Big_G

Active Member

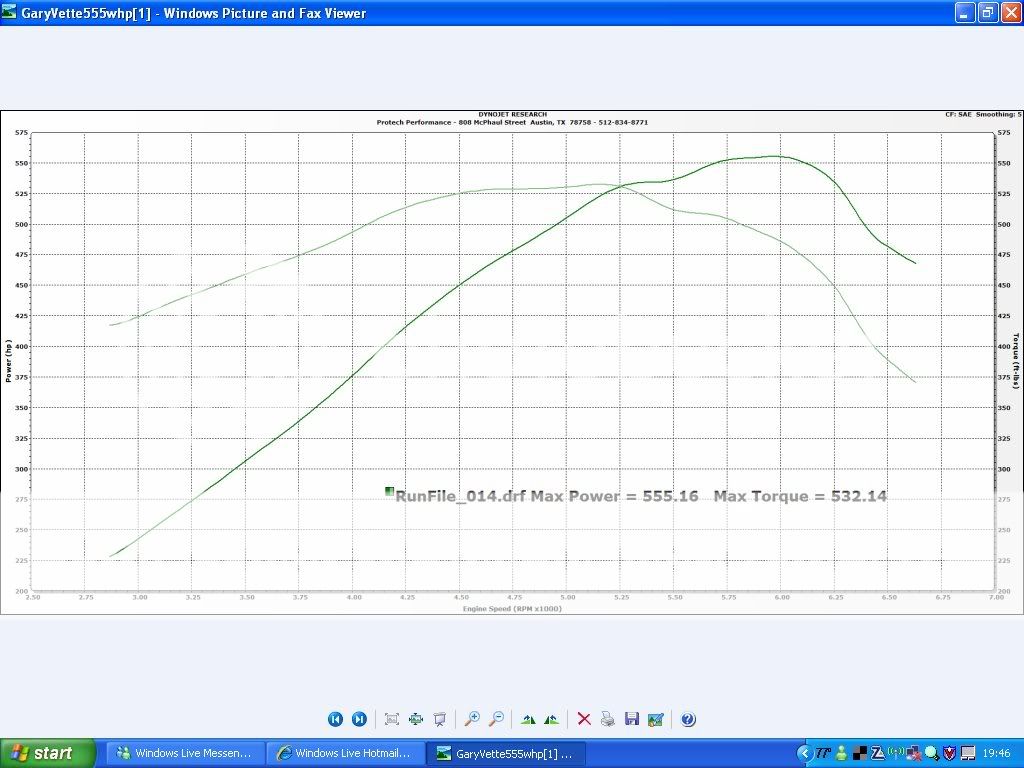

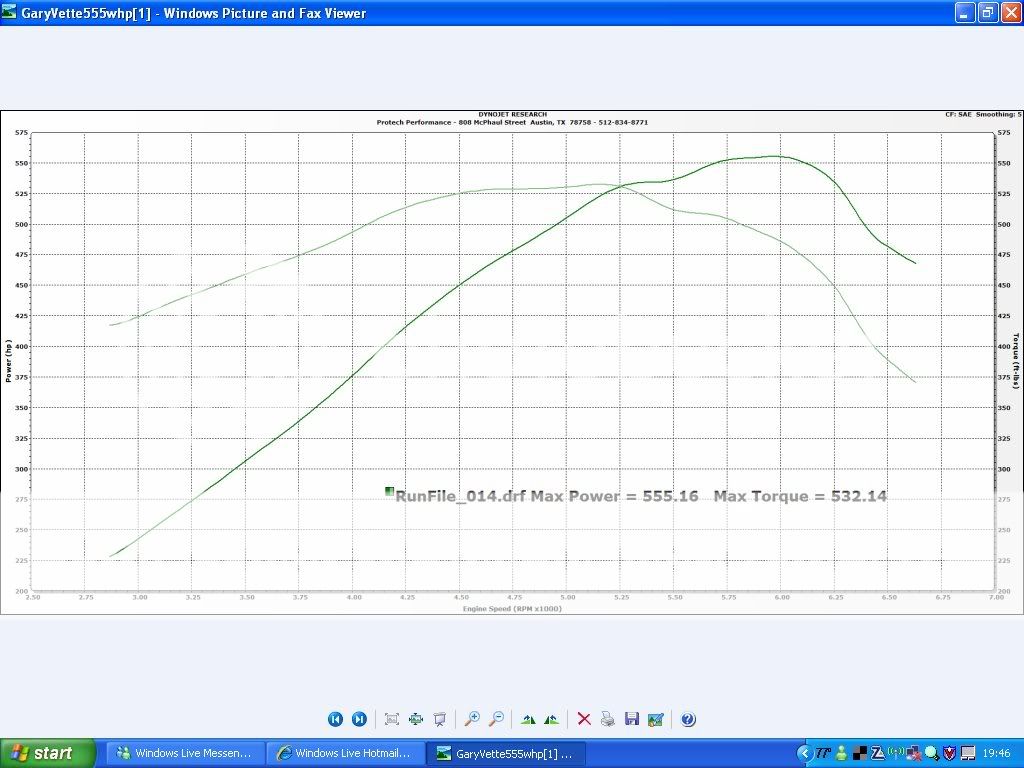

Combo: 383, Vic. J.r heads and EFI intake. ProCharger D1SC with 16-18 lbs. boost with large front-mount intercooler. 8.3:1 scr, cam currently is 230/236/114* solid roller, about .540 lift. A/F ratio is about 11.2 to 11.8 at boost. Timing is 30* at boost. Manual trans. Problem...I believe this combo. can make 2 hp/ci. at the flywheel. I have seen the dip in the dyno run at about 5,500 before...is it the intake manifold? Trying to find my missing 50 or so hp. Comp cams is suggesting a 244/248/114* with .615/.609.