yes theres almost ZERO difference in the result, or measurement,

(yes I personally tested this several times)

simply because the lubricant squeeze's out very easily , thus having nearly no effect,

BTW I generally spray the crank journal and bearing surfaces with WD40,

to prevent the plasti -gauge from sticking or stretching when removed

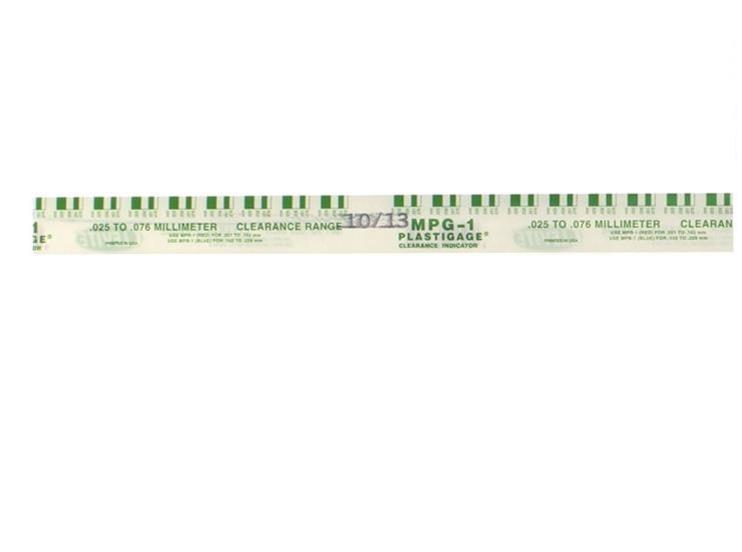

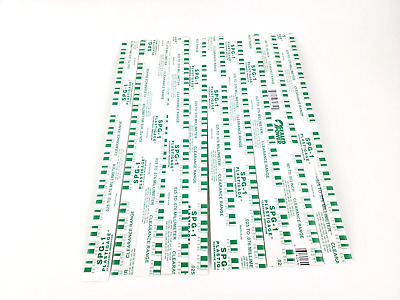

Free Shipping - Clevite 77 Plastigage with qualifying orders of $109. Shop Plastigage at Summit Racing.

www.summitracing.com

I’m looking for the best quality precision tools on a limited budget (i.e. I don't want to pay $300 for one mic). I plan on building the occasional small- & big-block Chevy (more than one, less than 1000). Names that come up on the limited results I’ve found on the web include Starrett...

garage.grumpysperformance.com

Bearings and oil flow

https://garage.grumpysperformance.com/index.php?threads/building-a-custom-wet-sump-oil-pan.65/ http://www.babcox.com/editorial/us/us90126.htm http://www.insightservices.net/testoil/ ... cation.htm

http://www.thirskauto.net/BearingPics.html...

garage.grumpysperformance.com

yeah a 2lb dead blow hammer to

gently whack or two on both sides and the bottom surface, on the blocks main caps after you've torqued them into place to verify they are firmly seated and a quick recheck on the torque settings is generally a good idea,

this is also a good idea when checking clearance's with plasti -gauge on main bearings)

and cutting a shallow , .006 thousands deep)oil groove in a thrust bearing vertical surface to add additional oil flow to the crank/bearing surface to help lube that surface as you depress the clutch with a jewelers file certainly aids increased durability

Amazing deals on this 2Lb Neon Orange Dead Blow Hammer at Harbor Freight. Quality tools & low prices.

www.harborfreight.com

Discover the Eze-Lap Diamond Needle Files. Buy this product now on our Lee Valley online store.

www.leevalley.com

I just got an e-mail asking what to do if you find that the blocks oil feed passage holes don,t line up exactly right with the holes in the oil feed holes in bearings shells?

http://garage.grumpysperformance.com/index.php?threads/viscosity-centistoke.15612/ paint, marker etc. tends to...

garage.grumpysperformance.com

Item for sale: 10pcs Plastigage Green Main Rod Bearing Clearance Gauge Indicator Tool. 001-.003. 10 pieces of green. Other uses include marine drive shaft bearings, turbine housing bearings, pump and pressure system bearings, shaft end-float, flatness and clearance in pipe-flanges and cylinder...

www.ebay.com

Make sure your bearing clearances are in spec.

www.ebay.com

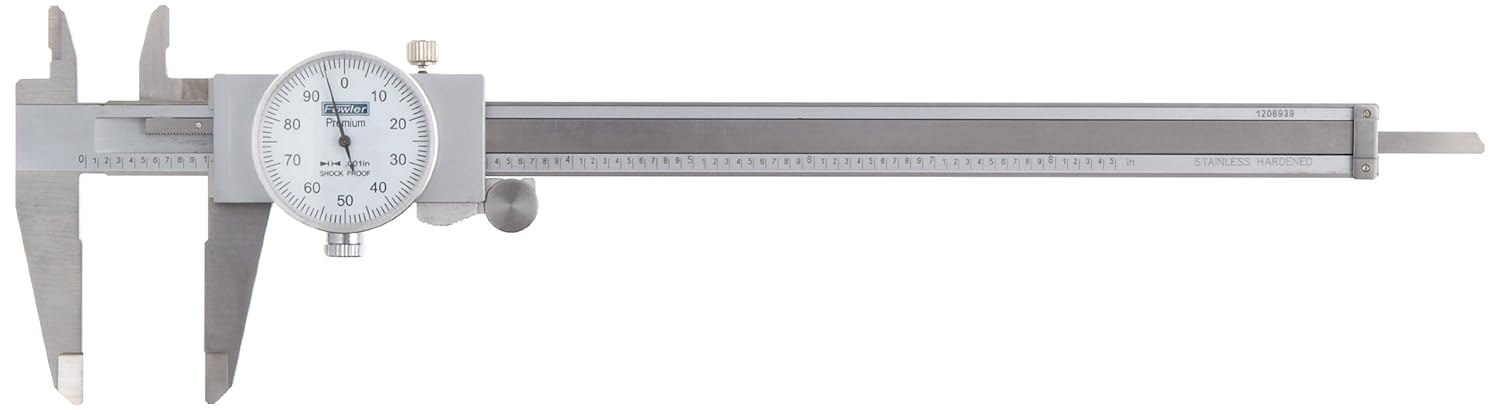

Hey GRUMPY, I need a few basic tools to measure bearing clearances and tools for installing a cam, etc, and suggestions? (and yeah, I'm not swimming in cash, so please take that into account!) keep in mind there's a long list of more expensive tools, like mills, lathes, various types of...

garage.grumpysperformance.com

Understanding Today’s Bearing Clearance Recipe related info. http://garage.grumpysperformance.com/index.php?threads/bearing-clearances.2726/page-2#post-75256 http://garage.grumpysperformance.com/index.php?threads/bearings-and-oil-flow.150/#post-68205...

garage.grumpysperformance.com

855-3851880

Discover VEVOR Micrometer Set 0-6" Machinist Tool Micrometer Set 0.0001" Accuracy 6 Pcs Precision Machinist Tool Set Micrometer, Laser-Etched Micrometer with Calibration Standards, Wrench, Professional Measurement Tools and Calibration Standards at lowest price, 2days delivery, 30days returns.

www.vevor.com

http://garage.grumpysperformance.co...guess-on-clearances-and-journal-surface.9955/

http://garage.grumpysperformance.com/index.php?threads/bearing-clearances.2726/

http://garage.grumpysperformance.co...tion-of-crank-durring-short-blk-assembly.852/

http://garage.grumpysperformance.com/index.php?threads/rotating-assembly-bearings.9527/