general rule for N/A engines is ring gaps should be between, .0040--.0045 per inch of bore dia.

example

a 4" bore like a 350 x .004--.0045 = .016-.018 ring gap

heres a chart and links to tools for referance

viewtopic.php?f=53&t=509

http://kb-silvolite.com/article.php?action=read&A_id=32

http://www.hanzenginehouse.com/HANZENGI ... nggap.html

http://www.muller.net/sonny/crx/rings/index.html

http://www.tavia.com/cat16.html#2

http://www.jegs.com/webapp/wcs/stores/s ... 2_74772_-1

http://www.jegs.com/webapp/wcs/stores/s ... 9_-1_10693

http://www.jegs.com/webapp/wcs/stores/s ... 2_55122_-1

http://www.jegs.com/webapp/wcs/stores/s ... 1_-1_10693

http://www.jegs.com/webapp/wcs/stores/s ... _841806_-1

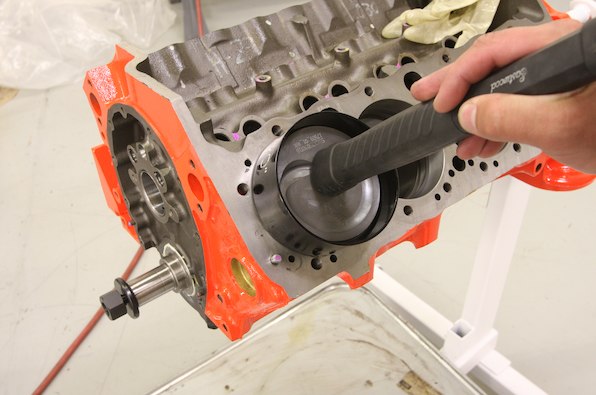

BTW when you go to buy a ring compressor....this type works far better than the others

http://store.summitracing.com/partdetail.asp?autofilter=1&part=PRO-66766&N=700+115&autoview=sku

Proform 66766 $31

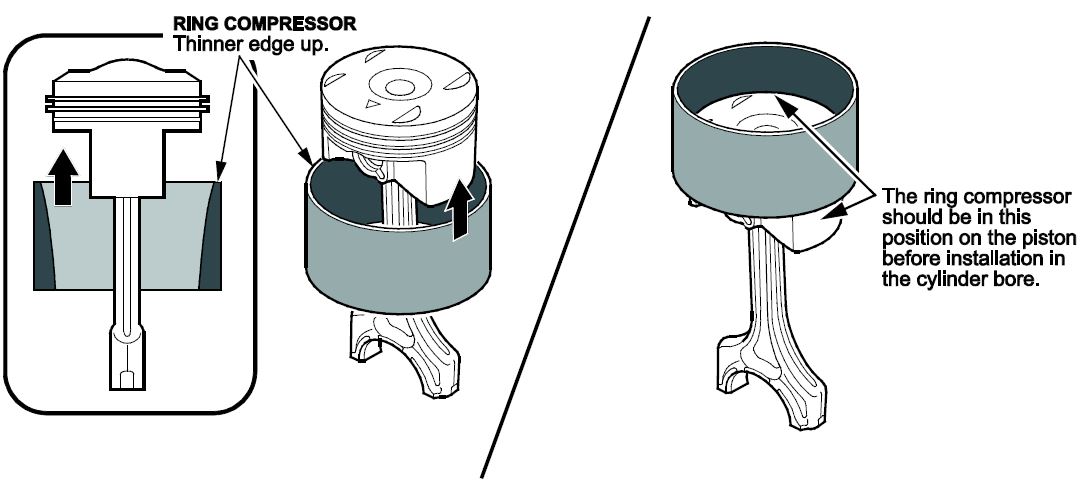

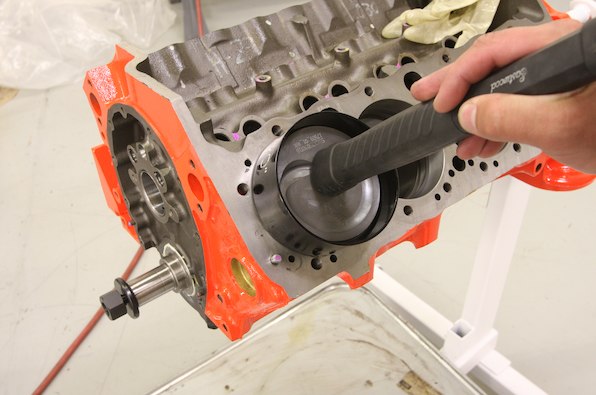

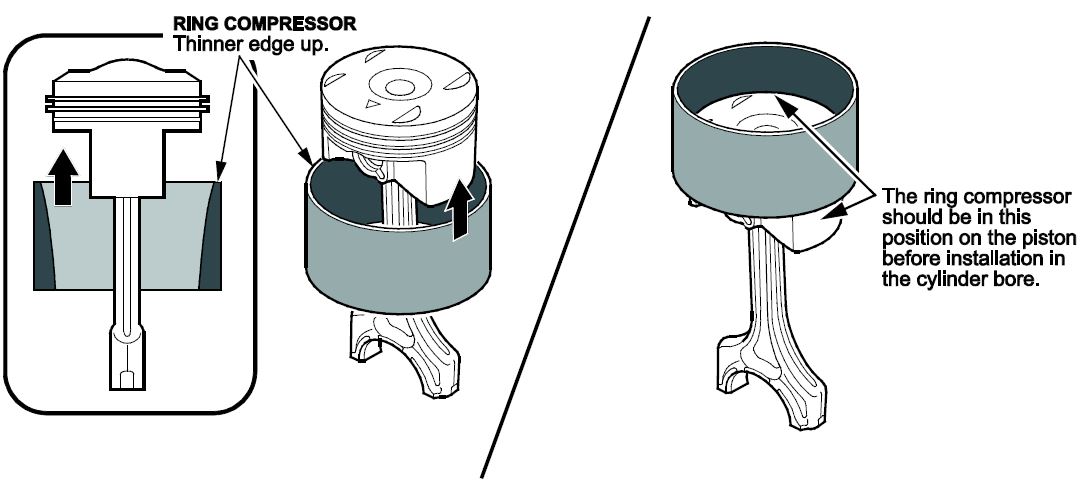

how they work is you clamp it around your piston and adjust it to that size before the rings are installed so the piston is a snug slide thru fit, then, install the rings, dip the rings and piston in clean oil, place the compressor over the cylinder on the block with the base firmly held against the block deck and push the piston into its much larger open entrance, as it slides thru the funnel like construction squeezes the rings into the groves and they can,t spring back out until they are in the bore, remember to line up the rod bolts and having them covered with the ends of a 3 ft long section or 3/8" fuel line to protect the crank journal is a good idea, having a ROD GUIDE TOOL you can use to guide and PULL THE PISTON INTO THE BORE WITH IS EVEN A BETTER IDEA

BTW I recommend THIS TYPE of piston ring compressor (below)as the type in the video can and occasionally does allow the rings to pop out and jam, or break far more frequently .

the picture lacks detail, but the interior of the compressors tapered, you tighten to a slide fit on the piston diam. and the rings compress fully as they are entering the cylinder entrance and only expand after entering the bore.

Proform 66766 $31

BTW I recommend THIS TYPE of piston ring compressor (below)as the type in the video can and occasionally does allow the rings to pop out and jam, or break far more frequently .

the picture lacks detail, but the interior of the compressors tapered, you tighten to a slide fit on the piston diam. and the rings compress fully as they are entering the cylinder entrance and only expand after entering the bore.

BTW when you go to buy a ring compressor....this type works far better than the others

http://store.summitracing.com/partdetail.asp?autofilter=1&part=PRO-66766&N=700+115&autoview=sku

Proform 66766 $31

youll be surprised at how much easier they slide into the bore if you BOTH pull/guide and push the pistons into the cylinders rather than just beat them in with a hammer handle, it takes some practice but a few taps to get them moving with a fist, while pulling and guiding the rod into its journal is usually all that necessary with a well oiled piston and that type of ring compressor.

IVE dunked my piston/ring assembly's in a can of MARVEL MYSTERY OIL just before installation with a ring compressor and have never seen the slightest indication of problems either on ring sealing getting the rings broken in, or on tearing the engines down later for inspections

KEEP IN MIND

any ring compressor design you use regardless ,of the design MUST have its lower surface kept firmly in contact with the block surface and parallel to the bore to allow the rings to smoothly transition from the inner surface of the compressor to the blocks bore, and IDEALLY the compressor internal diameter will be marginally smaller in internal diameter that the cylinder bore the pistons sliding into from it!

example

a 4" bore like a 350 x .004--.0045 = .016-.018 ring gap

heres a chart and links to tools for referance

viewtopic.php?f=53&t=509

http://kb-silvolite.com/article.php?action=read&A_id=32

http://www.hanzenginehouse.com/HANZENGI ... nggap.html

http://www.muller.net/sonny/crx/rings/index.html

http://www.tavia.com/cat16.html#2

http://www.jegs.com/webapp/wcs/stores/s ... 2_74772_-1

http://www.jegs.com/webapp/wcs/stores/s ... 9_-1_10693

http://www.jegs.com/webapp/wcs/stores/s ... 2_55122_-1

http://www.jegs.com/webapp/wcs/stores/s ... 1_-1_10693

http://www.jegs.com/webapp/wcs/stores/s ... _841806_-1

BTW when you go to buy a ring compressor....this type works far better than the others

http://store.summitracing.com/partdetail.asp?autofilter=1&part=PRO-66766&N=700+115&autoview=sku

Proform 66766 $31

how they work is you clamp it around your piston and adjust it to that size before the rings are installed so the piston is a snug slide thru fit, then, install the rings, dip the rings and piston in clean oil, place the compressor over the cylinder on the block with the base firmly held against the block deck and push the piston into its much larger open entrance, as it slides thru the funnel like construction squeezes the rings into the groves and they can,t spring back out until they are in the bore, remember to line up the rod bolts and having them covered with the ends of a 3 ft long section or 3/8" fuel line to protect the crank journal is a good idea, having a ROD GUIDE TOOL you can use to guide and PULL THE PISTON INTO THE BORE WITH IS EVEN A BETTER IDEA

BTW I recommend THIS TYPE of piston ring compressor (below)as the type in the video can and occasionally does allow the rings to pop out and jam, or break far more frequently .

the picture lacks detail, but the interior of the compressors tapered, you tighten to a slide fit on the piston diam. and the rings compress fully as they are entering the cylinder entrance and only expand after entering the bore.

Proform 66766 $31

BTW I recommend THIS TYPE of piston ring compressor (below)as the type in the video can and occasionally does allow the rings to pop out and jam, or break far more frequently .

the picture lacks detail, but the interior of the compressors tapered, you tighten to a slide fit on the piston diam. and the rings compress fully as they are entering the cylinder entrance and only expand after entering the bore.

BTW when you go to buy a ring compressor....this type works far better than the others

http://store.summitracing.com/partdetail.asp?autofilter=1&part=PRO-66766&N=700+115&autoview=sku

Proform 66766 $31

youll be surprised at how much easier they slide into the bore if you BOTH pull/guide and push the pistons into the cylinders rather than just beat them in with a hammer handle, it takes some practice but a few taps to get them moving with a fist, while pulling and guiding the rod into its journal is usually all that necessary with a well oiled piston and that type of ring compressor.

IVE dunked my piston/ring assembly's in a can of MARVEL MYSTERY OIL just before installation with a ring compressor and have never seen the slightest indication of problems either on ring sealing getting the rings broken in, or on tearing the engines down later for inspections

KEEP IN MIND

any ring compressor design you use regardless ,of the design MUST have its lower surface kept firmly in contact with the block surface and parallel to the bore to allow the rings to smoothly transition from the inner surface of the compressor to the blocks bore, and IDEALLY the compressor internal diameter will be marginally smaller in internal diameter that the cylinder bore the pistons sliding into from it!

Last edited by a moderator: