I was just over at a buddys home/ garage/shop where he was trying to assemble a fairly stock appearing muscle car, and recently rebuilt 377 displacement engine and install it in the car, from and with parts he had stock piled over the last year or so.

He had invited me over to help get it started but when I arrived he was having difficulty getting the accessories mounted correctly.

bolts can be too long or short, brackets can be installed incorrectly, etc.

http://www.kmjent.com/cart/sbc-chevy-37 ... block.html

http://www.summitracing.com/parts/CCA-5620/

http://www.fastnuf.com/crankcastingnumbers.html

every time you work on a car there always at least the potential for some component your working with to either not fit or function correctly and in most cases youll need to isolate the cause, if that does happen..

theres also the potential problem of your not having the correct tools or knowledge to fix the problem.

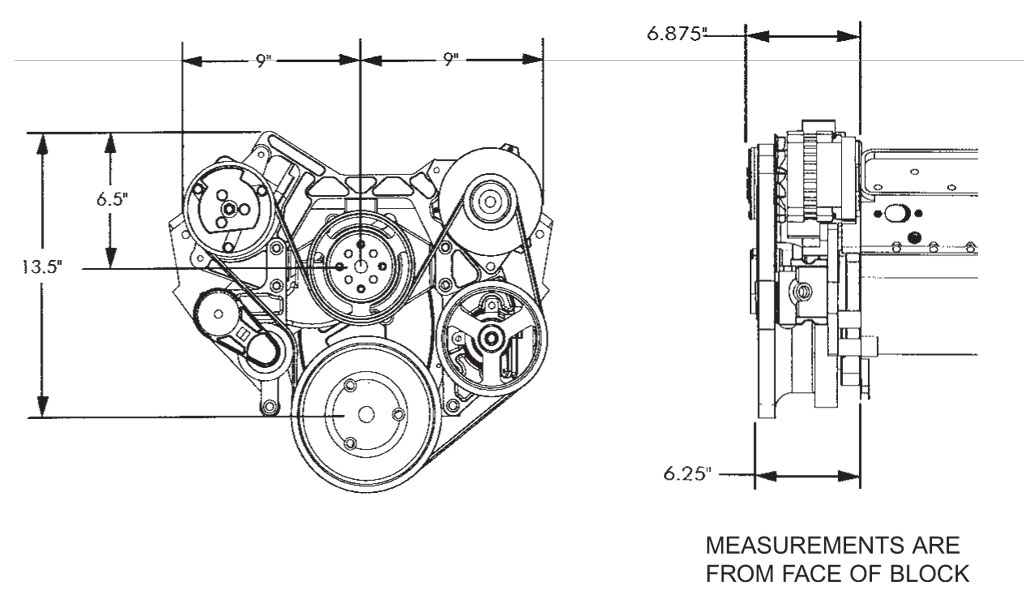

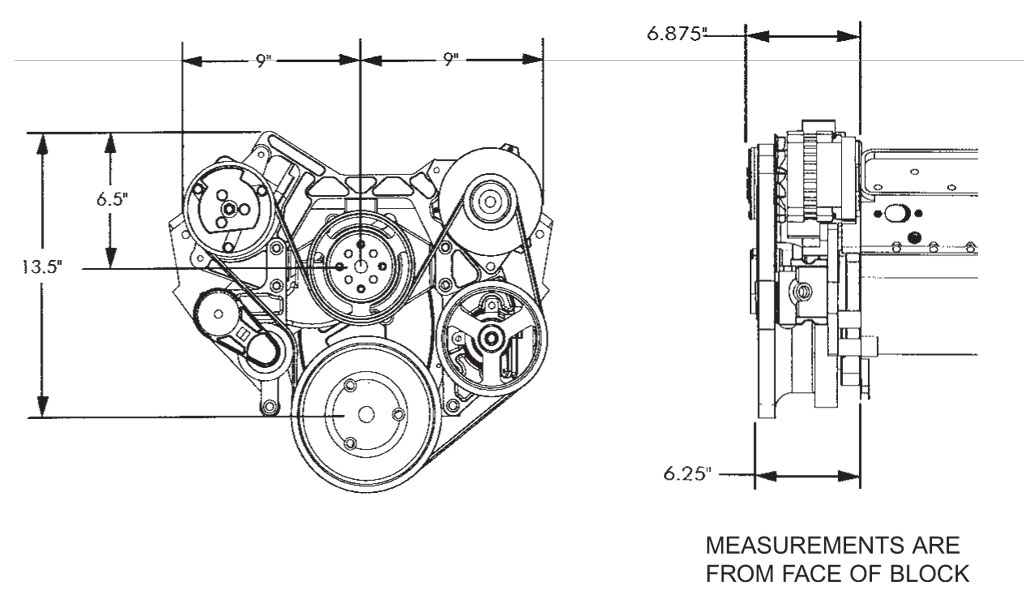

now in this case ,he had the block decked and heads milled during the machine work, and was using a thinner shim head gasket on a 377 sbc combo Id suggested, but he was having a really hard time mounting the accessory brackets, he had not yet realized the changes he had made moved two of the accessory mount hole center lines about 40 thou closer together and the accessory mounting bracket bolt holes would just need to be drilled a tiny bit larger to allow the bolts mounting the accessory's to line up correctly.

a good part of your time in this hobby will be devoted to making trips to local salvage yard, auto parts stores, machine shops or in modifying components so just accept the idea that its normal and part of the process and the better you get at minor problem solving fabrication and making the necessary tests to find out how and why things work or don,t work is a large part of what youll be doing.

I see silly stuff all the time like guys who can,t get a car started , who failed to check fuses, or batter charge level or just forgot to connect a ground wire or sensor connection, hey we ALL screw up, just think things thru and check all the stuff you KNOW you did, correctly...AGAIN!

when you find some part won,t fit or function, step back and figure out whats wrong and what you need to do to make it work, don,t get frustrated, theres always the chance its not the correct part, so think things thru, don,t force it, but don,t let minor fit issues make you crazy either

(if you find something won,t fit, stop , look closely use your brains, examine the application,and ask why, whats stopping it, don,t force it)

Once I pointed that his engines machine work, that he had had done , had changed dimensions,that the original bracket would no longer match, he looked closely and figured it out,things like oil pans and brackets don,t always fit until you make minor modifications.

(why he didn,t take a strong flash light and a mirror or just stick his head down and look closely at the problem, I don,t know)

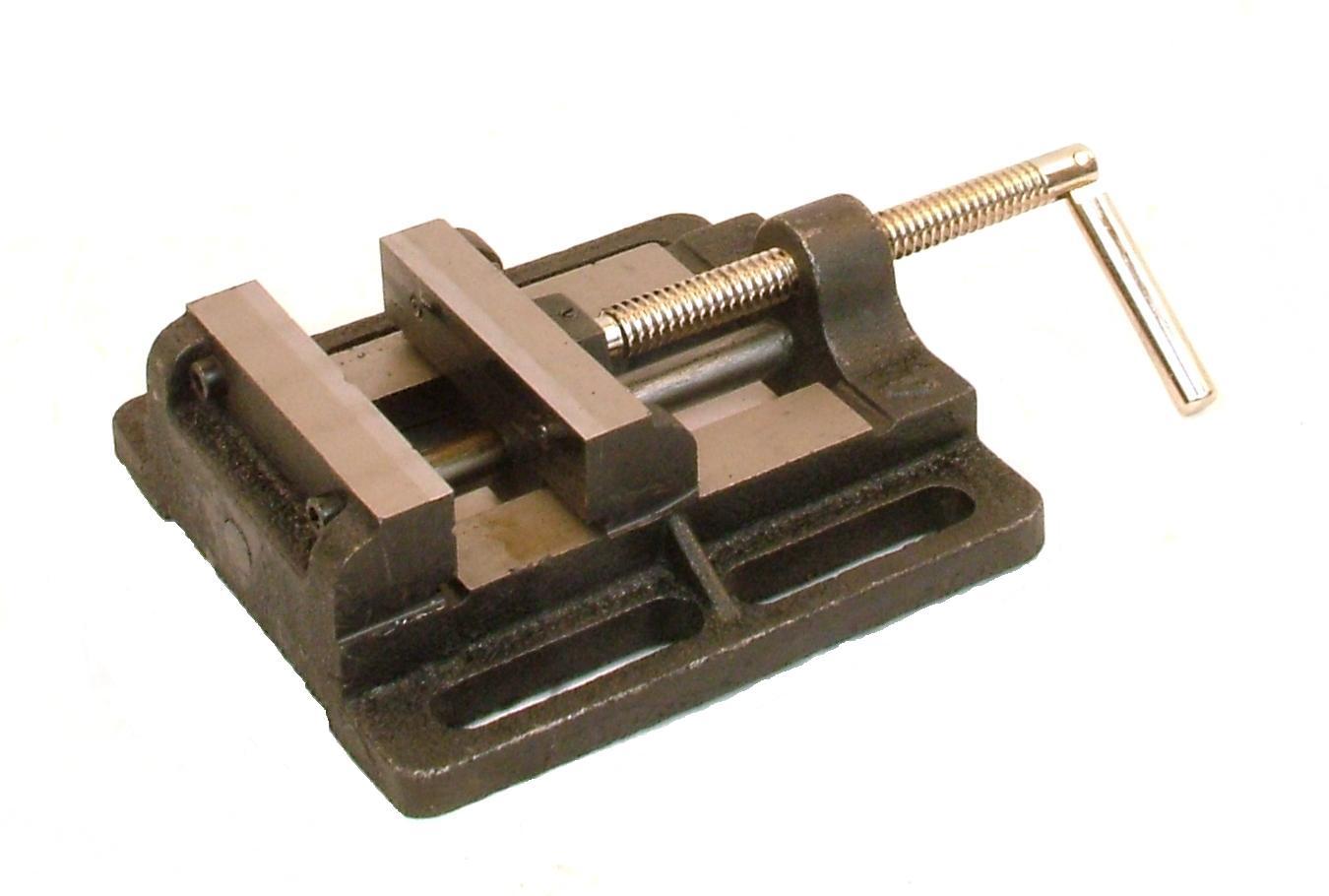

he removed the accessory mount bracket and took it over to an older drill press he had, purchased at a yard sale

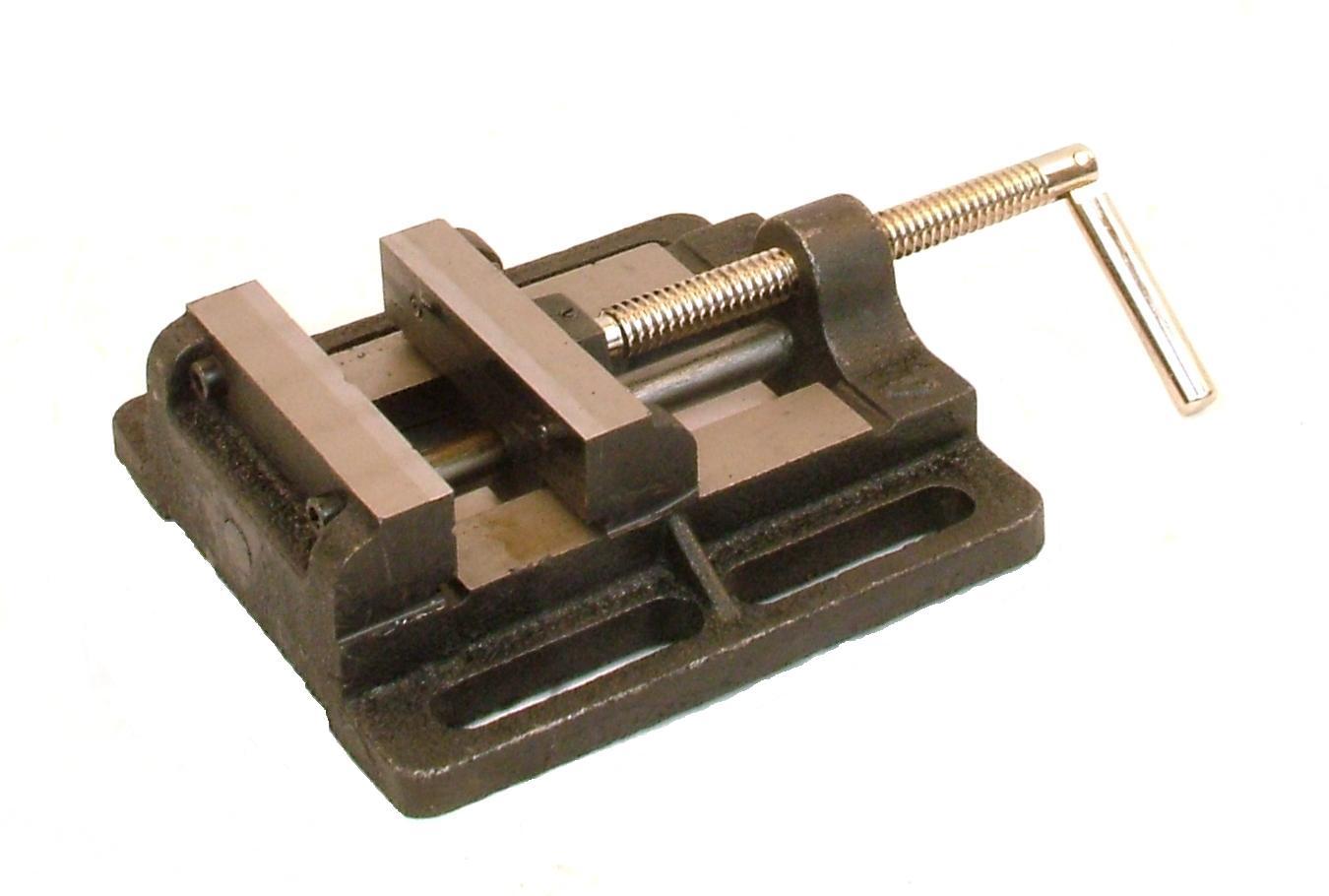

to drill the holes a bit larger, but he had no clamps or drill press vise mounted to the drill press table to hold the bracket to hold the part while he drilled the holes, when I ask him, he said he had purchased one, from HARBOR FREIGHT

http://www.harborfreight.com/4-inch-jaw ... 30999.html

but he had not thought of a way to fasten it to the drill press table, I suggested we, either buy the correct sliding clamp parts to fit the slots in his drill table or drill the drill press table after careful measurement and use a few carriage bolts and nuts or ideally buy the correct t-slot nuts designed for the application

http://www.grizzly.com/products/feature ... hines.aspx

PART NUMBERS g9510 -to-g9519

he decided to order the clamp nuts as they were cheap but we used a couple large c-clamps

http://www.grizzly.com/products/10-C-Clamp/G8090

btw the HARBOR FREIGHT LARGE C CLAMPS ARE VERY LOW QUALITY

on the vise base temporarily, and while it was a P.I.T.A. it worked well enough to allow the holes to be drilled and get the bracket modified and installed.

RELATED INFO

viewtopic.php?f=55&t=464&p=570&hilit=intake+dimple#p570

viewtopic.php?f=50&t=609&p=810#p810

http://garage.grumpysperformance.com/index.php?threads/sbc-spacer-bearings.3058/

He had invited me over to help get it started but when I arrived he was having difficulty getting the accessories mounted correctly.

bolts can be too long or short, brackets can be installed incorrectly, etc.

http://www.kmjent.com/cart/sbc-chevy-37 ... block.html

http://www.summitracing.com/parts/CCA-5620/

http://www.fastnuf.com/crankcastingnumbers.html

every time you work on a car there always at least the potential for some component your working with to either not fit or function correctly and in most cases youll need to isolate the cause, if that does happen..

theres also the potential problem of your not having the correct tools or knowledge to fix the problem.

now in this case ,he had the block decked and heads milled during the machine work, and was using a thinner shim head gasket on a 377 sbc combo Id suggested, but he was having a really hard time mounting the accessory brackets, he had not yet realized the changes he had made moved two of the accessory mount hole center lines about 40 thou closer together and the accessory mounting bracket bolt holes would just need to be drilled a tiny bit larger to allow the bolts mounting the accessory's to line up correctly.

a good part of your time in this hobby will be devoted to making trips to local salvage yard, auto parts stores, machine shops or in modifying components so just accept the idea that its normal and part of the process and the better you get at minor problem solving fabrication and making the necessary tests to find out how and why things work or don,t work is a large part of what youll be doing.

I see silly stuff all the time like guys who can,t get a car started , who failed to check fuses, or batter charge level or just forgot to connect a ground wire or sensor connection, hey we ALL screw up, just think things thru and check all the stuff you KNOW you did, correctly...AGAIN!

when you find some part won,t fit or function, step back and figure out whats wrong and what you need to do to make it work, don,t get frustrated, theres always the chance its not the correct part, so think things thru, don,t force it, but don,t let minor fit issues make you crazy either

(if you find something won,t fit, stop , look closely use your brains, examine the application,and ask why, whats stopping it, don,t force it)

Once I pointed that his engines machine work, that he had had done , had changed dimensions,that the original bracket would no longer match, he looked closely and figured it out,things like oil pans and brackets don,t always fit until you make minor modifications.

(why he didn,t take a strong flash light and a mirror or just stick his head down and look closely at the problem, I don,t know)

he removed the accessory mount bracket and took it over to an older drill press he had, purchased at a yard sale

to drill the holes a bit larger, but he had no clamps or drill press vise mounted to the drill press table to hold the bracket to hold the part while he drilled the holes, when I ask him, he said he had purchased one, from HARBOR FREIGHT

http://www.harborfreight.com/4-inch-jaw ... 30999.html

but he had not thought of a way to fasten it to the drill press table, I suggested we, either buy the correct sliding clamp parts to fit the slots in his drill table or drill the drill press table after careful measurement and use a few carriage bolts and nuts or ideally buy the correct t-slot nuts designed for the application

http://www.grizzly.com/products/feature ... hines.aspx

PART NUMBERS g9510 -to-g9519

he decided to order the clamp nuts as they were cheap but we used a couple large c-clamps

http://www.grizzly.com/products/10-C-Clamp/G8090

btw the HARBOR FREIGHT LARGE C CLAMPS ARE VERY LOW QUALITY

on the vise base temporarily, and while it was a P.I.T.A. it worked well enough to allow the holes to be drilled and get the bracket modified and installed.

RELATED INFO

viewtopic.php?f=55&t=464&p=570&hilit=intake+dimple#p570

viewtopic.php?f=50&t=609&p=810#p810

http://garage.grumpysperformance.com/index.php?threads/sbc-spacer-bearings.3058/

Last edited: