: grumpyvette

Hello there!

I have a question that I'd like to ask you. I plan to

rebuild my engine soon and while I'm there, I'll upgrade

some parts.

Right now I have stock bottom end 350 with ported

(mild porting) #113 heads, LPE #219 cam, complete

superram and LT headers.

I've allready bought .020" over flat top SRP forged

pistons and SCAT I-beam forged rods 5.7" long. I plan

to do more porting on the heads and install larger LT4

(2.00 and 1.56") valves.

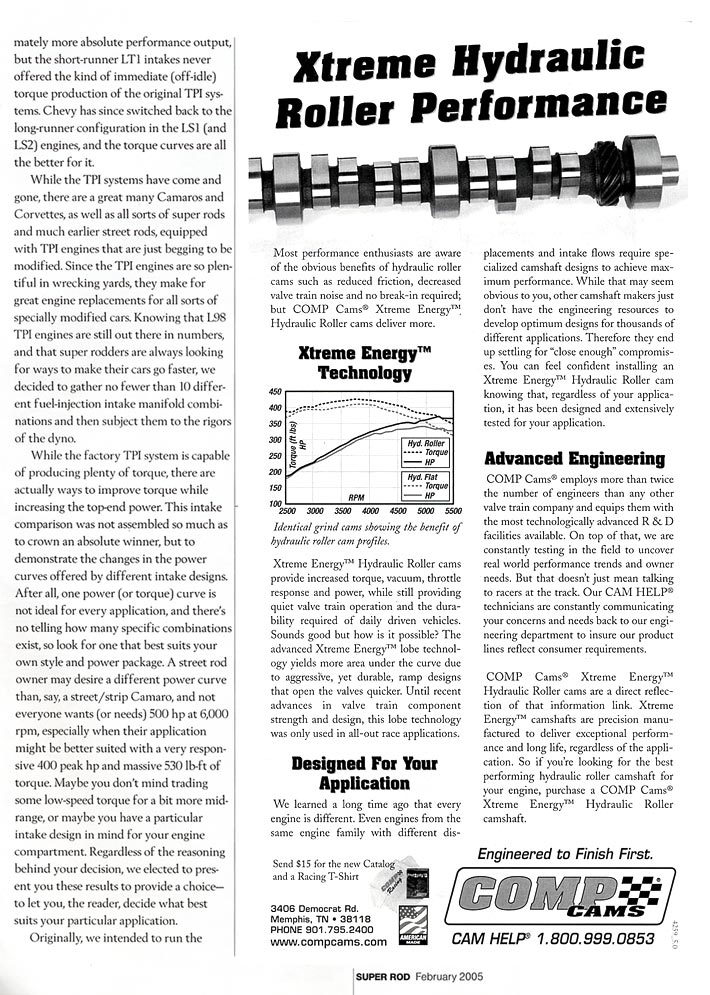

Also, I've allready bought Comp Cams cam:

Comp Cams XR288HR-10

Hydraulic roller

288 294 advertised duration

236 242 @0.050

520 540 lift

110* lobe separation

I'm aware that it's big cam for 350, but I'd like to move

the power band more up, into higher rpm range.

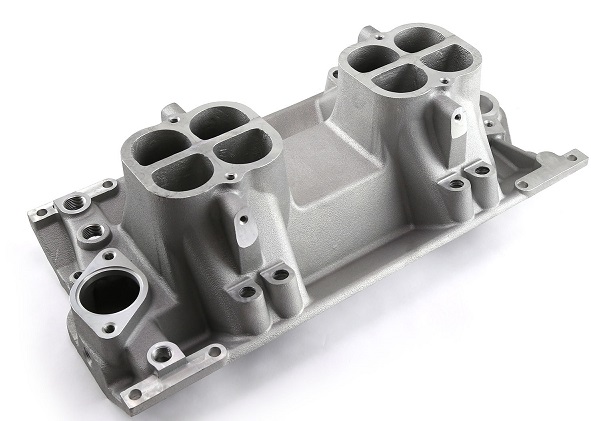

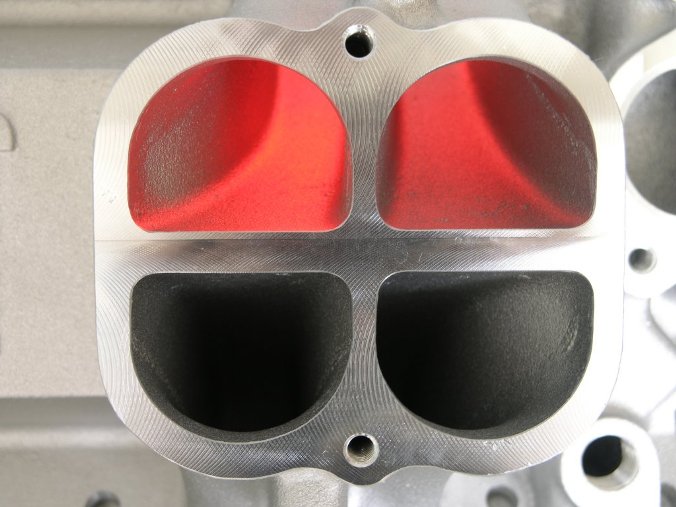

What I'm debating over is intake. There are 3 choices

that I have:

1. Fully port superram and use that.

2. Buy miniram

3. Buy modified HSR

What do you think would be best choice? First option

would be best for me financially, but I could sell

superram and buy one of other intakes instead.

Also, I've heard that miniram have some air distribution

problems (front cylinders running richer)??

Do you know something about that?

What about HSR? I've seen you name mentioned in

converstion about modified (for vette) HSR. Do you have

it available and if you do, what is the price?

I'm looking forward for any of your input.

Thanks,

Bruno

viewtopic.php?f=55&t=641&p=1004#p1004

http://www.speedwaymotors.com/RHS-1...MIxaWg5tXZ1gIVA6ppCh09DgVzEAYYAiABEgINIfD_BwE

http://www.westcoastoffshore.ca/Fue...ke-Manifold-w-Fuel-Rails-12903-KIT-P5412.aspx

it states it comes with the fuel rails , it fits standard 23 degree heads and fits vortec heads ,

and at $514 thats not a bad deal,for a high fow single plane SBC intake

Hello there!

I have a question that I'd like to ask you. I plan to

rebuild my engine soon and while I'm there, I'll upgrade

some parts.

Right now I have stock bottom end 350 with ported

(mild porting) #113 heads, LPE #219 cam, complete

superram and LT headers.

I've allready bought .020" over flat top SRP forged

pistons and SCAT I-beam forged rods 5.7" long. I plan

to do more porting on the heads and install larger LT4

(2.00 and 1.56") valves.

Also, I've allready bought Comp Cams cam:

Comp Cams XR288HR-10

Hydraulic roller

288 294 advertised duration

236 242 @0.050

520 540 lift

110* lobe separation

I'm aware that it's big cam for 350, but I'd like to move

the power band more up, into higher rpm range.

What I'm debating over is intake. There are 3 choices

that I have:

1. Fully port superram and use that.

2. Buy miniram

3. Buy modified HSR

What do you think would be best choice? First option

would be best for me financially, but I could sell

superram and buy one of other intakes instead.

Also, I've heard that miniram have some air distribution

problems (front cylinders running richer)??

Do you know something about that?

What about HSR? I've seen you name mentioned in

converstion about modified (for vette) HSR. Do you have

it available and if you do, what is the price?

I'm looking forward for any of your input.

Thanks,

Bruno

viewtopic.php?f=55&t=641&p=1004#p1004

http://www.speedwaymotors.com/RHS-1...MIxaWg5tXZ1gIVA6ppCh09DgVzEAYYAiABEgINIfD_BwE

http://www.westcoastoffshore.ca/Fue...ke-Manifold-w-Fuel-Rails-12903-KIT-P5412.aspx

it states it comes with the fuel rails , it fits standard 23 degree heads and fits vortec heads ,

and at $514 thats not a bad deal,for a high fow single plane SBC intake

Last edited by a moderator: