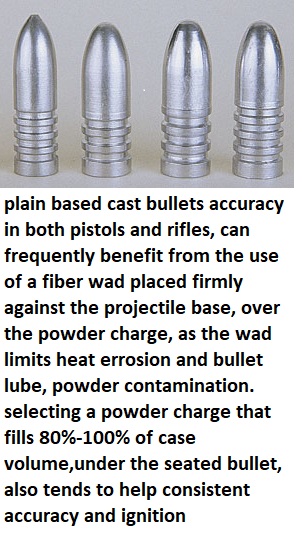

have you ever wondered why cheap cast reloads have poor accuracy and smoke so badly?

non-gas check bullets that are faster to make and cheaper too use,

are generally used and lube mixed with the powder is a common contributing factor.

the answer to how to improve the accuracy and reduce the smoke?

depends on both the lube and the amount of lube, and Ive investigated this rather extensively,

its my observation that some lube melts and contaminates/degrades the powder charge,

lube contaminated powder does not burn well, and because you have very little control,

on the amount of lube reaching the powder in weeks or months of storage

the cure is a properly installed barrier between the bullet and powder, an insert isolation wad

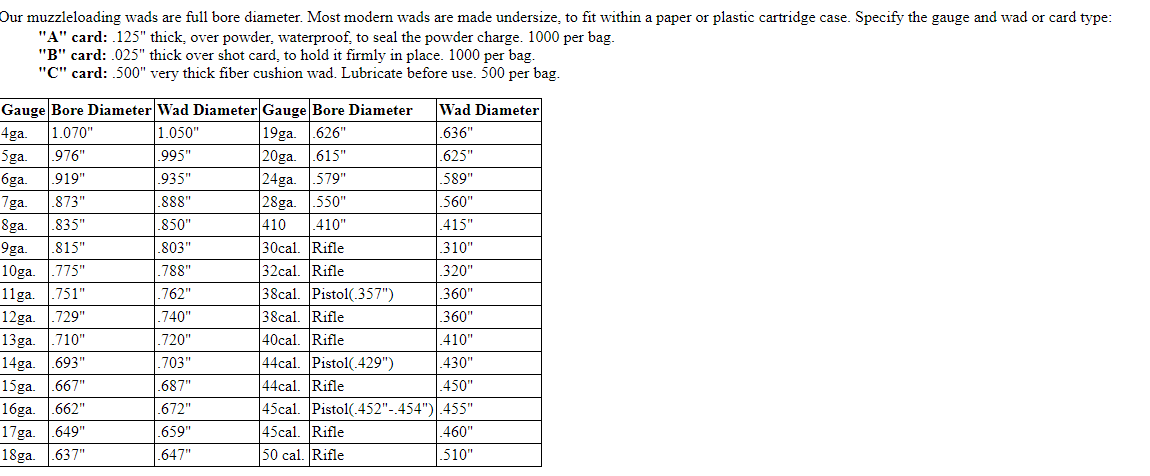

in the past bigger old school gun shops carried 357-44,45 caliber wads rather commonly

example on my 44 mag with non-gas check bullets

430" diameter Vegetable Fiber Wad, ideal for .44-40 caliber, .062" thick card, 1000, by Circle Fly Wads

if your loading non-gas check projectiles , especially with soft lube that may melt over time

,if left in a hot car or un-air-conditioned storage

load the powder charge, insert a spacer wad, then load and crimp the bullet,

remember the wad takes up powder space, thus it potentially raises pressure,at least marginally,

so you need to work up loads starting with about a 10% reduced load.

if this sounds like a P.I.T.A. your correct , most guys don,t shoot well enough to see a difference,

or at long enough ranges to see a difference and if you want to avoid the whole deal,

swapping to GAS CHECK BULLETS and harder lubes tends to eliminate the potential problem

the fiber wad you use should be pushed into the brass case as you seat the bullet,

and placed in solid contact with the base of the bullet,

there should be zero air space between the bullet base and the fiber wad

the wad acts like a fiber gas check thats not attached to the bullet base,

wads should be a tight fit in the brass case ,and in contact with the bullet base

leaving any air space between the bullet base,and wad like the pictures below, is a BIG POTENTIAL PROBLEM

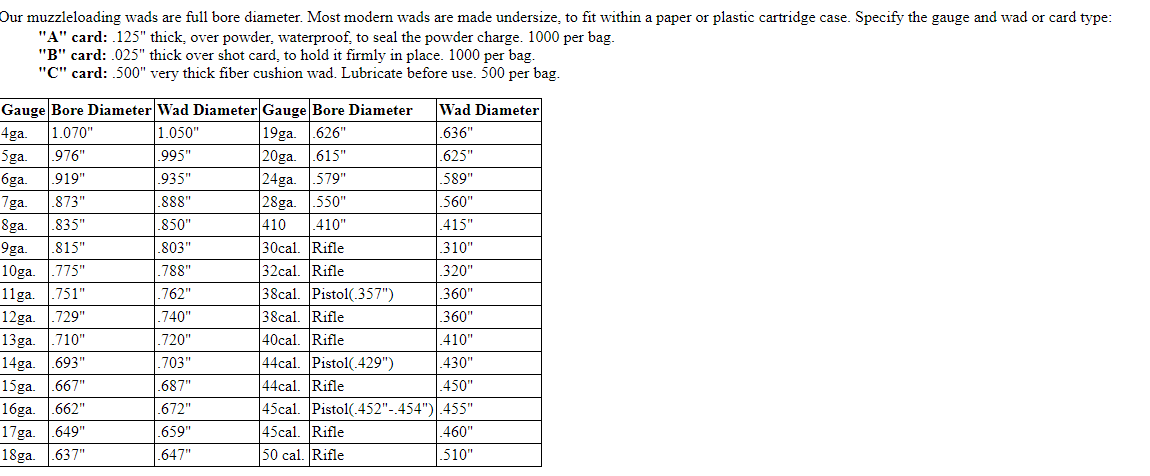

https://www.trackofthewolf.com/Searc.../2?search=wads

hardly new info

https://csharpsarms.com/cartridge%20...g%20manual.pdf

over card wads have been used since the 1860s to increase accuracy on cast bullet loads

read the sharps manual

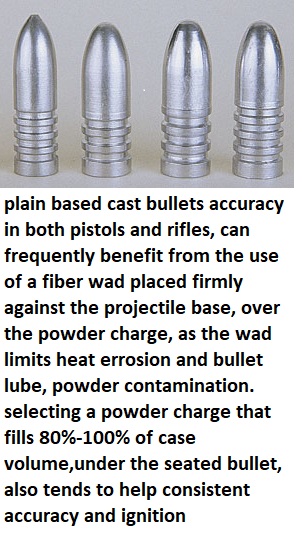

non-gas check bullets that are faster to make and cheaper too use,

are generally used and lube mixed with the powder is a common contributing factor.

the answer to how to improve the accuracy and reduce the smoke?

depends on both the lube and the amount of lube, and Ive investigated this rather extensively,

its my observation that some lube melts and contaminates/degrades the powder charge,

lube contaminated powder does not burn well, and because you have very little control,

on the amount of lube reaching the powder in weeks or months of storage

the cure is a properly installed barrier between the bullet and powder, an insert isolation wad

in the past bigger old school gun shops carried 357-44,45 caliber wads rather commonly

example on my 44 mag with non-gas check bullets

430" diameter Vegetable Fiber Wad, ideal for .44-40 caliber, .062" thick card, 1000, by Circle Fly Wads

if your loading non-gas check projectiles , especially with soft lube that may melt over time

,if left in a hot car or un-air-conditioned storage

load the powder charge, insert a spacer wad, then load and crimp the bullet,

remember the wad takes up powder space, thus it potentially raises pressure,at least marginally,

so you need to work up loads starting with about a 10% reduced load.

if this sounds like a P.I.T.A. your correct , most guys don,t shoot well enough to see a difference,

or at long enough ranges to see a difference and if you want to avoid the whole deal,

swapping to GAS CHECK BULLETS and harder lubes tends to eliminate the potential problem

the fiber wad you use should be pushed into the brass case as you seat the bullet,

and placed in solid contact with the base of the bullet,

there should be zero air space between the bullet base and the fiber wad

the wad acts like a fiber gas check thats not attached to the bullet base,

wads should be a tight fit in the brass case ,and in contact with the bullet base

leaving any air space between the bullet base,and wad like the pictures below, is a BIG POTENTIAL PROBLEM

https://www.trackofthewolf.com/Searc.../2?search=wads

hardly new info

https://csharpsarms.com/cartridge%20...g%20manual.pdf

over card wads have been used since the 1860s to increase accuracy on cast bullet loads

read the sharps manual

Last edited: