if you want to build custom windage screens, oil cooler mount plates,grills, exhaust baffles ,LIFTER VALLEY SHRAPNEL SCREENS etc

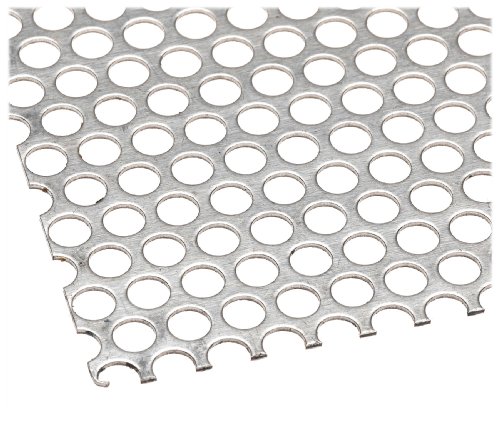

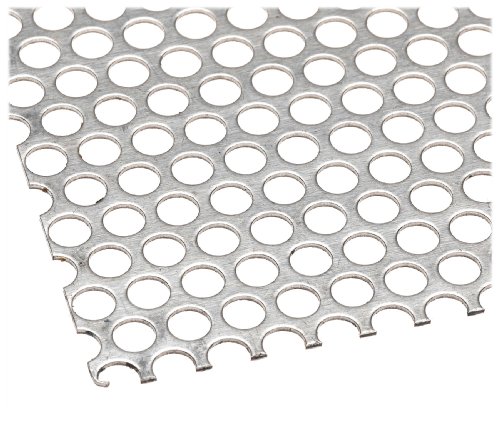

perforated steel or aluminum sheet comes in really handy, THE SIZE AND MATERIAL USED WILL NATURALLY VARY WITH THE APPLICATION

theres dozens of sizes of perforated sheet can be used for shrapnel screens or fabricating a windage screen,most sizes, with at least 40% open area should work ok,Ive used very similar looking perforated metal sheet in the past with good results,

it would be rather useful to find a cost effective high volume oil pan and matching oil pump pick-up matching your particular application before jumping into the purchase of related parts,

don,t blindly grab your credit card and start purchasing parts think things through, measure accurately and you'll find you save yourself a great deal of wasted time and effort

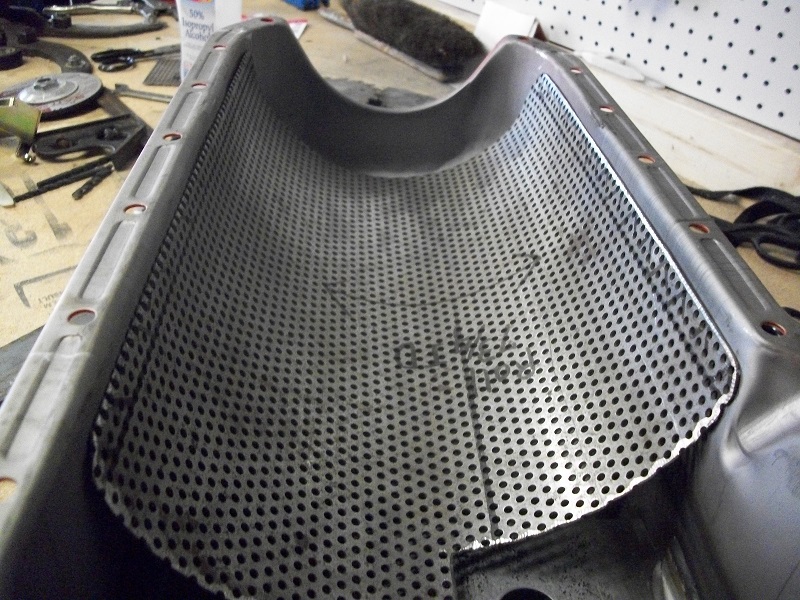

fabricating a custom built windage tray like this if properly done will more than likely be cheaper AND more effective than many you could purchase

I generally use perforated steel, stainless or mild steel, galvanized or aluminum can,t be safely or easily welded into a steel oil pan, with the common mig welder, galvanized won,t weld easily and gives off toxic fumes, you can,t weld aluminum to steel

I generally buy a 12" x 24" sheet like this and make a poster card board , pattern and tape it with duct tape in the oil pan to test fit before I cut the metal ,that way I don,t screw it up before I start to cut and fit and weld it into the oil pan, the cost will generally be under $20 an oil pan

one more in an endless list of reasons to buy a decent welder in their garage shop

yes one more in an ENDLESS LIST OF REASONS TO OWN A MIG OR TIG WELDER

http://garage.grumpysperformance.com/index.php?threads/most-versital-shop-welder.1594/

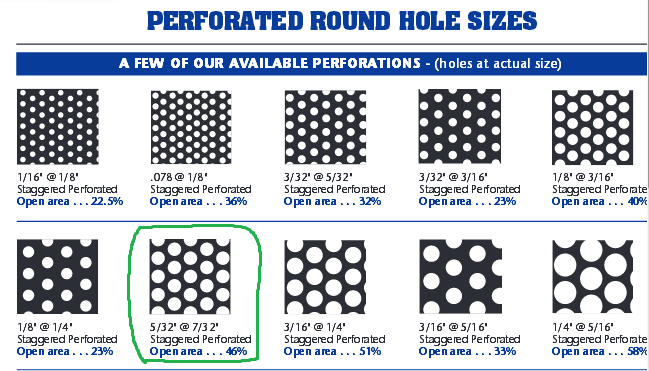

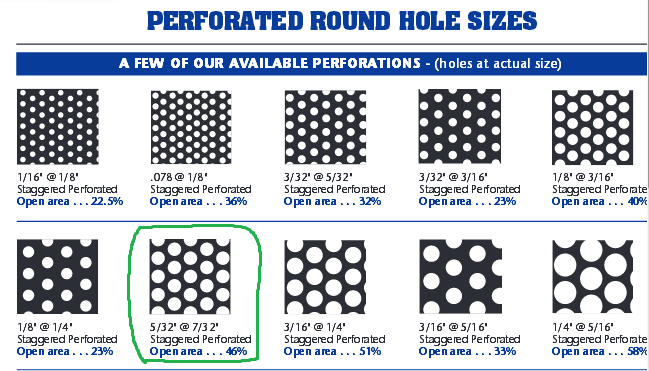

but look at this chart, I circled the type I used in green notice the percentage of open area vs closed sheet changes a great deal with the pattern and hole sizes selected , for a windage screen or a shrapnel , or windage screen I generally want holes covering at least 45%-50% coverage and at least 1/4"-3/16" in diam. in a windage screen perforated sheet

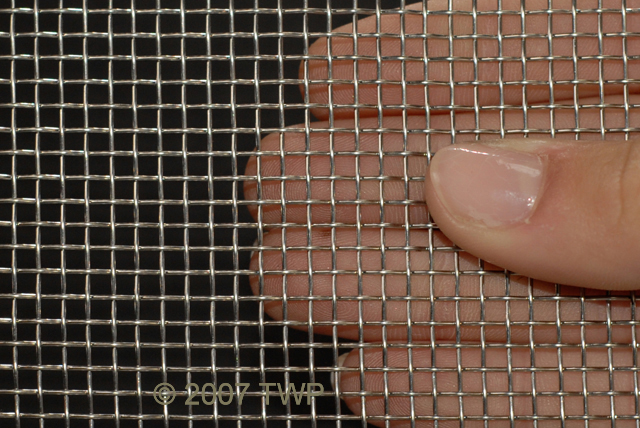

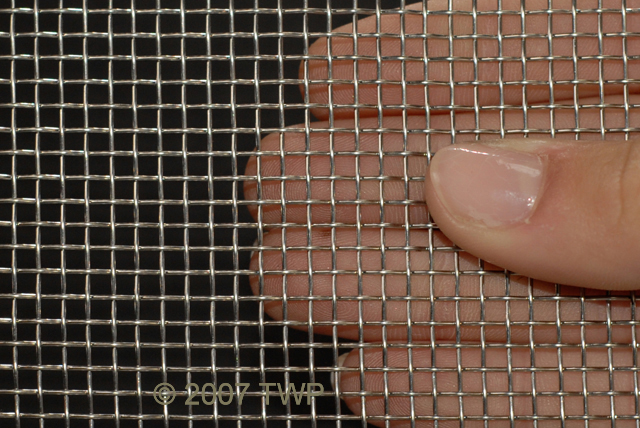

while I generally use stainless 6 or 8 mesh for shrapnel screens theres lots of options that will work just fine, just remember to keep the oil changed regularly or theres some potential for sludge to clog ANY size shrapnel screens

http://www.twpinc.com/twpinc/products/T ... 6T0350W36T

http://www.twpinc.com/twpinc/products/T ... 8S0280W36T

home depot and lowes carry some types

heres more sources

http://www.onlinemetals.com/merchant.cfm?id=1004&step=2

http://www.millerwireworks.com/perforatedplate.php

http://www.accurateperforating.com/patterns.php

http://www.mcnichols.com/perforated-steel.htm

http://www.mechanicalmetals.com/perforatedmetals.html

http://www.pwsteel.com/petro_perforated_metal.html

http://www.perforatedmetal.cn/

http://www.mcmaster.com/#perforated-sta ... ts/=1cchv0

http://www.perforatedsheet.net/

http://www.mechanicalmetals.ca/wiremesh.html

http://www.perforated-metal.biz/Plain_S ... _Metal.htm

http://perforatedmetalscreen.com/perfor ... heets.html

http://www.onlinemetals.com/merchant.cf ... op_cat=849

use a good 7-8 quart baffled oil pan

projects

viewtopic.php?f=51&t=1458&p=3265&hilit=screen#p3265

http://victorylibrary.com/mopar/baffle.htm

viewtopic.php?f=54&t=65

viewtopic.php?f=54&t=64

viewtopic.php?f=62&t=1519&p=3474#p3474

viewtopic.php?f=80&t=793&p=1150&hilit=baffle+exhaust#p1150

lowes, home depot and most large hardware stores either carry it or can easily order it, the guys that build custom stereo systems use alot of it and I used to buy it from those guys untill I found it was far cheaper from other sources, btw you can POWDER COAT most steel or aluminum prefforated sheet any collor you choose and its usually not that expensive to do, if you either do it yourself or have a local shop do it for you in a collor they are currently using for a production run

perforated steel or aluminum sheet comes in really handy, THE SIZE AND MATERIAL USED WILL NATURALLY VARY WITH THE APPLICATION

theres dozens of sizes of perforated sheet can be used for shrapnel screens or fabricating a windage screen,most sizes, with at least 40% open area should work ok,Ive used very similar looking perforated metal sheet in the past with good results,

it would be rather useful to find a cost effective high volume oil pan and matching oil pump pick-up matching your particular application before jumping into the purchase of related parts,

don,t blindly grab your credit card and start purchasing parts think things through, measure accurately and you'll find you save yourself a great deal of wasted time and effort

fabricating a custom built windage tray like this if properly done will more than likely be cheaper AND more effective than many you could purchase

I generally use perforated steel, stainless or mild steel, galvanized or aluminum can,t be safely or easily welded into a steel oil pan, with the common mig welder, galvanized won,t weld easily and gives off toxic fumes, you can,t weld aluminum to steel

I generally buy a 12" x 24" sheet like this and make a poster card board , pattern and tape it with duct tape in the oil pan to test fit before I cut the metal ,that way I don,t screw it up before I start to cut and fit and weld it into the oil pan, the cost will generally be under $20 an oil pan

one more in an endless list of reasons to buy a decent welder in their garage shop

yes one more in an ENDLESS LIST OF REASONS TO OWN A MIG OR TIG WELDER

http://garage.grumpysperformance.com/index.php?threads/most-versital-shop-welder.1594/

but look at this chart, I circled the type I used in green notice the percentage of open area vs closed sheet changes a great deal with the pattern and hole sizes selected , for a windage screen or a shrapnel , or windage screen I generally want holes covering at least 45%-50% coverage and at least 1/4"-3/16" in diam. in a windage screen perforated sheet

while I generally use stainless 6 or 8 mesh for shrapnel screens theres lots of options that will work just fine, just remember to keep the oil changed regularly or theres some potential for sludge to clog ANY size shrapnel screens

http://www.twpinc.com/twpinc/products/T ... 6T0350W36T

http://www.twpinc.com/twpinc/products/T ... 8S0280W36T

home depot and lowes carry some types

heres more sources

http://www.onlinemetals.com/merchant.cfm?id=1004&step=2

http://www.millerwireworks.com/perforatedplate.php

http://www.accurateperforating.com/patterns.php

http://www.mcnichols.com/perforated-steel.htm

http://www.mechanicalmetals.com/perforatedmetals.html

http://www.pwsteel.com/petro_perforated_metal.html

http://www.perforatedmetal.cn/

http://www.mcmaster.com/#perforated-sta ... ts/=1cchv0

http://www.perforatedsheet.net/

http://www.mechanicalmetals.ca/wiremesh.html

http://www.perforated-metal.biz/Plain_S ... _Metal.htm

http://perforatedmetalscreen.com/perfor ... heets.html

http://www.onlinemetals.com/merchant.cf ... op_cat=849

use a good 7-8 quart baffled oil pan

projects

viewtopic.php?f=51&t=1458&p=3265&hilit=screen#p3265

http://victorylibrary.com/mopar/baffle.htm

viewtopic.php?f=54&t=65

viewtopic.php?f=54&t=64

viewtopic.php?f=62&t=1519&p=3474#p3474

viewtopic.php?f=80&t=793&p=1150&hilit=baffle+exhaust#p1150

lowes, home depot and most large hardware stores either carry it or can easily order it, the guys that build custom stereo systems use alot of it and I used to buy it from those guys untill I found it was far cheaper from other sources, btw you can POWDER COAT most steel or aluminum prefforated sheet any collor you choose and its usually not that expensive to do, if you either do it yourself or have a local shop do it for you in a collor they are currently using for a production run

Last edited by a moderator: