(Z51l9889 posted much of this)

viewtopic.php?f=55&t=1509&p=3459&hilit=base+runner+plenum#p3459

http://www.firstfuelinjection.com/products.htm

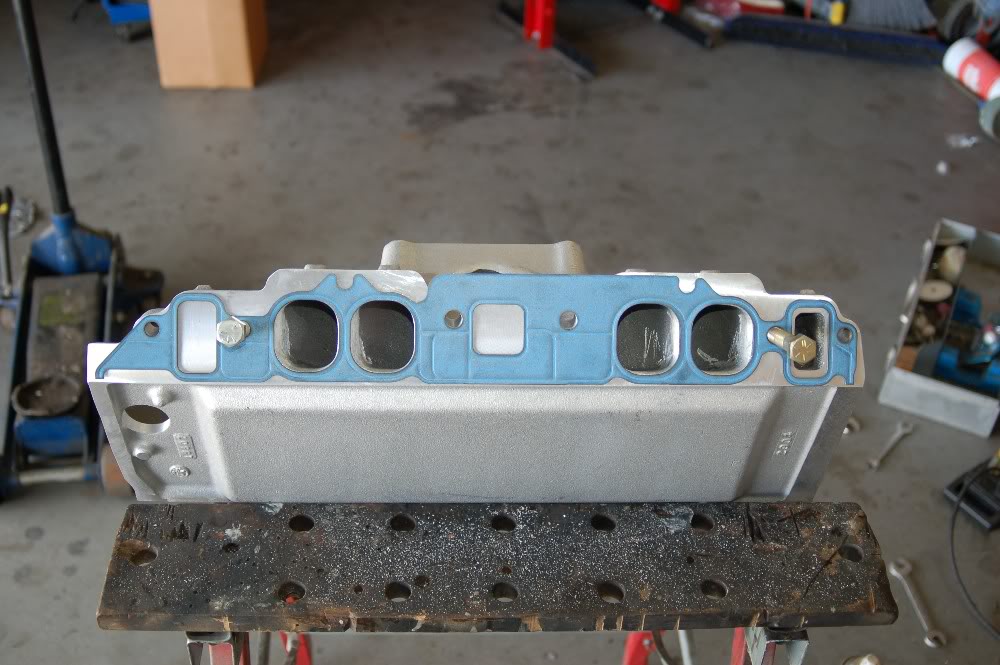

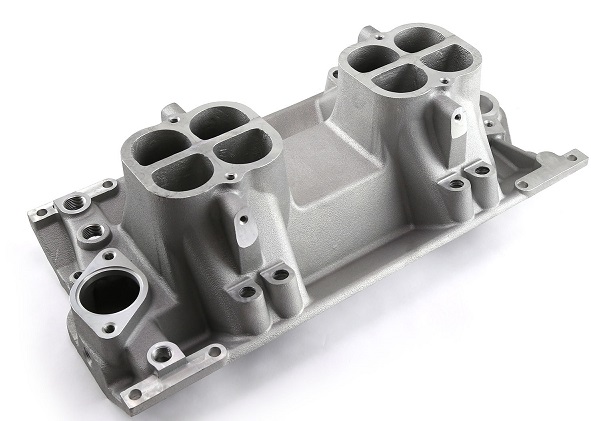

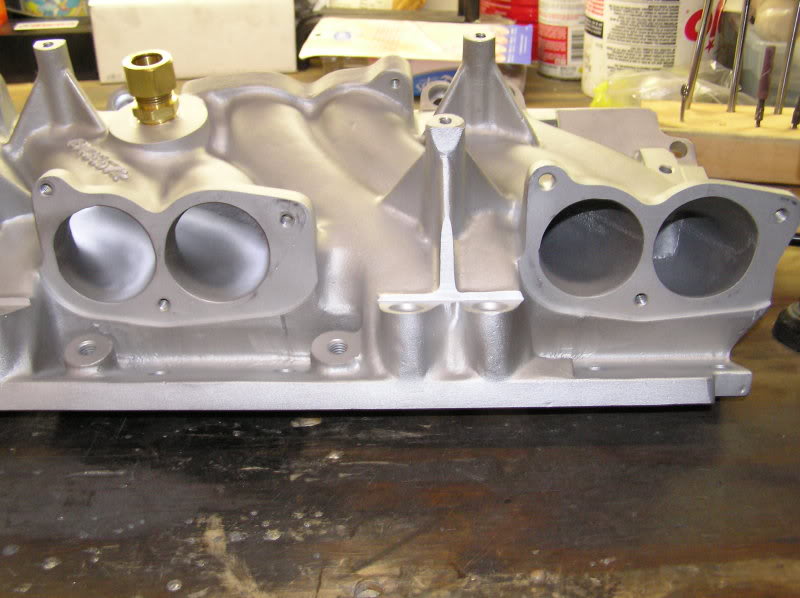

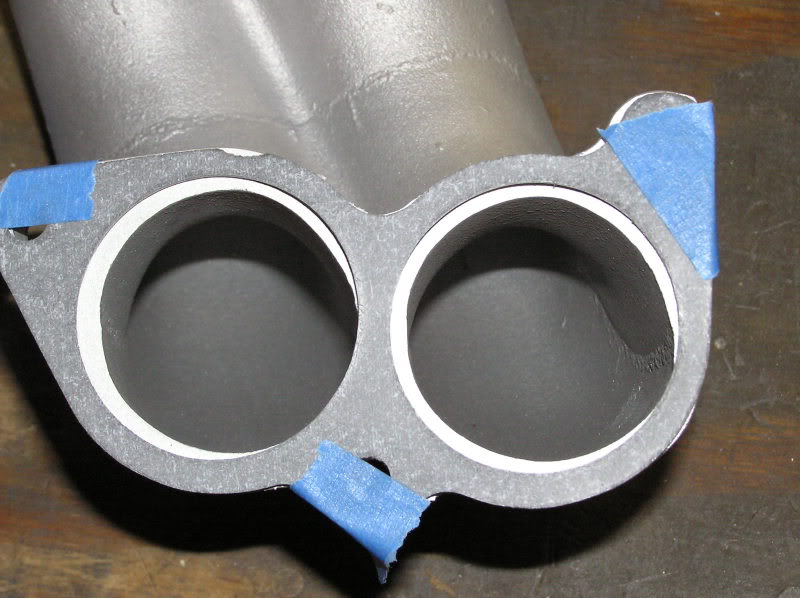

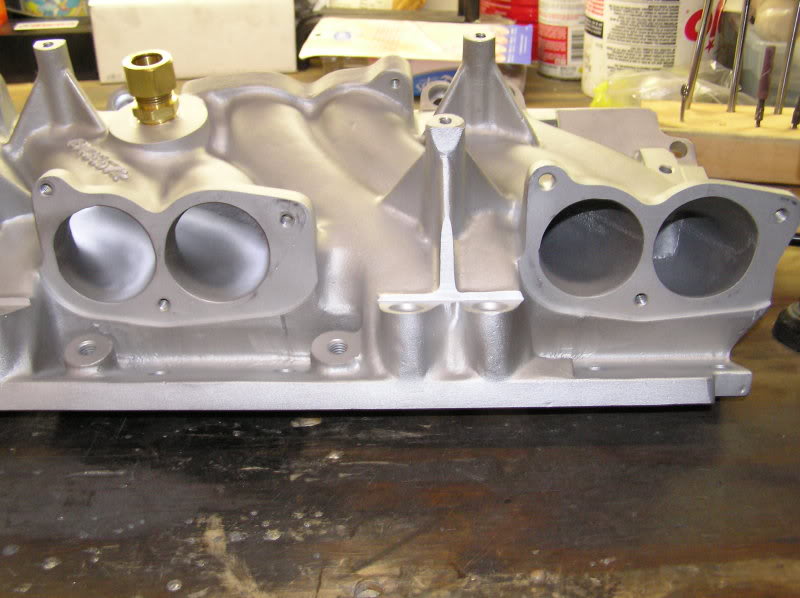

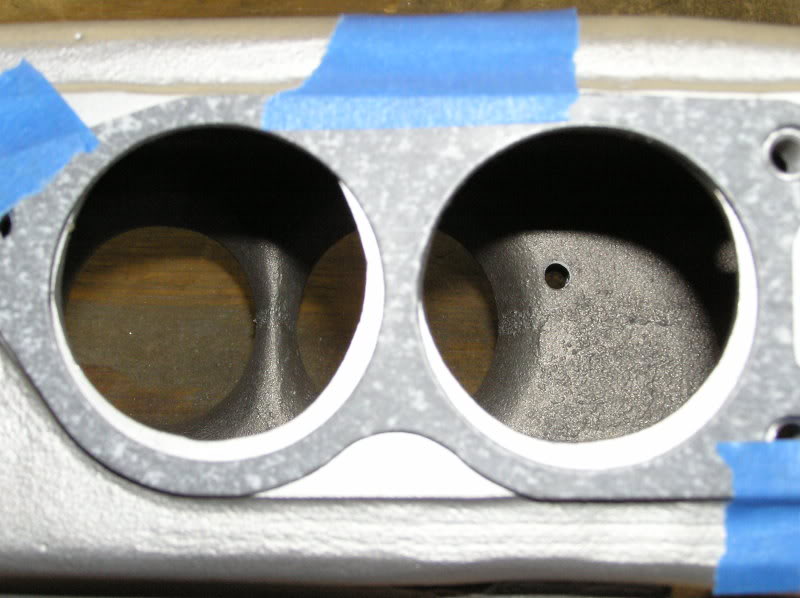

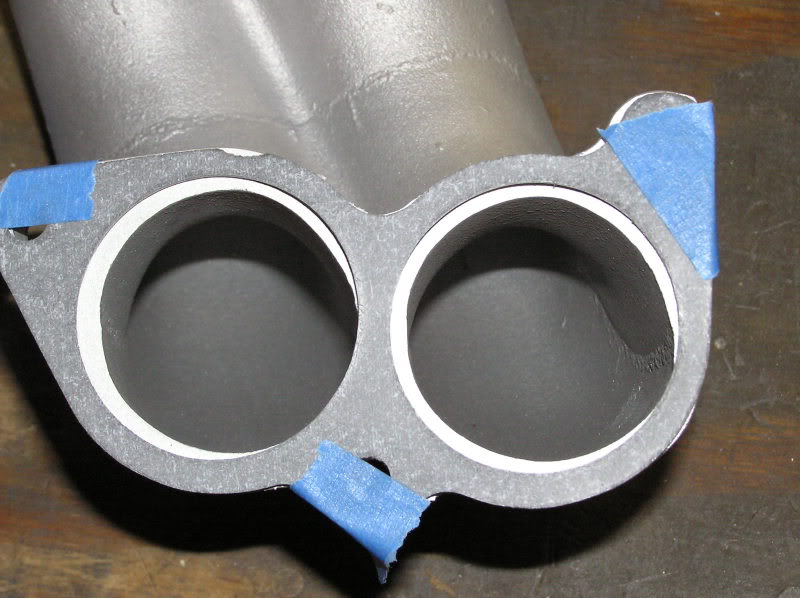

"I've begun porting my FIRST intake for my 383 build. I will be gasket matching the base to a FelPro 1205 and opening up the base and runners such that the passage tapers from the inlet at the plenum to the minimum area at the intake manifold exit.

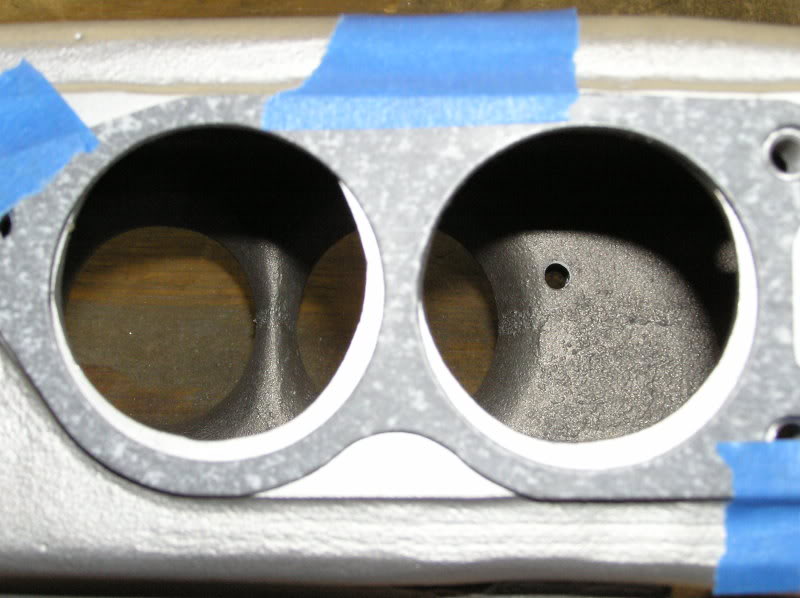

Here are some pictures of the intake parts before porting and my initial (very) rough-in of the first runner. As the pictures show, I've got a fair amount of material to remove, but these things have plenty of meat for porting. To give an idea of the size, the wooden balls shown in the porting pictures are 1.75" in diameter. A stock TPI base and runners have a diameter of 1.47". The goal is to get the runners sized to pass a 1.875" ball through the runner all the way into the manifold where the shape transitions to a rectangle. I'm at about 1.86" now -- I'm sneaking up on it so I don't break through.

I'll post more progress pics as I go. Enjoy. :cheers:

"

"

Ok Im impressed with the work done, pictures, in the thread, etc, but

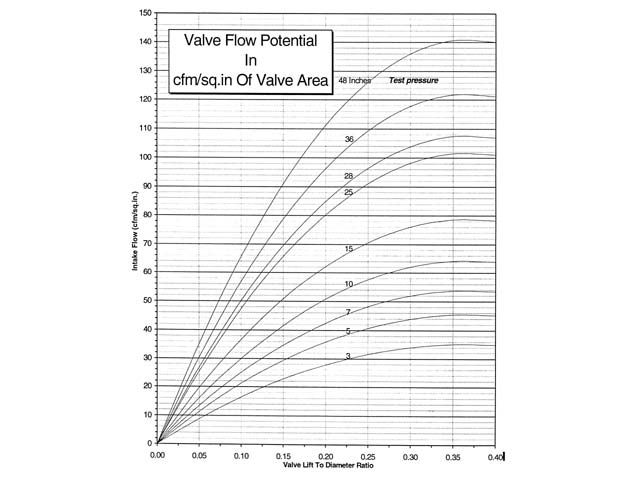

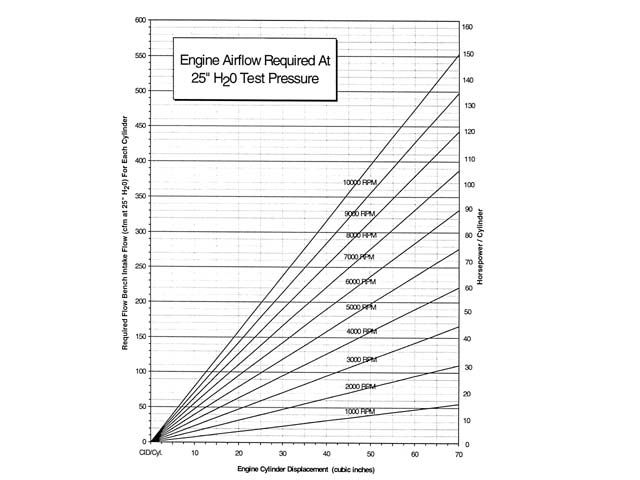

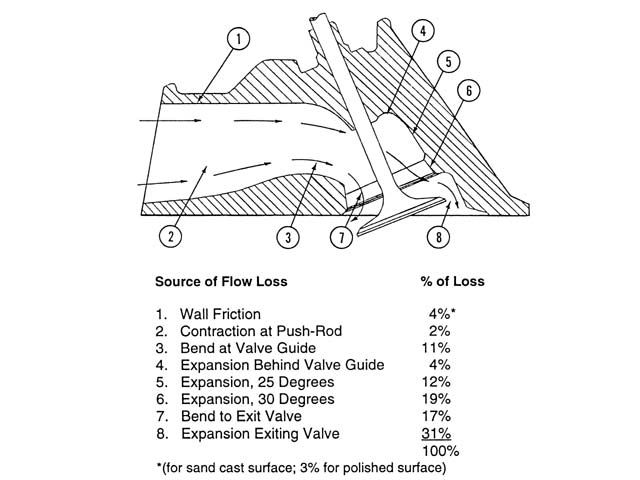

IM kind of sceptical of the benefits of porting the runners & plenum past the point where they flow equal too or only slightly more than the cylinder head ports, as its been my experiance that porting past that point tends to lower port velocity and reduce volumetric efficiency.

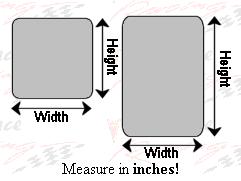

the 1206 intake gasket port is 2.150" x 1.2"=2.58 sq inches

the 1205 intake gasket port is 2.00" x 1.18"=2.36 sq inches

a round port of 1.75"=2.40 sq inches

a round port of 1.86"=2.72 sq inches

BTW READ THRU THIS

http://ncarboni.home.att.net/NCtpi.html

see the potential for a problem, youll port your runners past the point where the extra cross sectional area benefits the port flow rates and velocities will drop, off resulting in at least no benefits, from the additional porting, and at worst a reduction in flow and a tendency to have turbulance disrupting the air stream. now IM NOT saying your not going to have a huge improvement over a stock TPI intake , but at some point further port increases are counter productive.

viewtopic.php?f=55&t=1509&p=3459&hilit=base+runner+plenum#p3459

http://www.firstfuelinjection.com/products.htm

"I've begun porting my FIRST intake for my 383 build. I will be gasket matching the base to a FelPro 1205 and opening up the base and runners such that the passage tapers from the inlet at the plenum to the minimum area at the intake manifold exit.

Here are some pictures of the intake parts before porting and my initial (very) rough-in of the first runner. As the pictures show, I've got a fair amount of material to remove, but these things have plenty of meat for porting. To give an idea of the size, the wooden balls shown in the porting pictures are 1.75" in diameter. A stock TPI base and runners have a diameter of 1.47". The goal is to get the runners sized to pass a 1.875" ball through the runner all the way into the manifold where the shape transitions to a rectangle. I'm at about 1.86" now -- I'm sneaking up on it so I don't break through.

I'll post more progress pics as I go. Enjoy. :cheers:

Ok Im impressed with the work done, pictures, in the thread, etc, but

IM kind of sceptical of the benefits of porting the runners & plenum past the point where they flow equal too or only slightly more than the cylinder head ports, as its been my experiance that porting past that point tends to lower port velocity and reduce volumetric efficiency.

the 1206 intake gasket port is 2.150" x 1.2"=2.58 sq inches

the 1205 intake gasket port is 2.00" x 1.18"=2.36 sq inches

a round port of 1.75"=2.40 sq inches

a round port of 1.86"=2.72 sq inches

BTW READ THRU THIS

http://ncarboni.home.att.net/NCtpi.html

see the potential for a problem, youll port your runners past the point where the extra cross sectional area benefits the port flow rates and velocities will drop, off resulting in at least no benefits, from the additional porting, and at worst a reduction in flow and a tendency to have turbulance disrupting the air stream. now IM NOT saying your not going to have a huge improvement over a stock TPI intake , but at some point further port increases are counter productive.