question comes up, can you replace the oil pump or oil pan gasket while

the engine remains in the c4 corvette,

Ive replaced BOTH oil pumps alone and oil pumps and oil pans, or just oil pan gaskets or installed windage trays several dozen times, on c4 corvettes, and similar cars, both L98 and LT1s, and earlier GENERATION 1 and 2 v8 engines, while the engine was still in the car and on the motor mounts, obviously access to the oil pan depends on the location of the cross member and suspension can pose a huge limitation on access in some cars, but luckily its fairly easy to pull the pan and replace the oil pump on a C-4, corvette

the type transmission your car has does not prevent oil pan removal, but you might have to remove the motor mounts, and use a floor jack to raise the engine about 1"-2" to allow the oil pan to clear the crank counterweights for easier removal, remember to turn the crank to allow the counterweights to clear the oil pan, this precludes using the crank damper as a location to use the floor jack to raise the engine,

if you raise the engine be sure you remove the distributor on first gen engines to prevent damage against the fire wall

.place the car on a level concrete surface and on 4 jack stands one on all four corners at about a 18"-26" height so you can work under the car safely,

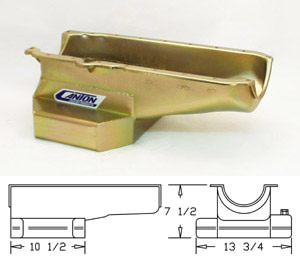

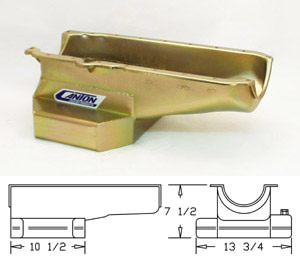

swapping to a higher capacity baffled oil pan, thats no more than 7.5" deep for road clearance adds reliability

its not that difficult to remove the oil pan, replace the gasket with a new one piece synthetic one and cure that leak,

most guys can do that in a single afternoon with the car up on 4 12 ton jack stands rather easily.

be aware that the crank counter weights rotated to the correct location makes removing the oil pan a bit easier.

it might be a great opportunity to swap to a higher capacity baffled oil pan.

obviously youll want to carefully research the correct oil pan for your engine and chassis before purchasing one

https://www.summitracing.com/parts/ctr-15-240/overview/make/chevrolet/model/corvette

7" deep

https://www.cantonracingproducts.com/cgi-bin/commerce.cgi?preadd=action&key=11-102

6.5" deep

https://www.carid.com/moroso/oil-pa...MIraOQn-602QIVBJ7ACh2mTwt4EAQYAyABEgJZWfD_BwE

7" deep

theres lots of 8" and 8.25" deep corvette oil pans but they don,t last too long with speed bumps and raised manhole cover rims

https://www.summitracing.com/parts/...MIytnIx-y02QIVHrjACh35mQ-OEAQYASABEgJnZvD_BwE

http://garage.grumpysperformance.co...etic-oil-cause-leaky-gaskets.2725/#post-13817

http://garage.grumpysperformance.com/index.php?threads/under-car-safety.26/page-4#post-69999

http://garage.grumpysperformance.co...-pan-gasket-still-small-leak.3084/#post-11971

On a c4 corvette theres the diagonal braces to the k frame that usually need to be temp removed and the coolant lines under the oil pan need to be disconnected, the starter usually needs to come off, but generally the only trick is the crank needs to be rotated slowly once the oil pans free to allow the counter weights on the crank to clear the front lip on the pan because you can only lower it slightly due to the cross member. make damn sure the oil pump pickup is 1/2"-3/8" off the oil pan floor once its installed and BRAZED or welded or bolted in place on the pump

now what does quite frequently happen is that the guys installing a high volume oil pump just swap out the standard pump, reinstall the stock or similar pick-up and bolt on the pan with the pick-up in the stock position on the oil pump. the stock pick-up is mounted about 3/8" off the pan bottom,the high volume pump is normally equipped with impeller gears about .3 inches longer than stock, the high volume pump body is that much lower in the pan, resulting in the pick-up being only about 1/8" from the pan bottom. the result is that on a normal Chevy oil pump pick-up this leave a space of about 1/8" x 2.5" for oil to flow into the pump. at low rpms this works but as the rpms climb the pick-up that can,t get any oil to pump cavitation as it spins and fails to pump oil, result oil pressure drops until rpms are lowered no matter how much oil is over the pick-up. simply checking to make sure that about 1/2" of space is under the pick-up when the pan is installed cures that problem (a simple trick is to weld a 1/2" thick nut to the oil pump Pick-up base and test fitting the pan BEFORE WELDING THE PICK-UP TO THE PUMP BODY)

I strongly suggest synthetic one piece oil pan gaskets and STUDS and use of BLACK weather strip adhesive to hold the gasket to the block while the oil pans put into place

you simply run a 1/8" bead on both the runner ends and the plenum and base runner contact areas and a thin matching bead on both sides of the gasket surface then place align and install the oil pan in alignment with both the front and rear seals, and get ALL the bolts or nuts on studs started before you tighten ANY of them, to make sure every things lined up correctly

be VERY sure its the newer BLACK type not the older YELLOW version

remember the stuffs basically contact cement so you apply it to all gasket surfaces, let it dry for 5 minutes THEN assemble

related threads

viewtopic.php?f=60&t=2194&p=5905#p5905

viewtopic.php?f=54&t=206&p=242#p242

viewtopic.php?f=51&t=1718&p=11956&hilit=synthetic+gasket#p11956

the engine remains in the c4 corvette,

Ive replaced BOTH oil pumps alone and oil pumps and oil pans, or just oil pan gaskets or installed windage trays several dozen times, on c4 corvettes, and similar cars, both L98 and LT1s, and earlier GENERATION 1 and 2 v8 engines, while the engine was still in the car and on the motor mounts, obviously access to the oil pan depends on the location of the cross member and suspension can pose a huge limitation on access in some cars, but luckily its fairly easy to pull the pan and replace the oil pump on a C-4, corvette

the type transmission your car has does not prevent oil pan removal, but you might have to remove the motor mounts, and use a floor jack to raise the engine about 1"-2" to allow the oil pan to clear the crank counterweights for easier removal, remember to turn the crank to allow the counterweights to clear the oil pan, this precludes using the crank damper as a location to use the floor jack to raise the engine,

if you raise the engine be sure you remove the distributor on first gen engines to prevent damage against the fire wall

.place the car on a level concrete surface and on 4 jack stands one on all four corners at about a 18"-26" height so you can work under the car safely,

under car safety

I had a guy forward me this info "I know we have all read and heard many a times,when you jack your car up to work on it PUT THE DAMN JACK STANDS UNDER THE CARS FRAME. Well I just got a call from my Aunt and Uncle that my cousin 2 years older than I am (and i'm 42)who's name is also Kevin was...

garage.grumpysperformance.com

swapping to a higher capacity baffled oil pan, thats no more than 7.5" deep for road clearance adds reliability

its not that difficult to remove the oil pan, replace the gasket with a new one piece synthetic one and cure that leak,

most guys can do that in a single afternoon with the car up on 4 12 ton jack stands rather easily.

be aware that the crank counter weights rotated to the correct location makes removing the oil pan a bit easier.

it might be a great opportunity to swap to a higher capacity baffled oil pan.

obviously youll want to carefully research the correct oil pan for your engine and chassis before purchasing one

https://www.summitracing.com/parts/ctr-15-240/overview/make/chevrolet/model/corvette

7" deep

https://www.cantonracingproducts.com/cgi-bin/commerce.cgi?preadd=action&key=11-102

6.5" deep

https://www.carid.com/moroso/oil-pa...MIraOQn-602QIVBJ7ACh2mTwt4EAQYAyABEgJZWfD_BwE

7" deep

theres lots of 8" and 8.25" deep corvette oil pans but they don,t last too long with speed bumps and raised manhole cover rims

https://www.summitracing.com/parts/...MIytnIx-y02QIVHrjACh35mQ-OEAQYASABEgJnZvD_BwE

http://garage.grumpysperformance.co...etic-oil-cause-leaky-gaskets.2725/#post-13817

http://garage.grumpysperformance.com/index.php?threads/under-car-safety.26/page-4#post-69999

http://garage.grumpysperformance.co...-pan-gasket-still-small-leak.3084/#post-11971

On a c4 corvette theres the diagonal braces to the k frame that usually need to be temp removed and the coolant lines under the oil pan need to be disconnected, the starter usually needs to come off, but generally the only trick is the crank needs to be rotated slowly once the oil pans free to allow the counter weights on the crank to clear the front lip on the pan because you can only lower it slightly due to the cross member. make damn sure the oil pump pickup is 1/2"-3/8" off the oil pan floor once its installed and BRAZED or welded or bolted in place on the pump

now what does quite frequently happen is that the guys installing a high volume oil pump just swap out the standard pump, reinstall the stock or similar pick-up and bolt on the pan with the pick-up in the stock position on the oil pump. the stock pick-up is mounted about 3/8" off the pan bottom,the high volume pump is normally equipped with impeller gears about .3 inches longer than stock, the high volume pump body is that much lower in the pan, resulting in the pick-up being only about 1/8" from the pan bottom. the result is that on a normal Chevy oil pump pick-up this leave a space of about 1/8" x 2.5" for oil to flow into the pump. at low rpms this works but as the rpms climb the pick-up that can,t get any oil to pump cavitation as it spins and fails to pump oil, result oil pressure drops until rpms are lowered no matter how much oil is over the pick-up. simply checking to make sure that about 1/2" of space is under the pick-up when the pan is installed cures that problem (a simple trick is to weld a 1/2" thick nut to the oil pump Pick-up base and test fitting the pan BEFORE WELDING THE PICK-UP TO THE PUMP BODY)

I strongly suggest synthetic one piece oil pan gaskets and STUDS and use of BLACK weather strip adhesive to hold the gasket to the block while the oil pans put into place

you simply run a 1/8" bead on both the runner ends and the plenum and base runner contact areas and a thin matching bead on both sides of the gasket surface then place align and install the oil pan in alignment with both the front and rear seals, and get ALL the bolts or nuts on studs started before you tighten ANY of them, to make sure every things lined up correctly

be VERY sure its the newer BLACK type not the older YELLOW version

remember the stuffs basically contact cement so you apply it to all gasket surfaces, let it dry for 5 minutes THEN assemble

related threads

viewtopic.php?f=60&t=2194&p=5905#p5905

viewtopic.php?f=54&t=206&p=242#p242

viewtopic.php?f=51&t=1718&p=11956&hilit=synthetic+gasket#p11956

Last edited by a moderator: