one of my pet peeves is rigged results from testing, in those magazine dyno results, we all read frequently,as most of the experienced guys know the engine is a SYSTEM of parts that must match in the rpm range and air flow/ horse power levels they need to run at to get valid results

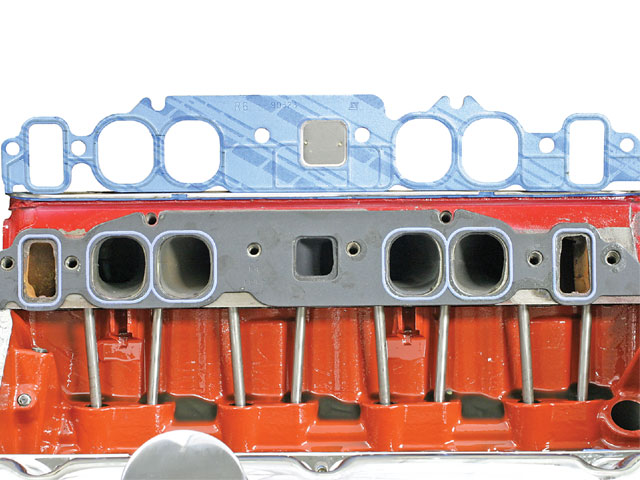

anyone can take a nearly stock 350 Chevy engine designed to run at 3500rpm or lower rpms most of the time and show a marked advantage in the power curve,on a dyno for the use of a well designed dual plane intake and matched 650 cfm carb,over the stock o.e.m intake and carb, or a well designed single plane intake, with a 850 cfm race carb and matched cam, and heads, on that same engine. Especially if the dyno run in that article only goes to about 4500rpm-5500rpm, yet there's not a thing wrong with the single plane intake, or a race cam or the O.E.M. parts if they are used under conditions they were designed to be use under,

the opposite result would be shown on a similar 350 engine equipped with an aggressive cam, high compression pistons, open headers and cylinder heads designed to run 7500rpm , if your testing intake manifolds, especially if the dyno testing started at 3500rpm and pulled to 7800rpm.

IVE found over the years that magazine dyno test results depend a great deal on the company that's paying for the testing to be done and the components they sell, seldom does the company's products come out looking badly,

automotive magazines have always been seen by the parts manufacturers as a less expensive way to promote extended advertising of the parts they want sold, they arrange for a minimal tech related blurb, and slant it's results, as far as they can stretch reality to make their product look totally indispensable

EXAMPLE

Ive had very good results with BOTH CLOYES chain drives and JACKSON cam drives, and ID doubt theres a two hp difference between them on an honest dyno test, in most engine combos.

yet Ive seen dyno test results in magazines, that say theres a 5% reduction in power for a gear drive (thats 25hp on a 500hp engine) that result is ludicrous, but its also easy to "PROVE" a chain drive OR a cam drive is superior with a skilled dyno operator doing the testing

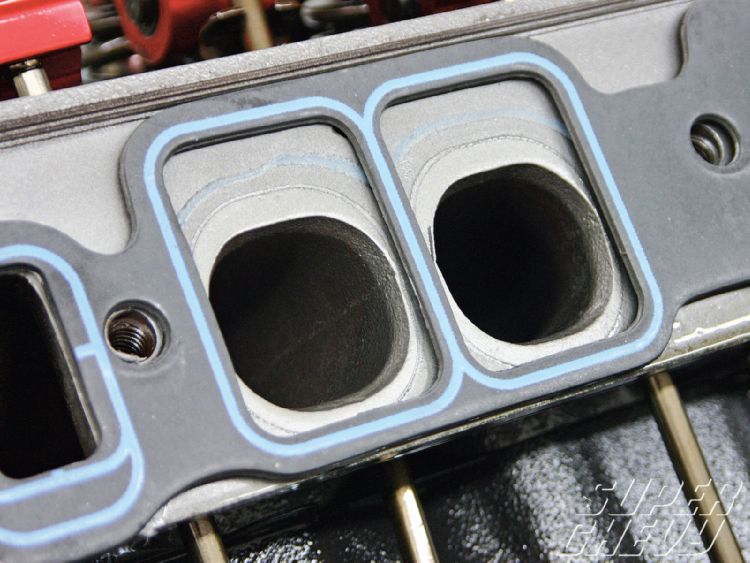

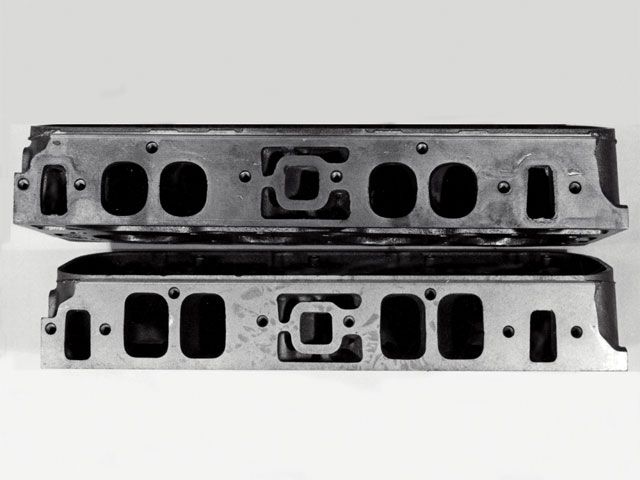

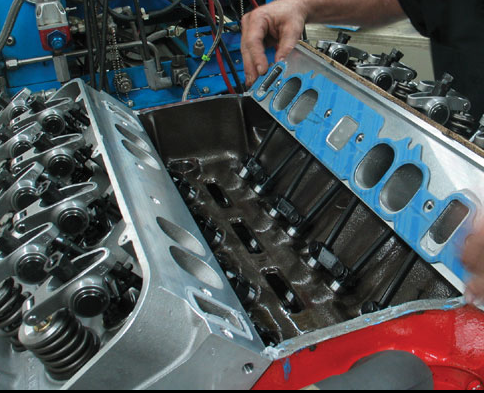

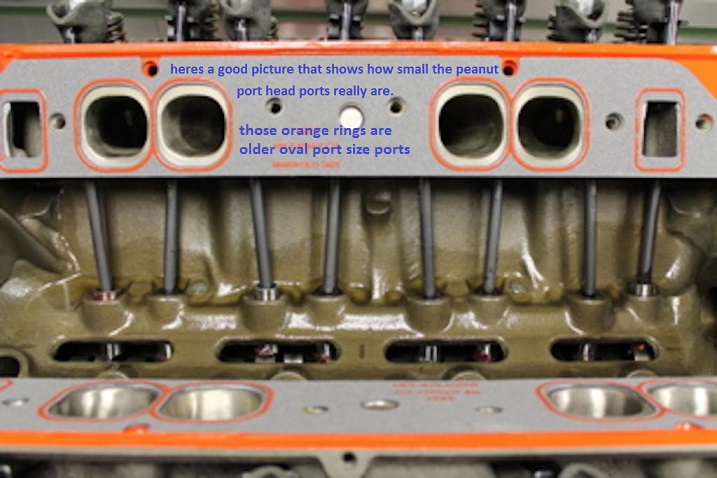

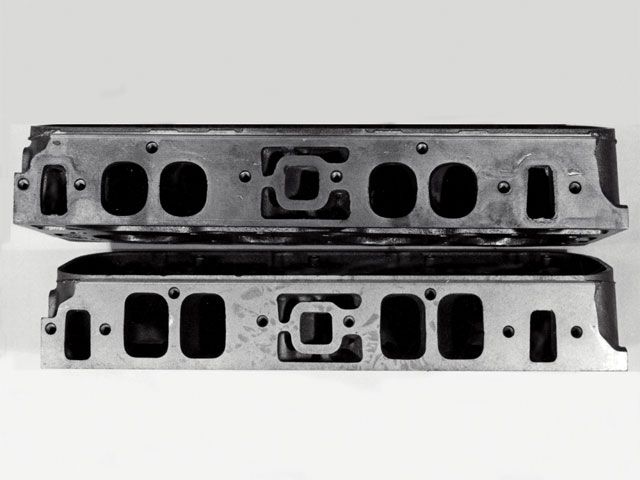

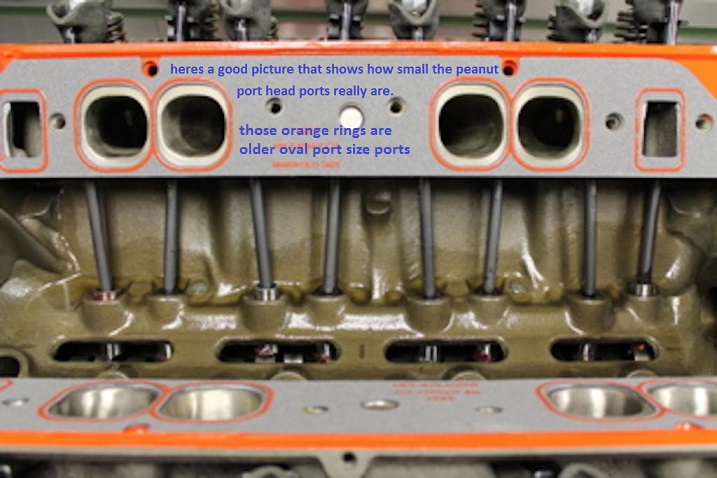

I just got thru reading a DYNO test on oval versus rectangle port heads on a bbc engine in one of the magazines, now the results they got while valid, for the tested engine combo, were intentionally rigged in my opinion, they were not a fair comparison, and any engine builder with experience would have picked up on the fact that the DYNO test was set up so that only one result was likely.

honestly some of the tech, used in magazine dyno testing, is absurd, it would rank up with some guy claiming ice made by the refrigerator he sells, never melts, and for a test he would leave a bag outside on the ground for a week in Antarctica in the middle of winter , to prove it!

in the article they first matched results on a 454 using rectangle then oval port heads, the results was 407hp (R) versus 419hp(O) N/A

then 558hp(R) versus 563hp(O) SUPERCHARGED

now that's fine UNTIL YOU LOOK AT THE OTHER COMPONENTS USED

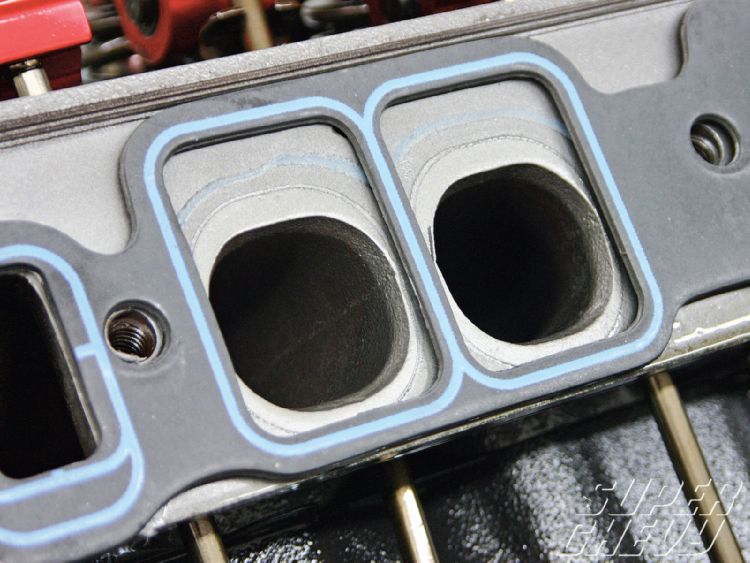

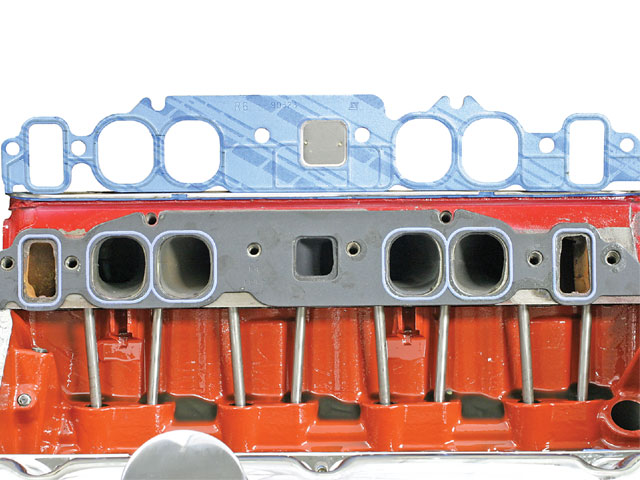

in the first test a cam was used with only 220/220 duration and .500/.500 lift,and the dyno was only run up to 5700rpm. now any engine builder knows that the advantage of the rectangle port heads will not show up until a cam is used that's been designed for rpm ranges of about 5000-6500rpm plus and lifts in the .550 plus ranges are used, and in most cases theres factors like compression ratio,displacement, exhaust scavenging,, cylinder heads being used, duration and lift of the cam, the cams LSA, and a good deal more factors that will have a very noticeable effect on your dyno power curve results.

MOST ENGINE BUILDERS WILL TELL YOU THAT CORRECTLY SET UP OVAL PORT HEADS ARE THE BEST CHOICE ON THE AVERAGE mild STREET,ENGINE COMBO, AND THEY ARE CORRECT! but in this case a look at the dyno torque curve shows very clearly the CAM selected for the testing, started causing the engine to run short on air at about 4300rpm, to 4500rpm, this meant the rectangle port heads had no chance at ever reaching the rpm range, that the larger port heads were designed to run in, efficiently.. in the second test, in that article, a supercharger was used on both cylinder heads, but it was a HOLLEY 174 power charger DESIGNED for efficient low rpm street use ,that's a supercharger that's not designed to feed a 454 displacement at anything close too 6000rpm, and again the same low rpm efficient cam ,design was used, that severely limited power potential at over about 4300rpm-4500rpm.

if you only open the valves enough to flow at the smaller tested ports limitations on both heads tested your obviously restricting the larger port heads potential, if your only allowing the engine to operate in the smaller ports head flow efficient power band the larger port head can never be expected to show any advantage, in fact its lower port speeds in the tested range are obviously going to be less efficient just as the smaller port would be if pushed well past its effective flow limitations in the higher rpm ranges

if your going to compare the results fairly to take ADVANTAGE of the STRONG POINTS OF BOTH CYLINDER HEADS, a longer CAM duration, used in a high compression engine combo and a LARGER SUPERCHARGER would need to be used, to show the marked superiority of the larger port heads with both sets of heads being tested along with the milder combo so you could see why the larger ports have advantages and dis-advantages , depending on the other components they are matched too, I would be VERY SURPRISED if the results still favored the oval port heads if both cylinder heads were tested with a cam like the CROWER #01488,

http://www.crower.com/misc/cam_spec/cam_finder.php

with a N/A dynamic compression ratio of about 8:1, which would obviously require a boost in the static compression ratio,

or if the HOLLEY, 871 supercharger driven at 1:1 engine speed ratio and spun up to 6000rpm was used on both engines with a lower compression matching the supercharges boost curve

http://www.holley.com/types/Big%20Block ... Series.asp

rectangle port heads generally work best on 500 or larger displacement engines

with at least 10:1 compression and cams with at least 245 duration at .050 lift and valve lifts over .600 to take advantage of the potential port flow rates

RELATED THREADS YOU SHOULD READ

http://garage.grumpysperformance.co...-peanut-port-big-block-combo.2900/#post-61085

http://garage.grumpysperformance.com/index.php?threads/porting-can-help.462/page-3#post-59145

http://garage.grumpysperformance.com/index.php?

http://garage.grumpysperformance.co...gine-build-up-for-the-street.3153/#post-11626

http://garage.grumpysperformance.co...tting-up-the-valve-train.181/page-2#post-7684

http://garage.grumpysperformance.co...a-peanut-port-big-block-combo.2900/#post-7532

http://garage.grumpysperformance.com/index.php?threads/cheaper-454-chevy-build.4620/#post-46849

http://garage.grumpysperformance.co...at-angles-and-air-flow.8460/page-2#post-32923

http://garage.grumpysperformance.co...olishing-combustion-chambers.2630/#post-50247

http://garage.grumpysperformance.com/index.php?threads/bbc-intake-manifold-choices.12949/

http://garage.grumpysperformance.co...ing-parts-and-a-logical-plan.7722/#post-57946

http://garage.grumpysperformance.com/index.php?threads/multi-angle-valve-job-related.3143/

btw DD-2000 guesses at a 190hp plus advantage to using the larger port, larger valve rectangle port heads on a combo like that ! THE POINT IM TRYING TO MAKE CLEAR HERE IS THAT ALL PARTS IN AN ENGINE BUILD MUST MATCH THE INTENDED USE FOR THAT ENGINE FOR THE PARTS TO WORK CORRECTLY IN THE INTENDED RPM RANGE AND AT THE INTENDED HORSEPOWER LEVEL, ANY PART NOT MATCHING THE THE REST OF THE COMBO CAN BE MADE TO LOOK BAD ON A DYNO TEST

READ THESE LINKS, carefully, each has interesting info

viewtopic.php?f=56&t=1303&p=2822#p2822

viewtopic.php?f=44&t=392&p=7281&hilit=+intake+test#p7281

viewtopic.php?f=56&t=495&p=2414&hilit=+tested+muffler#p2414

anyone can take a nearly stock 350 Chevy engine designed to run at 3500rpm or lower rpms most of the time and show a marked advantage in the power curve,on a dyno for the use of a well designed dual plane intake and matched 650 cfm carb,over the stock o.e.m intake and carb, or a well designed single plane intake, with a 850 cfm race carb and matched cam, and heads, on that same engine. Especially if the dyno run in that article only goes to about 4500rpm-5500rpm, yet there's not a thing wrong with the single plane intake, or a race cam or the O.E.M. parts if they are used under conditions they were designed to be use under,

the opposite result would be shown on a similar 350 engine equipped with an aggressive cam, high compression pistons, open headers and cylinder heads designed to run 7500rpm , if your testing intake manifolds, especially if the dyno testing started at 3500rpm and pulled to 7800rpm.

IVE found over the years that magazine dyno test results depend a great deal on the company that's paying for the testing to be done and the components they sell, seldom does the company's products come out looking badly,

automotive magazines have always been seen by the parts manufacturers as a less expensive way to promote extended advertising of the parts they want sold, they arrange for a minimal tech related blurb, and slant it's results, as far as they can stretch reality to make their product look totally indispensable

EXAMPLE

Ive had very good results with BOTH CLOYES chain drives and JACKSON cam drives, and ID doubt theres a two hp difference between them on an honest dyno test, in most engine combos.

yet Ive seen dyno test results in magazines, that say theres a 5% reduction in power for a gear drive (thats 25hp on a 500hp engine) that result is ludicrous, but its also easy to "PROVE" a chain drive OR a cam drive is superior with a skilled dyno operator doing the testing

I just got thru reading a DYNO test on oval versus rectangle port heads on a bbc engine in one of the magazines, now the results they got while valid, for the tested engine combo, were intentionally rigged in my opinion, they were not a fair comparison, and any engine builder with experience would have picked up on the fact that the DYNO test was set up so that only one result was likely.

honestly some of the tech, used in magazine dyno testing, is absurd, it would rank up with some guy claiming ice made by the refrigerator he sells, never melts, and for a test he would leave a bag outside on the ground for a week in Antarctica in the middle of winter , to prove it!

in the article they first matched results on a 454 using rectangle then oval port heads, the results was 407hp (R) versus 419hp(O) N/A

then 558hp(R) versus 563hp(O) SUPERCHARGED

now that's fine UNTIL YOU LOOK AT THE OTHER COMPONENTS USED

in the first test a cam was used with only 220/220 duration and .500/.500 lift,and the dyno was only run up to 5700rpm. now any engine builder knows that the advantage of the rectangle port heads will not show up until a cam is used that's been designed for rpm ranges of about 5000-6500rpm plus and lifts in the .550 plus ranges are used, and in most cases theres factors like compression ratio,displacement, exhaust scavenging,, cylinder heads being used, duration and lift of the cam, the cams LSA, and a good deal more factors that will have a very noticeable effect on your dyno power curve results.

MOST ENGINE BUILDERS WILL TELL YOU THAT CORRECTLY SET UP OVAL PORT HEADS ARE THE BEST CHOICE ON THE AVERAGE mild STREET,ENGINE COMBO, AND THEY ARE CORRECT! but in this case a look at the dyno torque curve shows very clearly the CAM selected for the testing, started causing the engine to run short on air at about 4300rpm, to 4500rpm, this meant the rectangle port heads had no chance at ever reaching the rpm range, that the larger port heads were designed to run in, efficiently.. in the second test, in that article, a supercharger was used on both cylinder heads, but it was a HOLLEY 174 power charger DESIGNED for efficient low rpm street use ,that's a supercharger that's not designed to feed a 454 displacement at anything close too 6000rpm, and again the same low rpm efficient cam ,design was used, that severely limited power potential at over about 4300rpm-4500rpm.

if you only open the valves enough to flow at the smaller tested ports limitations on both heads tested your obviously restricting the larger port heads potential, if your only allowing the engine to operate in the smaller ports head flow efficient power band the larger port head can never be expected to show any advantage, in fact its lower port speeds in the tested range are obviously going to be less efficient just as the smaller port would be if pushed well past its effective flow limitations in the higher rpm ranges

if your going to compare the results fairly to take ADVANTAGE of the STRONG POINTS OF BOTH CYLINDER HEADS, a longer CAM duration, used in a high compression engine combo and a LARGER SUPERCHARGER would need to be used, to show the marked superiority of the larger port heads with both sets of heads being tested along with the milder combo so you could see why the larger ports have advantages and dis-advantages , depending on the other components they are matched too, I would be VERY SURPRISED if the results still favored the oval port heads if both cylinder heads were tested with a cam like the CROWER #01488,

http://www.crower.com/misc/cam_spec/cam_finder.php

with a N/A dynamic compression ratio of about 8:1, which would obviously require a boost in the static compression ratio,

or if the HOLLEY, 871 supercharger driven at 1:1 engine speed ratio and spun up to 6000rpm was used on both engines with a lower compression matching the supercharges boost curve

http://www.holley.com/types/Big%20Block ... Series.asp

rectangle port heads generally work best on 500 or larger displacement engines

with at least 10:1 compression and cams with at least 245 duration at .050 lift and valve lifts over .600 to take advantage of the potential port flow rates

RELATED THREADS YOU SHOULD READ

http://garage.grumpysperformance.co...-peanut-port-big-block-combo.2900/#post-61085

http://garage.grumpysperformance.com/index.php?threads/porting-can-help.462/page-3#post-59145

http://garage.grumpysperformance.com/index.php?

http://garage.grumpysperformance.co...gine-build-up-for-the-street.3153/#post-11626

http://garage.grumpysperformance.co...tting-up-the-valve-train.181/page-2#post-7684

http://garage.grumpysperformance.co...a-peanut-port-big-block-combo.2900/#post-7532

http://garage.grumpysperformance.com/index.php?threads/cheaper-454-chevy-build.4620/#post-46849

http://garage.grumpysperformance.co...at-angles-and-air-flow.8460/page-2#post-32923

http://garage.grumpysperformance.co...olishing-combustion-chambers.2630/#post-50247

http://garage.grumpysperformance.com/index.php?threads/bbc-intake-manifold-choices.12949/

http://garage.grumpysperformance.co...ing-parts-and-a-logical-plan.7722/#post-57946

http://garage.grumpysperformance.com/index.php?threads/multi-angle-valve-job-related.3143/

btw DD-2000 guesses at a 190hp plus advantage to using the larger port, larger valve rectangle port heads on a combo like that ! THE POINT IM TRYING TO MAKE CLEAR HERE IS THAT ALL PARTS IN AN ENGINE BUILD MUST MATCH THE INTENDED USE FOR THAT ENGINE FOR THE PARTS TO WORK CORRECTLY IN THE INTENDED RPM RANGE AND AT THE INTENDED HORSEPOWER LEVEL, ANY PART NOT MATCHING THE THE REST OF THE COMBO CAN BE MADE TO LOOK BAD ON A DYNO TEST

READ THESE LINKS, carefully, each has interesting info

viewtopic.php?f=56&t=1303&p=2822#p2822

viewtopic.php?f=44&t=392&p=7281&hilit=+intake+test#p7281

viewtopic.php?f=56&t=495&p=2414&hilit=+tested+muffler#p2414

Last edited by a moderator: