preventing cam & lifter break-in failures

Even with roller valve train there is a break in period where the metals have to "mate". on flat tappet valve trains and non-roller rocker valve trains use of a good moly assembly lube is critical, Break in oils and assembly lubes have high pressure additives to help protect these new surfaces while this "mating" is taking place. Regular motor oil does not, always have the required additives or enough of them. thus using a good moly based assembly lube on lifters and bearings helps reduce wear , on roller rockers and roller lifter a mix of 50% assembly lube and 50% MARVEL MYSTERY OIL, thins this moly mix viscosity allowing it to penetrate roller bearings far faster

OPTIONS

it should be rather obvious that theres options, cam failures are usually the result of incorrect CLEARANCES or too much SPRING PRESSURE or LACK of ADEQUATE LUBRICATION,USE DECENT MOLY CAM LUBE, and decent quality oil, adding MAGNETS to trap metalic CRUD HELPS

READ

http://www.cranecams.com/?show=faq&id=1

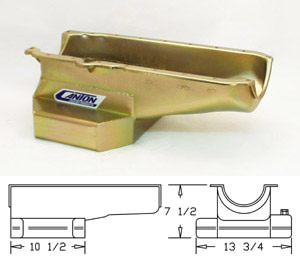

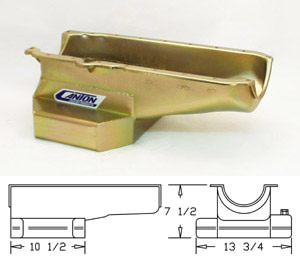

(1) get a decent ROLLER CAM, add a high voluum oil pump, baffled 8 qt oil pan, with a windage screen and check your clearances and avoid the problem,USE DECENT MOLY CAM LUBE,and decent quality oil,adding MAGNETS to trap metalic CRUD HELPS

(2) use a SOLID lifter flat tappet cam with lifters with the lube feed holes,add a high voluum oil pump, baffled 8 qt oil pan, with a windage screen and check your clearances and avoid the problem,USE DECENT MOLY CAM LUBE, and decent quality oil,adding MAGNETS to trap metalic CRUD HELPS

http://www.competitionproducts.com/prod ... r=651080DL

(3) mod the lifter bores for more oil flow,add a high voluum oil pump, baffled 8 qt oil pan, with a windage screen and check your clearances and avoid the problem,USE DECENT MOLY CAM LUBE,and decent quality oil,adding MAGNETS to trap metalic CRUD HELPS

http://www.compperformancegroupstores.c ... gory_Code=

(4)USE DECENT MOLY CAM LUBE

http://www.cranecams.com/index.php?show ... l=2&prt=15,

add a high voluum oil pump, baffled 8 qt oil pan, with a windage screen and check your clearances and avoid the problem,and decent quality oil,adding MAGNETS to trap metalic CRUD HELPS

(5) thinking things thru and verifying clearances and spring pressures, and having a well thought thru lube system will significantly lower your chances of having problems,USE DECENT MOLY CAM LUBE,and decent quality oil,adding MAGNETS to trap metalic CRUD HELPS

.......I have not seen a cam fail in years UNLESS the guy installing it failed to follow those tips

anyone see a PATTERN?

you might want to read thru this AGAIN

http://www.cranecams.com/?show=article&id=2]http://www.cranecams.com/?show=article&id=2

swapping to a higher capacity baffled oil pan, thats no more than 7.5" deep for road clearance adds reliability

FROM MORTEC

If you are building a SMALL or BIG block Chevy with a flat tappet cam, (solid or hydraulic lifters) be careful during the initial engine break in. It is very easy to lose a cam lobe and lifter during initial break in. This is especially true with a higher than stock lift cam and higher pressure valve springs. The increased pushrod angles found on the BBC and poor preparation can make cam lobe failure after initial fireup a distinct possibility. You can help prevent this cam lobe failure by making sure the engine is prelubed prior to intial fireup. Use a good high pressure lube on the cam lobes and lifter bottoms during assembly. If possible use a lighter pressure stock valve spring (or if using a valve spring with multiple springs, take out some of the inner springs) to intially run the engine. Then switch to the heavier pressure springs after break in. When the engine is first fired up, keep the engine rpms at 2,500 or above, don't let the engine idle for 20 minutes or longer. This keeps lots of oil splashing up on the cam lobes. Make sure the engine can be run for this time period by having enough fuel available, ignition timing set correctly, coolant available for the motor, valve lash set correctly, etc. The idea is not to crank the motor over excessively before it starts up for the first time. If your BBC flat tappet cam survives this initial break in period, it will be good to go for many miles. After the initial engine breakin, drain the oil and change the oil filter. Roller cams generally do not suffer these types of cam lobe failures during initial engine fireup.

if youve adjusted the valves correctly the lifter spins at all rpm levels,but that does NOT mean it wears EVENLY at all rpm levels due to several factors if you look closely AT FLAT TAPPET CAMS youll see that the center of the cam lobe is NOT centered under the lifter and that the lifter surface is slightly angled , BOTH these factors force the lifter to spin in its bore as the lobe passes under the lifter slightly off center.

MOLY adds a great deal of lubrication to sliding metal surfaces , as it embeds in the micro fissures in the metallic surface's

SOME of the reasons the higher rpm durring the break in phase is important is that

(1) the faster RPMs the better chances the lobe passes under the lifter floated on an oil film and the less time the oil film has to squeeze out between them

(2) the higher the RPM the greater the oil voluum and pressure the engine pumps and the more oil flow is available at the lobes

(3)the higher the rpm level the more oil is thrown from the rods onto the cam lobes

(4)the higher the rpm the greater the lifters weight and inertia tends to compensate for the springs pressure and lower the net pressure as the lifter passes over the cam lobes nose

(5) at higher rpm speed the better chance a small wedge of oil is trapped between the lifter base and lobe from the oil thrown from the lobes surface by centrifical force

(6) two differant metal surfaces scraping past each other at low speeds may tend to wear and GALL as the oil is sqeezed out but two differant hardness steel surfaces that impact each other at higher speeds covered with oil tend to work harden as they mate and will tend to be seperated by that oil

(7)as the lifter spins in its bore the contact point between the lobe and lifter base constantly changes and rotates with the lobe contact point not resisting its passage and the higher the rpms the faster the lifter rotates and the less time the lobe spends at any one point

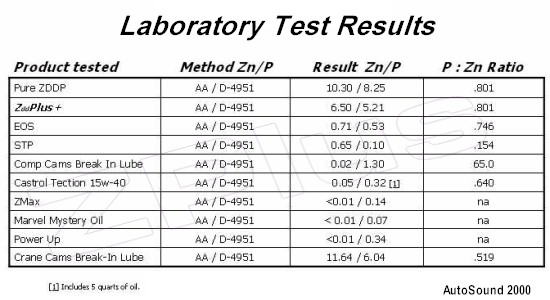

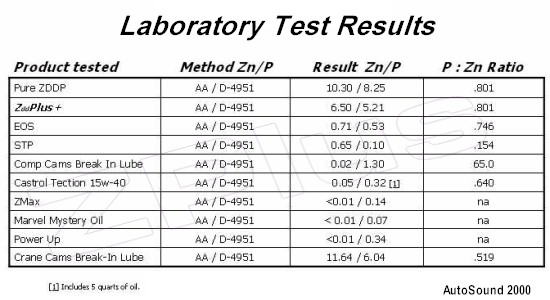

BTW ADD E.O.S. to the oil and MOLY break-in lube to the cam

before starting the engine and prefill the filter and pre-prime the oil system before starting the engine.

I normally pour it in just before starting the engines cam break in,procedure. because I want to make sure that nothing in the oil/E.O.S. mix can settle out from sitting over a long period of time. now if your running a flat tappet cam you should have also used a moly cam lube on the lobes and be useing a mineral base oil for the break-in procedure, and youll need to do an oil and filter change after about the first 3-4 hours running time to remove that moly cam lube from the engine after its served its purpose of protecting the cams lobes and lifters at start up, aND AS THE LOBES/LIFTERS LAPPED IN. MOSTLY to prevent that moly grease and E.O.S from potentially partially clogging the filter after that mix cools down,but also because both those lubes might leave deposites in the combustion chamber ,over time that might aggravate detonation.

even G.M. suggests that E.O.S. is not a great long term oil suppliment, and that its main function is to add extra oil film strength durring new engine break in.

http://www.gmpartsdirect.com/results.cf ... number=EOS

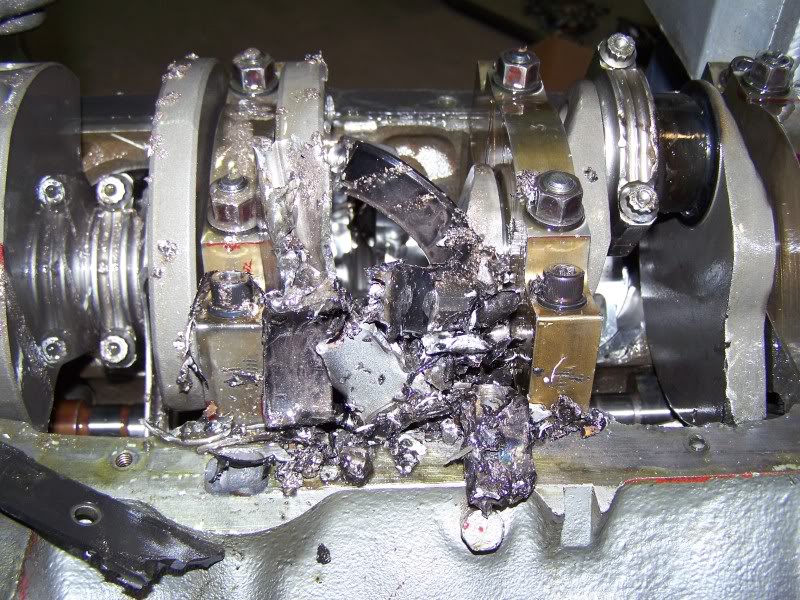

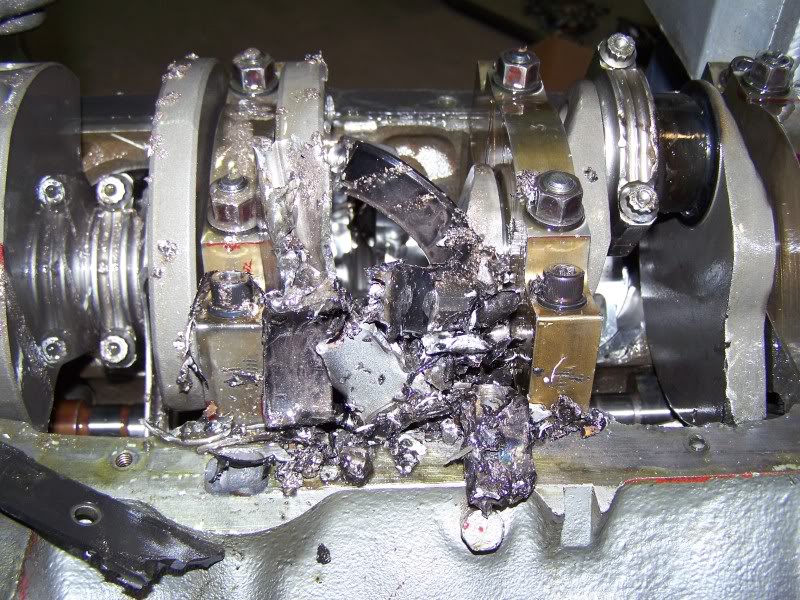

failure to maintain a correctly functioning lubrication system,maintain, valve train control, provide consistent cooling and an ignition advance curve and to stay out of detonation can result in expensive lessons in engine repair

don,t forget a few magnets in the oil pan goes a long way towards trapping unwanted metalic dust formed from the cam and rings lapping in durring break-in that might otherwise get imbedded in your bearings or cause other problems

heres the magnets I use in every engine

add a few magnets to the oil pan and drain back area in your engine, the trap and hold metalic dust that comes from wear and increase engine life span by preventing that crap embedding in the bearings

http://www.kjmagnetics.com/proddetai...d=D66SH&cat=13

http://www.kjmagnetics.com/proddetail.asp?prod=D66SH

http://www.kjmagnetics.com/proddetail.asp?prod=D82SH

http://www.kjmagnetics.com/proddetail.asp?prod=D44SH

these are even more tollerant of temp swings and retain strength at even higher engine oil temps plus they are smaller and easier to use

Even with roller valve train there is a break in period where the metals have to "mate". on flat tappet valve trains and non-roller rocker valve trains use of a good moly assembly lube is critical, Break in oils and assembly lubes have high pressure additives to help protect these new surfaces while this "mating" is taking place. Regular motor oil does not, always have the required additives or enough of them. thus using a good moly based assembly lube on lifters and bearings helps reduce wear , on roller rockers and roller lifter a mix of 50% assembly lube and 50% MARVEL MYSTERY OIL, thins this moly mix viscosity allowing it to penetrate roller bearings far faster

OPTIONS

it should be rather obvious that theres options, cam failures are usually the result of incorrect CLEARANCES or too much SPRING PRESSURE or LACK of ADEQUATE LUBRICATION,USE DECENT MOLY CAM LUBE, and decent quality oil, adding MAGNETS to trap metalic CRUD HELPS

READ

http://www.cranecams.com/?show=faq&id=1

(1) get a decent ROLLER CAM, add a high voluum oil pump, baffled 8 qt oil pan, with a windage screen and check your clearances and avoid the problem,USE DECENT MOLY CAM LUBE,and decent quality oil,adding MAGNETS to trap metalic CRUD HELPS

(2) use a SOLID lifter flat tappet cam with lifters with the lube feed holes,add a high voluum oil pump, baffled 8 qt oil pan, with a windage screen and check your clearances and avoid the problem,USE DECENT MOLY CAM LUBE, and decent quality oil,adding MAGNETS to trap metalic CRUD HELPS

http://www.competitionproducts.com/prod ... r=651080DL

(3) mod the lifter bores for more oil flow,add a high voluum oil pump, baffled 8 qt oil pan, with a windage screen and check your clearances and avoid the problem,USE DECENT MOLY CAM LUBE,and decent quality oil,adding MAGNETS to trap metalic CRUD HELPS

http://www.compperformancegroupstores.c ... gory_Code=

(4)USE DECENT MOLY CAM LUBE

http://www.cranecams.com/index.php?show ... l=2&prt=15,

add a high voluum oil pump, baffled 8 qt oil pan, with a windage screen and check your clearances and avoid the problem,and decent quality oil,adding MAGNETS to trap metalic CRUD HELPS

(5) thinking things thru and verifying clearances and spring pressures, and having a well thought thru lube system will significantly lower your chances of having problems,USE DECENT MOLY CAM LUBE,and decent quality oil,adding MAGNETS to trap metalic CRUD HELPS

.......I have not seen a cam fail in years UNLESS the guy installing it failed to follow those tips

anyone see a PATTERN?

you might want to read thru this AGAIN

http://www.cranecams.com/?show=article&id=2]http://www.cranecams.com/?show=article&id=2

swapping to a higher capacity baffled oil pan, thats no more than 7.5" deep for road clearance adds reliability

FROM MORTEC

If you are building a SMALL or BIG block Chevy with a flat tappet cam, (solid or hydraulic lifters) be careful during the initial engine break in. It is very easy to lose a cam lobe and lifter during initial break in. This is especially true with a higher than stock lift cam and higher pressure valve springs. The increased pushrod angles found on the BBC and poor preparation can make cam lobe failure after initial fireup a distinct possibility. You can help prevent this cam lobe failure by making sure the engine is prelubed prior to intial fireup. Use a good high pressure lube on the cam lobes and lifter bottoms during assembly. If possible use a lighter pressure stock valve spring (or if using a valve spring with multiple springs, take out some of the inner springs) to intially run the engine. Then switch to the heavier pressure springs after break in. When the engine is first fired up, keep the engine rpms at 2,500 or above, don't let the engine idle for 20 minutes or longer. This keeps lots of oil splashing up on the cam lobes. Make sure the engine can be run for this time period by having enough fuel available, ignition timing set correctly, coolant available for the motor, valve lash set correctly, etc. The idea is not to crank the motor over excessively before it starts up for the first time. If your BBC flat tappet cam survives this initial break in period, it will be good to go for many miles. After the initial engine breakin, drain the oil and change the oil filter. Roller cams generally do not suffer these types of cam lobe failures during initial engine fireup.

if youve adjusted the valves correctly the lifter spins at all rpm levels,but that does NOT mean it wears EVENLY at all rpm levels due to several factors if you look closely AT FLAT TAPPET CAMS youll see that the center of the cam lobe is NOT centered under the lifter and that the lifter surface is slightly angled , BOTH these factors force the lifter to spin in its bore as the lobe passes under the lifter slightly off center.

MOLY adds a great deal of lubrication to sliding metal surfaces , as it embeds in the micro fissures in the metallic surface's

SOME of the reasons the higher rpm durring the break in phase is important is that

(1) the faster RPMs the better chances the lobe passes under the lifter floated on an oil film and the less time the oil film has to squeeze out between them

(2) the higher the RPM the greater the oil voluum and pressure the engine pumps and the more oil flow is available at the lobes

(3)the higher the rpm level the more oil is thrown from the rods onto the cam lobes

(4)the higher the rpm the greater the lifters weight and inertia tends to compensate for the springs pressure and lower the net pressure as the lifter passes over the cam lobes nose

(5) at higher rpm speed the better chance a small wedge of oil is trapped between the lifter base and lobe from the oil thrown from the lobes surface by centrifical force

(6) two differant metal surfaces scraping past each other at low speeds may tend to wear and GALL as the oil is sqeezed out but two differant hardness steel surfaces that impact each other at higher speeds covered with oil tend to work harden as they mate and will tend to be seperated by that oil

(7)as the lifter spins in its bore the contact point between the lobe and lifter base constantly changes and rotates with the lobe contact point not resisting its passage and the higher the rpms the faster the lifter rotates and the less time the lobe spends at any one point

BTW ADD E.O.S. to the oil and MOLY break-in lube to the cam

before starting the engine and prefill the filter and pre-prime the oil system before starting the engine.

I normally pour it in just before starting the engines cam break in,procedure. because I want to make sure that nothing in the oil/E.O.S. mix can settle out from sitting over a long period of time. now if your running a flat tappet cam you should have also used a moly cam lube on the lobes and be useing a mineral base oil for the break-in procedure, and youll need to do an oil and filter change after about the first 3-4 hours running time to remove that moly cam lube from the engine after its served its purpose of protecting the cams lobes and lifters at start up, aND AS THE LOBES/LIFTERS LAPPED IN. MOSTLY to prevent that moly grease and E.O.S from potentially partially clogging the filter after that mix cools down,but also because both those lubes might leave deposites in the combustion chamber ,over time that might aggravate detonation.

even G.M. suggests that E.O.S. is not a great long term oil suppliment, and that its main function is to add extra oil film strength durring new engine break in.

http://www.gmpartsdirect.com/results.cf ... number=EOS

failure to maintain a correctly functioning lubrication system,maintain, valve train control, provide consistent cooling and an ignition advance curve and to stay out of detonation can result in expensive lessons in engine repair

don,t forget a few magnets in the oil pan goes a long way towards trapping unwanted metalic dust formed from the cam and rings lapping in durring break-in that might otherwise get imbedded in your bearings or cause other problems

heres the magnets I use in every engine

add a few magnets to the oil pan and drain back area in your engine, the trap and hold metalic dust that comes from wear and increase engine life span by preventing that crap embedding in the bearings

http://www.kjmagnetics.com/proddetai...d=D66SH&cat=13

http://www.kjmagnetics.com/proddetail.asp?prod=D66SH

http://www.kjmagnetics.com/proddetail.asp?prod=D82SH

http://www.kjmagnetics.com/proddetail.asp?prod=D44SH

these are even more tollerant of temp swings and retain strength at even higher engine oil temps plus they are smaller and easier to use

Last edited by a moderator: