many guys never stop to think thru the choices that they make,in components,has a major effect on how the finished engine will run and its durability, they assume that if a component is built for their engine application that it will work flawlessly.

you tend to get what you pay for up to a point and if you see roller lifters for less than half the price of the better name brand lifters in a similar design ,you can be reasonably sure the less expensive lifters are made of inferior quality materials,don,t have the same quality control and/or are imported. now that may not always be the case but Id bet that way in most cases.

small features like oil feed holes directly to the roller, larger oil passage clearance, harder & stronger steel, lighter weight,and more bore contact area may not be obvious but all effect durability.

many suppliers have both a standard, low price and a PREMIUM expensive line of lifters and in some cases theres a large difference in durability between them.

many guys also feel limited to the brand of the cam or engine and factory block dimensions or limitations when that's not always the best route to take. and many guys never think that minor mods may have major effects on a component durability.

example grooving the lower 1/2 of a lifter bore from the oil passage to the lower lifter bore over the cam lobe on the in-rotating side to provide extra cooling oil and lubrication can extend any lifters life expectancy

I can tell you from hearing dozens of guys who have had problems that most cam or valve train failures will be INSTANTLY blamed by any cam manufacturer on your use of MIXED brand components if you don,t use ALL that manufacturers components. (and I can see their point as they obviously can and don,t want to test every potential combination of components.) but ive used combos like crane billet cams with morel lifters or isky lifters and trickflow , or ERSON rockers etc with excellent durability as long as you research the combo and set up the clearances and geometry correcly

many aftermarket blocks and a few O.E.M. blocks have the required material thickness in the lifter gallery bore casting, that allows the lifter bores to be drilled and sleeved to larger sizes allowing lets say a mopar lifter in a chevy engine.

larger lifter bore allow larger and stronger wheel diam. and bearing and axle diam. components and while larger parts tend to weigh a bit more thats not always a significant factor, if you can add 50% to a component strength and 100% to expected durability adding 10%-15% to the weight may be an excellent trade off.

first let me point out that chevy , ford and mopar blocks all tend to use different lifter bore diameters

0.842'' Lifter Bore Diameter Grooving Tool (std. Chevy Diam.)

.844 Diameter Grooving Tool (Std. Ford Diam.)

0.904 Lifter Bore Diameter Grooving Tool (std. AMC-Chrysler Diam.

IVE FOUND THESE LIFTER BRANDS TO WORK WELL, PROVIDED YOU FOLLOW MANUFACTURERS APPLICATION INSTRUCTIONS, AND SPRING LOAD RATE LIMITATIONS

MOREL

ISKY

CRANE

LUNATI

CROWER

ISKY CAMS TECH TIPS

Roller Lifters: Keep 'Em Rolling Longer

Most racers are aware of the advantages of Roller Lifters. For those who are not, a brief review is in order. Roller Cams & Lifters are employed today in all-out racing engines where valve lift/area requirements preclude the possibility of employing a flat tappet (solid lifter cam). Higher Lift requires higher valve spring loads (pressures) and flat tappet cams can only handle so much. Additionally, increased rates of lift (cam lobe velocity) above .007" per degree for example on an .842" diameter G.M. lifter, would cause the lobe to reach-out over the edge of the lifters' cam face. Consequently, with either too much spring or too high a lift rate, most racers know that extremely radical flat tappet cams will eventually self-destruct.

But, what about Roller Lifters? Are they as indestructible as many believe? How do we prolong the life of their roller bearings in today's modern race only engines? Roller lifters require special care and maintenance if they are to provide good service life. Here are the 4 most important factors you should consider to insure their success.

1. AVOID DRY "START UP": Roller Lifter Bearings are assembled with a "tacky" rust-preventing grease that is not intended for lubrication. Therefore, new lifters should have their roller bearings thoroughly washed in clean solvent or acetone to completely remove this assembly grease. After air drying, premium motor-oil (non-synthetic) such as Penzoil SAE 25W50 GTP Racing Oil (The best of the mineral based oils) or Amzoil "Red" Racing Oil (synthetic) should be used to pre-lube the bearings just before installation.

2. AVOID "OVERLOAD": Increased load always means reduced service life. Want 50% more thrust from a jet engine? Ask Rolls Royce or G.E. and they'll tell you to expect about ¼th the service life between overhauls. Similarly, employing drag race valve springs in the 900, 1000 to 1100 lb. Range will reduce the life of your roller bearings between rebuilds much the same as will employing high-impact roller cam profiles.

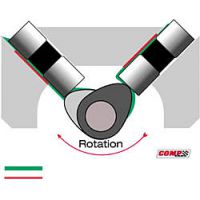

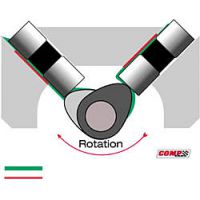

3. EMPLOY A REV KIT WHEN POSSIBLE: The primary advantage of Camfather Ed Isky's invention of the 1950's is that by pre-loading each Roller Lifter Bearing to its respective cam lobe, you eliminate needle roller bearing "skew". Skewing (the momentary mis-alignment of the bearings' needle rollers to their respective races) is provoked by the start-stop skidding action of the roller bearings each time the lash is taken-up. Eliminate it and you extend roller bearing life dramatically! Unfortunately, many engines such as the Big Block Chevy which could use one the most, don't lend themselves to such an installation because of the severe angularity of the pushrod coming out of the lifter.

4. EMPLOY LIFTERS WITH "PRESSURE-FED" OIL TO THE NEEDLE ROLLER BEARINGS: Hope is a good thing. But hoping oil will eventually find its way to your Roller Lifter bearings is not. Unfortunately, most roller lifters on the market do not pressure feed oil to the needle rollers, depending on the "splash & a little luck" system instead. In contrast, all Isky Roller Lifters feature pressure fed oil to their roller bearings. Isky's Top of the line "Red Zone" Series lifters feature an exclusive 3-Point "Multi-Port" oiling system to constantly bathe the needle rollers with cooling lubrication. Additionally, they feature our famous Marathon Roller bearing with the toughest shock absorbing heavy duty outer bearing race on the market for the highest possible load carrying capability and sustained Hi-Rpm Endurance. And, they're fully rebuildable, making them your best long-term value!

RELATED INFO

http://www.iskycams.com/camwalk.php

http://www.iskycams.com/durathon.php

http://74.6.238.254/search/srpcache?ei= ... mhsS6_fw--

http://ryanbrownracing.com/Bill_Jones_Page_13.html

http://www.koernerracing.com/lifterbush.htm

viewtopic.php?f=52&t=181

http://users.telenet.be/jov/opeltuners/ ... fters.html

viewtopic.php?f=52&t=2154&p=5812&hilit=comp+isky#p5812

viewtopic.php?f=52&t=788&p=1142&hilit=comp+isky#p1142

http://www.lewisracingengines.com/

http://www.gmpartsdirect.com/performanc ... D=476.html

you tend to get what you pay for up to a point and if you see roller lifters for less than half the price of the better name brand lifters in a similar design ,you can be reasonably sure the less expensive lifters are made of inferior quality materials,don,t have the same quality control and/or are imported. now that may not always be the case but Id bet that way in most cases.

small features like oil feed holes directly to the roller, larger oil passage clearance, harder & stronger steel, lighter weight,and more bore contact area may not be obvious but all effect durability.

many suppliers have both a standard, low price and a PREMIUM expensive line of lifters and in some cases theres a large difference in durability between them.

many guys also feel limited to the brand of the cam or engine and factory block dimensions or limitations when that's not always the best route to take. and many guys never think that minor mods may have major effects on a component durability.

example grooving the lower 1/2 of a lifter bore from the oil passage to the lower lifter bore over the cam lobe on the in-rotating side to provide extra cooling oil and lubrication can extend any lifters life expectancy

I can tell you from hearing dozens of guys who have had problems that most cam or valve train failures will be INSTANTLY blamed by any cam manufacturer on your use of MIXED brand components if you don,t use ALL that manufacturers components. (and I can see their point as they obviously can and don,t want to test every potential combination of components.) but ive used combos like crane billet cams with morel lifters or isky lifters and trickflow , or ERSON rockers etc with excellent durability as long as you research the combo and set up the clearances and geometry correcly

many aftermarket blocks and a few O.E.M. blocks have the required material thickness in the lifter gallery bore casting, that allows the lifter bores to be drilled and sleeved to larger sizes allowing lets say a mopar lifter in a chevy engine.

larger lifter bore allow larger and stronger wheel diam. and bearing and axle diam. components and while larger parts tend to weigh a bit more thats not always a significant factor, if you can add 50% to a component strength and 100% to expected durability adding 10%-15% to the weight may be an excellent trade off.

first let me point out that chevy , ford and mopar blocks all tend to use different lifter bore diameters

0.842'' Lifter Bore Diameter Grooving Tool (std. Chevy Diam.)

.844 Diameter Grooving Tool (Std. Ford Diam.)

0.904 Lifter Bore Diameter Grooving Tool (std. AMC-Chrysler Diam.

IVE FOUND THESE LIFTER BRANDS TO WORK WELL, PROVIDED YOU FOLLOW MANUFACTURERS APPLICATION INSTRUCTIONS, AND SPRING LOAD RATE LIMITATIONS

MOREL

ISKY

CRANE

LUNATI

CROWER

ISKY CAMS TECH TIPS

Roller Lifters: Keep 'Em Rolling Longer

Most racers are aware of the advantages of Roller Lifters. For those who are not, a brief review is in order. Roller Cams & Lifters are employed today in all-out racing engines where valve lift/area requirements preclude the possibility of employing a flat tappet (solid lifter cam). Higher Lift requires higher valve spring loads (pressures) and flat tappet cams can only handle so much. Additionally, increased rates of lift (cam lobe velocity) above .007" per degree for example on an .842" diameter G.M. lifter, would cause the lobe to reach-out over the edge of the lifters' cam face. Consequently, with either too much spring or too high a lift rate, most racers know that extremely radical flat tappet cams will eventually self-destruct.

But, what about Roller Lifters? Are they as indestructible as many believe? How do we prolong the life of their roller bearings in today's modern race only engines? Roller lifters require special care and maintenance if they are to provide good service life. Here are the 4 most important factors you should consider to insure their success.

1. AVOID DRY "START UP": Roller Lifter Bearings are assembled with a "tacky" rust-preventing grease that is not intended for lubrication. Therefore, new lifters should have their roller bearings thoroughly washed in clean solvent or acetone to completely remove this assembly grease. After air drying, premium motor-oil (non-synthetic) such as Penzoil SAE 25W50 GTP Racing Oil (The best of the mineral based oils) or Amzoil "Red" Racing Oil (synthetic) should be used to pre-lube the bearings just before installation.

2. AVOID "OVERLOAD": Increased load always means reduced service life. Want 50% more thrust from a jet engine? Ask Rolls Royce or G.E. and they'll tell you to expect about ¼th the service life between overhauls. Similarly, employing drag race valve springs in the 900, 1000 to 1100 lb. Range will reduce the life of your roller bearings between rebuilds much the same as will employing high-impact roller cam profiles.

3. EMPLOY A REV KIT WHEN POSSIBLE: The primary advantage of Camfather Ed Isky's invention of the 1950's is that by pre-loading each Roller Lifter Bearing to its respective cam lobe, you eliminate needle roller bearing "skew". Skewing (the momentary mis-alignment of the bearings' needle rollers to their respective races) is provoked by the start-stop skidding action of the roller bearings each time the lash is taken-up. Eliminate it and you extend roller bearing life dramatically! Unfortunately, many engines such as the Big Block Chevy which could use one the most, don't lend themselves to such an installation because of the severe angularity of the pushrod coming out of the lifter.

4. EMPLOY LIFTERS WITH "PRESSURE-FED" OIL TO THE NEEDLE ROLLER BEARINGS: Hope is a good thing. But hoping oil will eventually find its way to your Roller Lifter bearings is not. Unfortunately, most roller lifters on the market do not pressure feed oil to the needle rollers, depending on the "splash & a little luck" system instead. In contrast, all Isky Roller Lifters feature pressure fed oil to their roller bearings. Isky's Top of the line "Red Zone" Series lifters feature an exclusive 3-Point "Multi-Port" oiling system to constantly bathe the needle rollers with cooling lubrication. Additionally, they feature our famous Marathon Roller bearing with the toughest shock absorbing heavy duty outer bearing race on the market for the highest possible load carrying capability and sustained Hi-Rpm Endurance. And, they're fully rebuildable, making them your best long-term value!

RELATED INFO

http://www.iskycams.com/camwalk.php

http://www.iskycams.com/durathon.php

http://74.6.238.254/search/srpcache?ei= ... mhsS6_fw--

http://ryanbrownracing.com/Bill_Jones_Page_13.html

http://www.koernerracing.com/lifterbush.htm

viewtopic.php?f=52&t=181

http://users.telenet.be/jov/opeltuners/ ... fters.html

viewtopic.php?f=52&t=2154&p=5812&hilit=comp+isky#p5812

viewtopic.php?f=52&t=788&p=1142&hilit=comp+isky#p1142

http://www.lewisracingengines.com/

http://www.gmpartsdirect.com/performanc ... D=476.html