http://classiccars.about.com/od/res...m_medium=tcg&utm_campaign=zergnet-test-640224

This is not an article about coatings, brush on products or chemical treatments

designed to seal oxidized metal surfaces. This is an article about removing heavy rust from classic cars that are about to undergo a complete and thorough restoration. It's time to remove the old body filler repairs and rust from your vintage car and find out how much original metal is actually left to work with.

Getting Serious About the Rust

We've all driven by someone's house and seen a

poorly covered classic Chevrolet muscle car patiently waiting for its chance to be reborn through restoration.

The reason these cars sit for years or decades is because the first step is painful and difficult. If you plan to use a media blasting or chemical dipping process, it starts by removing absolutely everything, including the vehicle identification number plate. Stripping the old paint off and finding out what's underneath isn't really a fun do-it-yourself at home project.

Here we're going to talk about two popular methods of separating the remaining original metal from everything else. The goal is to start the restoration project on a strong foundation. Replacing quarter panels and floorboards are often the second step, but first we'll be talking about media blasting and chemical dips in depth. These methods are not for small budgets or the faint of heart, but they can help you stand in the truth of what is left of your vintage automobile.

http://garage.grumpysperformance.com/index.php?threads/1996-underbody-corrosion.10066/#post-39253

Media Blasting Classic Cars

When people think of media blasting they often think of sand blasting. Today they apply the same principles, but instead of sand there is a wide range of different small grain projectiles to shoot at the body panels and frame.

The age of the automobile, how heavily it's corroded and the thickness of the remaining sheet metal all play a role in determining what kind of media is best for the job.

On automobiles with a strong backbone and those not made out of fiberglass, many body shops choose a product

from DuPont called Star Blast.

This looks like sand, but the grain is larger, round and a consistent shape that provides the power without the damage caused by the jagged grains of sand. On automobiles that have more paint to remove than rust, many owners opt for media blasting with Walnut shells. This allows for an even gentler removal process with room for adjustment.

They make ground up walnut shells in course, medium and fine grit to meet the particular needs of the body panels. This is also gentle enough to remove paint from fiberglass for all of

the Chevrolet Corvette fans. It's hard to nail down the average cost of a media blast service, because it depends on the length of time invested by the body shop and the amount of materials used. However, using a friend’s repaint project on a

1971 Dodge Charger as an example, they broke out the media blast service as a separate line item costing $900.

Caustic Chemical Dips for Cars

Just like when we talked about the different types of media used in a blasting process, there are different kinds of chemicals a car can be immersed in to remove oxidized metal, paint and

old Bondo body repairs. The problems associated with using a caustic chemical or an acid dip is neutralizing the chemical after removing the automobile from the bath. Any residual will be harmful to the remaining sheet metal and damaging to the future paint job.

With that said, this process shouldn't be feared for those reasons. People that have invested in the equipment and the training of their employees to carry out the operation understand the process of neutralizing and flushing. Although the term acid is used as a blanket statement, companies providing this service offer different methods.

Body shops use phosphoric acid, iron phosphate salt solutions and they can even use electrolytic rust removal procedures. This is where they pass an electric current through a bath of electrolyte solution to reverse the rusting process. When discussing the cost of this operation a good rule of thumb is that it will be about twice as expensive as the media blasting process. The upside is you won't have to deal with walnut shells falling out of the rear deck lid every time you pull your folding chair out of the trunk at the car show.

http://classiccars.about.com/od/restorationbasics/ss/GotRust.htm

Rust is a complicated electrochemical process whereby a metal is converted to an oxide whenever it comes in contact with oxygen in the presence of moisture, and that can happen even in the protective custody of your garage. Because of that, the longer you own a car, it’s more than likely that one day you’ll find rust on it.

The standard approach to rust removal has been to sand blast or scrape down to bare metal, prime with a rust-inhibiting primer and then paint.

When we come across rust on our cars or restoration project, we found using rust converters in the form of brush-on liquids to be an attractive alternative.

To show you how well a rust converter can work, we'll demonstrate with this heavily rusted and flaking interior magazine holder we found in our most current restoration of a 1961 Jaguar Mark 2.

flaking rust removed but surface rust remains. The first thing you need to do before applying the rust converter is to remove loose particles of rust and debris with a wire brush, scrapper or rag. You can see that we took the flaky rusted metal down to a smooth surface but left plenty of surface rust. This is important because rust converters depend upon a layer of rust being present to be effective.

Remove any other surface contaminants.

Next, we used a vacuum cleaner to remove fine particles and denatured alcohol as a degreaser; mineral spirits would work as well. This step makes sure that other surface contaminants will not interfere with the reaction of the rust converter on the rusted area. Make sure that the surface dries completely before you apply the converter.

Choose a water based rust converter like

Eastwoods or

Corroseal that contain two active ingredients; tannic acid and an organic polymer. The tannic acid reacts with iron oxide (rust) and chemically converts it to iron tannate, a dark-colored stable material. The organic polymer (2-Butoxyethanol) provides a protective primer layer. The overall chemical reaction converts rust into a stable, black protective polymeric coating.

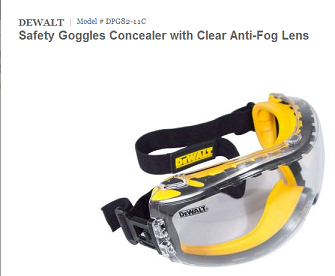

Make sure you use gloves and safety glasses in a well ventilated area that is between 50 and 90 degree Fahrenheit during the application process and follow the manufactures instruction. The consistency of most converters is pretty thick and is more easily rolled or brushed on, but it's thin enough to flow into cracks and seams.

Before and after rust converter.

We applied two thin coats to our Jags magazine holder within twenty minutes of each other and all the rust had turned to black. Once it cures for forty eight hours, we'll be able to paint and attach its accessories.

The entire process took about 2 hours and cost less than ten dollars to convert the rust into a paintable, protective, black layer that will seal out moisture and protect this part against any future corrosion.