hi grumpy

i get a little scared on my oil temp. engine is a 540bbc (world alum block and brodix heads, comp street solid roller). water temp is never an issue, as long as i can drive no matter if i let it scream or just cruise it stays at 180°f, if i get into stop and go traffic it can go up to 200°f but if i turn on my electric fan doesn´t move any further. i installed my autometer gauges right underneath the intake cause the world bbc block has a hole there for a sender. oil pan is a kicked out milodon. oil pressure was cold at 50psi @idle/revs and hot at 20psi idle and 45psi from 2000 up but doesn´t move up any further. oil temp reaches 210 very fast and stays at around 220-230° and can go up to 250° at hauling censored...

that scared me so i installed my old oil cooler and added a oil filter relocation kit. problem was that with the cooler sandwich adapter i couldn´t use long filters cause they hit the sump. so i installed the derale filter relocation with a long k&n gold oil filter (oil filter is a ford type) and my oil cooler. problem now is that i added a lot of oil which should help too lowering temp but nothing happened. temperature stays the same like before but oil pressure dropped to 45psi cold and around 35 hot. should i move back to the original oil filter just with the sandwich adapter for the cooler or just leave it that way? there´s no thermostat in the system and all oil is forced through the filter then the cooler and back into the engine.

BBC

SBC

well first it sounds like the oil cooler or oil cooler lines may be restricting oil flow and thats more than likely the cause of the pressure drop,Id suggest a minimum AN # 8 or 1/2" inside line diam. but what your describing is very common.

keep in mind the (WEAK LINK IN THE CHAIN CONCEPT) it does little good to feed a 3/8" oil cooler with 1/2" lines. the whole route from the feed to return in a cooling system should maintain at least a 1/2" diam, if the 3/8" is not providing the required flow rates, and you might need to go to a 5/8" lines and cooler in rare cases

keep in mind your oil temp sensors measuring oil after its heated in that location, not as it re-enters the engine, oil temps are usually measured in the port located just above the oil filter or in the sump, oil normally runs 50F higher as it leaves the valve train or bearings.

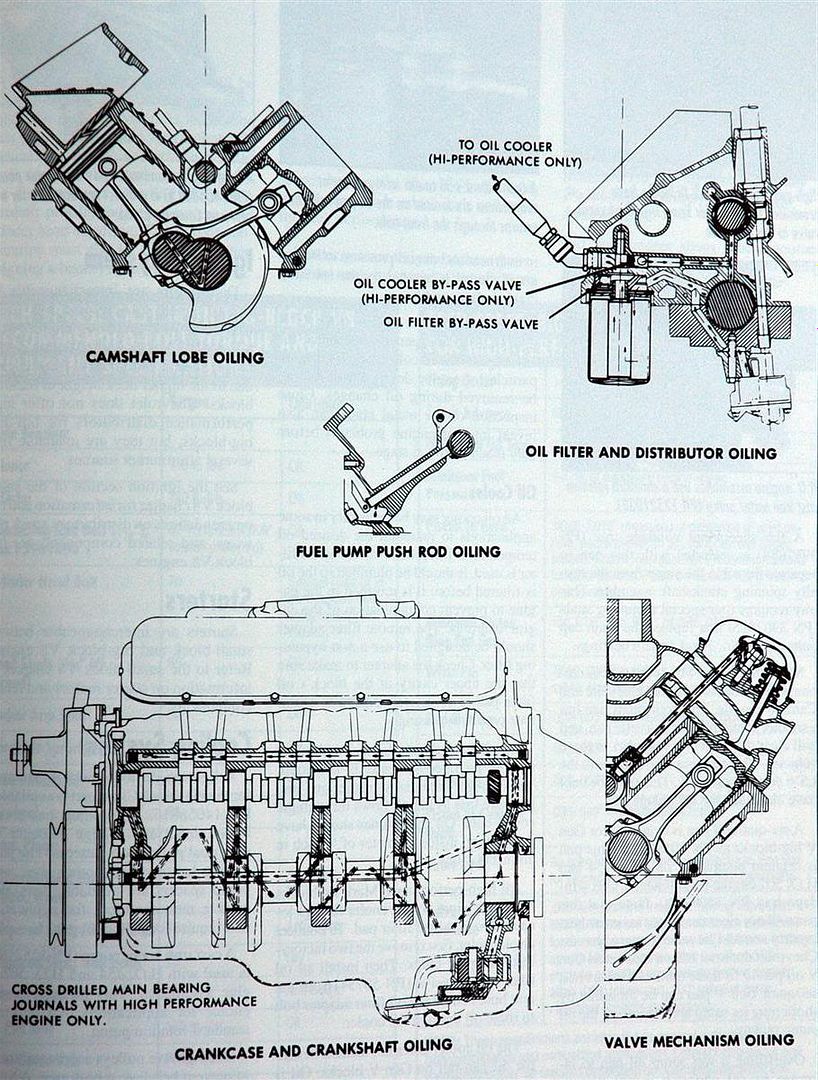

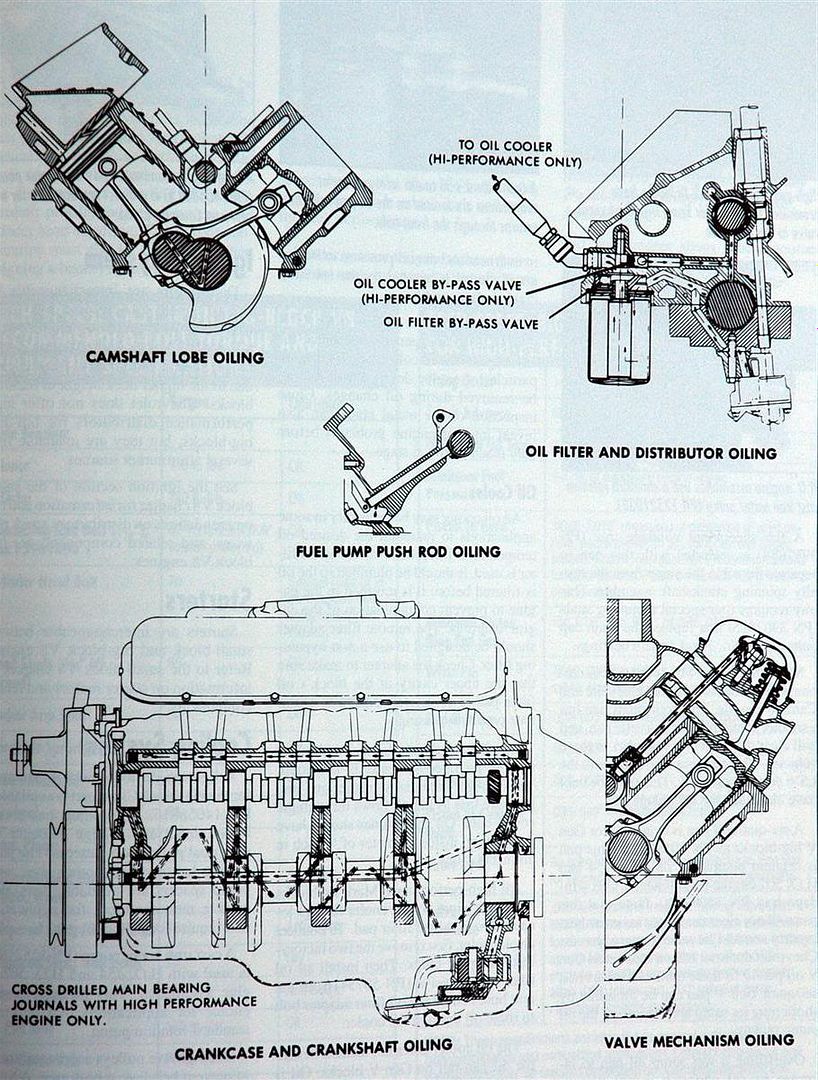

most guys don,t realize that the valve train friction and valve springs produce almost 1/2 of all engine heat generated, so oil flowing over the valve springs , and rockers and lifters ,absorbs a great deal of heat transfer to the oil

the better synthetic oils can easily handle the temp range your describing and can normally last 8K-10K between changes on a street car, if the oil filters changed every 3K-4K

pressure drops with remote coolers or filter mounts are almost always the result of using hydraulic lines AND hydraulic line connections with too small an INTERNAL cross sectional area, anything less than AN#8 is bound to be restrictive and AN#10 is far better, and much less likely to cause issues with pressure drops, obviously the adapters and fittings used for fluid transmission must also have at least AN# 8 OR PREFERABLY AN#10 CONNECTIONS , if you run 3/8" OR AN#6 LINES YOUR BOUND TO FIND IT DROPS RETURN LINE PRESSURE, and just as obviously this would mean the passage or tube size of the oil cooler must be at least AN#8 as the coolers with AN#6 internal passages tend to restrict flow so read carefully before you buy an oil or trans cooler

oil pressure is a measure of resistance to flow volume, if the oil cooler and lines restrict flow volume to the bearings and oil passages in the block,then the oil pressure drops, you either increase the line size to reduce flow restriction (BEST ROUTE) or install a larger high volume oil pump to try to compensate for the restriction,(WORKS BUT NOT IDEAL) or (ideally do BOTH )

Dino Oil

Minimum temp before you hammer on the engine 180f degrees

Safe operating temp 180f to 225f degrees

230f engine will work but continued use at this temp will fatigue oil and bearings

240f is max for a short time. Continued use and fatigue will degrade engine oil life

Synthetic

Minimum temp before you hammer engine 180f

Safe operating range is 190f to 240f

240f to 260f is max range you want synthetic to see before oil fatigue sets in

Above 260f-280f engine will run but needs very meticulous maintenance. and frequent oil changes

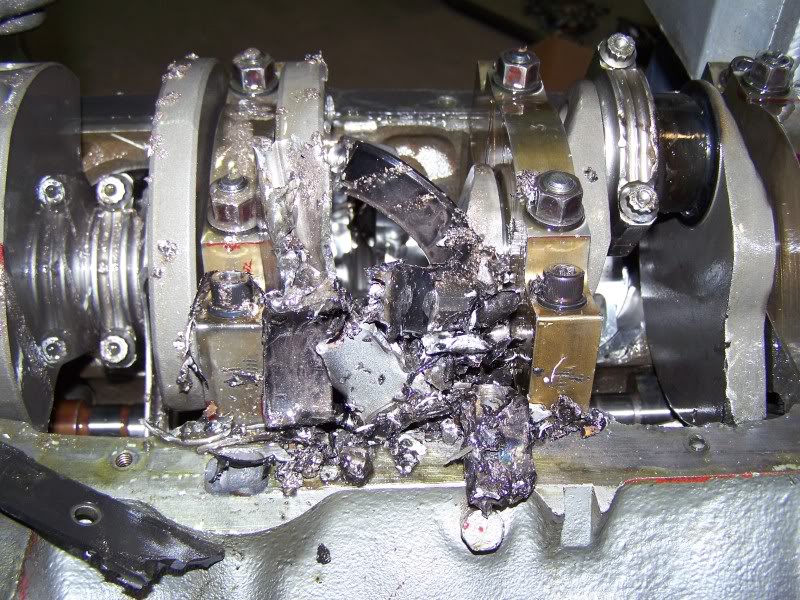

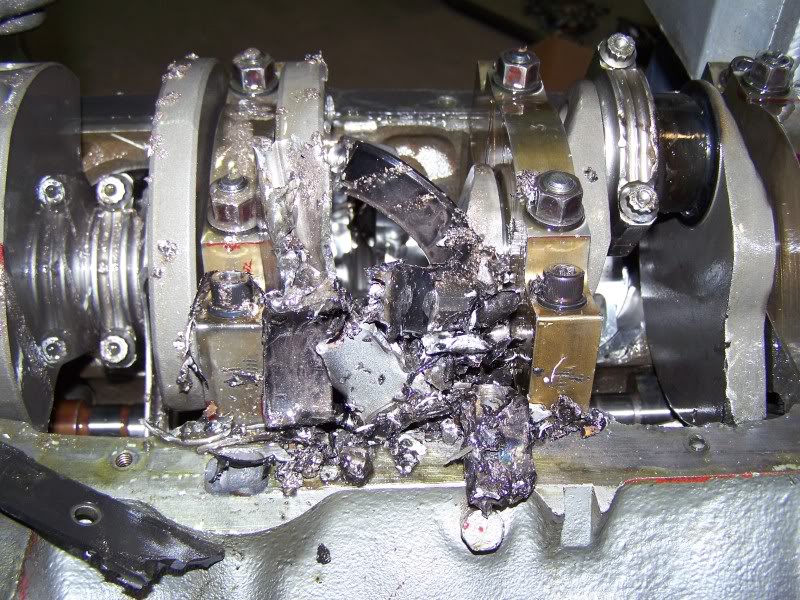

failure to maintain a correctly functioning lubrication system,maintain, valve train control, provide consistent cooling and an ignition advance curve and to stay out of detonation can result in expensive lessons in engine repair

BTW HERES AN IMPORTANT TIP, IT is really common for guys to use lines that are far to small, that restrict flow oil flow or select a transmission or oil cooler that has to small of internal passages, shop carefully you want a MINIMUM of 1/2, or AN8 line size and 5/8" or AN10 is BETTER

think about it, your measuring the oil pressure in most cases AFTER its been thru the cooler and returned to the oil passages in the block, oil leaves the oil pump and its routed to the oil filter where the oil filter adapter routes it thru the oil cooler and back to the adapter then into the block, your measuring the restricted oil flow after its returned to the block, if the lines or cooler passages restrict oil flow its potentially a problem for lubrication of the moving parts if pressure or oil volumes reduced

viewtopic.php?f=57&t=176

i get a little scared on my oil temp. engine is a 540bbc (world alum block and brodix heads, comp street solid roller). water temp is never an issue, as long as i can drive no matter if i let it scream or just cruise it stays at 180°f, if i get into stop and go traffic it can go up to 200°f but if i turn on my electric fan doesn´t move any further. i installed my autometer gauges right underneath the intake cause the world bbc block has a hole there for a sender. oil pan is a kicked out milodon. oil pressure was cold at 50psi @idle/revs and hot at 20psi idle and 45psi from 2000 up but doesn´t move up any further. oil temp reaches 210 very fast and stays at around 220-230° and can go up to 250° at hauling censored...

that scared me so i installed my old oil cooler and added a oil filter relocation kit. problem was that with the cooler sandwich adapter i couldn´t use long filters cause they hit the sump. so i installed the derale filter relocation with a long k&n gold oil filter (oil filter is a ford type) and my oil cooler. problem now is that i added a lot of oil which should help too lowering temp but nothing happened. temperature stays the same like before but oil pressure dropped to 45psi cold and around 35 hot. should i move back to the original oil filter just with the sandwich adapter for the cooler or just leave it that way? there´s no thermostat in the system and all oil is forced through the filter then the cooler and back into the engine.

BBC

SBC

well first it sounds like the oil cooler or oil cooler lines may be restricting oil flow and thats more than likely the cause of the pressure drop,Id suggest a minimum AN # 8 or 1/2" inside line diam. but what your describing is very common.

keep in mind the (WEAK LINK IN THE CHAIN CONCEPT) it does little good to feed a 3/8" oil cooler with 1/2" lines. the whole route from the feed to return in a cooling system should maintain at least a 1/2" diam, if the 3/8" is not providing the required flow rates, and you might need to go to a 5/8" lines and cooler in rare cases

keep in mind your oil temp sensors measuring oil after its heated in that location, not as it re-enters the engine, oil temps are usually measured in the port located just above the oil filter or in the sump, oil normally runs 50F higher as it leaves the valve train or bearings.

most guys don,t realize that the valve train friction and valve springs produce almost 1/2 of all engine heat generated, so oil flowing over the valve springs , and rockers and lifters ,absorbs a great deal of heat transfer to the oil

the better synthetic oils can easily handle the temp range your describing and can normally last 8K-10K between changes on a street car, if the oil filters changed every 3K-4K

pressure drops with remote coolers or filter mounts are almost always the result of using hydraulic lines AND hydraulic line connections with too small an INTERNAL cross sectional area, anything less than AN#8 is bound to be restrictive and AN#10 is far better, and much less likely to cause issues with pressure drops, obviously the adapters and fittings used for fluid transmission must also have at least AN# 8 OR PREFERABLY AN#10 CONNECTIONS , if you run 3/8" OR AN#6 LINES YOUR BOUND TO FIND IT DROPS RETURN LINE PRESSURE, and just as obviously this would mean the passage or tube size of the oil cooler must be at least AN#8 as the coolers with AN#6 internal passages tend to restrict flow so read carefully before you buy an oil or trans cooler

oil pressure is a measure of resistance to flow volume, if the oil cooler and lines restrict flow volume to the bearings and oil passages in the block,then the oil pressure drops, you either increase the line size to reduce flow restriction (BEST ROUTE) or install a larger high volume oil pump to try to compensate for the restriction,(WORKS BUT NOT IDEAL) or (ideally do BOTH )

Dino Oil

Minimum temp before you hammer on the engine 180f degrees

Safe operating temp 180f to 225f degrees

230f engine will work but continued use at this temp will fatigue oil and bearings

240f is max for a short time. Continued use and fatigue will degrade engine oil life

Synthetic

Minimum temp before you hammer engine 180f

Safe operating range is 190f to 240f

240f to 260f is max range you want synthetic to see before oil fatigue sets in

Above 260f-280f engine will run but needs very meticulous maintenance. and frequent oil changes

failure to maintain a correctly functioning lubrication system,maintain, valve train control, provide consistent cooling and an ignition advance curve and to stay out of detonation can result in expensive lessons in engine repair

BTW HERES AN IMPORTANT TIP, IT is really common for guys to use lines that are far to small, that restrict flow oil flow or select a transmission or oil cooler that has to small of internal passages, shop carefully you want a MINIMUM of 1/2, or AN8 line size and 5/8" or AN10 is BETTER

think about it, your measuring the oil pressure in most cases AFTER its been thru the cooler and returned to the oil passages in the block, oil leaves the oil pump and its routed to the oil filter where the oil filter adapter routes it thru the oil cooler and back to the adapter then into the block, your measuring the restricted oil flow after its returned to the block, if the lines or cooler passages restrict oil flow its potentially a problem for lubrication of the moving parts if pressure or oil volumes reduced

viewtopic.php?f=57&t=176