pumps in a SBC application thats length is between those lengths

oil pump drive shafts can be custom machined, to gain clearance, you should have about .050 clearance with the distributor seated

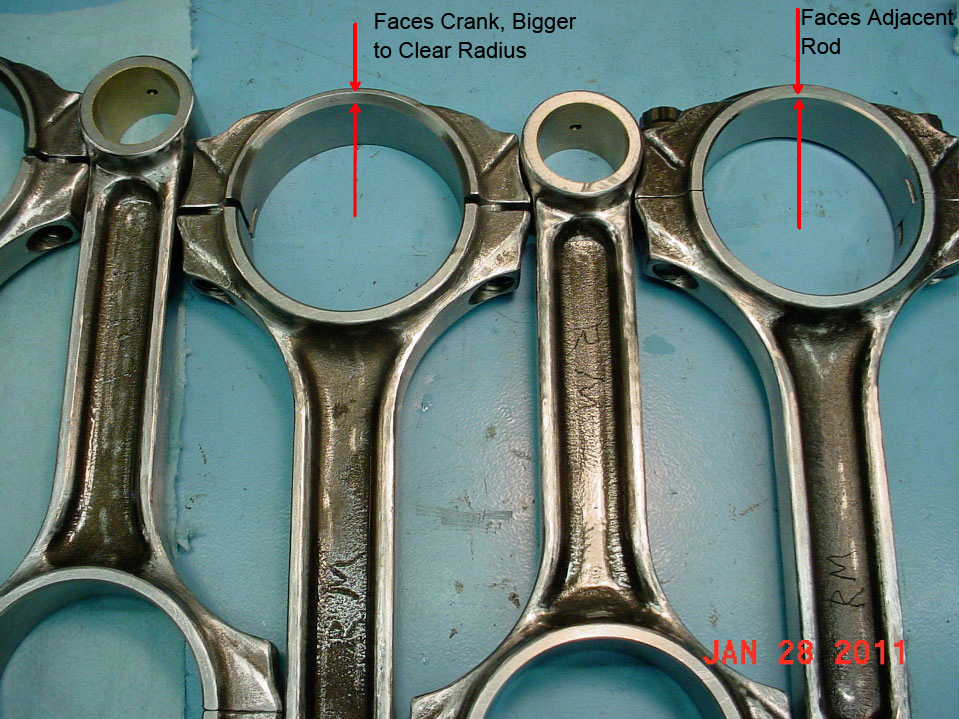

The oil pump drive shaft on the left fits any

Gen. I smallblock except the 400. The 400

shaft on the right is necked down in the center

portion to clear the wider main caps found on

the 400.

Small Block Chevy Oil & Lubrication Systems

The Chevy smallblock lubrication system is very reliable and presents no design defects to worry

about. Just keep everything clean. Change the oil and filter on a regular basis, and it will provide good

service for more than one hundred thousand miles. If the recommended main and rod bearing and

rod side clearances are maintained, a stock volume oil pump is all that is required. A high-volume or

high-pressure pump or an oil pump from a bigblock Chevy are not needed in most street applications.

These other pumps take additional horsepower to run and add more strain on the cam/distributor

drive gears and drive shaft. Checking the operating clearances on the stock oil pump and optimizing

them if necessary, will ensure adequate oil pressure. The clearance between the pump gears and the

pump gear cover should be .002" to .0025". If there is more clearance, take a sheet of 400-grit

sandpaper and some oil, then move the main pump body in a figure-8 motion over the wet sandpaper

to remove material until the clearance is correct. If there is less than the minimum clearance, you can

sand the pump gears. Remember to Loctite the pump cover bolts when you put the pump back

together.

keep in mind the distributor base forms one wall of the lifter gallery oil passage

so grooving the lower oil band helps spray extra oil on the distributor/cam gears contact area

obviously you can pre align the slot to accept the slot inside the distributor gear in the base of the distributor to allow the distributor get the rotor to face any direction when seated

remember the oil pump drive only seats in two locations 180 degrees apart but it can be lined up anyplace you want with a 18" long large flat blade screw driver prior to installing the distributor from the top of the engine rather easily before you re-seat the distributor, but as the distributor gear teeth mesh the distributor will turn the rotor about 15 degrees

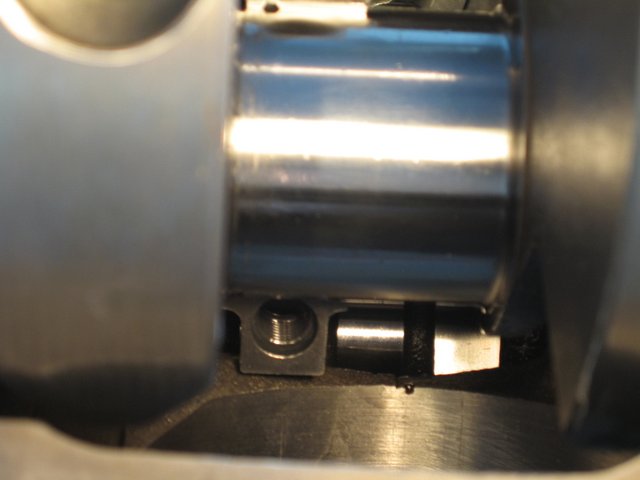

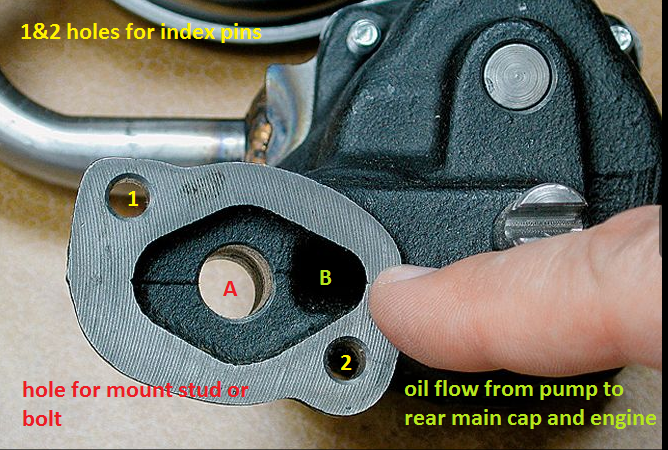

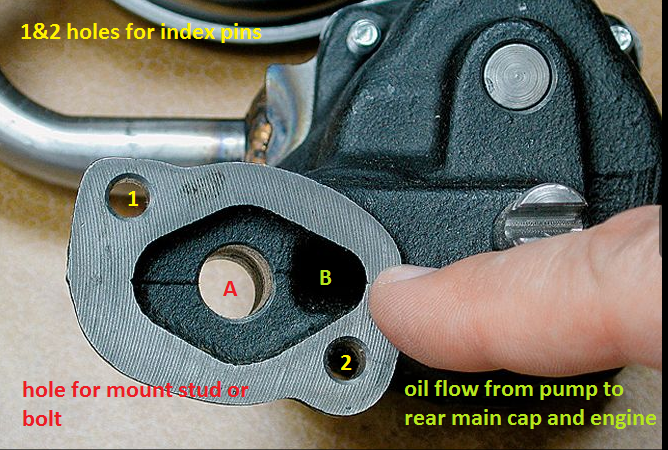

mounting the oil pump to the rear main cap

failure to use the correct oil pump,mounting stud, bolt or nut or carefully check clearances when mounting an oil pump can cause problems, AND THE HEIGHT OF THE MAIN CAPS AND OIL PUMP CASTINGS DO DIFFER, ESPECIALLY ON THE LATER BIG BLOCK VS THE EARLY BIG BLOCK COMPONENTS

BE 100% SURE that the oil pump bolt or STUD doesn,t protrude past the inner main cap surface , because if it bears on the rear main bearing shell it will almost always result in a quickly failed rear bearing[/b

ONE RATHER COMMON MISTAKE IS USING THE WRONG OIL PUMP STUD OR BOLT TO MOUNT THE OIL PUMP AS IF EITHER EXTENDS THRU THE REAR MAIN CAP SURFACE, IT CAN AND WILL BIND ON THE BEARING SHELL BACK SURFACE AND CAN LOCK OR RESTRICT, SMOOTH CRANK ROTATION.

STUDS ARE PREFERRED BECAUSE THEY GET THE THREADS THAT ENTER THE MAIN BEARING CAP COATED WITH THREAD LOCKER, LIQUID , THEN SCREWED IN TO THE MAIN CAP UNTIL THEY TOUCH THE BACK OF THE BEARING SHELL THEN BACKED OF 3/4 OF A TURN , THE OIL PUMP MOUNTED , AND THE WASHER AND FINE THREAD LOCKING NUT SECURED PER THE TORQUE SPECS.THIS INSURES THE STUD DOES NOT BEAR ON THE REAR BEARING SHELL , A BOLT WHEN TIGHTENED MUST BE TURNED DEEPER INTO THE THREADS IN THE REAR MAIN CAP, AND ITS MUCH HARDER TO PREVENT IT FROM BEARING OR CAUSING PRESSURE ON THE BACK OF THE BEARING SHELL IF ITS A BIT TOO LONG (A COMMON ISSUE, IN REBUILDS WHERE THE WRONG BOLTS USED.)

viewtopic.php?f=54&t=2187&p=5890#p5890

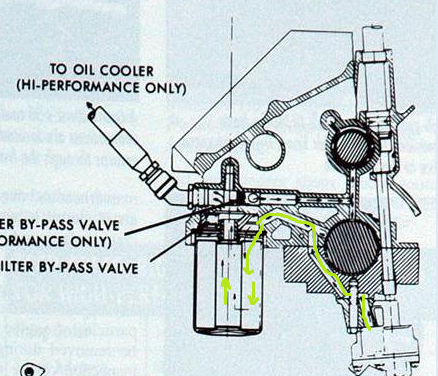

yes the oil flows around the mounting stud,from oil pump to main cap to reach the engine oil passages, thru the oil filter

just keep in mind that you'll need to very carefully blend and smooth and carefully clean,the edges of the beveled area where the oil port feeds the bearing surface with some 600 grit sand paper so the oil flows well and theres no edges to cause bearing wear issues or crud left from the process that would get embedded in the bearings.

http://www.summersbrothersracing.co...LF-CUT-DRIVE-FLANGE-BIG-BLOCK-CHEVY_p_30.html

related threads

viewtopic.php?f=54&t=3536&p=9372&hilit=pump+drive#p9372

viewtopic.php?f=54&t=123&p=326&hilit=pump+drive#p326

viewtopic.php?f=54&t=2598&p=6719&hilit=pump+drive#p6719

viewtopic.php?f=54&t=2376&p=6264&hilit=pump+drive#p6264

viewtopic.php?f=54&t=525&p=4063&hilit=pump+drive#p4063

viewtopic.php?f=70&t=1186&p=2440&hilit=pump+drive#p2440

viewtopic.php?f=54&t=615&p=819&hilit=pump+drive#p819

be sure you select the correct oil pump drive shaft

SB - is a bit shorter about 5.75"

BB - is a bit longer about - 6.50" or so

there are several other length sold by various manufacturers

there should be about .050 vertical movement, of the oil pump oi,l pump drive shaft between the oil pump and lower distributor gear with the manifold and distributor seated correctly

Id point out up front that oil pressure on the gauge is the result of the resistance the engines clearances cause to oil flow rates,and the viscosity and temperature of the oil.

if your having any problem, maintaining oil pressure you can either increase the flow rate , of viscosity of the oil used or decrease the engines clearances, increasing the oil flow or viscosity is treating a symptom, decreasing the clearances is treating the problem,both approaches will work if done correctly withing reasonable limits and both approaches have points in their favor, and potential problems, IF THE CORRECT PARTS ARE USED, but controlling the oil flow is key to success. a standard z28 sbc oil pump will provide enough oil for most applications

example of (engine building" vs parts assembly)

Id bet 80% or more of the people assembling parts have never checked most component clearances ,

except in most cases for ring end gap and bearing to crank journal, as thats almost mandatory.

things like,

piston to the cylinder head (quench)

piston to valve,

rocker slot to rocker stud,

connecting rod to cam lobe,

connecting rod to block skirt,

piston skirt to crank counterweight,

cam button to the timing cover,

spring bind height,

rod side clearance,

thrust bearing clearance,

ring end gap and piston slot back clearance on rings.

piston to bore clearance.

pushrod to the cylinder head, or guide plate,

crank journal taper and concentricity and surface smoothness

cylinder head surface and not being warped

cleaning out all the threaded holes with a tap.

sonic testing bore walls

having the block , crank and heads checked for micro-cracks

verifying the oil pump drive shaft has about .050 clearance with the distributor fully seated,

replace and shim distributor gear with new cam installation

verify oil pump relief spring function, test to ensure it opens at no higher than 70 psi

checking for crank straitness.

verify crank journal to counter weight junction has consistent radias

verify head gasket opening is at least .030 larger than bore diameter all the way around bore circumference

verifying main cap concentricity and shoulder depth.

verify pushrod length and valve train geometry.

timing chain slack, and/or lack of clearance to the timing cover.

verify theres no crud inside push rods or block oil passages.

verify the block oil passages and bearing oil holes align properly (correct and bevel as required)

MEASURE CAREFULLY

notice how the rod bolts come close to the cam bearings as the pistons reach top dead canter in the bores

reading links and sub-links will take days ,

but it's sure to save you hundreds of dollars ,

and weeks of wasted effort.

http://garage.grumpysperformance.com/index.php?threads/bearing-clearances.2726/

http://garage.grumpysperformance.co...tion-of-crank-durring-short-blk-assembly.852/

http://garage.grumpysperformance.com/index.php?threads/another-rings-end-gap-question.14994/

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/

http://garage.grumpysperformance.co...alves-and-polishing-combustion-chambers.2630/

http://garage.grumpysperformance.com/index.php?threads/valve-train-clearances-and-problems.528/

http://garage.grumpysperformance.com/index.php?threads/checking-piston-to-valve-clearances.399/

http://garage.grumpysperformance.com/index.php?threads/cam-bearing-install-tools-install-info.1479/

http://garage.grumpysperformance.com/index.php?threads/rocker-push-rod-wear-issues.9815/

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

http://garage.grumpysperformance.com/index.php?threads/cylinder-head-resurfacing.15767/

http://garage.grumpysperformance.co...ng-and-basic-piston-ring-info-youll-need.509/

http://garage.grumpysperformance.com/index.php?threads/engine-assembly-tips.4294/

read the linked info

https://www.onedirt.com/tech/engine...fusion-out-of-distributor-gear-compatibility/

ok, If your going to run a big block oil pump,in a 400 sbc, the drive shaft running the oil pump is NOT necessarily shorter, it depends on the oil pump that's being used.

but in a 400 block it will need a narrowed waist area to bypass the 400 sbc larger diam. main bearing so the

ARP part # 134-7901 is used, there should be .050 minimum vertical slack/clearance once the oil pump drive shaft and distributor are assembled, obviously best verified with the engine on the engine stand and the oil pan removed with the intake and distributor temporarily assembled. a high capacity baffle oil pan equipped with a windage screen is highly advised, and verifying that the oil pump pick-up is correctly clearanced and brazed into place is mandatory

notice the welded tabs bracing the oil pump pick-up and that big block pumps have 5 cover screws unlike the small block pump with its 4 screw cover

read these

http://www.jegs.com/i/ARP/070/134-7901/10002/-1

the milodon 18770 pump is used

http://www.jegs.com/i/Milodon/697/18770/10002/-1

the 3/4" oil pan pick up that fits your oil pan is used

http://www.milodon.com/oil-pans/circle- ... -chevy.asp

example

#31504 oil pan

LATE MODEL & SPRINT -

COMPETITION SERIES, 7" DEEP

Designed for Dirt or Asphalt racing in Late Models, Modifieds, Sprint Cars that don't use a stock cross member location. The highly effective tray door system and the quick release windage tray assembly that is fastened into the pan provide 100% oil control at all times. This results in consistent oil pressure both in and out of the corners, as well as increases power output. Accepts stock large diameter flywheels. A sealed, dirt proof, screw in style dipstick and temperature sender bung are also welded into the pan.

Pan will fit a 4" stroke crank and Carillo or Eagle style rod.

Pan Capacity is 7 Quarts Plus Filter -

12" Sump Length, 7" Sump Depth

Left Hand, without dipstick 31504

Left Hand, with dipstick 31525

Oil Pump and Pick-Up Required:

Pickup with Milodon 18770 or Melling M99HV 18305

Pickup with Milodon 18750 or Melling M55HV / 10550 18306

Oil Pump 18750

Pump Drive Shaft 23050

Oil Pan Gasket 40100

Oil Pan Gasket, 1 piece, 41000

Rear Pan Baffle 32500

Oil Pan Bolts, vibration resistant 85000

related info, you'll want to read thru

viewtopic.php?f=54&t=1800

viewtopic.php?f=54&t=2187

viewtopic.php?f=54&t=2080

viewtopic.php?f=60&t=1948&p=5176&hilit=braze#p5176

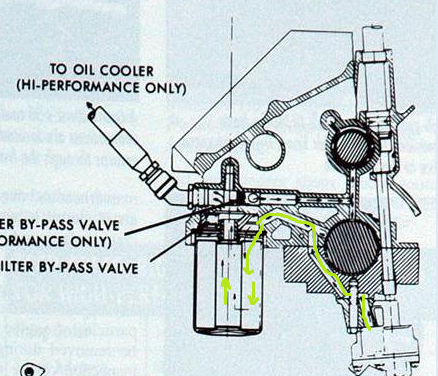

keep in mind the sbc oil pump has 7 tooth gears and the big block pumps have 12 teeth making the oil flow smoother and less pulsed, plus having larger gears they tend to supply more oil at lower rpms

look closely and youll see the big block oil pump has a 5 bolt lower cover and the oil pump pick-up with its 3/4" feed seats into the main pump casting while the small block oil pump has a 4 bolt cover and the sbc oil pump pick-up with its 5/8" feed seats into the pumps cover plate

look at the picture below, the restrictive stock O.E.M. pickup if placed to close to the oil pan floor becomes a HUGE restriction to oil flow rates

as many of you gentlemen know MELLING CHANGED the casting on their standard M55 high volume oil pumps making them weaker and thinner

but I understand that it caused a good deal of bad press and they are currently changing back to the thicker castings, but theres still thousands of the thin casting pumps in inventory that should not be use in high performance applications

did you replace the oil pump drive shaft?

theres three common lengths in those oil pump drive shafts

theres a difference in length between the drive shaft used for a common sbc oil pump,

the drive shaft used for a BIG BLOCK oil pump in a SMALL BLOCK APPLICATION,

and a BIG BLOCK oil pump drive shaft length

all can be placed in a small block,or a big block but only the correct length will function in each application

theres a difference between the sbc and bbc drive shaft designs so don,t mix them up

theres MARK IV and MARK V BBC oil pump drive shafts that differ also

theres both BBC and SBC oil pump drives and a less common oil pump drive shaft designed for using a BBC oil pumps in a SBC application thats length is between those lengths

oil pump drive shafts can be custom machined, to gain clearance, you should have about .050 clearance with the distributor seated

The oil pump drive shaft on the left fits any

Gen. I smallblock except the 400. The 400

shaft on the right is necked down in the center

portion to clear the wider main caps found on

the 400.

Small Block Chevy Oil & Lubrication Systems

The Chevy smallblock lubrication system is very reliable and presents no design defects to worry

about. Just keep everything clean. Change the oil and filter on a regular basis, and it will provide good

service for more than one hundred thousand miles. If the recommended main and rod bearing and

rod side clearances are maintained, a stock volume oil pump is all that is required. A high-volume or

high-pressure pump or an oil pump from a bigblock Chevy are not needed in most street applications.

These other pumps take additional horsepower to run and add more strain on the cam/distributor

drive gears and drive shaft. Checking the operating clearances on the stock oil pump and optimizing

them if necessary, will ensure adequate oil pressure. The clearance between the pump gears and the

pump gear cover should be .002" to .0025". If there is more clearance, take a sheet of 400-grit

sandpaper and some oil, then move the main pump body in a figure-8 motion over the wet sandpaper

to remove material until the clearance is correct. If there is less than the minimum clearance, you can

sand the pump gears. Remember to Loctite the pump cover bolts when you put the pump back

together.

keep in mind the distributor base forms one wall of the lifter gallery oil passage

so grooving the lower oil band helps spray extra oil on the distributor/cam gears contact area

obviously you can pre align the slot to accept the slot inside the distributor gear in the base of the distributor to allow the distributor get the rotor to face any direction when seated

remember the oil pump drive only seats in two locations 180 degrees apart but it can be lined up anyplace you want with a 18" long large flat blade screw driver prior to installing the distributor from the top of the engine rather easily before you re-seat the distributor, but as the distributor gear teeth mesh the distributor will turn the rotor about 15 degrees

mounting the oil pump to the rear main cap

failure to use the correct oil pump,mounting stud, bolt or nut or carefully check clearances when mounting an oil pump can cause problems, AND THE HEIGHT OF THE MAIN CAPS AND OIL PUMP CASTINGS DO DIFFER, ESPECIALLY ON THE LATER BIG BLOCK VS THE EARLY BIG BLOCK COMPONENTS

BE 100% SURE that the oil pump bolt or STUD doesn,t protrude past the inner main cap surface , because if it bears on the rear main bearing shell it will almost always result in a quickly failed rear bearing[/b

ONE RATHER COMMON MISTAKE IS USING THE WRONG OIL PUMP STUD OR BOLT TO MOUNT THE OIL PUMP AS IF EITHER EXTENDS THRU THE REAR MAIN CAP SURFACE, IT CAN AND WILL BIND ON THE BEARING SHELL BACK SURFACE AND CAN LOCK OR RESTRICT, SMOOTH CRANK ROTATION.

STUDS ARE PREFERRED BECAUSE THEY GET THE THREADS THAT ENTER THE MAIN BEARING CAP COATED WITH THREAD LOCKER, LIQUID , THEN SCREWED IN TO THE MAIN CAP UNTIL THEY TOUCH THE BACK OF THE BEARING SHELL THEN BACKED OF 3/4 OF A TURN , THE OIL PUMP MOUNTED , AND THE WASHER AND FINE THREAD LOCKING NUT SECURED PER THE TORQUE SPECS.THIS INSURES THE STUD DOES NOT BEAR ON THE REAR BEARING SHELL , A BOLT WHEN TIGHTENED MUST BE TURNED DEEPER INTO THE THREADS IN THE REAR MAIN CAP, AND ITS MUCH HARDER TO PREVENT IT FROM BEARING OR CAUSING PRESSURE ON THE BACK OF THE BEARING SHELL IF ITS A BIT TOO LONG (A COMMON ISSUE, IN REBUILDS WHERE THE WRONG BOLTS USED.)

viewtopic.php?f=54&t=2187&p=5890#p5890

yes the oil flows around the mounting stud,from oil pump to main cap to reach the engine oil passages, thru the oil filter

just keep in mind that you'll need to very carefully blend and smooth and carefully clean,the edges of the beveled area where the oil port feeds the bearing surface with some 600 grit sand paper so the oil flows well and theres no edges to cause bearing wear issues or crud left from the process that would get embedded in the bearings.

http://www.summersbrothersracing.co...LF-CUT-DRIVE-FLANGE-BIG-BLOCK-CHEVY_p_30.html

related threads

viewtopic.php?f=54&t=3536&p=9372&hilit=pump+drive#p9372

viewtopic.php?f=54&t=123&p=326&hilit=pump+drive#p326

viewtopic.php?f=54&t=2598&p=6719&hilit=pump+drive#p6719

viewtopic.php?f=54&t=2376&p=6264&hilit=pump+drive#p6264

viewtopic.php?f=54&t=525&p=4063&hilit=pump+drive#p4063

viewtopic.php?f=70&t=1186&p=2440&hilit=pump+drive#p2440

viewtopic.php?f=54&t=615&p=819&hilit=pump+drive#p819

Last edited by a moderator: