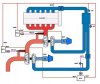

rick, the smaller turbo in the stage only sees an atmosphere going into the inlet, and then it converts it based on the settings in the wastegate to pressure in the outlet. as far as being a restriction to the VOLUME of air that passes through it... you need to see it as a form of working in a different atmosphere... if the inlet of the smaller turbo is seeing 30 or 100 psi, it would be as if it were functioning normally at an atmosphere something like 100,000 feet below sea level (if such a thing existed) so when we compress an atmosphere with the larger turbo, and seal its outlet path to the inlet of the smaller, we have made our own artificial atmosphere in that pipe. when the smaller turbo sees the compressed air, its just going to ingest it, and compress it further, and spit it out.

also of note, the interstage cooling condenses the already tightly compressed air molecules allowing the passage of more air for a given pipe diameter.