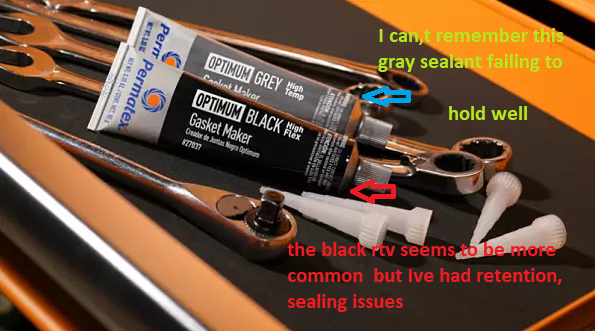

I was over helping bob today, for awhile and he was replacing the head gasket on a buddies car.

well once the old head, and head gasket was removed there was a bunch of old gasket sealer left on the block and head surface, and BOB reached for a rotary brush on a 1/2" chuck drill which I'm certain has been done by thousands of guys, in the past, but its a darn good way to screw up the gasket sealing surface.

(yes I know its been done thousands of times but its also resulted in dozens of guys with unexplained head gasket failures)

the problem is that its absolutely impossible to remove the old stuck on gasket material with a drill and rotary wire brush without doing at least some minor damage to the sealing surface and its all too easy to do damage that can cause head gaskets to leak

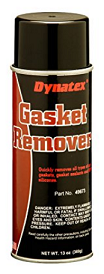

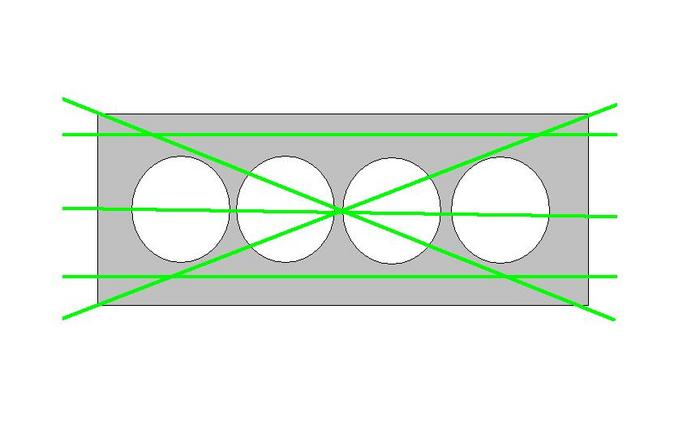

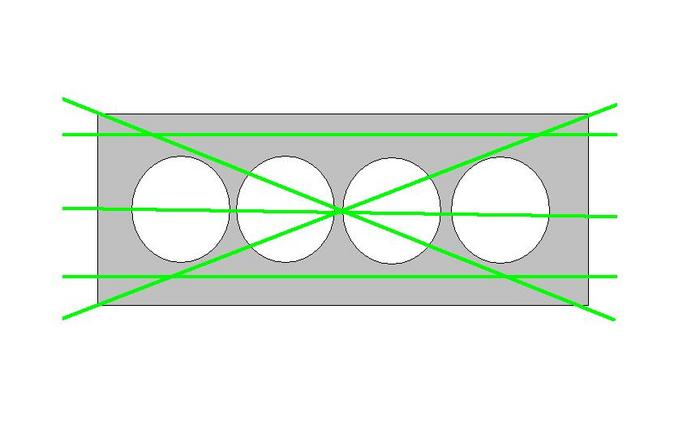

the correct route is to spray the surface down with a gasket solvent spray, let it sit 15 minutes, re-spray , it may take two or even three coats of solvent but the residue will tend to wipe off with minimal force once soft and partly dissolved and then use a 6 inch wide (minimum ) , under gaskets but over the bores without tipping a sharp edge, of the thin flexible blade edge into a bore,while using minimal pressure , THIS IS EXTREMELY CRITICAL ON ALUMINUM HEAD GASKET SURFACES,

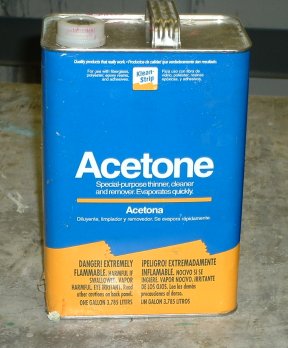

held almost parallel to the surface, the flex blade used with minimal pressure is used to loosen the old gasket residue, by slicing the loose gooey, mostly solvent soaked and mostly dissolved residue off the machined surface then wipe off the surface with a rag soaked in acetone. to remove any remaining residue, that way the mating surface is less likely to get gouged

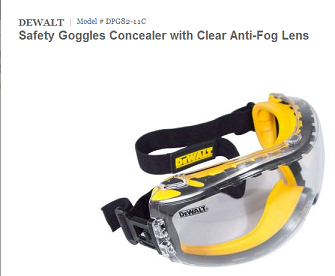

Item number :

CRC-03017

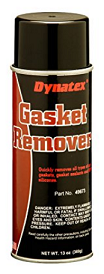

Dynatex 49673 Gasket Remover

be careful don,t get it on your skin, use plastic gloves

https://www.gtmidwest.com/2328353/Product/CRC®-03017?gclid=EAIaIQobChMIuLy_n8uv2QIVnLjACh2hgQ_vEAQYAyABEgLNDvD_BwE

using a decent shop vacuum while you remove gaskets tends to greatly reduce the chance or odd debris getting into places you don,t want or need that crap to get into

THIS IS THE ONE I PURCHASED AND I RECOMMEND IT, remember to change filter elements frequently and a couple quarts of water and a couple drops of dawn dish washing liquid in the water traps a great deal of dust in the lower body before it gets to the filter

http://www.homedepot.com/p/RIDGID-16-Ga ... 5yc1vZbv79

if you want to be sure you get all the metallic trash removed,removing gaskets and using a thread tap to clean bolt holes followed by a solvent spray wash and a long tip high pressure air nozzle blowing the passages dry and clear, of solvent and clear of debris, along with the ling spray nozzle ,high pressure air, solvent and the vacuum is a hard combo to beat

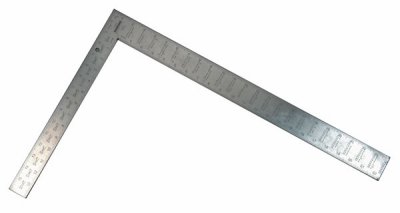

VERIFY THE BLOCK DECKS NOT WARPED

A CARPENTERS SQUARE , A BRIGHT LIGHT AND FEELER GAUGES CAN BE USED TO CHECK IF THE BLOCK DECK OR CYLINDER HEAD MATING SURFACE IS SQUARE AND NOT WARPED

IF YOUR SIMPLY TRYING TO GET A STOCK ENGINE BACK IN SERVICE AS CHEAPLY AS YOU CAN?

the heads and block surfaces must be very carefully examined for damage or warping issues and if found those issues must be corrected, before any new head gaskets installed, over time steam can and will cut grooves in even cast iron blocks and rather easily in softer aluminum. no head gasket will seal a badly machined or warped head or block

btw if youve managed to blow a head gasket on a 1986-91 TPI corvette with aluminum heads

the heads and block surfaces must be very carefully examined for damage or warping issues and if found those issues must be corrected, before any new head gaskets installed, over time steam can and will cut grooves in even cast iron blocks and rather easily in softer aluminum.

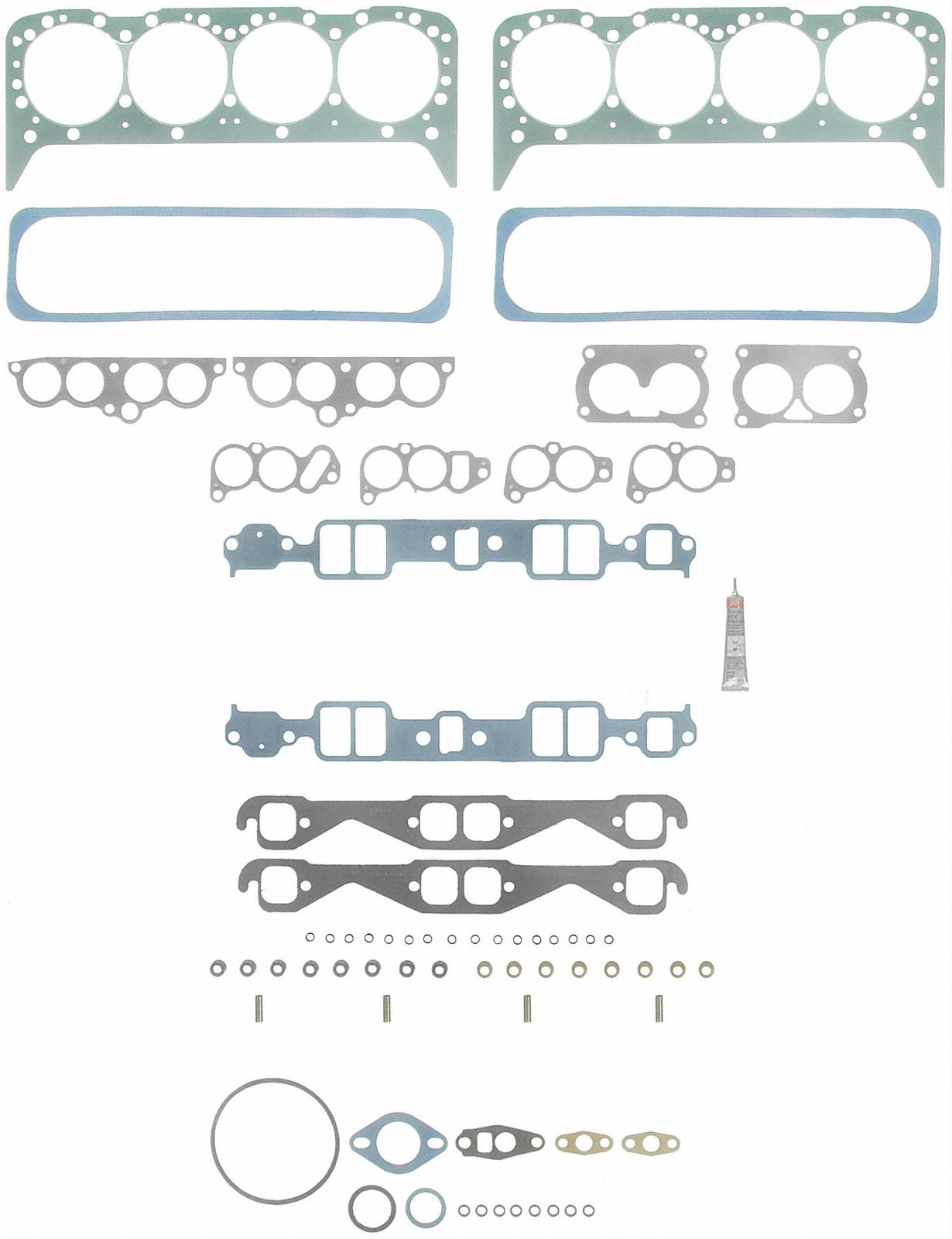

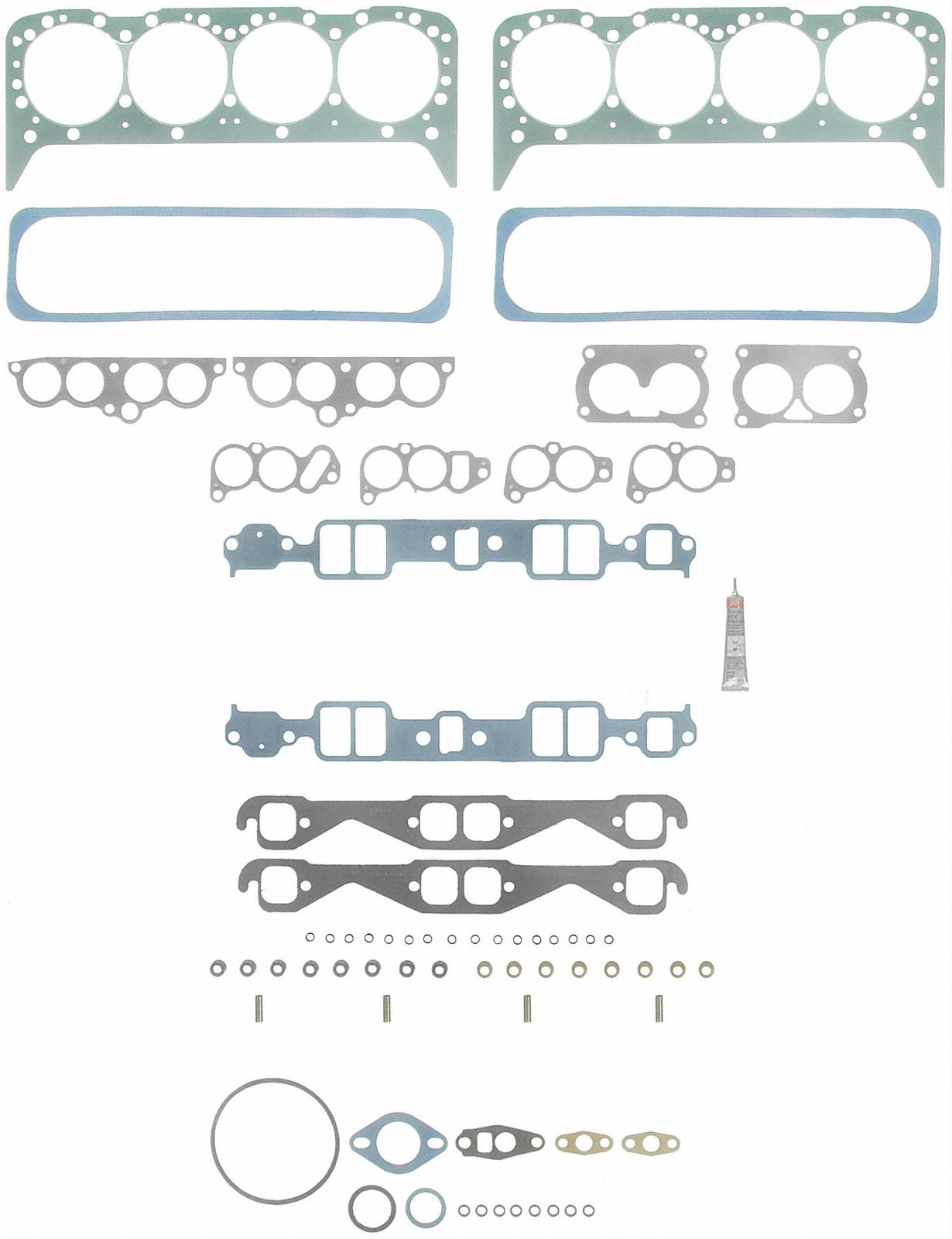

the stock 1986-91 tpi head gasket FELPRO HS7733pt9

heres a video on checking heads for warpage

youll also need a rust preventative oil

the new wd40 rust preventative spray works far better than the older version

http://www.dayattherange.com/?page_id=3667 READ THRU THIS LINK[/img]

HERES A VIDEO THAT SHOULD BE TITLED

"HOW TO SCREW UP A BLOCKS GASKET SURFACE"

HONESTLY HE IS REALLY DOING THE JOB BADLY, BUT IF YOUR NOT KNOWLEDGEABLE< HOW WOULD YOU KNOW?

before you spend a good deal of money porting and un-shrouding any iron cylinder heads, keep in mind aluminum heads are easily repaired in a skilled and experienced automotive machine shop thats equipped to do those repairs but damaged iron cylinder heads are either much harder to repair or good door stops

http://garage.grumpysperformance.com/index.php?threads/iron-vs-aluminum-heads.389/#post-7266

viewtopic.php?f=52&t=4081&p=10861#p10861

viewtopic.php?f=27&t=3379&p=8946&hilit=shop+vacuum#p8946

viewtopic.php?f=44&t=700&p=43768&hilit=head+gasket+bore#p43768

viewtopic.php?f=32&t=10376&p=42845&hilit=head+gasket+bore#p42845

viewtopic.php?f=52&t=4403&p=38976&hilit=head+gasket+bore#p38976

well once the old head, and head gasket was removed there was a bunch of old gasket sealer left on the block and head surface, and BOB reached for a rotary brush on a 1/2" chuck drill which I'm certain has been done by thousands of guys, in the past, but its a darn good way to screw up the gasket sealing surface.

(yes I know its been done thousands of times but its also resulted in dozens of guys with unexplained head gasket failures)

the problem is that its absolutely impossible to remove the old stuck on gasket material with a drill and rotary wire brush without doing at least some minor damage to the sealing surface and its all too easy to do damage that can cause head gaskets to leak

the correct route is to spray the surface down with a gasket solvent spray, let it sit 15 minutes, re-spray , it may take two or even three coats of solvent but the residue will tend to wipe off with minimal force once soft and partly dissolved and then use a 6 inch wide (minimum ) , under gaskets but over the bores without tipping a sharp edge, of the thin flexible blade edge into a bore,while using minimal pressure , THIS IS EXTREMELY CRITICAL ON ALUMINUM HEAD GASKET SURFACES,

held almost parallel to the surface, the flex blade used with minimal pressure is used to loosen the old gasket residue, by slicing the loose gooey, mostly solvent soaked and mostly dissolved residue off the machined surface then wipe off the surface with a rag soaked in acetone. to remove any remaining residue, that way the mating surface is less likely to get gouged

Item number :

CRC-03017

Dynatex 49673 Gasket Remover

be careful don,t get it on your skin, use plastic gloves

https://www.gtmidwest.com/2328353/Product/CRC®-03017?gclid=EAIaIQobChMIuLy_n8uv2QIVnLjACh2hgQ_vEAQYAyABEgLNDvD_BwE

using a decent shop vacuum while you remove gaskets tends to greatly reduce the chance or odd debris getting into places you don,t want or need that crap to get into

THIS IS THE ONE I PURCHASED AND I RECOMMEND IT, remember to change filter elements frequently and a couple quarts of water and a couple drops of dawn dish washing liquid in the water traps a great deal of dust in the lower body before it gets to the filter

http://www.homedepot.com/p/RIDGID-16-Ga ... 5yc1vZbv79

if you want to be sure you get all the metallic trash removed,removing gaskets and using a thread tap to clean bolt holes followed by a solvent spray wash and a long tip high pressure air nozzle blowing the passages dry and clear, of solvent and clear of debris, along with the ling spray nozzle ,high pressure air, solvent and the vacuum is a hard combo to beat

VERIFY THE BLOCK DECKS NOT WARPED

A CARPENTERS SQUARE , A BRIGHT LIGHT AND FEELER GAUGES CAN BE USED TO CHECK IF THE BLOCK DECK OR CYLINDER HEAD MATING SURFACE IS SQUARE AND NOT WARPED

IF YOUR SIMPLY TRYING TO GET A STOCK ENGINE BACK IN SERVICE AS CHEAPLY AS YOU CAN?

the heads and block surfaces must be very carefully examined for damage or warping issues and if found those issues must be corrected, before any new head gaskets installed, over time steam can and will cut grooves in even cast iron blocks and rather easily in softer aluminum. no head gasket will seal a badly machined or warped head or block

btw if youve managed to blow a head gasket on a 1986-91 TPI corvette with aluminum heads

the heads and block surfaces must be very carefully examined for damage or warping issues and if found those issues must be corrected, before any new head gaskets installed, over time steam can and will cut grooves in even cast iron blocks and rather easily in softer aluminum.

the stock 1986-91 tpi head gasket FELPRO HS7733pt9

heres a video on checking heads for warpage

the new wd40 rust preventative spray works far better than the older version

http://www.dayattherange.com/?page_id=3667 READ THRU THIS LINK[/img]

HERES A VIDEO THAT SHOULD BE TITLED

"HOW TO SCREW UP A BLOCKS GASKET SURFACE"

HONESTLY HE IS REALLY DOING THE JOB BADLY, BUT IF YOUR NOT KNOWLEDGEABLE< HOW WOULD YOU KNOW?

before you spend a good deal of money porting and un-shrouding any iron cylinder heads, keep in mind aluminum heads are easily repaired in a skilled and experienced automotive machine shop thats equipped to do those repairs but damaged iron cylinder heads are either much harder to repair or good door stops

http://garage.grumpysperformance.com/index.php?threads/iron-vs-aluminum-heads.389/#post-7266

Larry Carley said:Removing Gaskets The Wrong Way

Engine dis-assembly is a dirty, greasy, time-consuming job, so any shortcut that makes the work go faster is a good idea, right? Maybe not if the short cut ends up damaging parts or creating more work for you in the long run.

The practice we’re talking about here is using an abrasive pad in a drill to grind off gasket residue that may be stuck to the heads or block. The abrasive will certainly whiz the gasket debris right off, but it can also whiz off metal leaving a shallow depression, a dig or a groove that may create a sealing problem when the engine is put back together.

Another reason not to use an abrasive disk to grind off or clean a surface is that it generates a lot of dust. Some gasket fibers may be hazardous to breathe. A dust mask can protect your lungs, but the residue can end up in other places where it may cause problems later (like in the cylinders, intake ports, oil or coolant passages).

The best way to remove gaskets is with a sharp scraper and/or a can of aerosol chemical gasket remover. Spraying the gaskets with a chemical remover eliminates hard scraping and the risk of scratching or gouging the surface, especially on soft aluminum heads and blocks. The chemical does most of the work by softening the gaskets. The residue can then be easily scraped off the surface.

One mistake to avoid here is using the wrong tool to scrape off the gaskets. An old screw driver is not a gasket remover. Nor is a putty knife. A gasket scraper is the right tool to use because it has a sharp, beveled edge that gets under and lifts the old gasket from the surface. Just make sure the scraper is sharp (it should be sharp enough to cut paper).

The trick to using a gasket scraper correctly is to scrape at an angle that is almost parallel to the surface. By keeping the angle small, the tip of the scraper will slip under the gasket and shear it away from the surface without digging in. If you try to use it like a chisel, you’ll probably end up gouging the surface and damaging the surface. Also, hold the scraper so you push it forward (away from you) as you scrape. This way, if the tool slips it won’t gouge you.

viewtopic.php?f=52&t=4081&p=10861#p10861

viewtopic.php?f=27&t=3379&p=8946&hilit=shop+vacuum#p8946

viewtopic.php?f=44&t=700&p=43768&hilit=head+gasket+bore#p43768

viewtopic.php?f=32&t=10376&p=42845&hilit=head+gasket+bore#p42845

viewtopic.php?f=52&t=4403&p=38976&hilit=head+gasket+bore#p38976

Last edited by a moderator: