READ THRU THIS CAREFULLY

http://www.compcams.com/Community/Artic ... 2026144213

http://www.kennedysdynotune.com/Nitrous ... 20Tips.htm

http://www.compcams.com/CAMQUEST/

http://www.dragstuff.com/techarticles/P ... hafts.html

http://www.pontiacstreetperformance.com ... rArms.html

viewtopic.php?f=52&t=181

viewtopic.php?f=52&t=1751

http://www.compcams.com/Community/Artic ... 2026144213

http://www.chevyhiperformance.com/techa ... index.html

viewtopic.php?f=52&t=1070

http://www.aa1car.com/library/camshafts.htm

viewtopic.php?f=52&t=1477

I will try to answer that as simply as possible.

A nitrous cam is designed to work with more cylinder pressure and more exhaust voluum. than a N/A cam design

NITROUS use developed similar INCREASED exhaust pressure and VOLUMES of exhaust gases, to a super charged application, because atmospheric air,run in a N/A engine holds about 21% oxygen and you run a fuel air ratio about 12.6 pounds of air for every pound of gasoline.

with nitrous theres about 40% oxygen content available in the same volume of air as you would have with a supercharger at about 15 psi of boost, but without the intake being pressurized and with out the heat and weight a supercharger has, in fact nitrous is injected and radically cools the intake charge making it denser,so to maintain that similar 12.6:1 fuel air ratio you adding and burning a good deal more fuel,(obviously depending on the percentage of nitrous added to the outside air the engine ingests, vs pure nitrous and fuel which would require a bit more that twice as much fuel to maintain the ideal fuel/air ratio that extra fuel being burnt is where your getting the extra power nitrous used generates, thus the extra exhaust gas volume, you might want to think of nitrous as generating up to twice the volume of exhaust gases from about the same intake volume, thats running and burning extra fuel to generate higher cylinder pressures,up too, twice the oxygen content, means up to twice the fuel being burnt per compression,power and exhaust stroke.

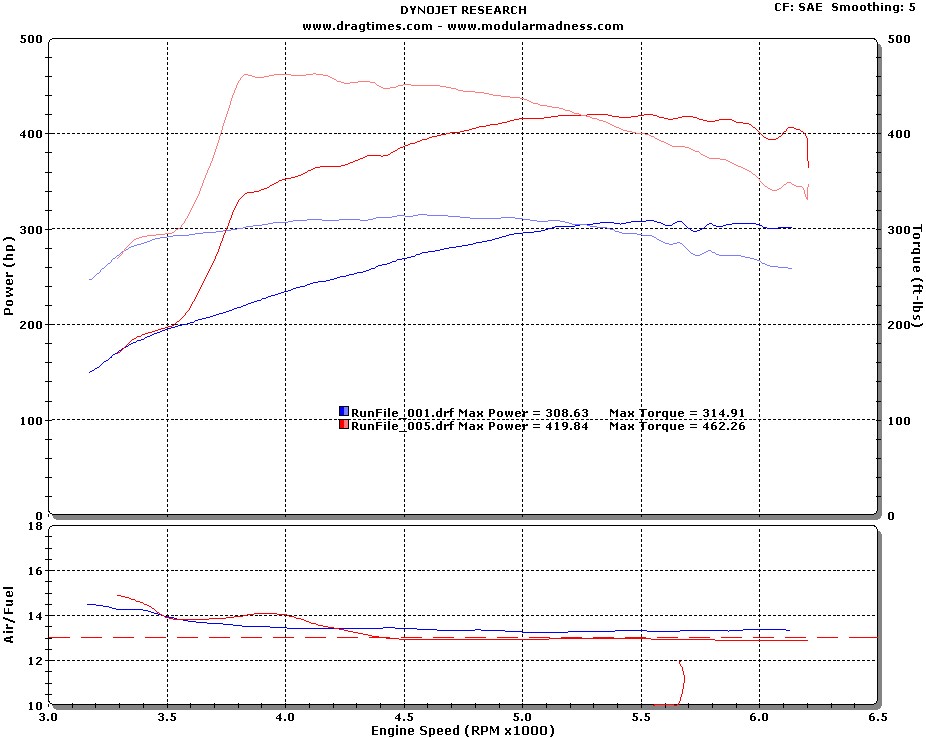

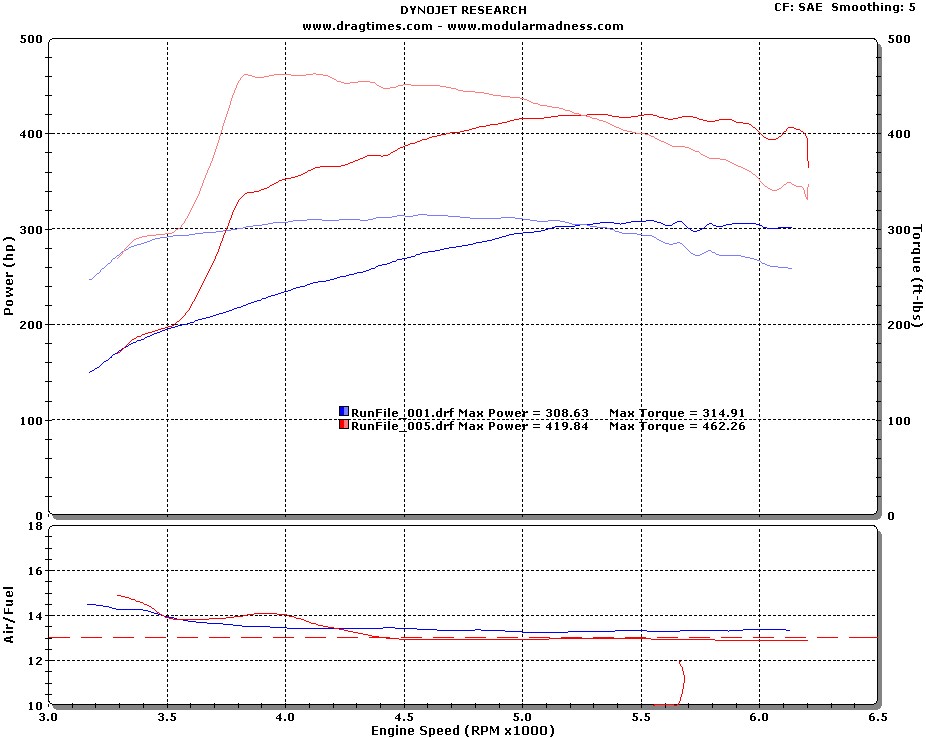

LOOK AT THESE TWO DYNO GRAPHS

http://mb-soft.com/public2/engine.html

below are two extremely similar cams, both have identical lift and duration, only the LSA differs

its always a good idea to call the cam manufacturer and ask what is the correct matching cam gear and distributor gear set,and how its correctly installed.

this one is considered better with nitrous

wide 114 LSA

http://www.crower.com/misc/cam_spec/cam ... 4&x=51&y=9

INTAKE Opens: 15.0 BTDC

Closes: 55.0 ABDC

EXHAUST Opens: 68.0 BBDC

Closes: 12.0 ATDC

tight 108 LSA

http://www.crower.com/misc/cam_spec/cam ... 7&x=51&y=9

INTAKE Opens: 21.0 BTDC

Closes: 49.0 ABDC

EXHAUST Opens: 62.0 BBDC

Closes: 18.0 ATDC

why?? well look closely, the 00234 compared to the 00227 the exhaust opens earlier on the 00234, and theres less overlap

a N/A engine runs on a fuel air mix ratio of between 12.7:1 to 14.7:1, oxygen content of normal air is approximately 20%

nitrous has approximately TWICE the oxygen content at about 40% and can effectively burn up to twice the fuel per cylinder full, now that produces a great deal higher pressures and a huge increase in exhaust volume, that extra volume produced the extra pressure that makes the power possible but it can also cause significant PUMPING LOSSES if the pressure in the cylinders does not drop off before the piston starts back up on the exhaust stroke and can limit the intake charge volume flowing into the cylinders if theres still positive cylinder pressure as the intake valve opens.

the intake valve opends at 29 degrees BTDC with the #114681 it opens at 34 degrees with the #110921,(5 degrees sooner) that makes the differance 5 degrees later opening for the #114681, this is not a problem when your filling the cylinders with the enriched nitrous/fuel mix

this effectively allows a greater time for the exhaust possitive pressure to blow off and less overlap time when both valves are open at the same time.

the later intake valve opening, matched to the lower overlap and earlier exhaust valve opening lowers the engines pumping losses when useing nitrous,gains of 30 hp plus have been shown swapping from the N/A to the NITROUS design WHEN ON NITROUS, but look for a few less hp running N/A with the nitrous cam simply because the nitrous cam does not scavage the cylinders as effectively due to lower overlap N/A at high rpms

these are the valve timing overlap ranges that are most likely to work correctly

trucks/good mileage towing 10-35 degs overlap

daily driven low rpm performance 30-55degs overlap

hot street performance 50-75 degs overlap

oval track racing 70-95degs overlap

dragster/comp eliminator engines 90-115 degs overlap

but all engines will need the correct matching dcr for those overlap figures to correctly scavage the cylinders in the rpm ranges that apply to each engines use range.

example

http://dab7.cranecams.com/SpecCard/DisplayCatalogCard.asp?PN=114681&B1=Display+Card

here is a hot street cam that works great in many 383 camaros with at least 10.5 static cpr with 3.5-4.1 gears

now the timeing is intake opens 29.0 btdc, closes 71.0 abdc exhaust opens 77.0 bbdc, closes 31.0 atdc so if we add the 29 to the 31 we get the overlap duration of 60 degs of which makes this cam fall in the center of HOT STREET

short answer, 110 LSA if its a engine used mostly at high RPM, 112 LSA if its street driven

(need more info,..look below)

The LSA, or lobe separation angle, is ground into the cam and cannot be changed. It is the angle that separates the intake and exhaust lobe for a particular cylinder, and is measured in camshaft degrees. The intake lobe center line is measured in crankshaft degrees. The #1 intake lobe center line is usually between 100° to 110° ATDC and is what you use to degree the cam. The cam manufacturer will publish the specs for the cam based on a given intake lobe center line. Comp Cams, for instance, produces a large number of cams with 110*° LSA ground 4° advanced, so they list the specs for the cam with a 106° intake lobe center line. You can calculate the ILC by adding the intake opening angle in °BTDC, the intake closing angle in °ABDC, plus 180° for the distance from TDC to BDC. Divide by 2 and subtract the intake opening angle and you will have the ILC. For example a 12-430-8 Comp Cam lists IO at 34°BTDC, IC at 66° ATDC, so 34 + 66 + 180 = 280. 280/2 = 140. 140 - 34 = 106° ILC

Figure 3 is a picture of both an intake and an exhaust lobe of a camshaft, seen end-on. It shows the relationship between the lobes, shows the overlap area, and illustrates this next section.

Overlap has a great deal to do with overall engine performance. Small overlap makes low-end torque but less high-end power. Large overlap reduces low-end torque but increases high-end power.

Overlap is determined by two other cam specifications, Duration and Lobe Center Angle.

Duration is the time, measured in crankshaft degrees, that a valve is open. A duration of 204 degrees means that while the valve is open, the crankshaft rotates through 204 degrees.

Duration is measured on two "standards," "advertised duration" and "duration at 0.050"." Advertised duration is measured from when the valve just starts to lift off its seat to when it just touches the seat again. This is measured in different ways by different manufacturers. Some measure when the valve lifter is raised 0.004", some at 0.006", and some at different points yet. So the industry agreed to another standard that was supposed to make it easier to compare cams. In this standard, the duration is measured between the point where the lifter is raised by 0.050", and the point where it is lowered again to 0.050".

The 0.050" standard is great for side-by-side "catalog" comparisons between cams. But if you use engine prediction software on your computer, the software is much more accurate when you can feed it "advertised" duration numbers.

Lobe Center Angle is the distance in degrees between the centers of the lobes on the camshaft.

To increase duration, cam makers grind the lobes wider on the base circle of the cam. This makes the lobes overlap each other more, increasing overlap. More duration = more overlap.

To increase overlap without changing duration, cam makers will grind the lobes closer together, making a smaller lobe center angle. Less lobe center angle = more overlap.

Overlap and duration are the two big factors in cam design. More overlap moves the power band up in the engine's RPM range.

Longer duration keeps the valves open longer, so more air/fuel or exhaust can flow at higher speeds. It works out that increasing the duration of the camshaft by 10 degrees moves the engine's power band up by about 500 rpm.

A smaller lobe separation increases overlap, so a smaller lobe separation angle causes the engine's torque to peak early in the power band. Torque builds rapidly, peaks out, then falls off quickly. More lobe separation causes torque to build more slowly and peak later, but it is spread more evenly over the power band. So a larger lobe separation angle creates a flatter torque curve.

So you can see how a cam maker can tailor the camshaft specs to produce a particular power band in an engine--

Short duration with a wide separation angle might be best for towing, producing a strong, smooth low-end torque curve.

Long duration with a short separation angle might be suited for high-rpm drag racing, with a high-end, sharp torque peak.

Moderate duration with wide separation angle might be best suited for an all-around street performance engine, producing a longer, smoother torque band that can still breathe well at higher RPM.

Remember, there's always a compromise made in this process.

One last item to consider is the lobe center line. The lobe center line is the angle of the lobe's center peak, measured in crankshaft degrees when the piston is at Top Dead Center (TDC). In general (but not always), when a cam is installed "straight up," the intake lobe center line and the lobe separation angle are the same.

The lobe center line can be altered when the camshaft is installed, by advancing or retarding the camshaft's position in relation to the crankshaft. Advancing the camshaft by 4 degrees will move the power band about 200 RPM lower in the RPM band. Retarding the cam by 4 degrees will likewise move the power band 200 RPM higher in the RPM band. This allows you to fine-tune the engine's performance according to your needs.

BTW once EITHER the duration exceeds about 225 @ .050 or the lift exceeds about .520 in a 383 SBC youll probably have clearance issues with stock connecting rods,and the cam lobes, aftermarket (H) or SOME (I) style stroker rods with 7/16" capscrew bolts are stronger and profiled to clear and use of both a small base billet roller cam and stroker profile rods will usually prevent that

if cams are a mystery please take the time to read these, it will get you a good start

http://www.iskycams.com/techtips.php

http://www.wighat.com/fcr3/confusion.htm

http://www.idavette.net/hib/camcon.htm

http://www.totalengineairflow.com/tech/valvelashing.htm

http://www.wighat.com/fcr3/camtruth.htm

http://www.wighat.com/fcr3/confusion.htm

viewtopic.php?f=50&t=575

http://www.babcox.com/editorial/ar/ar119736.htm

http://home.wxs.nl/~meine119/tech/camqa.html

https://www.holley.com/Map/Instructions7.asp

More than just the engines cam duration and lift must be considered when choosing a cam. the cam must work correctly with the intake and exhausts designed rpm band , a high-stall converter and lower (higher numerically) rear end gears, will allow the engine to accelerate thru its rpm band faster and stay in the upper rpm range longer, the engine will perform better with a bigger cam than if the car has a stock converter and highway gears, if matched to the correct components and drive train.. A heavy car is harder to get moving than a light car, so it needs more torque down low and that usually requires less duration.

when you select an intake manifold the goal is usually to maximize the engines volumetric efficiency, in the engines intended power band,(how efficiently you can fill the cylinders with a full fresh charge of fuel/air mix)

http://www.compcams.com/Community/Artic ... 2026144213

http://www.kennedysdynotune.com/Nitrous ... 20Tips.htm

http://www.compcams.com/CAMQUEST/

http://www.dragstuff.com/techarticles/P ... hafts.html

http://www.pontiacstreetperformance.com ... rArms.html

viewtopic.php?f=52&t=181

viewtopic.php?f=52&t=1751

http://www.compcams.com/Community/Artic ... 2026144213

http://www.chevyhiperformance.com/techa ... index.html

viewtopic.php?f=52&t=1070

http://www.aa1car.com/library/camshafts.htm

viewtopic.php?f=52&t=1477

I will try to answer that as simply as possible.

A nitrous cam is designed to work with more cylinder pressure and more exhaust voluum. than a N/A cam design

NITROUS use developed similar INCREASED exhaust pressure and VOLUMES of exhaust gases, to a super charged application, because atmospheric air,run in a N/A engine holds about 21% oxygen and you run a fuel air ratio about 12.6 pounds of air for every pound of gasoline.

with nitrous theres about 40% oxygen content available in the same volume of air as you would have with a supercharger at about 15 psi of boost, but without the intake being pressurized and with out the heat and weight a supercharger has, in fact nitrous is injected and radically cools the intake charge making it denser,so to maintain that similar 12.6:1 fuel air ratio you adding and burning a good deal more fuel,(obviously depending on the percentage of nitrous added to the outside air the engine ingests, vs pure nitrous and fuel which would require a bit more that twice as much fuel to maintain the ideal fuel/air ratio that extra fuel being burnt is where your getting the extra power nitrous used generates, thus the extra exhaust gas volume, you might want to think of nitrous as generating up to twice the volume of exhaust gases from about the same intake volume, thats running and burning extra fuel to generate higher cylinder pressures,up too, twice the oxygen content, means up to twice the fuel being burnt per compression,power and exhaust stroke.

LOOK AT THESE TWO DYNO GRAPHS

http://mb-soft.com/public2/engine.html

below are two extremely similar cams, both have identical lift and duration, only the LSA differs

its always a good idea to call the cam manufacturer and ask what is the correct matching cam gear and distributor gear set,and how its correctly installed.

this one is considered better with nitrous

wide 114 LSA

http://www.crower.com/misc/cam_spec/cam ... 4&x=51&y=9

INTAKE Opens: 15.0 BTDC

Closes: 55.0 ABDC

EXHAUST Opens: 68.0 BBDC

Closes: 12.0 ATDC

tight 108 LSA

http://www.crower.com/misc/cam_spec/cam ... 7&x=51&y=9

INTAKE Opens: 21.0 BTDC

Closes: 49.0 ABDC

EXHAUST Opens: 62.0 BBDC

Closes: 18.0 ATDC

why?? well look closely, the 00234 compared to the 00227 the exhaust opens earlier on the 00234, and theres less overlap

a N/A engine runs on a fuel air mix ratio of between 12.7:1 to 14.7:1, oxygen content of normal air is approximately 20%

nitrous has approximately TWICE the oxygen content at about 40% and can effectively burn up to twice the fuel per cylinder full, now that produces a great deal higher pressures and a huge increase in exhaust volume, that extra volume produced the extra pressure that makes the power possible but it can also cause significant PUMPING LOSSES if the pressure in the cylinders does not drop off before the piston starts back up on the exhaust stroke and can limit the intake charge volume flowing into the cylinders if theres still positive cylinder pressure as the intake valve opens.

the intake valve opends at 29 degrees BTDC with the #114681 it opens at 34 degrees with the #110921,(5 degrees sooner) that makes the differance 5 degrees later opening for the #114681, this is not a problem when your filling the cylinders with the enriched nitrous/fuel mix

this effectively allows a greater time for the exhaust possitive pressure to blow off and less overlap time when both valves are open at the same time.

the later intake valve opening, matched to the lower overlap and earlier exhaust valve opening lowers the engines pumping losses when useing nitrous,gains of 30 hp plus have been shown swapping from the N/A to the NITROUS design WHEN ON NITROUS, but look for a few less hp running N/A with the nitrous cam simply because the nitrous cam does not scavage the cylinders as effectively due to lower overlap N/A at high rpms

these are the valve timing overlap ranges that are most likely to work correctly

trucks/good mileage towing 10-35 degs overlap

daily driven low rpm performance 30-55degs overlap

hot street performance 50-75 degs overlap

oval track racing 70-95degs overlap

dragster/comp eliminator engines 90-115 degs overlap

but all engines will need the correct matching dcr for those overlap figures to correctly scavage the cylinders in the rpm ranges that apply to each engines use range.

example

http://dab7.cranecams.com/SpecCard/DisplayCatalogCard.asp?PN=114681&B1=Display+Card

here is a hot street cam that works great in many 383 camaros with at least 10.5 static cpr with 3.5-4.1 gears

now the timeing is intake opens 29.0 btdc, closes 71.0 abdc exhaust opens 77.0 bbdc, closes 31.0 atdc so if we add the 29 to the 31 we get the overlap duration of 60 degs of which makes this cam fall in the center of HOT STREET

short answer, 110 LSA if its a engine used mostly at high RPM, 112 LSA if its street driven

(need more info,..look below)

The LSA, or lobe separation angle, is ground into the cam and cannot be changed. It is the angle that separates the intake and exhaust lobe for a particular cylinder, and is measured in camshaft degrees. The intake lobe center line is measured in crankshaft degrees. The #1 intake lobe center line is usually between 100° to 110° ATDC and is what you use to degree the cam. The cam manufacturer will publish the specs for the cam based on a given intake lobe center line. Comp Cams, for instance, produces a large number of cams with 110*° LSA ground 4° advanced, so they list the specs for the cam with a 106° intake lobe center line. You can calculate the ILC by adding the intake opening angle in °BTDC, the intake closing angle in °ABDC, plus 180° for the distance from TDC to BDC. Divide by 2 and subtract the intake opening angle and you will have the ILC. For example a 12-430-8 Comp Cam lists IO at 34°BTDC, IC at 66° ATDC, so 34 + 66 + 180 = 280. 280/2 = 140. 140 - 34 = 106° ILC

Figure 3 is a picture of both an intake and an exhaust lobe of a camshaft, seen end-on. It shows the relationship between the lobes, shows the overlap area, and illustrates this next section.

Overlap has a great deal to do with overall engine performance. Small overlap makes low-end torque but less high-end power. Large overlap reduces low-end torque but increases high-end power.

Overlap is determined by two other cam specifications, Duration and Lobe Center Angle.

Duration is the time, measured in crankshaft degrees, that a valve is open. A duration of 204 degrees means that while the valve is open, the crankshaft rotates through 204 degrees.

Duration is measured on two "standards," "advertised duration" and "duration at 0.050"." Advertised duration is measured from when the valve just starts to lift off its seat to when it just touches the seat again. This is measured in different ways by different manufacturers. Some measure when the valve lifter is raised 0.004", some at 0.006", and some at different points yet. So the industry agreed to another standard that was supposed to make it easier to compare cams. In this standard, the duration is measured between the point where the lifter is raised by 0.050", and the point where it is lowered again to 0.050".

The 0.050" standard is great for side-by-side "catalog" comparisons between cams. But if you use engine prediction software on your computer, the software is much more accurate when you can feed it "advertised" duration numbers.

Lobe Center Angle is the distance in degrees between the centers of the lobes on the camshaft.

To increase duration, cam makers grind the lobes wider on the base circle of the cam. This makes the lobes overlap each other more, increasing overlap. More duration = more overlap.

To increase overlap without changing duration, cam makers will grind the lobes closer together, making a smaller lobe center angle. Less lobe center angle = more overlap.

Overlap and duration are the two big factors in cam design. More overlap moves the power band up in the engine's RPM range.

Longer duration keeps the valves open longer, so more air/fuel or exhaust can flow at higher speeds. It works out that increasing the duration of the camshaft by 10 degrees moves the engine's power band up by about 500 rpm.

A smaller lobe separation increases overlap, so a smaller lobe separation angle causes the engine's torque to peak early in the power band. Torque builds rapidly, peaks out, then falls off quickly. More lobe separation causes torque to build more slowly and peak later, but it is spread more evenly over the power band. So a larger lobe separation angle creates a flatter torque curve.

So you can see how a cam maker can tailor the camshaft specs to produce a particular power band in an engine--

Short duration with a wide separation angle might be best for towing, producing a strong, smooth low-end torque curve.

Long duration with a short separation angle might be suited for high-rpm drag racing, with a high-end, sharp torque peak.

Moderate duration with wide separation angle might be best suited for an all-around street performance engine, producing a longer, smoother torque band that can still breathe well at higher RPM.

Remember, there's always a compromise made in this process.

One last item to consider is the lobe center line. The lobe center line is the angle of the lobe's center peak, measured in crankshaft degrees when the piston is at Top Dead Center (TDC). In general (but not always), when a cam is installed "straight up," the intake lobe center line and the lobe separation angle are the same.

The lobe center line can be altered when the camshaft is installed, by advancing or retarding the camshaft's position in relation to the crankshaft. Advancing the camshaft by 4 degrees will move the power band about 200 RPM lower in the RPM band. Retarding the cam by 4 degrees will likewise move the power band 200 RPM higher in the RPM band. This allows you to fine-tune the engine's performance according to your needs.

BTW once EITHER the duration exceeds about 225 @ .050 or the lift exceeds about .520 in a 383 SBC youll probably have clearance issues with stock connecting rods,and the cam lobes, aftermarket (H) or SOME (I) style stroker rods with 7/16" capscrew bolts are stronger and profiled to clear and use of both a small base billet roller cam and stroker profile rods will usually prevent that

if cams are a mystery please take the time to read these, it will get you a good start

http://www.iskycams.com/techtips.php

http://www.wighat.com/fcr3/confusion.htm

http://www.idavette.net/hib/camcon.htm

http://www.totalengineairflow.com/tech/valvelashing.htm

http://www.wighat.com/fcr3/camtruth.htm

http://www.wighat.com/fcr3/confusion.htm

viewtopic.php?f=50&t=575

http://www.babcox.com/editorial/ar/ar119736.htm

http://home.wxs.nl/~meine119/tech/camqa.html

https://www.holley.com/Map/Instructions7.asp

More than just the engines cam duration and lift must be considered when choosing a cam. the cam must work correctly with the intake and exhausts designed rpm band , a high-stall converter and lower (higher numerically) rear end gears, will allow the engine to accelerate thru its rpm band faster and stay in the upper rpm range longer, the engine will perform better with a bigger cam than if the car has a stock converter and highway gears, if matched to the correct components and drive train.. A heavy car is harder to get moving than a light car, so it needs more torque down low and that usually requires less duration.

when you select an intake manifold the goal is usually to maximize the engines volumetric efficiency, in the engines intended power band,(how efficiently you can fill the cylinders with a full fresh charge of fuel/air mix)