Re: Right, I think my twin electric fans aren't running righ

JUST A BIT OF RELATED INFO

when I raced my big block 1968 corvette I started out using the stock mechanical fan ,belt driven off the engine and a really nice aftermarket aluminum radiator , that kept the engine cool with zero issues, but that was partly because of the cars speed forcing air thru the radiator.

I was originally setting the corvette up to road race, but when the local track closed I converted the car to a street/strip and drag race car. but I found out very quickly that having a larger electrically driven cooling fan that replaced the mechanical fan allowed more room to get access to the engine and mechanical fuel injection and the reduced drag and ability to hook up the auxiliary fan too cool off the engine while the engine was not actually running by jumping the car from a running car with jumper cables had benefits.

I also found a 200 amp alternator allowed the battery to charge rapidly and the fans that cooled the engine too spin faster keep the engine noticeably cooler when the engine was running because the extra current noticeably increased the engine cooling fans rotational speed.

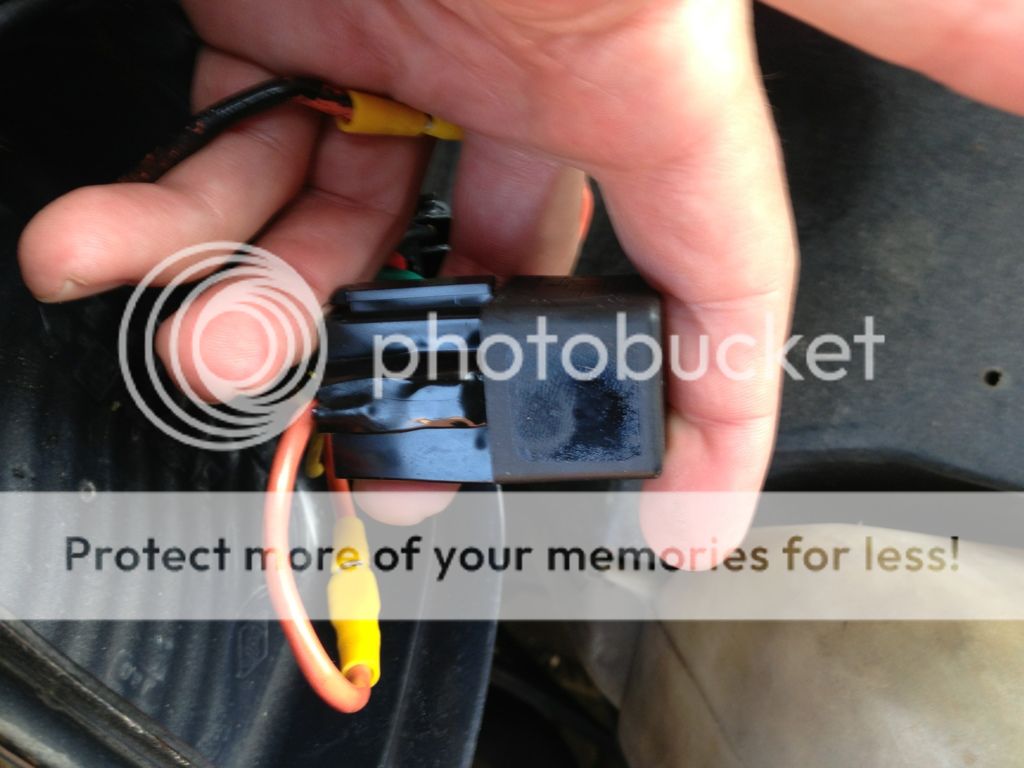

but during the process I found I could NOT use the original wiring in the car , too connect auxiliary cooling fans, I had to install a complete separate 10 ga wire system with 60 amp rated relays for the fans, none of the cars original wire was heavy enough nor was there any provision for a large electric puller fan.

BE AWARE THE WIRE GAUGE AND RELAY AMP RATES VARY SO SHOP CAREFULLY

http://www.aliexpress.com/item/10pcs-Ca ... 80067.html

IMAGE: 1. Voltage & Current Parameters of the relay in-scripted on the Case of the relay.

2. Voltage & Current Parameters of the relay in-scripted on the Case of the relay.

Most relays are available in different operating voltages like 5V, 6V, 12V, 24V, etc. If the required operating voltage is supplied to the relay, the relay is activated. The operating voltage of a relay is generally in DC.Small signal relays and low voltage power relays are usually in DC, but mains control relays and contactors quite frequently have AC coils.The rest of the terminals of a relay are used to connect either a AC(generally 50/60Hz) or DC circuit. The switching and contact pins of the relay have their respective Maximum voltage and current ratings/Parameters. These Parameters are generally in-scripted on the plastic or PVC case of the relay.On the contact ratings, they will frequently have something like 5A@250VAC / 10A@12VDC. These are the figures you have to be within. Having said that you can run a higher current than stamped on it if your voltage is lower, they aren't directionally proportional though and the datasheet for the relay should be consulted. If a relay is overloaded, it can burn out and damage the circuit or appliances connected to it. Be sure to choose a relay that can handle your voltage and current requirements to ensure the relay coil doesn't burn out and your circuit doesn't get damaged.

Choosing a Proper Relay Amperage

How to calculate for the Correct Relay

Relay Ratings and Limits

Relays often have two ratings: AC and DC. These rating indicate how much power can be switched through the relays. This does not necessarily tell you what the limits of the relay are. For instance, a 5 Amp relay rated at 125VAC can also switch 2.5 Amps at 250VAC. Similarly, a 5 Amp relay rated at 24VDC can switch 2.5 Amps at 48VDC, or even 10 Amps at 12VDC.

Volts x Amps = Watts - Never Exceed Watts!

An easy way to determine the limit of a relay is to multiply the rated Volts times the rated Amps. This will give you the total watts a relay can switch. Every relay will have two ratings: AC and DC. You should determine the AC watts and the DC watts, and never exceed these ratings.

Example Calculations

AC Volts x AC Amps = AC Watts DC Volts x DC Amps = DC Watts

Example: A 5 Amp Relay is Rated at 250 Volts AC. 5 x 250 = 1,250 AC Watts Example: A 5 Amp Relay is Rated at 24 Volts DC.

5 x 24 = 120 DC Watts

If you are switching AC Devices, Make Sure the AC Watts of the Device you are Switching DOES NOT Exceed 1,250 when using a 5A Relay. If you are switching DC Devices, Make Sure the DC Watts of the Device you are Switching DOES NOT Exceed 120 when using a 5A Relay.

Resistive and Inductive Loads

Relays are often rated for switching resistive loads. Inductive loads can be very hard on the contacts of a relay. A resistive load is a device that stays electrically quiet when powered up, such as an incandescent light bulb. An inductive load typically has a violent startup voltage or amperage requirement, such as a motor or a transformer.

Startup and Runtime Loads

Inductive loads typically require 2-3 times the runtime voltage or amperage when power is first applied to the device. For instance, a motor rate at 5 Amps, 125 VAC will often require 10-15 amps just to get the shaft of the motor in motion. Once in motion, the the motor may consume no more than 5 amps. When driving these types of loads, choose a relay that exceeds the initial requirement of the motor. In this case, a 20-30 Amp relay should be used for best relay life.

theres little sense in even having a relay in a car that won,t operate at a minimum of 12 volts and at least 30 amps minimum,

but Id have to point out that matched sets of relays and pigtails are readily available in several amp ranges rather cheaply.

once you understand how they are designed to function testing or replacing one is no

challenge

http://garage.grumpysperformance.com/index.php?threads/cleaning-out-older-radiator.15827/

https://www.amazon.com/ARTGEAR-Harness-Color-Labeled-Automotive-Motorcycle/dp/B078T3RC5T

https://www.summitracing.com/parts/pco-5593pt/overview/

https://www.amazon.com/Fastronix-Weatherproof-Automotive-Relay-Socket/dp/B01CXA42XK

https://www.ebay.com/bhp/60-amp-relay

https://www.ebay.com/bhp/80-amp-relay

https://www.summitracing.com/parts/...MIq4ObtvSz3wIVU57ACh0MfQn4EAQYAiABEgJsYfD_BwE

https://www.amazon.com/dp/B07F83159...&pd_rd_r=991c9f49-060a-11e9-bb5a-dff16524fffe

https://relaypros.com/choosing_proper_amperage.htm

https://www.12voltplanet.co.uk/relay-guide.html

https://www.instructables.com/id/All-You-Need-to-Know-About-Relays/

Typical Current Loads for Automotive Systems, Lighting and Accessories:

Engine Idling (no lights or accessories on)

- 35 to 50 amps. This will vary depending on the number of cylinders (more cylinders draw more power for the fuel injectors and coils), the type of fuel injectors (some draw higher amp loads than others), the type of ignition system (single coil or multi-coil), the amp draw of the PCM, and the fuel pump (the amp draw will be higher with higher pressure systems).

Engine Off (nothing on)

- 40 to 50 milliamps (power drain by modules in sleep mode, antitheft system and keyless entry)

Ignition Coil (single oil-filled coil older vehicle)

- 3 to 4 amps.

Ignition Coil (single DIS coil newer vehicle)

- 5 to 6 amps.

Ignition Coil (coil-on-plug)

- 6 amps per coil.

Ignition System (primary circuit)

- 6 to 20 amps.

Fuel Injectors - 4 to 6 amps peak, 1 amp hold

Electric Fuel Pump (depends on pressure and flow)

- 4 to 12 amps

Electric Cooling Fan (depends on size)

- 6 to 30 amps

Headlights (halogen low beam)

- 8 to 9 amps per pair

Headlights (halogen high beam)

- 9 to 10 amps per pair

Headlights (halogen high and low beams combined)

- 17 to 19 amps

Headlights (High Energy Discharge)

- 12 to 14 amps during initial start, 7 to 8 amps once bulbs are hot

Headlights (LED)

- 0.6 to 1 amps per bulb

Small bulbs (incandescent)

- 0.3 to 0.4 amps per bulb

Small bulbs (LED)

- 0.04 to 0.06 amps per bulb

Starter Motor - 200 to 350 amps

500 Watt Sound System - 42 amps

Electric Rear Window Defroster - 10 to 20 amps

Windshield wipers - 2 to 10 amps depending on load

Heated Seats - 3 to 4 amps per seat

Power Windows - 3 amps

Electric Power Steering - 2 to 40 amps depending on load

Air Conditioner Compressor Clutch - 2.5 to 5 amps

Heater A/C blower motor (depends on load, size and speed setting)

- 2 to 30 amps